Académique Documents

Professionnel Documents

Culture Documents

Mpx10 Sensor de Presion Motorola

Transféré par

Gloria Estefanía TorrezCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mpx10 Sensor de Presion Motorola

Transféré par

Gloria Estefanía TorrezDroits d'auteur :

Formats disponibles

Distributed by:

www.Jameco.com 1-800-831-4242

The content and copyrights of the attached material are the property of its owner.

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Order this document by MPX10/D

10 kPa Uncompensated Silicon Pressure Sensors

The MPX10 and MPXV10GC series devices are silicon piezoresistive pressure sensors providing a very accurate and linear voltage output directly proportional to the applied pressure. These standard, low cost, uncompensated sensors permit manufacturers to design and add their own external temperature compensation and signal conditioning networks. Compensation techniques are simplified because of the predictability of Motorolas single element strain gauge design. Figure 1 shows a schematic of the internal circuitry on the standalone pressure sensor chip. Features Low Cost Patented Silicon Shear Stress Strain Gauge Design Ratiometric to Supply Voltage Easy to Use Chip Carrier Package Options Differential and Gauge Options Durable Epoxy Unibody Element or Thermoplastic (PPS) Surface Mount Package Application Examples Air Movement Control Environmental Control Systems Level Indicators Leak Detection Medical Instrumentation Industrial Controls Pneumatic Control Systems Robotics

3 + VS 2 SENSING ELEMENT + Vout 1 2 3 4 - Vout MPXV10GC7U CASE 482C MPXV10GC6U CASE 482A SMALL OUTLINE PACKAGE

MPX10 MPXV10GC SERIES

0 to 10 kPa (01.45 psi) 35 mV FULL SCALE SPAN (TYPICAL)

UNIBODY PACKAGE

MPX10D CASE 344

PIN NUMBER

Gnd +Vout Vs Vout 5 6 7 8 N/C N/C N/C N/C 1 2 MPX10DP CASE 344C

PIN NUMBER

Gnd +Vout 3 4 VS Vout

GND

NOTE: Pin 1 is noted by the notch in the lead.

NOTE: Pin 1 is noted by the notch in the lead.

Figure 1. Uncompensated Pressure Sensor Schematic VOLTAGE OUTPUT versus APPLIED DIFFERENTIAL PRESSURE The output voltage of the differential or gauge sensor increases with increasing pressure applied to the pressure side (P1) relative to the vacuum side (P2). Similarly, output voltage increases as increasing vacuum is applied to the vacuum side (P2) relative to the pressure side (P1).

REV 10

Motorola Sensor Device Data Motorola, Inc. 2001

MPX10 MPXV10GC SERIES

MAXIMUM RATINGS(NOTE)

Rating Maximum Pressure (P1 > P2) Burst Pressure (P1 > P2) Storage Temperature Operating Temperature Symbol Pmax Pburst Tstg TA Value 75 100 40 to +125 40 to +125 Unit kPa kPa C C

NOTE: Exposure beyond the specified limits may cause permanent damage or degradation to the device.

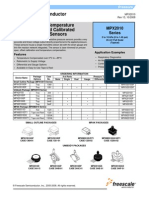

OPERATING CHARACTERISTICS (VS = 3.0 Vdc, TA = 25C unless otherwise noted, P1 > P2)

Characteristic Differential Pressure Range(1) Supply Voltage(2) Supply Current Full Scale Span(3) Offset(4) Sensitivity Linearity(5) Pressure Hysteresis(5) (0 to 10 kPa) Temperature Hysteresis(5) (40C to +125C) Temperature Coefficient of Full Scale Span(5) Temperature Coefficient of Offset(5) Temperature Coefficient of Resistance(5) Input Impedance Output Impedance Response Time(6) (10% to 90%) WarmUp Time(7) Offset Stability(8) Symbol POP VS Io VFSS Voff V/P TCVFSS TCVoff TCR Zin Zout tR Min 0 20 0 1.0 0.22 0.28 400 750 Typ 3.0 6.0 35 20 3.5 0.1 0.5 15 1.0 20 0.5 Max 10 6.0 50 35 1.0 0.16 0.34 550 1250 Unit kPa Vdc mAdc mV mV mV/kPa %VFSS %VFSS %VFSS %VFSS/C V/C %Zin/C ms ms %VFSS

