Académique Documents

Professionnel Documents

Culture Documents

Dynamic Control2

Transféré par

Audrey Patrick KallaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dynamic Control2

Transféré par

Audrey Patrick KallaDroits d'auteur :

Formats disponibles

Chemical Process

Dynamics and Control

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

Some Notes

Instructor:

Cheng-Liang Chen (CCL@ntu.edu.tw)

Teaching Assistant:

Ying-Jyuan Ciou (D93524013@ntu.edu.tw)

Textbook:

Smith, C.A., and A. Corripio (2006).

Principles and Practice of Automatic Process Control (3

rd

Ed.)

Lecture Time: Mon 9 : 10 10 : 00; Wed 10 : 20 12 : 10

Examination: 2 Mid-terms and 1 Final (20 2 + 30 = 70%)

Homework: 10 (20%)

Computer Exercise: Simulink, (PControLab

3

) (10%)

Chen CL 2

Learning Objectives

Understand how the basic components of control systems

work (Sensor, Valve, Controller, Process)

Develop dynamic mathematical process models that will help

in the analysis, design, and operation of control systems

Design and tune feedback controllers

Apply a variety of techniques that enhance feedback control,

including cascade control, selective control, override control,

ratio control, and feedforward control

Master the fundamentals of dynamic simulation of process

control systems using MATLAB and Simulink

Chen CL 3

Course Outline

Process Control: Essentials Chapter 1

Basic Control Elements: Sensor Chapter 5

Basic Control Elements: Valve Chapter 5

Basic Control Elements: Controller Chapter 5

Basic Control Elements: Process Chapters 3,4

Analysis of Feedback Control Loops Chapters 6,2

Adjusting Controller Parameters Chapter 7

Frequency Response Techniques Chapter 8

Enhanced PID Control: Cascade Control Chapter 9

Enhanced PID Control: Selective Control Chapter 10

Enhanced PID Control: Feedforward Control Chapter 11

Control Systems and Dynamic Simulation Chapter 13

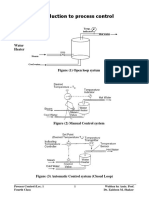

Basic Concept of

Process Control

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

A Process Heat Exchanger

The Problem

Control Objectives: to keep T at T

D

(and q at q

D

)

T: controlled variable T

D

: set point

Environment: varying q

s

, P

s

, T

a

, T

i

, q, E (eciency)

P

s

, T

a

, T

i

, E: hard to handle disturbances

q

s

, q: easy for adjusting manipulated variable

Chen CL 2

A Process Heat Exchanger

The Tools

We need one sensor to know current status of T

We need one valve to adjust q

s

We need one method to make decision

We have to check if CV = SP from time to time

Chen CL 3

A Process Heat Exchanger

Manual Method to Achieve Control Objective

To know: reading T (inuenced by P

s

, T

a

, T

i

, E)

To decide: comparing T with T

D

and decide adjusting action

To do: implementing new q

s

manually by a eld operator

Repeat above actions for every second

Chen CL 4

A Process Heat Exchanger

Automatic Method to Achieve Control Objective

To know: reading T (inuenced by P

s

, T

a

, T

i

, E)

To decide: comparing T with T

D

and decide adjusting action

To do: implementing new q

s

automatically by a controller

Repeat above actions for every second

Chen CL 5

A Process Heat Exchanger

Four Basic Elements

Primary/Secondary Element (sensor/transmitter)

to know current status for CV

(fast, accurate, standard)

T (

o

C)

TE

=

T (mV )

TT

= y (4 20 mA; 1 5V ; 0% 100%)

Example: desired zero = 50

o

C, span = 100

o

C

50

o

C 4 mA 1 V 0%

TE/TT

or or

150

o

C 20 mA 5 V 100%

Chen CL 6

A Process Heat Exchanger

Four Basic Elements

Decision-making Element (operator or controller)

to calculate the trial corrective action

(simple to use, acceptable performance, robust, reliable)

inputs: set-point y

sp

(mA or %), (from T

D

o

C)

measured PV y(t) (mA or %), (from T

o

C)

output: control action u(t) (mA or %)

Chen CL 7

A Process Heat Exchanger

Four Basic Elements

Final Control Element (I/P transducer + valve)

to realize operators or controllers decision

u(t) (4 20 mA)

I/P

= u

(t) (3 15 psi)

valve

= 0% 100% valve opening

= q

s

(t) (kg/sec) ( MV)

Chen CL 8

A Process Heat Exchanger

Four Basic Elements

Process

to wait for new value of CV

inputs: q

s

(kg/sec) (MV)

P

s

, T

i

, T

a

, (Disturbances)

output: T (

o

C) (PV, CV)

Chen CL 9

A Process Heat Exchanger

Four Basic Elements

Summary

Primary/Secondary Element (sensor/transmitter)

Decision-making Element (controller)

Final Control Element (I/P transducer/valve)

Process (the heat exchanger)

Chen CL 10

Chen CL 11

Basic Concept of Process Control

Summary

Process Control:

adjusting a Manipulated Variable ( MV)

to maintain the Controlled Variable ( CV)

at desired operating value ( Set Point) ( SP)

in the presence of output Disturbances ( Ds)

Chen CL 12

Control Strategies

Feedback Control

Adjusting MV if CV is not equal to SP

Advantage: simple, can compensate all disturbances

Disadvantage: CV is not equal to SP in most time

Chen CL 13

Control Strategies

Feed-forward Control

Adjusting MV to compensate inuence of multiple Ds on CV

Advantage:

simultaneously consider inuence of multiple Ds and MV on CV

detecting Ds adjusting MV BEFORE CV deviates from SP

Disadv.s: modeling error ?; not considering ALL disturbances ?

Chen CL 14

Control Strategies

Feed-forward Control with Feedback Trim

Chen CL 15

Incentives for Chemical Process Control

Safety:

temperature, pressure, concentration of chemicals

should be within allowable limits

Production Specications:

a plant should produce desired amounts and quality of nal products

Environmental Regulations:

various laws specify concentrations of chemicals of euent from a

plant be within certain limits

Chen CL 16

Incentives for Chemical Process Control

Operational Constraints:

various types of equipment have constraints inherent to their

operation

Economics:

operating conditions are controlled at given optimum levels of

minimum operating cost and maximum prot

Chen CL 17

Design Aspects of A Process Control System

Dene Control Objectives:

Q 1: What are the operational objectives that a control system is called

upon to achieve ?

Ensuring stability of the process, or

Suppressing the inuence of external disturbances, or

Optimizing the economic performance of a plant, or

A combination of the above

Select Measurements:

Q 2: What variables should we measure to monitor the operational

performance of a plant ?

Chen CL 18

Design Aspects of A Process Control System

Select Manipulated Variables:

Q 3: What are the manipulated variables to be used to control a

chemical process ?

Select Control Conguration: (control structure)

Q 4: What is the best control conguration for a given chemical

process control situation ?

Feedback control cascade ? override ?

Feedforward control feedback trim ?

Inferential control

Chen CL 19

Design Aspects of A Process Control System

Design the Controller: (control law)

Q 5: How is the information, taken from the measurements, used to

adjust the values of the manipulated variables ?

Control law (controller structure, P - PI - PID ?)

Controller tuning (K

c

,

I

,

D

?)

