Académique Documents

Professionnel Documents

Culture Documents

Efd1000 PFD and Efd1000 MFD - Installation Manual

Transféré par

Marcus DragoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Efd1000 PFD and Efd1000 MFD - Installation Manual

Transféré par

Marcus DragoDroits d'auteur :

Formats disponibles

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 1-202 Revision C

Copyright 2008 Aspen Avionics Inc.

EFD1000

Installation Manual

Includes Instructions for Continued Airworthiness

Aspen Document #A-01-126-00 Revision C

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 2-202 Revision C

Copyright 2008 Aspen Avionics Inc.

DOCUMENT REVISIONS

Revision Description of Change

A INITIAL RELEASE

B INITIAL RELEASE FAA APPROVED

C Corrected Figure 9.17 STEC Autopilot Interface to add P1-12 CRS Datum Lo connection. Updated

Section 5.2.4 to add SL-30 limitations. Updated Figure 8.5 ACU Flight Director definitions. Added Table

10.1 EFD1000 Configuration Chart for inclusion in ICAs. Moved ICAs from Section 12 to Appendix D.

Updated Appendix D ICAs. Moved Section 13 Operation to Section 12. Moved Appendix D

Environmental Qualification Forms to Section 13.

Prepared By: TLM Release Authorization

Reviewed By: PDL

Original signatures

on file. See ECO for

release date and

dispositions. Release Date: 3/28/08

Release Initials: DTS

Usage Authorization / Master Control Number:

Release Signature

David T.Stewart

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 3-202 Revision C

Copyright 2008 Aspen Avionics Inc.

The conditions and tests required for TSO approval of the EFD1000 System are minimum

performance standards. It is the responsibility of those installing this article either on or within

specific type or class of aircraft to determine that the aircraft installation conditions are within

the TSO standards. TSO articles must have separate approval for installation in an aircraft. The

article may be installed only if performed under 14 CFR part 43 or the applicable airworthiness

requirements.

This manual contains FAA Approved installation instructions for installation of the Aspen

EFD1000 system under the EFD1000 AML STC for use as a primary electronic flight display

during day/night IFR and VFR operations in those Part 23 Class I and II aircraft (as defined in AC

23.1309-1C) listed on the EFD1000 AML. Installation of the EFD1000 into part 23 Class I or II

aircraft not included in the EFD1000 AML, into any part 23 class III or IV aircraft, or into any part

25, 27, or 29 aircraft requires separate airworthiness approval.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 4-202 Revision C

Copyright 2008 Aspen Avionics Inc.

THIS PAGE IS INTENTIONALLY LEFT BLANK

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 5-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Table of Contents

1 INTRODUCTION ................................................................................................................. 11

1.1 PART NUMBERS......................................................................................................... 11

1.2 INSTALLATION KIT CONTENTS....................................................................................... 11

1.3 ACCESSORIES REQUIRED BUT NOT SUPPLIED...................................................................... 12

1.4 OPTIONAL ACCESSORIES NOT SUPPLIED ........................................................................... 13

1.5 SPECIAL TOOLS REQUIRED............................................................................................ 13

1.6 VENDOR INFORMATION ............................................................................................... 13

1.7 WARRANTY REGISTRATION........................................................................................... 14

1.8 REGULATORY COMPLIANCE .......................................................................................... 14

1.8.1... Technical Standard Order .......................................................................... 14

1.8.2... Software Certification................................................................................ 14

1.8.3... Environmental Compliance ........................................................................ 14

2 EQUIPMENT SPECIFICATIONS AND LIMITATIONS................................................................... 15

2.1 PRIMARY FLIGHT DISPLAY (PFD) & CONFIGURATION MODULE (CM) ........................................ 15

2.1.1... General Specifications ............................................................................... 15

2.1.2... Operational Specifications: ........................................................................ 15

2.1.3... I/O Specifications:..................................................................................... 15

2.1.4... Certification Specifications: ....................................................................... 15

2.1.5... Outline Drawing: ....................................................................................... 16

2.2 REMOTE SENSOR UNIT (RSM): ...................................................................................... 17

2.2.1... General Specifications ............................................................................... 17

2.2.2... Operational Specifications: ........................................................................ 17

2.2.3... I/O Specifications:..................................................................................... 17

2.2.4... Certification Specifications: ....................................................................... 17

2.2.5... Outline Drawing: ....................................................................................... 18

2.3 ANALOG CONVERTER UNIT (ACU): ................................................................................ 19

2.3.1... General Specifications ............................................................................... 19

2.3.2... Operational Specifications: ........................................................................ 19

2.3.3... I/O Specifications:..................................................................................... 19

2.3.4... Certification Specifications: ....................................................................... 19

2.3.5... Outline Drawing: ....................................................................................... 20

3 SYSTEM DESCRIPTION......................................................................................................... 21

3.1 PRIMARY FLIGHT DISPLAY (PFD).................................................................................... 21

3.2 REMOTE SENSOR MODULE (RSM) .................................................................................. 22

3.3 CONFIGURATION MODULE ........................................................................................... 23

3.4 ANALOG CONVERTER UNIT (ACU) ................................................................................. 23

3.5 SYSTEM ARCHITECTURE............................................................................................... 24

4 SUPPORTED INSTALLED CONFIGURATIONS .......................................................................... 25

4.1 PILOT CONFIGURATIONS.............................................................................................. 25

4.2 SIMPLE PRO CONFIGURATION........................................................................................ 26

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 6-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4.3 PRO CONFIGURATIONS WITH AUTOPILOT.......................................................................... 27

4.4 PRO CONFIGURATION WITH AUTOPILOT AND DIGITAL/ANALOG VLOC..................................... 28

4.5 PRO CONFIGURATION WITH AUTOPILOT AND DUAL ANALOG VLOC......................................... 29

5 PRE MODIFICATION PLANNING............................................................................................ 31

5.1 PRE MODIFICATION CHECKLIST ..................................................................................... 31

5.2 REQUIREMENTS AND LIMITATIONS .................................................................................. 32

5.2.1... Standby Attitude Positioning...................................................................... 34

5.2.2... Standby Airspeed and Altimeter Positioning ............................................... 35

5.2.3... Directional Gyro/ HSI................................................................................. 35

5.2.4... Back Up Nav Indicator ............................................................................... 36

5.2.5... GPS Annunciators...................................................................................... 37

5.2.6... Power Requirements.................................................................................. 37

5.3 PART 135 IFR OPERATIONS........................................................................................ 37

5.4 SETTING V-SPEED TEXTUAL MARKERS ........................................................................... 37

5.5 OPTIONAL INTERFACES................................................................................................ 38

5.5.1... Autopilot .................................................................................................. 38

5.5.2... GPSS ........................................................................................................ 38

5.5.3... GPS/ NAV Switching .................................................................................. 39

5.5.4... Sonalert .................................................................................................... 39

5.5.5... Heading Output ........................................................................................ 39

5.5.6... Second ACU.............................................................................................. 39

6 MECHANICAL INSTALLATION .............................................................................................. 41

6.1 UNPACKING AND INSPECTING EQUIPMENT......................................................................... 41

6.2 EQUIPMENT LOCATION DOCUMENTATION......................................................................... 41

6.3 LOG BOOK ENTRY ..................................................................................................... 41

6.4 WEIGHT AND BALANCE................................................................................................ 41