NOTES: 1. 1.0 kPa (kiloPascal) equals 0.145 psi. 2. Device is ratiometric within this specified excitation range. Operating the device above the specified excitation range may induce additional error due to device selfheating. 3. Full Scale Span (VFSS) is defined as the algebraic difference between the output voltage at full rated pressure and the output voltage at the minimum rated pressure. 4. Offset (Voff) is defined as the output voltage at the minimum rated pressure. 5. Accuracy (error budget) consists of the following: Linearity: Output deviation from a straight line relationship with pressure, using end point method, over the specified pressure range. Temperature Hysteresis: Output deviation at any temperature within the operating temperature range, after the temperature is cycled to and from the minimum or maximum operating temperature points, with zero differential pressure applied. Pressure Hysteresis: Output deviation at any pressure within the specified range, when this pressure is cycled to and from the minimum or maximum rated pressure, at 25C. TcSpan: Output deviation at full rated pressure over the temperature range of 0 to 85C, relative to 25C. TcOffset: Output deviation with minimum rated pressure applied, over the temperature range of 0 to 85C, relative to 25C. TCR: Zin deviation with minimum rated pressure applied, over the temperature range of 40C to +125C, relative to 25C. 6. Response Time is defined as the time for the incremental change in the output to go from 10% to 90% of its final value when subjected to a specified step change in pressure. 7. Warmup Time is defined as the time required for the product to meet the specified output voltage after the pressure has been stabilized. 8. Offset Stability is the products output deviation when subjected to 1000 hours of Pulsed Pressure, Temperature Cycling with Bias Test.

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES

TEMPERATURE COMPENSATION Figure 2 shows the typical output characteristics of the MPX10 and MPXV10GC series over temperature. Because this strain gauge is an integral part of the silicon diaphragm, there are no temperature effects due to differences in the thermal expansion of the strain gauge and the diaphragm, as are often encountered in bonded strain gauge pressure sensors. However, the properties of the strain gauge itself are temperature dependent, requiring that the device be temperature compensated if it is to be used over an extensive temperature range. Temperature compensation and offset calibration can be achieved rather simply with additional resistive components, or by designing your system using the MPX2010D series sensor. Several approaches to external temperature compensa80 70 OUTPUT (mVdc) 60 50 40 30 20 10 0 PSI 0 kPa 0.3 2.0 0.6 0.9 1.2 OFFSET (TYP) 1.5 10 VS = 3 Vdc P1 > P2 +25C -40C

tion over both 40 to +125C and 0 to +80C ranges are presented in Motorola Applications Note AN840. LINEARITY Linearity refers to how well a transducers output follows the equation: Vout = Voff + sensitivity x P over the operating pressure range (Figure 3). There are two basic methods for calculating nonlinearity: (1) end point straight line fit or (2) a least squares best line fit. While a least squares fit gives the best case linearity error (lower numerical value), the calculations required are burdensome. Conversely, an end point fit will give the worst case error (often more desirable in error budget calculations) and the calculations are more straightforward for the user. Motorolas specified pressure sensor linearities are based on the end point straight line method measured at the midrange pressure.

70 60 LINEARITY

OUTPUT (mVdc)

+125C

SPAN RANGE (TYP)

50 40 30 20 10 0 0 PRESSURE (kPA) THEORETICAL OFFSET (VOFF) MAX POP ACTUAL SPAN (VFSS)

4.0 6.0 8.0 PRESSURE DIFFERENTIAL

Figure 2. Output versus Pressure Differential

Figure 3. Linearity Specification Comparison

WIRE BOND

LEAD FRAME

DIE P1 P2

SILICONE DIE COAT

STAINLESS STEEL METAL COVER EPOXY CASE

RTV DIE BOND

Figure 4. Unibody Package CrossSectional Diagram (not to scale) Figure 4 illustrates the differential or gauge configuration in the basic chip carrier (Case 344). A silicone gel isolates the die surface and wire bonds from the environment, while allowing the pressure signal to be transmitted to the silicon diaphragm. The MPX10 and MPXV10GC series pressure sensor operating characteristics and internal reliability and qualification tests are based on use of dry air as the pressure media. Media other than dry air may have adverse effects on sensor performance and long term reliability. Contact the factory for information regarding media compatibility in your application.