Chen CL 20

Why Laplace Transform

Ex: PID Controller 4 signals 2 signals

PID Controller: u(t) = K

c

e(t) +

1

T

I

t

0

e()d + T

D

de(t)

dt

+ u

b

Steady States: u = K

c

e +

1

T

I

t

0

e d + T

D

de

dt

+ u

b

[u = u

b

; e = 0]

Deviation Variables: U(t) = K

c

E(t) +

1

T

I

t

0

E()d + T

D

dE(t)

dt

U(t) u(t) u

b

; E(t) = e(t) 0)

Chen CL 21

Why Laplace Transform

PID Controller: (cont)

Laplace Transform: U(s) = K

c

E(s) +

1

T

I

E(s)

s

+ T

D

sE(s)

= K

c

1 +

1

T

I

1

s

+ T

D

s

E(s)

Transfer Function:

U(s)

E(s)

= K

c

1 +

1

T

I

1

s

+ T

D

s

G

c

(s)

Chen CL 22

Why Laplace Transform

Ex: Simple Process 3 signals 2 signals

First-Order Model: T

dy(t)

dt

+ y(t) = Ku(t d)

Steady States: T

dy

dt

+ y = Ku

Deviation Variables: T

d[y(t)y]

dt

+ [y(t) y] = K[u(t d) u]

T

dY (t)

dt

+ Y (t) = KU(t d)

Laplace Transform: TsY (s) + Y (s) = KU(s)e

ds

Transfer Function:

Y (s)

U(s)

=

Ke

ds

Ts + 1

G

p

(s)

Chen CL 23

Why Laplace Transform

Dynamic relation (y

sp

to y): time-domain vs. s-domain

Time domain: simultaneous dynamic equations

S-domain:

y(s)

y

sp

(s)

=

G

c

G

p

1 + G

c

G

p

Sensors and Transmitters

(Transducer)

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

Transducer

Transducer:

to convert a physical quantity into an electrical signal

The sensor produces a phenomenonmechanical,

electrical, or the likerelated to the process variable

it measures

The transmitter converts this phenomenon into a

signal that can be transmitted

Measured Quantities:

position, force, velocity, acceleration,

pressure, level, ow, temperature,

Output Signals:

current, voltage, resistance, capacitance, or frequency

Chen CL 2

Transducer Specications

Static Specications:

Accuracy

Resolution

Repeatability

Hysteresis

Linearity

Dynamic Specications

Dead time

Rise time

Time constant

Frequency response

Chen CL 3

Accuracy

Percent of Full Scale Output (%FPO)

Example:

A load cell is a transducer used to measure weight (100 kg 20

mV). A calibration record is given in table. Plot calibration curve

(skip). Determine the accuracy of the transducer. Express answer in

both %FSO (percent of full scale output) and % of reading. Assume

linear relationship between output.

v

true

=

v

full scale

load

full scale

load

=

20 mV

100 kg

load = 0.2

mV

kg

load

Chen CL 4

True output Actual output Error Accuracy

(mV) (mV) (mV) %FSO %reading

0 0 0.08 0.08 0.40 -

5 1.00 0.45 0.55 2.75 55.00

10 2.00 1.02 0.98 4.90 49.00

15 3.00 1.71 1.29 6.45 43.00

20 4.00 2.55 1.45 7.25 36.25

25 5.00 3.43 1.57 7.85 31.40

30 6.00 4.48 1.52 7.60 25.33

35 7.00 5.50 1.50 7.50 21.43

40 8.00 6.53 1.47 7.35 27.01

45 9.00 7.64 1.36 6.80 15.11

50 10.00 8.70 1.30 6.50 13.00

55 11.00 9.85 1.15 5.75 10.45

60 12.00 11.01 0.99 4.95 8.25

65 13.00 12.40 0.60 3.00 2.77

70 14.00 13.32 0.68 3.40 7.14

75 15.00 14.35 0.65 3.25 4.33

80 16.00 15.40 0.60 3.00 3.75

85 17.00 16.48 0.52 2.60 3.06

90 18.00 17.66 0.34 1.70 1.89

95 19.00 18.90 0.10 0.50 0.53

100 20.00 19.93 0.07 0.35 0.35

Chen CL 5

Resolution

This optical encoder has a 90

o

resolution

Chen CL 6

Resolution: Example

A 2.5-m-long vane is rotated slowly in a circle. The motor and gears

attach to the vane at its center. It is necessary to know the position

of the vane within 2 cm. What must be the resolution of the optical

encoder attached to the shaft that positions the vane ?

Solution:

c = d = (2.5 m) = 7.854 m = 785.4 cm

arc

360

o

=

2 cm

785.4 cm

arc =

(360

o

)(2 cm)

785.4 cm

= 0.917

o

360

o

0.917

o

= 392.6 ( 400 500) pulses per revolution

Chen CL 7

Repeatability

accurate repeatable both accurate

not repeatable not accurate and repeatable

Chen CL 8

Hysteresis ( Increasing= Decreasing)

Chen CL 9

Linearity

Chen CL 10

Dead Time

Chen CL 11

Rise Time

Chen CL 12

Time Constant

Chen CL 13

Settling Time

Chen CL 14

Frequency Response

Chen CL 15

Block Diagram of A Transducer

H(s) =

C(s)

PV(s)

=

K

T

T

s + 1

K

T

=

(20 4) mA

(200 0) pisg

= 0.08 mA/pisg

K

T

=

(100 0) %TO

(200 0) pisg

= 0.5 %TO/pisg

Chen CL 16

Position Transducer

Linear and Angular Potentiometers

Chen CL 17

Linear and Angular Potentiometers: Example

It is necessary to measure the position of a panel. It moves 0.8 m.

Its position must be known within 0.1 cm. Part of the mechanism

which moves the panel is a shaft that rotates 250

o

when the panel is

moved from one extreme to the other. A control potentiometer has

been found which is rated at 300

o

full-scale movement. It has 1000

turns of wire. Can this be used ?

Solution:

300

o

1000

= 0.300

o

(resolution of the potentiometer)

250

o

0.8 m

= 312.5

o

/m or 3.125

o

/cm (conversion of shaft)

0.1 cm3.125

o

/cm = 0.3125

o

(panel required resolution)

> 0.300

o

the potentiometer will work

Chen CL 18

Position Transducer

Linear Variable Dierential Transformer (LVDT)

One primary coil,

two secondary coils,

one free-moving rod-shaped

magnetic core inside coil

assembly

Chen CL 19

Force Transducer

Bounded Resistance Strain Gage

Stress: =

force

area

=

F

A

Strain: =

deformation

length

=

L

L

=

Chen CL 20

Force Transducer

Bounded Resistance Strain Gage

Stress Strain Electrical Resistance

Gage Factor, GF =

fractional change in resistance

fractional change in length

=

R/R

L/L

Chen CL 21

Example:

A strain gage is bounded to a steel beam which is 10.00 cm long and

has a cross-sectional area of 4.00 cm

2

. Youngs modulus (E = /)

of elasticity for steel is 20.7 10

10

N/m

2

. The strain gage has a

nominal (unstrained) resistance of 240 and a gage factor of 2.20.

When a load is applied, the gages resistance changes by 0.013.

Calculate the change in length of the steel beam and the amount of

force applied to the beam.

Chen CL 22

Solution:

L =

1

GF

L

R

R

=

1

2.20

0.1(m)

0.013

240

= 2.46 10

6

m

F

A

= = E = E

L

L

= E

1

GF

R

R

= 20.7 10

10

(N/m

2

)