6.5 INSTALLATION LIMITATIONS ......................................................................................... 42

6.6 EQUIPMENT BONDING................................................................................................. 42

6.7 COOLING ................................................................................................................ 43

6.8 PFD INSTALLATION.................................................................................................... 43

6.8.1... PFD Mounting Location.............................................................................. 43

6.8.2... Mounting Bracket Installation .................................................................... 44

6.8.3... PFD Bonding Strap..................................................................................... 44

6.8.4... Pitot and Static Connections ...................................................................... 47

6.8.5... Quick Connector Installation...................................................................... 47

6.8.6... Leak Check Requirements.......................................................................... 48

6.9 RSM INSTALLATION................................................................................................... 49

6.9.1... Proposed RSM Location Check ................................................................... 50

6.9.2... Pressurized Aircraft................................................................................... 51

6.9.3... Second RSM Placement (MFD) .................................................................... 51

6.9.4... RSM Mounting Angles................................................................................ 51

6.9.5... RSM Doubler ............................................................................................. 53

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 7-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6.9.6... RSM Doubler Fabrication ........................................................................... 54

6.9.7... RSM Installation ........................................................................................ 57

6.9.8... RSM mounting on Composite or Fabric ...................................................... 57

6.9.9... RSM Shim Fabrication (if necessary) ........................................................... 58

6.10 ACU INSTALLATION................................................................................................... 60

6.10.1. ACU Mounting........................................................................................... 60

6.11 CONFIGURATION MODULE INSTALLATION......................................................................... 62

7 ELECTRICAL INSTALLATION ................................................................................................ 63

7.1 ELECTRICAL LOAD ANALYSIS......................................................................................... 63

7.2 ELECTRICAL INSTALLATION........................................................................................... 63

7.2.1... HIRF/Lightning Requirements.................................................................... 64

7.2.2... PFD to GPS/VLOC/ACU Wiring.................................................................... 65

7.2.3... RSM Wiring ............................................................................................... 66

7.2.4... Configuration Module Wiring..................................................................... 67

7.2.5... ACU Wiring ............................................................................................... 68

7.2.6... Back Up NAV Indicator Wiring .................................................................... 68

7.2.7... Autopilot Wiring........................................................................................ 68

8 ELECTRICAL CONNECTIONS ................................................................................................ 69

8.1 PFD ELECTRICAL SPECIFICATIONS .................................................................................. 69

8.1.1... Power Input .............................................................................................. 69

8.1.2... Tone (Sonalert) Output .............................................................................. 69

8.1.3... RS-232 GPS Input...................................................................................... 69

8.1.4... ARINC 429 GPS Inputs ............................................................................... 71

8.1.5... ARINC 429 VLOC Input .............................................................................. 72

8.1.6... ARINC 429 GPS Output .............................................................................. 72

8.2 ACU ELECTRICAL SPECIFICATIONS.................................................................................. 72

8.2.1... Power Input .............................................................................................. 72

8.2.2... VLOC Receiver........................................................................................... 73

8.2.3... GPS Receiver ............................................................................................. 73

8.2.4... Autopilot .................................................................................................. 75

8.2.5... ARINC 429 GPS Output .............................................................................. 77

8.3 PFD PIN OUT........................................................................................................... 78

8.4 RSM PIN OUT.......................................................................................................... 79

8.5 CONFIGURATION MODULE PIN OUT................................................................................ 80

8.6 ACU PIN OUT.......................................................................................................... 80

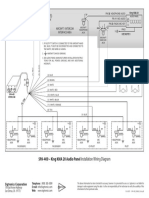

9 INSTALLATION WIRING DIAGRAMS ...................................................................................... 83

10 CONFIGURATION AND EQUIPMENT CHECKOUT.................................................................. 111

10.1 TEST EQUIPMENT..................................................................................................... 111

10.2 WIRING VERIFICATION............................................................................................... 111

10.3 BONDING CHECK FAR 23.867(B) ............................................................................. 112

10.4 SYSTEM CONFIGURATION........................................................................................... 113

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 8-202 Revision C

Copyright 2008 Aspen Avionics Inc.

10.4.1. Main Menu Access................................................................................... 113

10.4.2. Menu Navigation..................................................................................... 113

10.4.3. Edit Mode ............................................................................................... 113

10.4.4. Main Menu Configuration ........................................................................ 113

10.4.5. INSTALLATION MENU UNIT CONFIGURATION.......................................... 118

10.5 RSM CALIBRATION .................................................................................................. 133

10.5.1. Calibration Overview ............................................................................... 133

10.5.2. RSM Calibration Procedure....................................................................... 135

10.5.3. Heading Offset Adjustment ..................................................................... 137

10.5.4. Heading Accuracy Test ............................................................................ 138

10.5.5. Heading Interference Test ....................................................................... 138

10.6 GROUND TEST PROCEDURE ........................................................................................ 139

10.6.1. Indicated Airspeed Display ...................................................................... 139

10.6.2. Altitude Display ...................................................................................... 139

10.6.3. System Leak Test .................................................................................... 139

10.6.4. Outside Air Temperature ......................................................................... 140

10.6.5. AHRS Sensor Test.................................................................................... 140

10.6.6. GPS Sensor Test ...................................................................................... 140

10.6.7. NAV Receiver Sensor Test ........................................................................ 141

10.6.8. Backup Navigation Indicator .................................................................... 141

10.6.9. Autopilot Sensor Test .............................................................................. 141

10.6.10 Flight Director Test ......................................................................... 142

10.6.11 Sonalert Test................................................................................... 143

10.6.12 Ancillary Equipment Heading Check................................................. 143

10.6.13 TAPES Configuration Check ............................................................. 143

10.6.14 EMI Test.......................................................................................... 143

11 POST INSTALLATION FLIGHT CHECK.................................................................................. 145

11.1 BASIC ADI FLIGHT CHECKS ........................................................................................ 145

11.2 BASIC HSI/DG FLIGHT CHECKS .................................................................................. 145

11.3 ILS FLIGHT CHECKS (IF NO AUTOPILOT, OTHERWISE JUMP TO SECTION 11.4)............................ 145

11.4 AUTOPILOT FLIGHT CHECKS (IF INSTALLED)..................................................................... 146

12 OPERATION...................................................................................................................... 149

12.1 PILOT CONTROLS .................................................................................................... 149

12.1.1. Overview................................................................................................. 149

12.1.2. Power Control ......................................................................................... 150

12.1.3. Display and Control Layout...................................................................... 151

12.1.4. Control Knobs......................................................................................... 152

12.2 SETTING FLIGHT INSTRUMENTS.................................................................................... 152

12.3 KNOB SYNC FUNCTION ............................................................................................. 153

12.4 HOT KEY OPERATION ............................................................................................... 154

12.5 CDI AND BEARING POINTER SOURCE SELECTION .............................................................. 156

12.6 BACK LIGHT CONTROL.............................................................................................. 157

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 9-202 Revision C

Copyright 2008 Aspen Avionics Inc.

