Académique Documents

Professionnel Documents

Culture Documents

Bulletin PVS-80021011-TGS - Turbine Gland Seal Systems

Transféré par

Javad AmnianCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bulletin PVS-80021011-TGS - Turbine Gland Seal Systems

Transféré par

Javad AmnianDroits d'auteur :

Formats disponibles

The Unique VIP Service Advantage

Value, Integrity, Professionalism & Service

TURBINE GLAND SEAL SYSTEMS ENGINEERING DATA

BULLETIN # PVS-80021011-TGS PAGE 1 OF 3

GENERAL

These systems generally consist of single- or two-stage

100% capacity ejectors, single 100% surface-type pre- or

inter/aftercondensers, suction & steam isolation valves and

interconnecting vacuum piping. They are designed to

remove air & steam from the turbine gland seal area to

prevent air from flowing into the condenser on condensing

steam turbines.

Power Plant Turbine Requirements

Gland Steam ejectors designed to meet the turbine

manufacturers specified requirements for dry air leakage and water vapor at the specified

vacuum level. These systems are typically two-stage units with inter- & aftercondenser, or a

single-stage unit with pre-condenser, depending on the operating pressure requirement.

Condensate is the most common cooling medium for the condensers.

Commercial Standard Requirements

Gland Steam ejectors designed to meet typical HVAC Standards should handle the air leakage

specified plus water vapor at the pressure specified by the turbine manufacturer. Single-

stage, single-element systems with pre- or aftercondenser are typical. Also common is one,

single-stage ejector only on smaller turbines. Condensate or cooling water is used for the

condensers.

STANDARD MATERIALS OF CONSTRUCTION

EJECTORS INTERCONNECTING VACUUM PIPING

Steam Chest: Carbon Steel Pipe & Fittings: Carbon Steel

Steam Nozzle: 303SS

VACUUM VALVES (Gate-Type), Manual

Suction Chamber: Carbon Steel Body: Cast Iron

Diffuser: Carbon Steel Trim: Carbon Steel

CONDENSERS STEAM PIPING

Shell: Carbon Steel

Steam piping, valves & strainers are suitable for the design

motive pressure and temperature of system motive steam

supply. Standard is Sch. 80 pipe (A106) with 3,000# fittings

and 800# class valves (A105).

Water Boxes: Carbon Steel

Tube Sheets: Carbon Steel

Tubes: 304LSS

Baffles: Carbon Steel

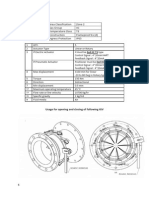

MODEL PC23E GLAND SEAL SYSTEM

with Quickcheck

Steam Chest

The Unique VIP Service Advantage

Value, Integrity, Professionalism & Service

TURBINE GLAND SEAL SYSTEMS ENGINEERING DATA

BULLETIN # PVS-80021011-TGS PAGE 2 OF 3

Most steam turbines have a shaft-sealing system which uses carbon rings to isolate the rotor

assemblies on both ends with steam injected to prevent air in-leakage into the turbine. This leakage

would reduce turbine efficiency and flow into the condenser downstream of the turbine further

reducing system efficiency. This gland steam must be removed by an ejector or other vacuum-

producing device to prevent it from flowing back into the turbine.

Unique Systems has developed standard gland steam exhauster equipment, with both single- and

twin-element ejector systems, to serve commercial application and power industry requirements.

For larger power generation turbines, a two-stage gland steam system is common, as the unit must

operate at medium vacuum levels (4 to 15 HgA). Inter- & aftercondensers are required, commonly

using condensate as the cooling medium. Some turbines require a gland steam system to operate at

low vacuum levels (25+ HgA) but with high steam flow rates. This results in a gland steam system

that utilizes a pre-condenser with a single-stage ejector, typically using condensate as the cooling

medium.

Commercial-duty turbines (commonly used on HVAC, power cogeneration or gas compressor drive

applications) typically require single-stage ejector gland steam systems with either a pre- or

aftercondenser for condensate recovery. Some smaller turbines require only a single ejector without

a condenser. We offer a line of standard gland steam systems and single-stage ejectors to

accommodate all these requirements.

Custom gland steam systems using liquid ring vacuum pumps and centrifugal blowers are also

available. Unique Systems offers the most comprehensive line of gland steam systems in the

industry.

SERIES PCE GLAND STEAM EXHAUSTERS

Designed for high leakage rates, low pressure differential requirements

Suction pressures from 3 to 15 HgV

Capacities from 10-200 #/hour air + steam to saturate

Aftercondenser for condensate recovery (Optional)

Accessories include steam isolation valves, strainers, condensate traps & instrumentation

Models: PC11E, PC15E, PC23E, PC32E Complete Systems

Custom-engineered systems are available for any requirement or specification.