1

2.20

0.013

240

F = 2.037 10

3

N

1 b

4.482N

= 454 b

Chen CL 23

Force Transducer

Two Strain Gages

Chen CL 24

Pressure Transducer

Diaphragm with Strain Gage

Chen CL 25

Pressure Transducer

Diaphragm with Strain Gage

Chen CL 26

Pressure Transducer

Capacitive Absolute-Pressure Transducer

Chen CL 27

Pressure Transducer

Pressure-to-Displacement Transducer

Capsule, Bellow, Bourdon tube, Spiral, Helix

Chen CL 28

Pressure Transducer

LVDT Sensing Pressure Transducer

Chen CL 29

Pressure Transducer

Potentiometer Sensing Pressure Transducer

Chen CL 30

Flow Transducer

Dierential Pressure Obstruction Flow Sensors

Orice plate, Venturi, Pitot tube

f = C

o

A

o

p

o

d

D

Chen CL 31

Flow Transducer

Deection-type Flow Transducers

Cantilever beam, Variable-area rotameter

Chen CL 32

Flow Transducer

Spin-type Flow Transducers

Paddle wheel, Flow turbine

Chen CL 33

Flow Transducer

Electromagnetic Flow Meter

Chen CL 34

Flow Transducer

Ultrasonic Flow Transducer

Chen CL 35

Flow Transducer: Characteristics

Chen CL 36

Level Transducer

Discrete-type Level Transducer

Float switch, Photoelectric

Chen CL 37

Level Transducer

By Sensing Pressure with

Oset transducer, Sealed tank

Chen CL 38

Level Transducer

By Sensing dierential Pressure

Chen CL 39

Level Transducer

with Float-driven Control System

Chen CL 40

Level Transducer

Capacitance Level Transducer

Chen CL 41

Level Transducer

Top-mounted Ultrasonic Level Sensor

Chen CL 42

Common Temperature Transducers

Chen CL 43

Common Temperature Transducers

Chen CL 44

Common Temperature Transducers

Chen CL 45

Thermocouple

Seebeck Eect

Current in a closed circuit

Voltage across an open circuit

Chen CL 46

Thermocouple

Equivalent Circuits

Chen CL 47

Thermocouple

with External Reference

Chen CL 48

Thermocouple

External Reference Junction with No Ice Bath

Chen CL 49

Thermocouple

Scanning Many Thermocouples

Chen CL 50

Thermocouple

Electronic Ice-point Compensation

Control Valves

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

Why Focus on Valve ?

Valves are often the least understood component of the

control loop

Valves are often the most neglected component of the

control loop

Valves are often the biggest contributor to poor control

loop performance

Chen CL 2

A Typical Globe Valve

Chen CL 3

Energy and Pressure Grades

Ideal/Real Flows Across An Ideal Restriction

Chen CL 4

Energy and Pressure Grades

A Valve or Orice Is Not Ideal

Chen CL 5

Inception of Cavitation in An Orice

Chen CL 6

Efect of Vaporization on Flow Rate

Chen CL 7

Energy and Pressure Grades Across A Valve

Chen CL 8

Valves Cost Energy

A control valve is simply an orice with a variable area of ow

all control valves and regulators cost energy

Chen CL 9

A Full Speed Pump and Throttling Valve Cost Energy

Chen CL 10

Variable Speed Drive Saves Energy

Chen CL 11

Anity Laws

Const Impeller Diameter:

Q

1

Q

2

=

_

N

1

N

2

_

H

1

H

2

=

_

N

1

N

2

_

2

bhp

1

bhp

2

=

_

N

1

N

2

_

3

Const Pump Speed:

Q

1

Q

2

=

_

D

1

D

2

_

H

1

H

2

=

_

D

1

D

2

_

2

bhp

1

bhp

2

=

_

D

1

D

2

_

3

Chen CL 12

Eciency remains virtually constant for changes in speed

and small impeller diameter changes

A 10% speed reduction (90% of nominal speed)

capacity = 90% of original operating conditions

head = 81% of original required head

bhp = 73% of nominal brake horsepower

Chen CL 13

Comparative Performances of Valve and

Variable Speed Drive

Item

Control

Valve

Variable Speed

Drive

Ease of Installation - -

Equipment Eciency - Better

Motor Eciency - Better

Power Factor - Better

Operating Costs - Better

Flexibility of Location - Better

Exposure to Process - Better

Specication - Better

Ability to Control - Better

Potential for Leaks - Better

Installed Cost: small - Better

large Better -

Shuto Capability Better -

Maintenance: expertise Better -

valve/drive - Better

equipment - Better

spare parts - -

Why Control Valve ?

Chen CL 14

Important Issues in Control Valves

Types

Actions: air-failure-open ( FO), air-failure-close ( FC)

Sizing

Characteristics: inherent (manufactured) and installed

Valves in common loops: ow, temperature, level,

pressure

Software characterizer

Diagnosis

Chen CL 15

Types of Control Valves

Globe Valve

A Single-Ported Two Way Valve

Chen CL 16

Types of Control Valves

Globe Valve

A Double-Ported Globe Valve

Chen CL 17

Types of Control Valves

Globe Valve

An Angle Valve and A Y-Pattern Valve

Chen CL 18

Types of Control Valves

Globe Valve

Valves with Three-Way Bodies

Chen CL 19

Types of Control Valves

Globe Valve

Anti-Cavitation Valve

Chen CL 20

Types of Control Valves

Ball Valve

Full Ball Valve

Chen CL 21

Types of Control Valves

Ball Valve

Three-Way Ball Valve

Chen CL 22

Types of Control Valves

Ball Valve

Segmented Ball Valve

Chen CL 23

Types of Control Valves

Buttery Valve

Chen CL 24

Types of Control Valves

Diaphragm Valve

Chen CL 25

Types of Control Valves

Digital Valve

A digital valve is made up of a group of on-o valve elements

installed in a common body

Each valve element has a dierent capacity

sequence of sizes form a binary series

These valves have the capability to change from one capacity to

another instantaneously

Chen CL 26

Example:

6 valve elements with capacity ratios 1, 2, 4, 8, 16, 32

Each incremental step will vary by

1

63

(1 + 2 + + 32 = 63)

Ratio of maximum to minimum capacity will be 63 : 1

8 elements 1, 2, . . . , 128 255 : 1

Limited to use with clean uids and moderate temperatures

Chen CL 27

Digital Valve Operation

A collection of individual on-o valves arranged in parallel

All elements have dierent owrates

All elements are controlled by pneumatic or electrical means upon

command from a computer/controller

By adjusting the combination of open and closed valves

= desired owrate: quick, exact, high resolution

Digital Valve: adds or subtracts xed area orices

responds quickly

Analog Valve: seeks a new orice (opening) size

responds slowly with overshoot

Chen CL 28

IF increasing number of individual on/o valves, and

valve openings are sized in a binary progression (1-2-4...)

(doubling area openings doubling owrates)

THEN ow range in increased substantially

EX: 6-bit = range - 63 : 1; resolution -

1

63

EX: 20-bit = range - 1, 048, 575 : 1; resolution -

1

1,048,575

Chen CL 29

Advantages of Digital Valves

Fast Response

Analog Valve: 3 8 sec.

Digital Valve: 50 100 msec. (milli-sec)

Instantaneous response from zero ow to full ow

Same speed from 1 to 2, and 0 to full

Wide Rangeability

Analog valve: far less than 100 to 1

Digital valve: 7-bit exceeds 100 to 1

Chen CL 30

Precise Repeatability

no position error absolutely repeatable

High Resolution

Analog valve: 1% of maximum ow

Digital valve:

6-bit: r = 1 part in 63 (1.59%)

8-bit: r = 1 part in 255 (0.39%)

10-bit: r = 1 part in 1,023 (0.09%)

20-bit: r = 1 part in 1,048,575 (0.0001%)

Flow Measurement Capability

Computer Compatibility

Chen CL 31

A Globe Valve again

Chen CL 32

Overview

Some Descriptive Terms:

single-seated, air-actuated, spring-opposed,

fail-closed with a plug-and-seat trim

Air pressure under the diaphragm causes the stem to rise

As stem rises, area of opening between valve plug and seat

increases

Area of opening is maximum at maximum seat position

Pressure drop across valve and valve opening determine ow rate

through valve

Chen CL 33

Valve Coecient: C

v

(gal/

psig) (C

v

max

?)

ow rate of water through the valve

in US gallons per minute at 70

o

F

when p across the valve is 1 psig

(function of valve opening)

Flow of Liquid Through Valve:

F = C

v

= C

v

max

f(m)

F: ow rate, US gpm (or, q)

p: dierential pressure, psig

: specic gravity of uid, relative to water at 70

o

F

m%: 0 100%; or vp: valve position, 0 1

Chen CL 34

Note: instrumentation schematic for a control valve

Chen CL 35

Action of Control Valves

Safety Consideration

SAFETY is the only consideration in selecting the

action of the control valve

Control valve action directly aects the action of the

feedback controller

Air-Failure-Close (AFC) Air-Failure-Open (AFO)

or

Air-to-Open (ATO) Air-to-Close (ATC)

vp =

m

100

vp = 1

m

100

Chen CL 36

Example:

Chen CL 37

Sizing of Control Valve

A Basic Trade-o Problem

Process Engineer: bigger valve lower p

v

smaller pump

lower operating cost

lower operability !!