12.7 MAP RANGE CONTROL.............................................................................................. 158

12.8 DISPLAY REVERSION CONTROL AND ABNORMAL SHUTDOWN................................................ 158

12.9 PRIMARY FLIGHT INSTRUMENTS ................................................................................... 158

12.9.1. Attitude Indicator .................................................................................... 158

12.9.2. Airspeed Indicator................................................................................... 160

12.9.3. Altimeter ................................................................................................ 162

12.9.4. Vertical Speed Indicator (VSI) ................................................................... 163

12.9.5. Rate of Turn Indicator ............................................................................. 164

12.9.6. Data Bar (TAS, GS, OAT, Winds, Barometric pressure Set) .......................... 164

12.9.7. Horizontal Situation Indicator .................................................................. 164

12.9.8. Bearing Pointers...................................................................................... 168

12.10 SITUATIONAL AWARENESS MAP DISPLAY ........................................................................ 168

12.11 AUTOPILOT INTEGRATION.......................................................................................... 171

12.12 MAIN MENU........................................................................................................... 175

12.12.1 Menu Controls ................................................................................ 175

12.12.2 Menu Options ................................................................................. 176

13 ENVIRONMENTAL QUALIFICATION FORMS ......................................................................... 179

APPENDIX A ..................................................................................................................... 183

TROUBLESHOOTING.................................................................................................. 184

APPENDIX B...................................................................................................................... 187

INSTALLATION FINAL CHECK SHEET .............................................................................. 188

APPENDIX C ..................................................................................................................... 191

OPERATOR CONFIGURATION CHECKLIST......................................................................... 192

APPENDIX D..................................................................................................................... 193

INSTRUCTIONS FOR CONTINUED AIRWORTHINESS.............................................................. 193

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 10-202 Revision C

Copyright 2008 Aspen Avionics Inc.

THIS PAGE IS INTENTIONALLY LEFT BLANK

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 11-202 Revision C

Copyright 2008 Aspen Avionics Inc.

1 Introduction

This Installation Manual is FAA Approved and contains detailed installation instructions for

installing the EFD1000 System into specific aircraft as listed in the EFD1000 AML-STC. There are

required FARs that must be complied with and followed to insure an airworthy installation.

Section 5 Pre Modification Planning will guide you through these requirements.

1.1 Part Numbers

The EFD1000 Electronic Flight Display System consists of the following components:

A-05-110-00 EFD1000, TSO

A-05-111-00 REMOTE SENSOR MODULE (RSM)

A-05-112-00 ANALOG CONVERTER UNIT (ACU) optional

A-05-113-00 CONFIGURATION MODULE, PFD PILOT

OR

A-05-114-00 CONFIGURATION MODULE, PFD PRO

A-08-130-00 INSTALLATION KIT, EFD1000

A-08-131-00 INSTALLATION KIT, RSM

A-08-132-00 INSTALLATION KIT, ACU - optional

1.2 Installation Kit Contents

A-08-130-00 EFD1000 Install Kit

Aspen P/N Description Manufacturers P/N

A-08-125-00-A PFD Mounting Bracket Aspen

A-06-564-00 44 Pin HD D-Sub connector with

contacts

Positronics P/N DD44F10000

A-06-573-00 EMI Metal Back shell Positronics P/N D25000GE0

A-06-505-00 Pitot Quick Connector Aspen

A-06-507-00 Static Quick Connector Aspen

A-08-144-00-A Configuration Module Connector

Assembly with pigtail

Aspen

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 12-202 Revision C

Copyright 2008 Aspen Avionics Inc.

A-08-131-00 RSM Install Kit

Aspen P/N Description Manufacturers P/N

A-06-566-00 RSM Circular Connector Hirose P/N SR30-10JF-7S(71)

A-06-567-00 8-32 Stainless Steel screws (4) MS27039C08-17

A-06-568-00 Stainless Steel locking nuts (4) MS21044C08

A-06-569-00 Stainless Steel washers (4) Cad Plated NAS1149EN0832P

A-08-132-00 ACU Install Kit

Aspen P/N Description Manufacturers P/N

A-06-570-00 15 pin D-Sub connector AMP P/N 205163-1

A-06-571-00 25 pin D-Sub connector AMP P/N 205165-1

A-06-572-00 37 pin D-Sub connector AMP P/N 205167-1

A-06-408-00 DB15 pin EMI Back shell NorComp 970-015-030R121

A-06-409-00 DB25 EMI Back shell NorComp 970-025-030R121

A-06-410-00 DB37 EMI Back shell NorComp 970-037-030R121

A-06-574-00 Crimp Sockets (77) Positronics P/N FC6020D

1.3 Accessories Required but Not Supplied

Description Manufacturers P/N

Tee Fittings for pitot/static (2 req) Thogus Products P/N TT-9444

(1/4x1/4x1/4) or equivalent

1/4 pitot and static tubing Imperial Eastman 44PN or equivalent

Over Braid tinned copper light

Over Braid tinned copper med

Alpha Wire P/N 2142 (1/4), P/N 2146 (1/2)

Daburn P/N 2350-X, X=diameter (i.e., 1/2)

Circuit Breaker pull to open (PFD) 7.5 amp MS 26574-7.5 or equivalent

Circuit Breaker (ACU) 2 amp (1 for each ACU) MS26574-2 or equivalent

PFD to GPS/ACU double shielded cable M27500-22TG2V64 or equivalent

Hose Clamps (8 req) Aero Seal 6604 or equiv.

7 conductor shielded cable (PFD to RSM) M27500-A24SD7T23/ M27500-22TG7T14 or

equivalent

Single stranded 24, 22, 20 AWG MIL-W-22759/16 or equiv.

Shielded Wire 22 AWG MIL-C-27500 or equiv.

PFD Mounting Screws #6-32 MS24693-S30 or equiv.

PFD and ACU Mounting Lock Nuts #6-32 MS21044N06 or equiv.

PFD and ACU Mounting Washers NAS1149FN632P or equiv.

ACU mounting Screw #6-32 MS24694-X or equiv.

Miscellaneous screws, washers, cable ties,

etc.

Installer supplied

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 13-202 Revision C

Copyright 2008 Aspen Avionics Inc.

1.4 Optional Accessories Not Supplied

Description Manufacturer

Sonalert (continuous type) Mallory PK or PS series or equivalent

EFIS Master switch rated for 7.5 amps cont. MS35059-22 or equivalent

Circuit Breaker/Switch 7.5amp (PFD) Potter Brumfield W31M-7.5 or equivalent

RSM Doubler Installer fabricated per Section 6.9.5

RSM Shim may be required on extreme

mounting angles

Installer fabricated per Section 6.9.9

RSM sealant non-pressure vessel mounting MIL-A-46146, Dow 738 or equiv.

RSM sealant pressure vessel mounting MIL-PRF-81733D, PS 870B-1/2 or equiv.

1.5 Special Tools Required

D-SUB connectors:

Hand Crimp Tool: Positronics P/N 9507-0-0-0 or equivalent

Insertion/Extraction Tools: Positronics P/N M81969/1-02 or equivalent

1.6 Vendor Information

Aspen Avionics Inc. Alpha Wire Company Over Braid

5001 Indian School Road NE 711 Liderwood Ave.

Albuquerque, NM 87110 Elizabeth, NJ 07207

(505) 856-5034 (908) 925-8000

support@aspenavionics.com info@alphawire.com

A.E. Petsche Co. Double Shielded & RSM Cable Daburn Electronics & Cable Corp Over Braid

2112 West Division St. 224 Pegasus Ave.

Arlington, TX 76012-3693 Northvale, NJ 07647

(817) 461-9473 (201) 768-5400

Info@aepetsche.com daburn@daburn.com

Positronic Industries Inc. - Crimpers, Connectors

423 N. Campbell Ave.

Springfield, MO 65801

(417) 866-2322

info@connectpositronic.com

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 14-202 Revision C

Copyright 2008 Aspen Avionics Inc.