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES PRESSURE (P1)/VACUUM (P2) SIDE IDENTIFICATION TABLE

Motorola designates the two sides of the pressure sensor as the Pressure (P1) side and the Vacuum (P2) side. The Pressure (P1) side is the side containing silicone gel which isolates the die from the environment. The Motorola presPart Number MPX10D MPX10DP MPX10GP MPX10GS MPXV10GC6U MPXV10GC7U Case Type 344 344C 344B 344E 482A 482C

sure sensor is designed to operate with positive differential pressure applied, P1 > P2. The Pressure (P1) side may be identified by using the table below:

Pressure (P1) Side Identifier Stainless Steel Cap Side with Part Marking Side with Port Attached Side with Port Attached Side with Part Marking Side with Part Marking

ORDERING INFORMATION UNIBODY PACKAGE MPX10 series pressure sensors are available in differential and gauge configurations. Devices are available in the basic element package or with pressure port fittings which provide printed circuit board mounting ease and barbed hose pressure connections.

MPX Series Device Type Basic Element Ported o ed Elements e e s Options Differential Differential Gauge Gauge Case Type Case 344 Case 344C Case 344B Case 344E Order Number MPX10D MPX10DP MPX10GP MPX10GS Device Marking MPX10D MPX10DP MPX10GP MPX10D

ORDERING INFORMATION SMALL OUTLINE PACKAGE (MPXV10GC SERIES)

Device Type/Order No No. MPXV10GC6U MPXV10GC6T1 MPXV10GC7U Packing Options Rails Tape and Reel Rails Case Type Case 482A Case 482A Case 482C Device Marking MPXV10G MPXV10G MPXV10G

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES UNIBODY PACKAGE DIMENSIONS

C R M

1

A N

PIN 1

1 2 3 4

NOTES: 1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION -A- IS INCLUSIVE OF THE MOLD STOP RING. MOLD STOP RING NOT TO EXCEED 16.00 (0.630). INCHES MIN MAX 0.595 0.630 0.514 0.534 0.200 0.220 0.016 0.020 0.048 0.064 0.100 BSC 0.014 0.016 0.695 0.725 30 _ NOM 0.475 0.495 0.430 0.450 0.048 0.052 0.106 0.118 MILLIMETERS MIN MAX 15.11 16.00 13.06 13.56 5.08 5.59 0.41 0.51 1.22 1.63 2.54 BSC 0.36 0.40 17.65 18.42 30 _ NOM 12.07 12.57 10.92 11.43 1.22 1.32 2.68 3.00

T J

SEATING PLANE

G F

4 PL

F Y

0.136 (0.005)

T A

DAMBAR TRIM ZONE: THIS IS INCLUDED WITHIN DIM. F 8 PL

DIM A B C D F G J L M N R Y Z

STYLE 1: PIN 1. 2. 3. 4.

GROUND + OUTPUT + SUPPLY - OUTPUT

STYLE 2: PIN 1. 2. 3. 4.

VCC - SUPPLY + SUPPLY GROUND

STYLE 3: PIN 1. 2. 3. 4.