Control Engineer: smaller valve larger p

v

larger pump

higher operating cost

higher operability

Design Logic:

to design (select) the valve and the pump on having

a process that can obtain specied q

min

, q

max

Chen CL 38

Sizing of Control Valve

Select A Larger Valve

Larger Valve

q = 100 gpm, p

h

= 40 psi, f(x) = 0.5

p

1

= pressure after pump

p

2

= 150 psi, pressure at system output

p

t

= p

1

p

2

= f(q) (constant)

let q = q

min

at f = 0.1

Chen CL 39

Select one valve such that p

v

= 20 psi

p

1

= 150 + 40 + 20 = 210 psi pump

q = C

v

max

f(x)

_

p

v

/G

C

v

max

=

100

0.5

_

20

1

= 44.72 gpm/

_

psi valve

assume p

h

= 40

_

q

100

_

2

p

v

= p

1

p

2

p

h

= 210 150 40

_

q

100

_

2

q(x) = 44.72 f(x)

_

210 150 40

_

q(x)

100

_

2

Chen CL 40

f(x) = 1 q

max

= 44.72 1

_

210 150 40

_

q

max

100

_

2

q

max

= 115 gpm

f(x) = .1 q

min

44.72 .1

_

210 150 40

_

q

min

100

_

2

q

min

= 33.3 gpm

q

max

q

min

=

115

33.3

= 3.46 (turndown ratio)

Chen CL 41

Sizing of Control Valve

Select A Small Valve

Smaller Valve

q = 100 gpm, p

h

= 40 psi, f(x) = 0.5

p

1

= pressure after pump

p

2

= 150 psi, pressure at system output

p

t

= p

1

p

2

= f(q) (constant)

let q = q

min

at f = 0.1

Chen CL 42

Select one valve such that p

v

= 80 psi

p

1

= 150 + 40 + 80 = 270 psi pump

q = C

v

max

f(x)

_

p

v

/G

C

v

max

=

100

0.5

_

80

1

= 22.36 gpm/

_

psi valve

assume p

h

= 40

_

q

100

_

2

p

v

= p

1

p

2

p

h

= 270 150 40

_

q

100

_

2

q(x) = 22.36 f(x)

_

270 150 40

_

q(x)

100

_

2

Chen CL 43

f(x) = 1 q

max

= 22.36 1

_

270 150 40

_

q

max

100

_

2

q

max

= 141 gpm

f(x) = .1 q

min

22.36 .1

_

270 150 40

_

q

min

100

_

2

q

min

= 24.2 gpm

q

max

q

min

=

141

24.2

= 5.83 > 3.46

Chen CL 44

Control Valve Capacity

C

v

coecient: ow in US gpm of water that ows

through a valve at a pressure drop of 1 psi across valve

Liquid:

q = C

v

p

v

G

f

= C

v

max

f(vp)

p

v

G

f

(liquid ow, US gpm)

p

v

: pressure drop across valve, psi G

f

: specic gravity

w =

_

q

gal

min

_ _

60

min

h

_

_

8.33G

f

lb

gal

_

= 500C

v

_

G

f

p

v

lb/h

Chen CL 45

Compressible Flow: (Masoneilan Inst. Inc.)

q

s

= 836C

v

C

f

p

1

GT

(y 0.148y

3

)

w =

_

_

_

2.8C

v

C

f

p

1

_

G

520

T

(y 0.148y

3

) gas or vapor

1.83C

v

C

f

p

1

(1+0.0007T

SH

)

(y 0.148y

3

) steam ow

y =

1.63

C

f

_

p

v

p

1

q

s

: gas ow, scfh (ft

3

/h at standard conditions of 14.7 psia, 60

o

F)

G : gas specic gravity w.r.t. air, = MW/29

T : temperature at valve inlet,

o

R =

o

F + 460

C

f

: critical ow factor (0.6 0.95)

p

1

: pressure at valve inlet w : gas ow, lb/h

T

SH

: degree of superheat

p = p

1

p

2

pressure drop across valve

Chen CL 46

Chen CL 47

Compressible Flow: (Fisher Controls)

q

s

= C

g

_

502

GT

p

1

sin

__

59.64

C

1

__

p

v

p

1

_

rad

Note: the above sine function is basically the same

function of y

Chen CL 48

Chen CL 49

Chen CL 50

Control Valve Capacity: Example

From Fig. C-10-1a, a 3-in. Masoneilan valve with full trim has a

capacity factor of 110 gpm/(psi)

1/2

when fully opened. The pressure

drop across the valve is 10 psi.

(a) Calculate the ow of a liquid solution with density 0.8 g/cm

3

(1.0 g/cm

3

for water).

q = 110

_

10

0.8

= 389 gpm

w = 500(110)

_

(0.8)(10) = 155, 600 lb/h

Chen CL 51

(b) Calculate the ow of gas with average MW of 35 when valve inlet

conditions are 100 psig and 100

o

F.

G = 35/29 = 1.207 p

1

= 100 + 14.7 = 114.7 psia

T = 100 + 460 = 560

o

R C

f

= 0.9

y =

1.63

0.9

_

10

114.7

= 0.535

q

s

= 836(110)(0.9)

114.7

(1.207)(560)

[0.535 0.148(0.535)

3

]

. .

0.512

= 187, 000 scfh

w = 2.8(110)(0.9)(114.7)

_

1.207

520

560

(0.512) = 17, 240 lb/h

Chen CL 52

(c) Calculate the ow of gas from part (b) when the inlet pressure is

5 psig. Calculate the ow both in volumetric and mass rate units,

and compare the results for a 3-in. Fisher Control valve.

p

1

= 5 + 14.7 = 19.7 psia

y = 1.290 [y 0.148y

3

] = 0.972

q

s

= 836(110)(0.9)

19.7

(1.207)(560)

(0.972) = 61, 000 scfh

= 5, 620 lb/h

Fisher: q

s

= 4280

_

520

(1.207)(560)

(114.7) sin

_

59.64

35.7

_

10

114.7

_

= 204, 000 scfh (9% higher)

q

s

= 4280

_

520

(1.207)(560)

(19.7) sin

_

59.64

35.7

_

10

19.7

_

= 68, 700 scfh (13% higher)

Chen CL 53

Sizing of Control Valves: Example

A control valve is to regulate the ow of steam into a distillation

column reboiler with a design heat transfer rate of 15 million Btu/h.

The supply steam is saturated at 20 psig. Size the control valve for

a pressure drop of 5 psi and 100% over-capacity.

H = 930 Btu/lb latent heat of cond., from steam table

q

s

= 15, 000, 000/930 = 16, 130 lb/h

p

1

= 20 + 14.7 = 34.7 (valve inlet pressure)

C

f

= 0.8

y =

1.63

0.8

_

5

34.7

= 0.773 y 0.148y

3

= 0.705

C

v

= f

_

G

f

p

v

=

16,130

(1.83)(0.8)(34.7)(.705)

= 450

gpm

psi

C

v

max

= 2.0C

v

= 900

gpm

psi

C

v

= 1000 (select a valve with this C

v

)

Chen CL 54

Fisher: G = 18/29 = 0.621 C

1

35

q

s

= (16, 130)(380)/18 = 341, 000 scfh (380 scf/lbmole)

sin

_

59.64

35

_

5

34.7

_

= sin(0.647) = 0.603

C

g

=

341,000

520

(0.621)(710)

(34.7)(0.603)

= 15, 000

C

g

= 30, 000 C

v

= C

g

/C

1

= 30, 000/35 = 856

gpm

psi

Chen CL 55

Sizing of Control Valves: Example

The following gure shows a process for transferring an oil from a

storage tank to a separation tower. The tank is at atmospheric

pressure, and the tower works at 25.9 in.Hg absolute (12, 7 psia).