1.7 Warranty Registration

Registration of LRU part numbers and serial numbers must be recorded on the dealer portal of

the Aspen Avionics website at www.aspenavionics.com/dealerramp. Activating the warranty on

the EFD1000 system is just one important aspect of providing a satisfying installation

experience for our customers.

1.8 Regulatory Compliance

1.8.1 Technical Standard Order

All components of the EFD1000 system are produced under Technical Standard Order

Authorization (TSOA).

1.8.2 Software Certification

All software components of the EFD1000 system are developed to RTCA DO-178B

criticality Level C with the exception of the GPS receiver software, which is for

emergency use only.

1.8.3 Environmental Compliance

All system components meet the categories of RTCA/DO-160E according to the

environmental qualification form in Section 13.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 15-202 Revision C

Copyright 2008 Aspen Avionics Inc.

2 Equipment Specifications and Limitations

2.1 Primary Flight Display (PFD) & Configuration Module (CM)

2.1.1 General Specifications

Part Number .............................. A-05-110-00

Width ........................................ 3.50 in. (Measured at Bezel)

Height ....................................... 7.00 in. (Measured at Bezel)

Can Depth................................. 4.15 in. (Rear of Bezel to Rear of Can)

Overall Depth ............................ 6.35 in. (Knob to Rear Pressure Fitting)

Weight....................................... 2.9 lbs with bracket

Display Type.............................. 6.0 in. Diagonal TFT Active Matrix LCD (400x760)

Display Colors ........................... 32,768

Face .......................................... Anti-Reflective Coated Glass

Backlight ................................... High Intensity White LED

Rotary Knobs............................. Optical Encoder with Momentary Push

Dimming ................................... Manual & Automatic (Front Bezel Mounted Sensor)

2.1.2 Operational Specifications:

Operating Temp: ...................... -20C to +55C

Storage Temp: .......................... -55C to +85C

Max Operating Altitude.............. 35,000 ft Unpressurised/ 55,000 ft Pressurized

Cooling ..................................... Integral Fan

Max Humidity............................ 95% at 50C

Input Voltage............................. +8 to +32 Volts DC

Nominal Current ........................ 2.4/4.8 Amps (28v/14v)

2.1.3 I/O Specifications:

ARINC 429 Inputs ...................... 5 Low Speed

ARINC 429 Outputs ................... 1 Low Speed

RS-232 Inputs ........................... 5

RS-232 Outputs ........................ 3

Pitot / Static .............................. Quick Connect

2.1.4 Certification Specifications:

Technical Standard Order:

TSO-C2d .................................. Airspeed Instruments

TSO-C3d .................................. Turn and Slip Instrument

TSO-C4c .................................. Bank and Pitch Instruments

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 16-202 Revision C

Copyright 2008 Aspen Avionics Inc.

TSO-C6d .................................. Direction Instrument Magnetic (Gyroscopically

Stabilized)

TSO-C8d .................................. Vertical Velocity Instrument (Rate-of-Climb)

TSO-C10b ................................ Altitude Pressure Activated Sensitive Type

TSO-C106 ................................ Air Data Computer

TSOC113 ................................ Airborne Multipurpose Electronic Display

Software:

RTCA DO-178B ......................... Level C

Environmental:

RTCA DO-160E.......................... See Environmental Qualification Form Section 13

2.1.5 Outline Drawing:

Figure 2.1 - PFD Outline Drawing (inches)

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 17-202 Revision C

Copyright 2008 Aspen Avionics Inc.

2.2 Remote Sensor Unit (RSM):

2.2.1 General Specifications

Part Number .............................. A-05-111-00

Width ........................................ 2.65 in. (Measured at Base)

Height ....................................... 1.00 in. (Measured from Base)

Length....................................... 4.40 in. (Front to Rear)

Weight....................................... 0.2 lbs

2.2.2 Operational Specifications:

Operating Temp ....................... -55C to +70C

Storage Temp ........................... -55C to +85C

Max Operating Altitude.............. 55,000 ft Unpressurized

Cooling ..................................... None Required

Max Humidity............................ 95% at 50C

Input Voltage............................. Provided by PFD

Nominal Current ........................ Included in PFD Current

2.2.3 I/O Specifications:

Magnetometer ........................... Proprietary Digital

OAT........................................... Proprietary Digital

GPS ........................................... Proprietary Digital

2.2.4 Certification Specifications:

The RSM is certified as a component of the EFD1000 system

Environmental:

RTCA DO-160E.......................... See Environmental Qualification Form Section 13

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 18-202 Revision C

Copyright 2008 Aspen Avionics Inc.

2.2.5 Outline Drawing:

24 inches

4.36

0.99

2.64

1.750

1.625

4 X 0.194

CABLE FEEDTHRU

0.75

Figure 2.2 - RSM Outline Drawing (inches)

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 19-202 Revision C

Copyright 2008 Aspen Avionics Inc.

2.3 Analog Converter Unit (ACU):

2.3.1 General Specifications

Part Number .............................. A-05-112-00

Width ........................................ 5.75 in. including mounting flanges

Height ....................................... 1.60 in.

Length....................................... 4.30 in.

Weight....................................... 0.8 lbs

2.3.2 Operational Specifications:

Operating Temp: ...................... -20C to +55C

Storage Temp: .......................... -55C to +85C

Max Operating Altitude.............. 35,000 ft Unpressurized/ 55,000 ft Pressurized

Cooling ..................................... none required

Max Humidity............................ 95% at 50C

Input Voltage............................. +11 to +32 Vdc

Nominal Current ........................ 0.5/1.0 Amps (28v/14v)

2.3.3 I/O Specifications:

ARINC 429 Inputs ...................... 2 Low Speed

ARINC 429 Outputs ................... 2 Low Speed

RS-232 Inputs ........................... 1 (software loading only)

VHF Nav Receiver....................... 1 Analog input

GPS Receiver.............................. 1 Analog input

GPS OBS Interface ...................... 1 Output

GPS Discrete.............................. 4 Active low inputs

DH Discrete ............................... 1 Active low input

Flight Director ........................... 1 output port

Autopilot Interface..................... 1 Analog port

2.3.4 Certification Specifications:

The ACU is certified as a component of the EFD1000 system

Environmental:

RTCA DO-160E.......................... See Environmental Qualification Form Section 13

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 20-202 Revision C

Copyright 2008 Aspen Avionics Inc.

2.3.5 Outline Drawing:

4

.7

2

4

.3

0

Figure 2.3 - ACU Outline Drawing (inches)

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 21-202 Revision C

Copyright 2008 Aspen Avionics Inc.

3 System Description

The EFD1000 system is comprised of the Primary Flight Display (PFD), Remote Sensor Module

(RSM), Configuration Module (CM) and optional Analog Converter Unit (ACU). The flight deck

display is designed specifically for general aviation aircraft.

The EFD1000 system provides display of attitude, airspeed, altitude, direction of flight, vertical

speed, turn rate, and turn quality. The system may optionally provide display of navigation

information, pilot-selectable indices (bugs), and annunciations to increase situational awareness

and enhance flight safety.