GND -VOUT VS +VOUT

CASE 34415 ISSUE Z

SEATING PLANE

T R H N

PORT #1 POSITIVE PRESSURE (P1)

A U L

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5, 1982. 2. CONTROLLING DIMENSION: INCH. DIM A B C D F G H J K L N P Q R S U INCHES MIN MAX 1.145 1.175 0.685 0.715 0.305 0.325 0.016 0.020 0.048 0.064 0.100 BSC 0.182 0.194 0.014 0.016 0.695 0.725 0.290 0.300 0.420 0.440 0.153 0.159 0.153 0.159 0.230 0.250 0.220 0.240 0.910 BSC MILLIMETERS MIN MAX 29.08 29.85 17.40 18.16 7.75 8.26 0.41 0.51 1.22 1.63 2.54 BSC 4.62 4.93 0.36 0.41 17.65 18.42 7.37 7.62 10.67 11.18 3.89 4.04 3.89 4.04 5.84 6.35 5.59 6.10 23.11 BSC

B

PIN 1

1 2 3 4

K S F G D 4 PL 0.13 (0.005)

P 0.25 (0.010) J C

M

T Q

T S

CASE 344B01 ISSUE B

STYLE 1: PIN 1. 2. 3. 4.

GROUND + OUTPUT + SUPPLY - OUTPUT

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES UNIBODY PACKAGE DIMENSIONS CONTINUED

V R

PORT #2 PORT #1

A U W H

PORT #2 VACUUM (P2)

L

PORT #1 POSITIVE PRESSURE (P1)

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. DIM A B C D F G H J K L N P Q R S U V W INCHES MIN MAX 1.145 1.175 0.685 0.715 0.405 0.435 0.016 0.020 0.048 0.064 0.100 BSC 0.182 0.194 0.014 0.016 0.695 0.725 0.290 0.300 0.420 0.440 0.153 0.159 0.153 0.159 0.063 0.083 0.220 0.240 0.910 BSC 0.248 0.278 0.310 0.330 MILLIMETERS MIN MAX 29.08 29.85 17.40 18.16 10.29 11.05 0.41 0.51 1.22 1.63 2.54 BSC 4.62 4.93 0.36 0.41 17.65 18.42 7.37 7.62 10.67 11.18 3.89 4.04 3.89 4.04 1.60 2.11 5.59 6.10 23.11 BSC 6.30 7.06 7.87 8.38

Q

SEATING PLANE

SEATING PLANE PIN 1

1 2 3 4

P T J C 0.13 (0.005)

M

K

S

0.25 (0.010)

T Q

S G D 4 PL

T S

CASE 344C01 ISSUE B

STYLE 1: PIN 1. 2. 3. 4.

GROUND + OUTPUT + SUPPLY - OUTPUT

PORT #1 POSITIVE PRESSURE (P1)

C

BACK SIDE VACUUM (P2)

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. DIM A B C D F G J K N R S V INCHES MIN MAX 0.690 0.720 0.245 0.255 0.780 0.820 0.016 0.020 0.048 0.064 0.100 BSC 0.014 0.016 0.345 0.375 0.300 0.310 0.178 0.186 0.220 0.240 0.182 0.194 STYLE 1: PIN 1. 2. 3. 4. MILLIMETERS MIN MAX 17.53 18.28 6.22 6.48 19.81 20.82 0.41 0.51 1.22 1.63 2.54 BSC 0.36 0.41 8.76 9.53 7.62 7.87 4.52 4.72 5.59 6.10 4.62 4.93

V

4 3 2 1 PIN 1

K J R

SEATING PLANE

S G F D 4 PL 0.13 (0.005)

M

T B

GROUND + OUTPUT + SUPPLY - OUTPUT

CASE 344E01 ISSUE B

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES SMALL OUTLINE PACKAGE DIMENSIONS

A

5 4

D 8 PL 0.25 (0.010)

M

T B

N B

8

G

1

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION A AND B DO NOT INCLUDE MOLD PROTRUSION. 4. MAXIMUM MOLD PROTRUSION 0.15 (0.006). 5. ALL VERTICAL SURFACES 5_ TYPICAL DRAFT. DIM A B C D G H J K M N S V W INCHES MIN MAX 0.415 0.425 0.415 0.425 0.500 0.520 0.038 0.042 0.100 BSC 0.002 0.010 0.009 0.011 0.061 0.071 0_ 7_ 0.444 0.448 0.709 0.725 0.245 0.255 0.115 0.125 MILLIMETERS MIN MAX 10.54 10.79 10.54 10.79 12.70 13.21 0.96 1.07 2.54 BSC 0.05 0.25 0.23 0.28 1.55 1.80 0_ 7_ 11.28 11.38 18.01 18.41 6.22 6.48 2.92 3.17