Nominal oil ow is 700 gpm, its specic gravity is 0.94, and its

vapor pressure at the following temperature of 90

o

F is 13.85 psia.

The pipe is 8-in. Schedule 40 commercial steel pipe, and the

eciency of the pump is 75%. Size a valve to control the ow of oil.

From liquid ow correlations, the frictional pressure drop in the line

is found to be 6 psi.

Chen CL 56

Note: the liquid may ash if we place valve at entrance of tower

(12.7 psia < 13.85 psia)

Place valve at pump discharge: hydrostatic pressure is

12.7 + (62.3 lb/ft

2

)(0.94)(60 ft)/(144 in

2

/ ft

2

)

. .

24.4 psia

= 37.1 psia

Select p

v

= 5 psi

annual oper cost =

700 gal

1 min

1 ft

3

7.48 gal

5 lbf

1 in

2

144 lbf

1 ft

2

1 kW-min

44250 ft-lbf

8200 h

1 yr

$0.03

1 kW-h

1

0.75

= $500/yr

C

v

max

= 2(700)

_

0.94

5

= 607

gpm

psi

select an 8-in. Masoneilan valve with C

v

= 640

Chen CL 57

Valve Inherent Characteristics

Inherent Characteristics:

_

q(x)

q

max

_

p

v

=c

q(x) = C

v

max

f(x)

. .

C

v

_

p

v

G

x : 0 1 (= vp)

q

max

= C

v

max

1

_

p

v

G

(valve full open)

_

q(x)

q

max

_

p

v

=c

= f(x) (ratio of ow area)

=

_

_

x linear

R

x1

equal percentage

quick opening

Chen CL 58

Valve Inherent Characteristics

Chen CL 59

Valve Inherent Characteristics

Note: equal percentage ?

df(x)

dx

= kf(x)

df(x)

f

= kdx

a + ln[f(x)] = kx

a = k (x = 0 f = 0; x = 1 f = 1)

ln[f(x)] = k(x 1)

f(x) = e

k(x1)

= R

x1

Chen CL 60

Valve Installed Characteristics

Installed Characteristics:

_

q(x)

q

max

_

p

t

=c

q(x) = C

v

max

f(x)

_

p

v

G

x : 0 1

= C

v

max

f(x)

_

p

t

p

h

G

= C

v

max

f(x)

_

p

t

p

max

h

_

q(x)

q

max

_

2

G

q

max

= C

v

max

1

p

t

p

max

h

1

G

Chen CL 61

Valve Installed Characteristics

_

q(x)

q

max

_

p

t

=c

= f(x)

_

p

t

p

max

h

_

q(x)

q

max

_

2

p

t

p

max

h

_

q(x)

q

max

_

p

t

=c

= f(x)

p

t

p

t

[1 f

2

(x)] p

max

h

> f(x)

= f(x)

1

1 [1 f

2

(x)]

_

p

max

h

p

t

_

= f(x)

1

_

1 [1 f

2

(x)] (1 )

=

f(x)

_

+ (1 )f

2

(x)

Chen CL 62

Valve Installed Characteristics

where =

_

p

v

p

t

_

q(x)

max

=

_

p

v

p

t

_

q

max

=

=

_

p

v

p

t

_

q

note:

_

q(x)

q

max

_

p

t

=c

=

f(x)

_

1 [1 f

2

(x)]

_

1

_

q

max

q

__

Chen CL 63

Valve Installed Characteristics again

p

L

= k

L

G

f

q

2

k

L

=

p

L

G

f

q

2

p

v

= G

f

q

2

C

2

v

(C

v

= C

v

max

f(x))

p

o

= p

v

+ p

L

=

_

1

C

2

v

+k

L

_

G

f

q

2

q =

C

v

1+k

L

C

2

v

_

p

0

G

f

q

max

=

C

v

max

1+k

L

C

2

v

max

_

p

0

G

f

_

q

q

max

_

p

o

=c

=

C

v

C

v

max

. .

f(x)

_

1+k

L

C

2

v

max

1+k

L

C

2

v

Chen CL 64

Valve Installed Characteristics: Example

For last example, nd the maximum ow through the valve, the

installed ow characteristics, and the rangeability of the valve.

Assume both linear and equal percentage characteristics with

rangeability parameter of R = 50. Analyze the eect of varying the

pressure drop across the valve at nominal ow.

Chen CL 65

k

L

=

6 psi

(0.94)(700 gpm)

2

= 13.0 10

6

psi

(gpm)

2

p

o

= p

v

+ p

L

= 5 + 6 = 11 psi (constant)

q

max

=

640

1+(13.010

6

)(640)

2

_

11

0.94

= 870 gpm (< 2 700)

Linear:

q

.95

=

(640)(0.95)

1+(13.010

6

)(640)

2

_

11

0.94

= 862 gpm

q

.05

=

(640)(0.05)

1+(13.010

6

)(640)

2

_

11

0.94

= 109 gpm

rangeability =

862

109

= 7.9 (inherent range =

.95

.05

= 19)

Equal %:

q

.95

=

(640)(50

0.951

)

1+(13.010

6

)(640)

2

_

11

0.94

= 839 gpm

q

.05

=

(640)(50

0.051

)

1+(13.010

6

)(640)

2

_

11

0.94

= 53.2 gpm

rangeability =

839

53.2

= 15.8 (inherent range =

50

0.951

50

0.051

= 34.8)

Chen CL 66

valve pressure drop, psi

2 5 10

total pressure drop 8 11 16

calculated C

v

max

960 607 429

required valve size 10-in. 8-in. 8-in.

actual C

v

max

1000 640 640

maximum ow, gpm 779 870 1049

linear rangeability 5.4 7.9 7.9

Equal % rangeability 10.8 15.8 15.8

Chen CL 67

Installed ow characteristics:

(a) linear inherent characteristics.

(b) equal percentage characteristics with = 59

Chen CL 68

Application I: Fluid Transfer

Self-Regulated Processes

Chen CL 69

Application I: Fluid Transfer

Liquid Transferred by Pressure Dierence

Chen CL 70

Application I: Fluid Transfer

Liquid Transferred by Pressure Dierence

Chen CL 71

Application I: Fluid Transfer

A Flow-Controlled Pump

Chen CL 72

Application I: Fluid Transfer

Steam Ejector

Chen CL 73

Application II: Heat Transfer

Steam Heaters and Dryers

Chen CL 74

Application II: Heat Transfer

Heat Exchangers

Chen CL 75

Application II: Heat Transfer

Antifreeze Applications

Chen CL 76

Application III: Chemical Reactions

A pH Control System

Chen CL 77

Application III: Chemical Reactions

Combustion Processes

Chen CL 78

Application III: Chemical Reactions

Vaporized Control for Safety

Proportional-Integral-Derivative

PID Controllers

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

Outline

Proportional-Integral-Derivative Controller:

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

Chen CL 2

Steady Oset of PID when using Constant bias

Series PID Parallel PID

Response of PID Controllers to Typical Inputs

Operational Aspects of PID Controllers

problems of D action: sensitivity to noise

problems of I action: moving PB and reset windup

manual control requirement

bump-less transfer

Chen CL 3

PID Controller: A Survey

More Than 95% of Controllers Are of PID Type

Bialkowski (1993): paper mills in Canada

A typical mill has more than 2000 control loops

97% of loops use PI control

Only 20% of control loops were found to work well

and decrease process variability

Reasons for poor performance were

Poor tuning (30%)

Valve problems (30%)

Others (20%): sensor, bad sampling rates

Chen CL 4

PID Controller: A Survey

More Than 95% of Controllers Are of PID Type

Ender (1993)

30% of installed process controllers operate in manual

20% of loops use default parameters (factory tuning)

30% of loops function poorly because of equipment

problems (valves, sensors )

Chen CL 5

Why PID Controllers Are So Popular ?