Two configurations, Pilot and Pro are available, which support different software feature sets.

3.1 Primary Flight Display (PFD)

The PFD is a digital system that consists of a high resolution 6 diagonal color LCD display,

user controls, photocell and Micro SD data card slot. The rear portion of the unit consists of a

non-removable electronics module which contains a full air data computer, attitude heading

reference system, power supplies, backup battery, and dual processor electronics. Also on

the rear of the unit, a fan is provided to cool the backlight and electronics.

The PFD mounts to the front surface of most instrument panels. The electronics module and

cooling fins on the back are sized to fit into existing mechanical attitude and heading

indicator instrument panel holes.

The mechanical design allows the instrument to be installed in the place of the mechanical

gyroscopic attitude and heading indicators, without interfering with the surrounding

instruments. The installation will require minimal, if any, mechanical modifications to most

general aviation aircraft instrument panels.

The PFD contains a microSD card port and reader at the bottom of the display bezel. In the

future, software updates and system upgrades will be loaded via this port.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 22-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Figure 3.1 - PFD

The PFD is a pure digital system and natively supports both ARINC 429 and RS-232 digital

interfaces. In installations with a modern digital radio installation, the PFD connects directly

to the interfaced equipment.

In installations that require interfaces to non-ARINC avionics (i.e., older VLOC radios and

autopilots) the ACU is required to convert these signals into ARINC 429 for the PFD.

3.2 Remote Sensor Module (RSM)

The RSM is required and connects directly to the PFD. It physically resembles a traditional GPS

antenna and follows the industry standard mounting hole pattern.

However, internally it is substantially more complex in that it contains all of the sensors that

must be remotely located from the PFD display unit.

The RSM is powered by the PFD through a shielded wire harness and contains the following

sub-systems:

Outside Air Temperature (OAT) sensor

Emergency backup GPS engine

Heading flux sensors

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 23-202 Revision C

Copyright 2008 Aspen Avionics Inc.

The RSM is mounted externally in a magnetically quite environment to provide acceptable

reception for the integral GPS antenna and to minimize magnetic disturbances that would

impact accurate magnetometer operation.

3.3 Configuration Module

The Configuration Module contains an EEPROM device which retains system configuration and

calibration data. The Configuration Module connects to the PFD through a short fabricated

harness and is fastened to the main wiring bundle of the PFD.

The Configuration Module provides two primary functions:

Retains aircraft specific configuration, calibration data and user settings, allowing the

PFD to be swapped for service purposes without re-entering or re-calibrating the

installation.

Contains a license key that configures the PFD software to either the Pilot or Pro

feature set.

3.4 Analog Converter Unit (ACU)

For the Pro model only, the optional Analog Converter Unit (ACU) provides compatibility with

older, analog-based avionics when required. The ACU converts and concentrates multiple

analog interfaces to digital ARINC 429 buses supported by the PFD. Control parameters, such

as desired heading, are also sent from the PFD to the ACU for conversion to analog format for

autopilot support.

The feature set of the Pilot system does not support interface to navigation equipment, and

therefore does not support the ACU interface. The ACU is required when any of the following

capabilities are required in a Pro installation:

Interface to supported autopilots

Interface to supported non-ARINC 429 VLOC navigation radios

Interface to supported non-ARINC 429 GPS navigators

Interface to supported radar altimeter decision height

If digital radios (i.e., Garmin 4XX/5XX series radios) are equipped in the aircraft, and no other

aircraft interfaces are desired, the ACU is not required.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 24-202 Revision C

Copyright 2008 Aspen Avionics Inc.

3.5 System Architecture

The system architecture in Figure 3.2 shows the relationships of the PFD, RSM, Configuration

Module and ACU.

Figure 3.2 - EFD1000 System Architecture

Note: Radar Altimeter DH will be functional in

future software release

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 25-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4 Supported Installed Configurations

The following diagrams show the different options for integrating with existing avionics in the

installed fleet. Most common digital VLOC radios (such as the Garmin 4xx/5xx series), and

analog VLOC radios are supported. The following diagrams show common installation

configurations, but do not represent all possible combinations.

4.1 Pilot Configurations

The following configurations show a basic Pilot installation. The Pilot model does not support

the display of VLOC or GPS navigation deviation, only the GPS flight plan and position is

received and displayed. The Pilot model does not support the ACU and therefore autopilot

interfaces are not available.

Figure 4.1 - Pilot Configurations

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 26-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4.2 Simple Pro Configuration

The following configuration shows a simple Pro installation, without an advanced autopilot

and flight director. No ACU is required for this installation. This installation would be used

when there is no analog VLOC receiver and the autopilot L/R input is dedicated to the GPS.

The PFD navigation source selection has no control over the autopilot input.

Tracker autopilots that use L/R steering can also be wired to an ACU so that the PFD displayed

navigation source L/R output is switched to the autopilot. These installations will be wired as

shown in Figure 4.3 minus the heading and course datum, flag, ILS Energize, and glide slope

signals.

Figure 4.2 - Simple Pro Configurations

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 27-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4.3 Pro Configurations with Autopilot

The following configurations show Pro installations with autopilot integration, but without

analog VLOC interfaces. A backup Navigation indicator is required in installations that do not

have an integral CDI display on the GPS receiver or VLOC receiver. There must be one

navigation indicator available to the pilot in the event of a PFD or ACU failure.

Figure 4.3 Pro Configurations with Autopilot

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 28-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4.4 Pro Configuration with Autopilot and Digital/Analog VLOC

The following configuration shows a Pro installation with autopilot integration, a single digital

VLOC/GPS, a single analog VLOC, and a single RS-232/ analog GPS. A backup Navigation

indicator is required in installations that do not have an integral CDI display on the GPS

receiver or VLOC receiver. There must be one navigation indicator available to the pilot in the

event of a PFD or ACU failure.

Figure 4.4 - Pro Configuration with AP and VLOC

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 29-202 Revision C

Copyright 2008 Aspen Avionics Inc.

4.5 Pro Configuration with Autopilot and Dual Analog VLOC

The following configuration shows a Pro installation with autopilot integration and dual analog

VLOC interfaces. Two ACUs are required for this installation. A backup Navigation indicator

is required in installations that do not have an integral CDI display on the GPS receiver or

VLOC receiver. There must be one navigation indicator available to the pilot in the event of a

PFD or ACU failure.

Figure 4.5 - Pro Configuration with AP and Dual VLOC

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 30-202 Revision C

Copyright 2008 Aspen Avionics Inc.

THIS PAGE IS INTENTIONALLY LEFT BLANK

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 31-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5 Pre Modification Planning

This section contains requirements that must be considered before installing the EFD1000. This

section will guide you through the requirements to ensure FAR compliance; including required

equipment, required secondary equipment, secondary equipment relocation and placement, and

optional equipment.

5.1 Pre Modification Checklist

Complete Table 5.1 to insure that the aircraft to be modified is a candidate for installation of

the EFD1000 system using this AML-STC. It is required to have a PASS or NA for all rows in

order to use this AML-STC as the certification basis for the EFD1000 installation. NA means

Not Applicable because no interface will be made to that device. Only items 5, 8, 9, 10, 11 &

12 below may use NA in the PASS box.