V C H J K M

PIN 1 IDENTIFIER

T

SEATING PLANE

CASE 482A01 ISSUE A

A

5 4

N B

8

G

1

0.25 (0.010)

T B

D 8 PL S A

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION A AND B DO NOT INCLUDE MOLD PROTRUSION. 4. MAXIMUM MOLD PROTRUSION 0.15 (0.006). 5. ALL VERTICAL SURFACES 5_ TYPICAL DRAFT. 6. DIMENSION S TO CENTER OF LEAD WHEN FORMED PARALLEL. S DIM A B C D G J K M N S V W SEATING PLANE INCHES MIN MAX 0.415 0.425 0.415 0.425 0.500 0.520 0.026 0.034 0.100 BSC 0.009 0.011 0.100 0.120 0_ 15 _ 0.444 0.448 0.540 0.560 0.245 0.255 0.115 0.125 MILLIMETERS MIN MAX 10.54 10.79 10.54 10.79 12.70 13.21 0.66 0.864 2.54 BSC 0.23 0.28 2.54 3.05 0_ 15 _ 11.28 11.38 13.72 14.22 6.22 6.48 2.92 3.17

DETAIL X S W

V C

PIN 1 IDENTIFIER

T K M J DETAIL X

CASE 482C03 ISSUE B

Motorola Sensor Device Data

MPX10 MPXV10GC SERIES

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Typical parameters which may be provided in Motorola data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including Typicals must be validated for each customer application by customers technical experts. Motorola does not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us: USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; P.O. Box 5405, Denver, Colorado 80217. 13036752140 or 18004412447 Technical Information Center: 18005216274

JAPAN: Motorola Japan Ltd.; SPS, Technical Information Center, 3201, MinamiAzabu. Minatoku, Tokyo 1068573 Japan. 81334403569 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; Silicon Harbour Centre, 2, Dai King Street, Tai Po Industrial Estate, Tai Po, N.T., Hong Kong. 85226668334

HOME PAGE: http://www.motorola.com/semiconductors/

Motorola Sensor Device Data

MPX10/D

Vous aimerez peut-être aussi

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsD'EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Map Sensor Technical SpecificationDocument13 pagesMap Sensor Technical SpecificationEdward Fisher100% (2)

- III-1 & III-2 Specifications Volume 2Document588 pagesIII-1 & III-2 Specifications Volume 2saleem buksh100% (1)

- 1282094111153Document9 pages1282094111153PaperCraft VNPas encore d'évaluation

- Geogrid ReinforcementDocument5 pagesGeogrid ReinforcementphilipyapPas encore d'évaluation

- T83840en PDFDocument6 pagesT83840en PDFshareyhou100% (1)

- NPCP Chapter 2 PDFDocument12 pagesNPCP Chapter 2 PDFbenPas encore d'évaluation

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageD'EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StoragePas encore d'évaluation

- BS 4514 2001 PDFDocument18 pagesBS 4514 2001 PDFanas shehabi100% (1)

- Spent Caustic Treatment Options-Saudi AramcoDocument20 pagesSpent Caustic Treatment Options-Saudi Aramcoonizuka-t22630% (1)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsD'EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsPas encore d'évaluation

- Cathelco ICCP Hull Protection SystemsDocument8 pagesCathelco ICCP Hull Protection SystemsdalianbouriPas encore d'évaluation

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- PuneDocument564 pagesPuneANSHUMANPas encore d'évaluation

- General Electric - Inlet Air RecommendationDocument28 pagesGeneral Electric - Inlet Air Recommendationhussain mominPas encore d'évaluation

- MPX10GSDocument9 pagesMPX10GSJoseph BurgosPas encore d'évaluation

- MPX2200Document9 pagesMPX2200Josimar Marquez GarciaPas encore d'évaluation

- MPX200Document8 pagesMPX200Hugo ContrerasPas encore d'évaluation

- MPX10Document9 pagesMPX10rezaPas encore d'évaluation

- Semiconductor Technical Data: Order This Document by MPX2010/DDocument13 pagesSemiconductor Technical Data: Order This Document by MPX2010/DTaTa ArroyavePas encore d'évaluation