Structure: simple

Easy for understanding

A few adjustable parameters, easy for tuning

Performance: good or acceptable level

Robustness: strong to uncertain operating conditions

Applicability: wide to dierent processes/industries

Chen CL 6

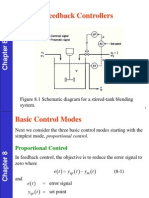

A Heat Exchanger with Feedback Control

Valve: AFC (ATO); Controller: Reverse Action

Chen CL 7

Simplest Controller: On-O Control

u(t) =

_

_

u

b

+ u if y(t) < y

sp

d

u

b

u if y(t) > y

sp

+ d

Problem: oscillatory response !

On-o cares about control direction only;

On-o gives same control action for dierent error magnitudes

Solution: control action considering error magnitude

Chen CL 8

Current-Error-Based P Control

with Constant Bias (SS value)

current control corrective action, u(t)

current error magnitude, e(t) y

sp

y(t)

u(t) e(t) y

sp

y(t)

u(t) = K

c

e(t) p(t) (K

c

: adjustable proportionality)

u(t) = K

c

e(t)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Chen CL 9

Problem of Current-Error-Based P Control

u(t) = K

c

e(t)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Too late to correct current error

It takes time to know eect of control on output

conservative action to guarantee stability

limited achievable control performance

Chen CL 10

Solution: Future-Error-Based P Control

Back to the Future

Control action based on future condition (error)

take control action in advance

better control performance

u(t) = K

c

e(t+T

d

)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

u(t) = K

c

e(t+T

d

)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Chen CL 11

Future-Error-Based P Control

Gives Better Performance

HE: pulse decrease in input temperature

At t

1

: e(t

1

+ T

d

) > e(t

1

)

P control based on e(t

1

+ T

d

) has larger action

more steam smaller undershoot in T

( Pre-Act P)

..

K

c

e(t

1

+ T

d

) + u

b

> K

c

e(t

1

) + u

b

. .

( Normal P)

Chen CL 12

Future-Error-Based P Control

Gives Better Performance

HE: pulse decrease in input temperature

At t

2

: e(t

2

+ T

d

) < e(t

2

)

P control based on e(t

2

+ T

d

) has smaller action

less steam smaller overshoot in T

( Pre-Act P)

..

K

c

e(t

2

+ T

d

) + u

b

< K

c

e(t

2

) + u

b

. .

( Normal P)

Chen CL 13

Implement Future-Error-Based P Control

As Current-Error-Based PD Control

Original P: u(t) = K

c

e(t) + u

b

PreAct P: u(t) = K

c

e(t + T

d

) + u

b

K

c

_

e(t) + T

d

de(t)

dt

_

. .

e

(t)e(t+T

d

)

+ u

b

Chen CL 14

u(t) = K

c

e(t + T

d

) + u

b

K

c

_

e(t) + T

d

de(t)

dt

_

. .

e

(t)e(t+T

d

)

+ u

b

Chen CL 15

Sub-Summary

P control based on current error with constant bias

e(t) e(t + T

d

)

P control based on future error with constant bias

u(t) = K

c

e(t + T

d

) + u

b

K

c

e(t) + T

d

de(t)

dt

(t)

+u

b

PD control based on current error with constant bias

Chen CL 16

Steady Oset for P (PD) Control

Non-zero Steady State Oset (I): Setpoint Change

Initial steady state: (all variables [0, 100%])

y = y

sp

= y e = 0 u = u

b

= u =

Chen CL 17

Case I: Setpoint change y

sp

: y y +

New steady state: y =?, u =?, e =?

(change in y) = K

p

{change in process input}

= K

p

{(change in CO) + (change in load)}

y y = K

p

_

_

_

u u

. .

change in CO

+

..

change in load=0

_

_

_

= K

p

_

K

c

e

..

_

_

(y + )

. .

new sp

y

_

_

+u

b

. .

u

u +

..

=0

_

_

y = y +

K

c

K

p

1 + K

c

K

p

. .

new steady state

= y +

. .

desired sp

Chen CL 18

Non-zero Steady State Oset (II): Load Change

Initial steady state: (all variables [0, 100%])

y = y

sp

= y e = 0 u = u

b

= u =

Chen CL 19

Case II: Load change : +

New steady state: y =?, u =?, e =?

(change in y) = K

p

{change in process input}

= K

p

{(change in CO) + (change in load)}

y y = K

p

_

_

_

u u

. .

change in CO

+

..

change in load=

_

_

_

= K

p

_

K

c

e

..

_

_

(y)

..

sp

y

_

_

+u

b

. .

u

u +

_

_

y = y +

K

p

1 + K

c

K

p

. .

new steady state

= y

..

desired sp

Chen CL 20

Current-Error-Based P Control

with Reset Bias

Question:

using P or PD control with constant bias,

how to guarantee zero steady-state oset ?

(at steady state: e = 0, y = y

sp

)

Answer: u = u

b

at SS

desired: e = 0 (y = y

sp

) at SS

u = u

b

at SS

Chen CL 21

Reset Bias for Zero SS Oset

Simplest Method

Simplest method to guarantee u = u

b

at SS:

Let u

b

(t) = u(t) for all t

then u

b

= u at steady state

e = 0 y = y

sp

P control based on current error with reset bias

via a unity-gain dynamics (not workable !)

Chen CL 22

Reset Bias for Zero SS Oset

Feasible Method

Feasible method to guarantee u = u

b

at SS:

desired: u

b

= u at SS

simplest method: u

b

(t) equals u(t) t

feasible method: u

b

(t) tracks u(t) t

u

b

(t) tracks u(t) with rst-order dynamics:

(use T

i

to adjust tracking velocity)

T

i

du

b

(t)

dt

+ u

b

(t) = u(t)

. .

equal

. .

tracking

Chen CL 23

P control based on current error with reset bias

via rst-order dynamics

Chen CL 24

Reset Bias Integral Action

(1) u(t) = K

c

e(t) + u

b

(t) (P with reset bias)

(2) u(t) = T

i

du

b

(t)

dt

+ u

b

(t) (u

b

(t) tracks u(t))

T

i

du

b

(t)

dt

= K

c

e(t) = p(t)

u

b

(t) u

b

=

1

T

i

_

t

0

p(t)dt

. .

change in bias

=

K

c

T

i

_

t

0

e(t)dt

. .

=u

b

(t)

Chen CL 25

(1) u(t) = K

c

e(t)

. .

p(t)

+

u

b

(t)

..

1

T

i

_

t

0

p(t)(t)dt

. .

u

b

(t)

+u

b

(PI)

= K

c

e(t) +

K

c

T

i

_

t

0

e(t)dt + u

b

= K

c

_

e(t) +

1

T

i

_

t

0

e(t)dt

_

+ u

b

Reset bias: interpreted as integral action

current-error-based P control with reset bias

(reseting bias according to integral of error)

= current-error-based PI control with constant bias

Chen CL 26

Reset Bias Integral Action

Chen CL 27

Chen CL 28

Future-Error-Based P Control with Reset Bias

P control based on future error

. .

PD

with reset bias

. .

PI

Interpreted As PD +PI (series PID ) Controller

e(t + T

d

) e(t) + T

d

de(t)

dt

e

(t)

Chen CL 29

u

b

(t) =

1

T

i

_

K

c

e

(t)dt + u

b

u(t) = K

c

e

(t)

. .

p(t)

+

u

b

(t)

..