ITEM Criteria PASS

1 Is the aircraft to be modified on the Approved Model List (AML)?

2 Does aircraft have sufficient electrical capacity to supply all required

equipment given the current draw in Table 7.1?

3 Is there an acceptable location to mount or relocate the required standby

instruments in the pilots field of view? (see Figure 5.2)

4 Do the standby instruments meet the requirements of Figure 5.1?

5 Is a backup navigation indicator required (see section 5.2.4) - NA if no

Backup Nav indicator is required. If a backup indicator is required, is there

an acceptable location to mount or relocate a required backup Nav

Indicator in the pilots field of view? (see Figure 5.2)

6 Is there an acceptable location to mount the RSM? (see Section 6.9)

7 Is there a location to mount a PFD circuit breaker that will be accessible

to the pilot while seated?

8 If mounting an optional PFD Master switch is there a mounting location

accessible to the pilot while seated? NA if not installed.

9 If installing an optional ACU or ACUs is there a location to mount a

circuit breaker or breakers that is accessible to the pilot while seated? -

NA if no ACU installed.

10 Does the aircraft have a compatible GPS receiver or will one be installed?

(see Electrical Interface Section 8 to determine compatibility) - NA if no

GPS interface.

11 Does the aircraft have a compatible Navigation receiver or will one be

installed? (see Electrical Interface Section 8 to determine compatibility) -

NA if no NAV interface.

12 If the aircraft is equipped with an autopilot is the Autopilot compatible?

(see Electrical Interface Section 8 to determine compatibility) - NA if no

autopilot interface.

Table 5.1 Pre Modification Checklist

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 32-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.2 Requirements and Limitations

FAR 23.1311(a)(5) requires that independent secondary instruments be installed (existing

units may be relocated) for Attitude, Altitude, Airspeed, and magnetic direction indicator

whisky compass when an Electronic Display (i.e., EFD1000) is used as the primary

instrument.

Part 23 aircraft that have no existing attitude Indicator must install a standby attitude

indicator along with the PFD as required by FAR 23.1311(a)(5) even though the aircraft

operates under VFR rules as per 91.205(b). Any deviation from this regulation requires

separate FAA approval.

The existing outside air temperature probe (if installed) and magnetic direction indicator

whisky compass may not be removed during the installation of the EFD1000 system.

Pneumatic Standby Instruments

Aircraft with existing pneumatic attitude, altitude, and airspeed instruments may relocate

them as necessary as described in Section 5.2.1. The standby airspeed and altimeter should

be connected to an independent pitot and static line (independent from PFD) whenever

available.

Electric Standby Instruments

Aircraft that are all electric must keep the EFD1000 PFD on an independent power source from

the standby instruments as determined from the flow chart of Figure 5.1. The installer must

verify that the standby instruments are electrically isolated from the PFD through either of the

following two methods:

A) Standby instruments are powered by a dedicated standby battery separate from the

aircraft starter battery. [Note: The EFD1000 internal battery does not qualify as an

independent battery under FAR 23.1353(h)]

B) Dual independent electrical systems (dual alternators and dual batteries) with the PFD

on one system and the standby instruments on the other system.

Removal of pneumatic standby instruments and installation of electric standby instruments is

not authorized by this STC. Separate installation approval would be required.

The installation of dual independent electrical systems or a standby (emergency) battery is not

authorized by this STC. Separate installation approval would be required.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 33-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Figure 5.1 Standby Instrument Power Requirements

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 34-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.2.1 Standby Attitude Positioning

The Attitude indicator must be relocated to a position that meets FAR 23.1321(a). The

requirements are 35 degrees from the pilots center line horizontally ( 21 inches

from centerline as defined by AC23-11) to an area just below the basic T configuration

to the glare shield vertically (see Figure 5.2 below). Standby instruments should be

mounted as close as practical to the primary instruments, but in no case outside 35.

NOTE: The existing instrument holes for the Turn and Bank and the Vertical Speed

indicator meet this requirement.

Figure 5.2 Standby Instrument Placement

Also note that some attitude indicators are the primary pitch and roll reference for the

autopilot and must remain in the aircraft (i.e., KI-256). For rate based autopilots the

Turn and Bank Indicator will need to remain in the aircraft, and may be relocated to the

co-pilot side or blind mounted provided it is not used as the autopilot mode controller.

If used as the autopilot mode controller then it must be located where it can be easily

reached by the pilot while seated.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 35-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.2.2 Standby Airspeed and Altimeter Positioning

In a single PFD installation the existing airspeed indicator and altimeter may remain in

their original location. However, if the original location does not satisfy the basic T

configuration per FAR 23.1321(d) it will be required to LOCK the airspeed and

altitude tape in the PFD to ON via the installation menu. If the airspeed indicator is

not in position (AS) and the altimeter in position (AL) of Figure 5.3 below then the

TAPES must be LOCKED ON so that the pilot cannot de-clutter them from the display

during flight.

WARNING: Failure to adhere to the specific instrument layout requirements and

EFD1000 configuration requirements will violate the STC.

Likewise older aircraft panel layouts that do not have the airspeed indicator to the left,

or the altimeter to the right of the attitude indicator (AI) must either relocate the

instrument(s) to these positions or set the TAPES setting to LOCK ON in the

installation configuration menu.

Figure 5.3 Basic T configuration

5.2.3 Directional Gyro/ HSI

The EFD1000 Flight Display will replace the existing Directional Gyro or HSI in the

panel. Provided the existing compass system is not driving a heading input to another

device in the aircraft, it may be removed from the aircraft at the operators discretion.

If another device is bootstrapped off of the compass then it will need to be

determined whether low speed ARINC 429 heading is accepted by this device and

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 36-202 Revision C

Copyright 2008 Aspen Avionics Inc.

rewired appropriately. If the other device only accepts ARINC 407 synchro heading

then it may be necessary to keep the existing compass system in the aircraft and move

the indicator to another location.

A magnetic direction indicator whisky compass or equivalent is required as a

secondary direction indicator per FAR 23.1311(a)(5).

5.2.4 Back Up Nav Indicator

For certification reasons a backup navigation indicator is required in any installation

where the EFD1000 is the only display of navigation information in the cockpit. This

will ensure that a failure of the EFD1000 system does not result in a complete loss of

all navigation data to the flight crew

Thus, for example, an installation that includes a panel mount GPS with an integral LCD

display that includes a CDI indicator would not require a backup nav indicator.

However, a configuration with no GPS and dual legacy VLOC radios that do not include

an integral display with CDI indications will require a backup nav indicator.

If there is already a dedicated indicator wired to an existing NAV Receiver or GPS then

it can be paralleled to the ACU as shown in Section 9.

WARNING: Failure to provide a backup Nav indicator when required will violate the

STC.

Garmin SL-30 Interface

The Garmin SL-30 when connected to the EFD1000 system through the composite

video input requires that the SL-30 be configured for Converter in the set-up mode.

When you configure the SL-30 for Converter it disables the OBS input to the radio

thereby disabling the Left/Right/To/From analog outputs and it also disables VOR

Monitor mode and Back Course mode. Therefore the SL-30 cannot be used to directly

drive a backup HSI or Nav indicator without an internal converter. If you desire to

connect the SL-30 to the EFD1000 you must do one of the following: use one of the

backup Nav indicators in Figure 9.24, use a KN-72 VLOC Converter between the SL-30

composite out and Nav indicator analog in, or use a backup Nav indicator connected to

another navigation receiver in the aircraft.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 37-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.2.5 GPS Annunciators

The EFD1000 is capable of displaying GPS annunciations on the HSI portion of the

display from those ARINC 429 connected GPS receivers that output these labels. If

using the PFD display for any required GPS annunciations verify that the GPS receiver

outputs these messages on the ARINC 429 bus.