- DatasheetDocument8 pagesDatasheetkunal5959Pas encore d'évaluation

- MPX2010Document12 pagesMPX2010Arni IrenawatiPas encore d'évaluation

- MPX2202DDocument19 pagesMPX2202DCristhian Omar Goicochea EscobarPas encore d'évaluation

- Mpx2050 Data SheetDocument9 pagesMpx2050 Data SheetKarthi Manthangudi SellanPas encore d'évaluation

- MPX2053 MPXV2053G DatasheetDocument12 pagesMPX2053 MPXV2053G DatasheetkurmakkPas encore d'évaluation

- MPXV7007Document11 pagesMPXV7007Phi MacPas encore d'évaluation

- MPX2010 PDFDocument17 pagesMPX2010 PDFEnte Bliss OnixPas encore d'évaluation

- MPX4100ASDocument9 pagesMPX4100ASFahriz D. AuliaPas encore d'évaluation

- Freescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument22 pagesFreescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedRafanuñez RodriguezPas encore d'évaluation

- MPX5050 PDFDocument18 pagesMPX5050 PDFKurniaBagusPas encore d'évaluation

- MPX4250Document9 pagesMPX4250mohsihummerPas encore d'évaluation

- MPX5010Document16 pagesMPX5010Arsonval FleuryPas encore d'évaluation

- MPX5500 Sensor de Presion para ArduinoDocument7 pagesMPX5500 Sensor de Presion para ArduinoMarvin Melendez VanegasPas encore d'évaluation

- Mpx4250ap PDFDocument8 pagesMpx4250ap PDFLeonard OnsikPas encore d'évaluation

- MPX10DPDocument8 pagesMPX10DPsuperpuma86Pas encore d'évaluation

- MPX5700Document11 pagesMPX5700frederypsPas encore d'évaluation

- Datasheet MPX5100DPDocument16 pagesDatasheet MPX5100DPKemahyanto Exaudi SiahaanPas encore d'évaluation

- Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument11 pagesIntegrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and Calibratedsuri_girishPas encore d'évaluation

- MPX5100Document17 pagesMPX5100Andri PaoPas encore d'évaluation

- Freescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument7 pagesFreescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedJavier GuzmánPas encore d'évaluation

- MPX5700Document11 pagesMPX5700mardonioandradePas encore d'évaluation

- Semiconductor Technical Data: Integrated Pressure Sensor 0 To 10 Kpa (0 To 1.45 Psi) 0.2 To 4.7 V OutputDocument11 pagesSemiconductor Technical Data: Integrated Pressure Sensor 0 To 10 Kpa (0 To 1.45 Psi) 0.2 To 4.7 V Outputjose ulloaPas encore d'évaluation

- Freescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument10 pagesFreescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and Calibrateddafs10Pas encore d'évaluation

- MPX5010 PDFDocument17 pagesMPX5010 PDFAdán LópezPas encore d'évaluation

- MPX4115 (Sensor Presion)Document10 pagesMPX4115 (Sensor Presion)Ricardo Xavier Otazo LópezPas encore d'évaluation

- Data Sheet Motorola SensorDocument6 pagesData Sheet Motorola SensorLuis Angel BaldenegroPas encore d'évaluation

- Data Sheet - MPX5050DPDocument18 pagesData Sheet - MPX5050DPRudi SetiyawanPas encore d'évaluation

- MPX5050DP DatasheettDocument12 pagesMPX5050DP DatasheettCulun HabisPas encore d'évaluation

- MPX4250ADocument11 pagesMPX4250ARenivaldoPas encore d'évaluation

- Motorola MPX5700-Series Pressure Sensor PDFDocument9 pagesMotorola MPX5700-Series Pressure Sensor PDFIvo AlvesPas encore d'évaluation

- 040shj60h8k5a4yex8yk4dhwa53y PDFDocument9 pages040shj60h8k5a4yex8yk4dhwa53y PDFRenivaldoPas encore d'évaluation