1

T

i

_

K

c

e

(t)

. .

p(t)

dt +u

b

. .

u

b

(t)

Chen CL 30

Series PID Parallel PID

K

p

c

= K

c

_

1 +

T

d

T

i

_

K

c

= K

p

c

_

0.5 +

_

0.25

T

p

d

T

p

i

_

T

p

i

= T

i

_

1 +

T

d

T

i

_

T

i

= T

p

i

_

0.5 +

_

0.25

T

p

d

T

p

i

_

T

p

d

= T

d

/

_

1 +

T

d

T

i

_

T

d

= T

p

d

/

_

0.5 +

_

0.25

T

p

d

T

p

i

_

Chen CL 31

Series PID Parallel PID

p(t) = K

c

_

e(t) + T

d

de(t)

dt

_

u(t) = p(t) + u

b

(t)

T

i

du

b

(t)

dt

+ u

b

(t) = u(t)

P(t) = K

c

_

E(t) + T

d

dE(t)

dt

_

U(t) = P(t) + U

b

(t)

T

i

dU

b

(t)

dt

+ U

b

(t) = U(t)

P(s) = K

c

(E(s) + T

d

sE(s)) = K

c

(1 + T

d

s)E(s)

U(s) = P(s) + U

b

(s)

T

i

sU

b

(s) + U

b

(s) = U(s) U

b

(s) =

1

T

i

s+1

U(s)

Chen CL 32

U(s) = P(s) + U

b

(s) = P(s) +

1

T

i

s+1

U(s)

U(s) =

T

i

s+1

T

i

s

P(s)

=

T

i

s+1

T

i

s

K

c

(1 + T

d

s)E(s) (series PID)

=

K

c

T

i

s

_

T

i

T

d

s

2

+ (T

i

+ T

d

)s + 1

_

E(s)

= K

c

T

i

+T

d

T

i

_

1 +

1

(T

i

+T

d

)s

+

T

i

T

d

T

i

+T

d

s

_

E(s)

= K

c

_

1 +

T

d

T

i

_

_

1 +

1

T

i

1+

T

d

T

i

s

+ T

d

_

1 +

T

d

T

i

_

s

_

E(s)

= K

p

c

_

1 +

1

T

p

i

s

+ T

p

d

s

_

E(s) (parallel PID)

Chen CL 33

P Control Based on {Current, Future} Error

with {Constant, Reset} Bias

const. bias reset bias

current error P PI

future error PD PID

Chen CL 34

P Action to Step Error

Chen CL 35

PD Action to Step Error

Chen CL 36

PI (P-Reset) Action to Step Error

Chen CL 37

PID Action to Step Error

Chen CL 38

PD Action to Ramp Error

Chen CL 39

PID Action to Ramp Error

Chen CL 40

Problem of D Action (I):

Sensitive to High-Frequency Noise

Derivative action without lter:

Problem: sinusoidal input output mag. frequency

e(t) = Asin(t) D(t) = T

d

de(t)

dt

= T

d

A cos (t)

Chen CL 41

Solution: (rst-order) low-pass lter

T

d

N

dD(t)

dt

+ D(t) = T

d

de(t)

dt

. .

D action

. .

equal

. .

follow

Chen CL 42

Problem: (again)

derivative + ltering large inner signal (e

d

)

Solution: ltering derivative

Chen CL 43

Problem of D Action (II):

Bump Response to Step Input

Solution 1: D action on measurement

Derivative on measurement:

y(t + T

d

) y(t) + T

d

dy(t)

dt

e(t + T

d

) = y

sp

y(t + T

d

)

= y

sp

_

y(t) + T

d

dy(t)

dt

_

e(t) T

d

dy(t)

dt

For noise: ltering + derivative action

T

d

N

dy

f

(t)

dt

+ y

f

(t) = y(t) (y

f

(t) follows y(t))

D(t) = K

c

T

d

dy

f

(t)

dt

(derivative on y

f

(t))

Chen CL 44

Solution 2: ltering on setpoint signal

(use r(t) as the practical setpoint)

Solution 3: setpoint weighting (skip)

Chen CL 45

Problem of Reset (I):

Moving Proportional Band

(Reverse) P with reset bias: ([u

min

, u

max

] = [0%, 100%])

u(t) = K

c

_

y

sp

y(t)

+ u

b

(t) (K

c

> 0)

y(t) = y

max

= ? u(t) = K

c

_

y

sp

y

max

+ u

b

(t) = u

min

= 0%

y(t) = y

min

= ? u(t) = K

c

_

y

sp

y

min

+ u

b

(t) = u

max

= 100%

y(t) > y

max

u(t) < u

min

(saturation !)

y(t) < y

min

u(t) > u

max

(saturation !)

y(t) {y

min

, y

max

} u(t) {u

max

, u

min

} (normal operation)

Chen CL 46

Proportional Band: (for normal operation)

PB = [y

min

, y

max

] =

_

y

sp

+

u

b

(t)u

min

K

c

, y

sp

+

u

b

(t)u

max

K

c

_

=

_

y

sp

+

u

b

(t)0

K

c

, y

sp

+

u

b

(t)100

K

c

_

If y(t) PB, Then controller output is normal

width of PB: aected by K

c

y

max

y

min

=

u

max

u

min

K

c

=

100

K

c

%

position of PB: aected by K

c

, y

sp

, u

b

(t)

Chen CL 47

Example:

y

sp

= 50%, K

c

= 2, u

b

(t) = 50% t,

u

min

= 0%, u

max

= 100%

PB =

_

50 +

u

b

(t) 100

K

c

% , 50 +

u

b

(t) 0

K

c

%

_

= [ 25% , 75% ]

Chen CL 48

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

ZN-PI tuning: K

c

= 3.40, T

i

= 37 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 49

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

Faster reset: K

c

= 3.40, T

i

= 18.5 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 50

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

Slower reset: K

c

= 3.40, T

i

= 74 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 51

Problem of

Reset (II)

Reset Windup

HE Example

Chen CL 52

Anti Reset-Windup:

Use A Saturation Model to Limit Control Signal

u(t) =

_

_

100% for v(t) 100%

v(t) for 0% v(t) 100%

0% for v(t) 100%

Chen CL 53

Anti Reset-Windup for Parallel PID

If v > u = u

max

Then e

s

= u v < 0

1

T

t

_

e

s

dt < 0 v until v = u

max

Chen CL 54

Modication of PID (I):

High-Frequency Noise

Problem of D Action: sensitive to high frequency noise

Solution: low-pass lter on D (P & D)

Chen CL 55

Modication of PID (II):

Anti Reset-Windup

Problem of Reset Action: reset windup (saturation)

Solution: limiter

Chen CL 56

Modication of PID (III):

Manual Control

Manual control: with an integrator

Chen CL 57

Modication of PID (IV):

Bumpless A/M Transfer

When in automatic control: m(t) (manual ) tracks u(t) (auto)

m(t): always ready to control

Chen CL 58

Modication of PID (V):

Bumpless M/A Transfer

Method 1: resetting bias during M/A (keep original y

sp

)

let u

b

(t) = m(t) K

c

e(t) (when M/A transfer)

thus u(t) = u

b

(t) + K

c

e(t) (auto control action)

= m(t) (nal manual action)

Chen CL 59

Method 2: set-point tracking (y

sp

(t) tracks y(t) when manual control)

T

s

dy

sp

(t)

dt

+ y

sp

(t) = y(t) (when manual control)

Disadvantage: y

sp

moved to undesired value ?