GPS Annunciations on PFD (if provided by GPS):

MSG

WPT

TERM

APPR

INTEG

5.2.6 Power Requirements

An electrical load analysis must be performed to ensure the installed EFD1000

components do not exceed the current capacity of the aircrafts charging system (see

Section 7.1).

An EFIS MASTER switch or switch breaker to the PFD may be installed if the customer

desires to isolate the PFD during engine starts. The PFD breaker must be a pull type

breaker and should be connected to the switched battery bus. A location will need to

be found for the ACU breaker(s) and they should be connected to the avionics bus

(switched battery bus if no avionics bus).

5.3 PART 135 IFR Operations

The 30 minute back-up battery in the PFD is not approved for use as a power source to meet

the electrical power source requirement for single engine Part 135 IFR operations under 14

CFR 135.163.

5.4 Setting V-SPEED Textual Markers

Have the aircraft operator complete Operator Configuration Checklist in Appendix C so that

this data is available prior to configuring the system in Section 10. We suggest making a copy

of this form and have it signed by owner/operator, then put a copy in Installation Package.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 38-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.5 Optional Interfaces

5.5.1 Autopilot

The EFD1000 Pro with ACU emulates a KI-525A HSI by providing HDG Datum, CRS

Datum, and navigation L/R outputs to a connected autopilot. Any autopilot compatible

with the KI-525 HSI is compatible with the EFD1000 System.

Similarly, the EFD1000 Pro with ACU emulates the KI-254/KI-256 flight director

indicator by accepting FD signals compatible with these indicators and displaying them

on the EFD. Any autopilots that output a flight director signal that is compatible with

the KI-254/256 is compatible with the EFD1000 System.

Section 9 of this document shows interconnect diagrams for common autopilots that

are KI-525A and KI 254/256 compatible, and therefore also compatible with the

EFD1000. Because the EFD1000 outputs Heading Datum and Course Datum via the

ACU the existing HSI/DG is no longer required to provide this output to the autopilot.

In addition, some existing autopilots that have only a DG installed (i.e. no HSI) will gain

full HSI features with the installation of the EFD1000 System. Please check the

manufacturers installation data for any jumpers or hardware that needs to be added or

removed from the autopilot to add the HSI interface.

When the EFD1000 System is installed, the ACU controls all analog navigation signals

provided to the autopilot. Navigation signal output to the autopilot is switched

depending on which sensor is coupled to the EFD1000 HSI. Therefore the

LT/RT/UP/DN, flags, and ILS Energize must only be connected between the ACU and

autopilot, and there should be no direct connection between the navigation receiver

and the autopilot.

The autopilots flight director output may be paralleled from the autopilot to the

existing Flight Director and ACU so that it is displayed on both instruments. The FD

may also be connected to just the ACU for Flight Director display on the PFD when

there is no existing flight director.

5.5.2 GPSS

GPS Steering provides a steering command to the autopilot through the HDG Datum

channel to provide for enroute, procedure turn, holding pattern, and turn anticipation

operation. GPSS through the EFD1000 is only available if Label 121 is transmitted by

the GPS over the ARINC 429 bus. RS-232 interfaces do not provide label 121;

therefore, for RS-232 GPS systems GPSS functionality is not provided.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 39-202 Revision C

Copyright 2008 Aspen Avionics Inc.

5.5.3 GPS/ NAV Switching

Existing GPS/NAV switching from the GPS and VLOC receiver to the original HSI will be

removed as the PFD will provide this capability. The existing GPS and VLOC receivers

will be wired directly to the PFD or ACU(s) as per the installation drawings in Section 9.

Any analog connections from the GPS and/or VLOC receiver to the autopilot will be

removed and wired per the ACU to autopilot interfaces shown in Section 9.

5.5.4 Sonalert

A Sonalert may be installed to provide an audio tone to the pilot whenever an altitude

or minimums advisory is generated by the system.

5.5.5 Heading Output

It may be necessary to use a digital bus, in lieu of a synchro output, to supply an

external device such as a TCAS or StormScope system with heading. Label 320 is

output from the ACU on P3 pins 4 & 5 via a low speed ARINC 429 bus, if no ACU is

installed then label 320 is available from the PFD pins 26 and 27.

Figure 5.4 Low Speed ARINC 429 Heading

(Note- the Bendix/King KTA810/910 and KMH820/920 only accept High Speed A429

and therefore are not compatible with this output). Contact Aspen Avionics product

support for suggestions on using an ARINC 429 low to high speed converter.

5.5.6 Second ACU

A second ACU is required when two (2) analog VLOC receivers are installed.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 40-202 Revision C

Copyright 2008 Aspen Avionics Inc.

THIS PAGE IS INTENTINALLY LEFT BLANK

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 41-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6 Mechanical Installation

The EFD1000 installation will require mechanical modifications to the aircraft. The PFD, RSM, and

Configuration Module will be installed in all installations, while one (1) or two (2) ACU(s) may be

required in others. Most installations will require removing and relocating existing flight

instruments to alternate locations in the instrument panel to be used as standby instrumentation.

6.1 Unpacking and Inspecting Equipment

Perform a visual inspection of all equipment for evidence of damage that might have occurred

during shipment. If a damage claim is to be filed save all shipping boxes and packing

material to substantiate your claim.

6.2 Equipment Location Documentation

It is required by the AML-STC that the PFD, RSM, CM, and ACU mounting locations be

recorded on Figure D1 of Appendix D. It is also required that an accurate description of wire

and cable routing be noted on the figure. This information will be required later to comply

with the ICAs. Make a copy of the form and give to owner for inclusion in permanent aircraft

records.

6.3 Log Book Entry

Make a log book entry at the completion of the installation indicating that the aircraft has

been modified in accordance with the EFD1000 AML-STC.

6.4 Weight and Balance

Using the component weights in Table 6.1 and the moment arm of the component mounting

locations perform a weight and balance calculation per AC 43.13-1B. Also account for

equipment removed during the modification process.

Component Weight (Ibs)

EFD1000 including bracket 2.9

RSM Remote Sensor Module 0.2

ACU Analog Converter Unit 0.8

Configuration Module 0.1

Table 6.1 Component Weights

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 42-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6.5 Installation Limitations

The following mounting limitations must not be exceeded during the installation of the PFD

and RSM:

The PFD must be mounted within 8 of perpendicular to the aircraft waterline.

The PFD must be mounted within 0.00.1 of the zero degree roll wings level axis.

The RSM must be mounted within 4 to the longitudinal axis of the aircraft (see

Figure 6.8)

The RSM must be mounted within 10 to the zero degree roll wings level axis (see

Figure 6.10)

The RSM must be mounted within 10 to the zero pitch axis waterline of the

airframe (see Figure 6.9). In no case may the PFD to RSM difference be greater than

18 (8 of PFD tilt plus 10 of RSM tilt).

RSM must be mounted to a relatively flat surface such that when installed it will not

deform the aircraft skin and must not allow more than a .030 gap between RSM and

skin.