- MPXHZ6115ADocument17 pagesMPXHZ6115Ad.c.delatorre2200Pas encore d'évaluation

- MPX 4115Document8 pagesMPX 4115Mohamed AwadPas encore d'évaluation

- Multi Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelDocument22 pagesMulti Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelMasroor RasoolPas encore d'évaluation

- MPXA4511A Pressure SensorDocument9 pagesMPXA4511A Pressure SensorGiuseppe ZangariPas encore d'évaluation

- SensorDocument6 pagesSensorFarhan ZafarPas encore d'évaluation

- ASDX Pressure SensorDocument6 pagesASDX Pressure SensorGuilherme VilaçaPas encore d'évaluation

- General Specifications: EJX118A Diaphragm Sealed Differential Pressure TransmitterDocument20 pagesGeneral Specifications: EJX118A Diaphragm Sealed Differential Pressure TransmitterapisituPas encore d'évaluation

- PT SiemensDocument82 pagesPT SiemensAnthony AdamsPas encore d'évaluation

- Barometer Mpx2100apDocument10 pagesBarometer Mpx2100apVurdalack666Pas encore d'évaluation

- Pressure Sensor ModulesDocument3 pagesPressure Sensor Modulesphani22Pas encore d'évaluation

- Traductor de PresiuneDocument22 pagesTraductor de PresiuneCamelia PăduraruPas encore d'évaluation

- GS01C25B01 01eDocument14 pagesGS01C25B01 01epredrag123Pas encore d'évaluation

- Argus General Brochure V8Document20 pagesArgus General Brochure V8danieldayettddPas encore d'évaluation

- Manual Catia V5 R12Document262 pagesManual Catia V5 R12Leandro SebastiánPas encore d'évaluation

- 66210-76110-76115 Weathercoat GP. Water ProofingDocument2 pages66210-76110-76115 Weathercoat GP. Water ProofingUpulHettiarachchiPas encore d'évaluation

- Hanser BooksDocument30 pagesHanser Bookshabiba jamilPas encore d'évaluation

- Level 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetDocument2 pagesLevel 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetAnand AmanPas encore d'évaluation

- Stud Welding Instruction ManualDocument5 pagesStud Welding Instruction Manualedwin jimenezPas encore d'évaluation

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- Capstone Report On Wheel Chair Cum StretcherDocument40 pagesCapstone Report On Wheel Chair Cum StretcherRakesh Moparthi100% (1)

- Comfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаDocument28 pagesComfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаJohn SmithPas encore d'évaluation

- Delayed CokingDocument7 pagesDelayed CokingMatheus RodriguesPas encore d'évaluation

- TD Operators ManualDocument84 pagesTD Operators Manualsivan_sg1800Pas encore d'évaluation

- Experiment 1Document4 pagesExperiment 1Kathrine E. BautistaPas encore d'évaluation

- Specifications Virgin Fuel Oil D6: Method Units Test Result UnitDocument1 pageSpecifications Virgin Fuel Oil D6: Method Units Test Result UnitDavid garzaPas encore d'évaluation

- A560 - Castings Chromium Nickel AlloyDocument3 pagesA560 - Castings Chromium Nickel AlloychemtausifPas encore d'évaluation

- Summer Internship At: Haldia Petrochemicals LTDDocument11 pagesSummer Internship At: Haldia Petrochemicals LTDJyoti PrakashPas encore d'évaluation

- Dow Therm J SpecificationsDocument28 pagesDow Therm J SpecificationsClintronicPas encore d'évaluation

- Sample Medium Maintenance PlanDocument20 pagesSample Medium Maintenance PlanRajipah OsmanPas encore d'évaluation

- Act 6+14Document4 pagesAct 6+14min95Pas encore d'évaluation

- Carbon Alloy Steel Stainless SteelDocument4 pagesCarbon Alloy Steel Stainless Steelaswar_mhPas encore d'évaluation

- Biomedical Waste Rule 2016 ReviewDocument5 pagesBiomedical Waste Rule 2016 ReviewRakesh VermaPas encore d'évaluation