Chen CL 60

A Complete PID Controller (I)

Automatic control

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

Manual setpoint adjustment

Chen CL 61

A Complete PID Controller (II)

Manual control

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

(Manual setpoint adjustment)

Chen CL 62

A Complete PID Controller (III)

External setpoint (used in Cascade Control)

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

Setpoint tracking:

Chen CL 63

A Complete PID Controller (IV)

Automatic control (used in Override Control)

Anti-reset windup

Bias tracking: bias tracks external signal z(t)

Manual tracking: m(t) tracks nal output u(t)

Setpoint tracking:

Chen CL 64

Thank You for Your Attention

Modeling Dynamic and Static

Behavior of Chemical Processes

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

State Variables and State Equations

State Variables:

A set of fundamental dependent quantities whose values

will describe the natural state of a given system

(temperature, pressure, ow rate, concentration )

State Equations:

A set of equations in the state variables above which

will describe how the natural state of a given system

changes with time

Chen CL 2

Principle of Conservation of A Quantity S

S =

_

_

total mass

mass of individual components

total energy

momentum

Chen CL 3

accumulation of S

within a system

time period

=

ow of S

in the system

time period

ow of S

out the system

time period

+

amount of S generated

within the system

time period

amount of S consumed

within the system

time period

Chen CL 4

Total Mass Balance:

d(V )

dt

=

i:inlet

i

F

i

j:outlet

j

F

j

Mass Balance on Component A:

dn

A

dt

=

d(c

A

V )

dt

=

i:inlet

c

A

i

F

i

j:outlet

c

A

j

F

j

rV

Total Energy Balance:

dE

dt

=

d(U +K +P)

dt

=

i:inlet

i

F

i

h

i

j:outlet

j

F

j

h

j

QW

s

Chen CL 5

Mathematical Model

A Stirred Tank Heater

Mathematical model of a process

= state equations with associated state variables

Chen CL 6

Total mass in tank: V = Ah

Total energy of liquid in tank:

E = U +K +P

dU

dt

dH

dt

;

dK

dt

=

dP

dt

= 0

H = Ahc

p

_

T T

ref

_

State variables: h, T

Total mass balance:

d(Ah)

dt

= F

i

F

=c

A

dh

dt

= F

i

F

Chen CL 7

Total energy balance:

d

_

Ahc

p

_

T T

ref

_

dt

= F

i

c

p

_

T

i

T

ref

_

Fc

p

_

T T

ref

_

+Q

T

ref

=0

A

d(hT)

dt

= F

i

T

i

FT +

Q

c

p

A

d(hT)

dt

= Ah

dT

dt

+T A

dh

dt

..

=F

i

F

= F

i

T

i

FT +

Q

c

p

Ah

dT

dt

= F

i

(T

i

T) +

Q

c

p

Chen CL 8

Summary: State equations

A

dh

dt

= F

i

F

Ah

dT

dt

= F

i

(T

i

T) +

Q

c

p

Summary: variables

state variables: h, T

output variables: h, T

disturbances: T

i

, F

i

manipulated variables: Q, F

parameters: A, , c

p

Chen CL 9

Mathematical Model

A Stirred Tank Heater (cont)

Assumed initial steady states:

0 = A

dh

dt

= F

i,s

F

s

0 = Ah

dT

dt

= F

i,s

(T

i,s

T

s

) +

Q

s

c

p

Chen CL 10

Temperature response to a step decrease in inlet temperature:

Dynamic response to a step decrease in inlet ow rate:

Chen CL 11

Additional Element:

Transport Rate Equations

Transport Rate Equations:

To describe rate of mass, energy, and momentum transfer between

a system and its surroundings

Example: a stirred tank heater

heat supplied by steam:

Q = UA

t

(T

st

T)

Chen CL 12

Additional Element:

Kinetic Rate Equations

Kinetic Rate Equations:

To describe rates of chemical reactions taking place in a system

Example: a 1st-order reaction in a CSTR

reaction rate equation:

r = k

0

e

E/RT

c

A

Chen CL 13

Additional Element:

Reaction and Phase Equilibrium Relationships

Reaction and Phase Equilibrium Relationships:

To describe equilibrium situations reached during a chemical

reaction or by two or more phases

Example: a ash drum

temperature of liquid phase

= temperature of vapor phase

pressure of liquid phase

= pressure of vapor phase

chemical potential of component i

in liquid phase =

chemical potential of component i

in vapor phase

Chen CL 14

Additional Element:

Equations of States

Equations of States:

To describe the relationship

among intensive variables

describing the

thermodynamic state

of a system

Example: a ash drum

Ideal gas law for vapor phase:

pV

vapor

= (moles of A + moles of B)RT

=

mass of A + mass of B

average MW

RT

=

mass of A + mass of B

y

A

M

A

+y

B

M

B

RT

vapor

=

mass of A + mass of B

V

vapor

= [y

A

M

A

+y

B

M

B

]

p

RT

liquid

= (T, x

A

)

Chen CL 15

Dead Time

Dead Time:

Whenever an input variable of a system changes

there is a time interval (short or long) during which

no eect is obsrved on outputs of the system

dead time, transportation lag, pure delay,

distance-velocity lag

Chen CL 16

Example: liquid through a pipe

A: temperature of inlet changes

B: temperature of outlet response

dead time: d

d =

volume of pipe

volumetric ow rate

=

A L

A U

av

=

L

U

av

T

out

(t) = T

in

(t d)

Chen CL 17

Modeling Diculties

Poorly understood processes

Imprecisely known parameters

Size and complexity of a model

Chen CL 18

Additional Examples of Mathematical Modeling

Continuous Stirred Tank Reactor (CSTR)

Exothermic Rx: A B

Chen CL 19

Total Mass Balance:

d(V )

dt

=

i

F

i

F 0

=c

=

dV

dt

= F

i

F

Mass Balance on Component A:

(r: rate of reaction per unit volume)

dn

A

dt

=

d(c

A

V )

dt

= c

A

i

F

i

c

A

F rV

V

dc

A

dt

+c

A

dV

dt

..

=F

i

F

= c

A

i

F

i

c

A

F k

0

e

E/RT

c

A

V

dc

A

dt

=

F

i

V

_

c

A

i

c

A

_

k

0

e

E/RT

c

A

Chen CL 20

Total Energy Balance:

total energy E = U +K +P = U H(T, n

A

, n

B

) (enthalpy)

dE

dt

=

dU

dt

dH

dt

=

i

F

i

h

i

(T

i

) Fh(T) Q (1)

also

dH

dt

=

H

T

..

V c

p

dT

dt

+

H

n

A

..

H

A

(T)

dn

A

dt

+

H

n

B

..

H

A

(T)

dn

B

dt

note

dn

A

dt

=

d(c

A

V )

dt

= c

A

i

F

i

c

A

F rV

dn

B

dt

=

d(c

B

V )

dt

= c

B

i

F

i

. .

=0

c

B

F +rV

dH

dt

= V c

p

dT

dt

+

H

A

_

c

A

i

F

i

c

A

F rV

_

+

H

B

_

c

B

F rV

(2)

Chen CL 21

(1) = (2) V c

p

dT

dt

=

H

A

_

c

A

i

F

i

c

A

F rV

_

H

B

_

c

B

F rV

+F

i

i

h

i

(T

i

)

. .

i

h

i

(T)

. .

c

A

i

H

A

(T)

+

i

c

p

i

(T

i

T)

F h(T)

. .

c

A

H

A

(T)+c

B

H

B

(T)

Q

=

H

A

c

A

i

F

i

. .

(i)

+

H

A

c

A

F

. .

(ii)

+

H

A

rV

+

H

B

c

B

F

. .

(iii)

H

B

rV +F

i

c

A

i

H

A

. .

(i)

+F

i

i

c

p

i

(T

i

T) Fc

A

H

A

. .

(ii)

Fc

B

H

B

. .

(iii)

Q

=

_

H

A

H

B

_

. .

H

r

rV +F

i

i

c

p

i

(T

i

T) Q

=

i

,c

p

=c

p

i

= V

dT

dt

= F

i

(T

i

T) +

(H

r

)

c

p

. .

J

rV

Q

c

p

Chen CL 22

Summaries:

state var.s: V, c

A

, T

state eqn.s:

dV

dt

= F

i

F

dc

A

dt

=

F

i

V

_

c

A

i

c

A

_

k

0

e

E/RT

c

A

dT

dt

=

F

i

V

(T

i

T) +Jk

0

e

E/RT

c

A