RSM must not be mounted to a NO ZONE as pictured in Figure 6.7.

Mounting the RSM to, or making other penetrations through, the aircraft pressure

vessel is beyond the scope of this STC. Separate FAA approval of pressure vessel

penetrations required to accommodate RSM mounting is required prior to the

installation of the remaining EFD1000 system components under the EFD1000 AML-

STC.

Mounting the RSM to a composite or fabric skinned aircraft is beyond the scope of this

STC. On composite and fabric skin aircraft, separate FAA approval of the RSM

mounting is required prior to the installation of the remaining EFD1000 system

components under the EFD1000 AML-STC.

6.6 Equipment Bonding

All metal components must be grounded and bonded to the airframe with less than 3

milliohms resistance in accordance with FAR 23.867(a).

The PFD uses an installer fabricated braided bonding strap to ensure proper bonding to the

panel. The bond strap is attached with supplied screw (3/8

th

inch length) to back of PFD at

location just below and left of static port. The other end of strap is attached to PFD mounting

bracket screw at backside of panel.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 43-202 Revision C

Copyright 2008 Aspen Avionics Inc.

The RSM does not require an RF ground plane, but it must be bonded to the airframe to meet

compliance with DO-160E EMI and Lightning certification requirements. The attached ground

wire on the RSM is not a bonding wire but is a shield ground for the pigtail over braid and

must be connected to airframe ground.

The ACU is bonded through its six (6) mounting holes and chassis when mounted to a metal

surface, otherwise a braided or single stranded wire bonding strap to airframe ground will

need to be fabricated for mounting on composite structures.

6.7 Cooling

The PFD has an integral fan mounted to the lower backside of the unit. The fan must not be

covered as to restrict airflow through the unit. The RSM, ACU, and Configuration Module have

no specific cooling requirements.

6.8 PFD Installation

Mechanical installation of the PFD requires installing the included mounting bracket,

connecting a braided bonding strap between the PFD and panel, and installing pitot and static

connections to the two keyed quick release pressure fittings.

6.8.1 PFD Mounting Location

The PFD must be mounted in the center position of the instrument panel per FAR

23.1321(d). If the two existing instrument holes that contain the attitude indicator and

direction indicator are not exactly centered, but are the closest instruments to the

center, then that position is acceptable for mounting the PFD.

NOTE: Modification to the existing instrument panel is not authorized

under this STC. Any modification must be approved separately.

PFD

PFD Mounting Location

Figure 6.1 - PFD Mounting Location

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 44-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6.8.2 Mounting Bracket Installation

The pre-drilled holes in the mounting bracket (see Figure 6.4) support both standard

3 round instrument holes, and 3ATI square cutouts. The bracket is centered on the

upper instrument hole. The lower portion of the bracket is provisioned with screw

slots, allowing variable vertical spacing configurations.

If the lower cutout is a 3ATI or other larger standard cutout, a commercially available

metal blanking plate should be used to flush fill the cutout. Use the PFD Mounting

Bracket as a template to cut the 2.10 diameter cutout for the fan and two 0.150

diameter mounting holes. All cut edges should be treated to prevent corrosion.

The PFD is attached to the instrument panel in 6 places with MS24693-S30 (#6-32

flathead screws), NAS1149FN632P (washers), and MS21044N06 (#6-32 Nuts). It is also

acceptable to use existing #6 nutplates or equivalent.

1) Burnish the back of the instrument panel around one of the 6 mounting holes to

allow for bracket to instrument panel bonding through the screw/washer/nut.

2) Loosely install the bracket with the upper two mounting screws/nuts/washers as

shown in Figure 6.3.

3) Use an inclinometer on the top of the PFD bracket with the aircraft level to make

this adjustment. It may be necessary to slot the existing holes to align the bracket

in the roll axis.

4) The PFD must be mounted within 0.00.1 of the zero degree roll wings level

axis.

5) Fabricate an 8 bonding strap from braid and two ground lugs. Attach one ground

lug to a mounting screw on the backside of the panel (see Figure 6.2).

6) Install remaining PFD mounting bracket screws and nuts.

7) Tighten all six (6) mounting screws and nuts to 12 in-lbs anchoring the bracket to

the panel.

Aircraft with tilted instrument panels of 8 or less can install the PFD flat against the

panel. The tilt will later be removed electronically in the system configuration using

the Pitch Attitude Trim adjustment.

6.8.3 PFD Bonding Strap

An 8 or shorter braided bonding strap is required between the screw (below and left

of the static port- see Figure 6.2) on the backside of the PFD to a location on the

backside of the instrument panel using one of the mounting screws and nuts. Verify

less than 3 milliohms resistance to airframe ground at bonding strap connection point.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 45-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Bonding Strap

Attachment Screw

Rear View of PFD

Figure 6.2 PFD Bonding Strap Connection

Figure 6.3 PFD and Bracket Installation

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 46-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Figure 6.4 - PFD Mounting Bracket (inches)

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 47-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6.8.4 Pitot and Static Connections

Pitot and Static connections are made to the PFD via two keyed quick connect fittings.

These connections will typically require a T fitting to be installed in-line with the

existing altimeter and airspeed indicators.

The quick connectors are keyed such that they cannot be interchanged. Once the

correct quick connector is fastened to the pitot and static lines, they cannot be

inadvertently swapped on the rear of the PFD unit.

NOTE: The pitot quick connector will fit on the PFD static port but the static quick

connector cannot be inadvertently connected to the PFD pitot port due to the

keying.

Each connector has a 0.256 diameter barbed fitting that accepts a hose.

Figure 6.5 - Pitot & Static Quick Connector

6.8.5 Quick Connector Installation

1) Insert T fitting into existing aircraft Pitot line and secure with Aero Seal 6604 or

equivalent hose clamp (see Figure 6.6).

2) Connect a length of pitot line tubing between the T fitting and the P quick

connector. Verify the length of tubing can be installed with no drip loop and that it

can be secured away from flight controls. Secure each end with Aero Seal 6604 or

equivalent hose clamps.

3) Insert T fitting into existing aircraft Static line and secure with Aero Seal 6604 or

equivalent hose clamp (see Figure 6.6).

4) Connect a length of pitot line tubing between the T fitting and the P quick

connector. Verify the length of tubing can be installed with no drip loop and that it

can be secured away from flight controls. Secure each end with Aero Seal 6604 or

equivalent hose clamps.

5) Secure pitot and static lines as necessary to prevent interference with other aircraft

structures and components.

CAUTION: Secure pitot and static lines so that they will not interfere with flight

controls and are not at risk of mechanical damage.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 48-202 Revision C

Copyright 2008 Aspen Avionics Inc.

Figure 6.6 Pitot & Static Line Connections

6.8.6 Leak Check Requirements

A pitot static leak check is required after the installation of the quick connectors and

the PFD is installed. The quick connectors are designed such that they seal when

disconnected.

EFD1000 Installation Manual

DOCUMENT # A-01-126-00 PAGE 49-202 Revision C

Copyright 2008 Aspen Avionics Inc.

6.9 RSM Installation

The RSM is typically installed near the tail of the aircraft on an unpressurized portion of the

airframe. As the RSM incorporates both the OAT sensor and the emergency GPS antenna, it

must be mounted on the top outside of the airframe. In addition, the RSM includes the