The Unique VIP Service Advantage

Value, Integrity, Professionalism & Service

TURBINE GLAND SEAL SYSTEMS ENGINEERING DATA

BULLETIN # PVS-80021011-TGS PAGE 3 OF 3

SERIES TCE GLAND STEAM EXHAUSTERS

Designed for low to moderate leakage rates,

medium to high pressure differential requirements

Suction pressures from 29 to 20 HgV

Capacities from 10-200 #/hour air + steam to saturate

Complete packaged system including inter- &

aftercondenser, valves, piping & instrumentation

Models: TC23E, TC32E, TC42E, TC62E Complete Systems

Options: Automation & single-element configurations

Custom-engineered systems are available for any requirement or specification.

SERIES P3136 GLAND STEAM EJECTORS

Designed for low pressure differential requirements

& low leakage rates

Operating range from 28.8 to 32+ HgA

Capacities from 80-275 #/hour DAE

Aftercondenser for condensate recovery (Optional)

Low capital cost & fast delivery!

PERFORMANCE DATA FOR P3136 SERIES EJECTORS

For preliminary estimate only. Please consult Unique Systems for actual figures relating to your application.

EJECTOR FRAME SIZE

CAPACITY(#/HOUR)

70F DRY AIR

NOMINAL STEAM

CONSUMPTION (#/HOUR)

100 PSIG Motive Steam *

P3136A500 80 50

P3136A600 160 100

P3136A700 275 175

Additional Information:

Minimum steam pressure is 20 PSIG. * Please consult Unique Systems for steam pressures other than 100 PSIG.

Motive steam consumption will be less at higher steam pressures and more at lower pressures.

Also available using air as a motive fluid. Air consumption is 2x listed steam consumption.

Custom configurations, including our patented Quickcheck

design, are available for other conditions.

NOTICE OF PROPRIETARY RIGHTS: This brochure, drawings and/or information shown, is the sole property of Unique Systems, Inc.

Receipt or possession thereof does not confer of transfer any right to make, copy, manufacture and/or sell this or these devices by method shown.

The information contained in this document is subject to change at any time and without prior notice.

No warranties or guarantees of any kind are made or implied by any of the content of this document.

QUICKCHECK, UNIQUE SYSTEMS and its logo are registered trademarks of Unique Systems, Inc.

2009 Unique Systems, Inc.

Vous aimerez peut-être aussi

- Research Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodDocument12 pagesResearch Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodJavad AmnianPas encore d'évaluation

- Mechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsDocument7 pagesMechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsJavad AmnianPas encore d'évaluation

- Axial and Radial Turbines - TMI 11-12 - P 32 PDFDocument1 pageAxial and Radial Turbines - TMI 11-12 - P 32 PDFJavad AmnianPas encore d'évaluation

- An Educational Guide To Extract The Parameters of Heavy Duty Gas Turbines Model in Dynamic Studies Based On Operational DataDocument9 pagesAn Educational Guide To Extract The Parameters of Heavy Duty Gas Turbines Model in Dynamic Studies Based On Operational DataJavad AmnianPas encore d'évaluation

- Thesis - An Approach To Ventilation DesignDocument79 pagesThesis - An Approach To Ventilation DesignJavad AmnianPas encore d'évaluation

- JK DissDocument100 pagesJK DissBheemesh GudelliPas encore d'évaluation

- Mechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsDocument7 pagesMechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsJavad AmnianPas encore d'évaluation

- Rowen, Simplified Mathematic Representations of Heavy-Duty Gas Turbines PDFDocument17 pagesRowen, Simplified Mathematic Representations of Heavy-Duty Gas Turbines PDFJavad AmnianPas encore d'évaluation

- Dynamical Modeling, Control and Simulation of Single Shaft Gas TurbineDocument8 pagesDynamical Modeling, Control and Simulation of Single Shaft Gas TurbineJavad AmnianPas encore d'évaluation

- Spec Sheet - EquipmentDocument2 pagesSpec Sheet - EquipmentJavad AmnianPas encore d'évaluation

- Emvin PHD Introduction1Document68 pagesEmvin PHD Introduction1Javad AmnianPas encore d'évaluation

- MatlabDocument47 pagesMatlabalkadyasPas encore d'évaluation

- Dimensionless numbers and universal constants summaryDocument1 pageDimensionless numbers and universal constants summaryatiqPas encore d'évaluation

- T1359 65Document8 pagesT1359 65Javad AmnianPas encore d'évaluation

- Air Pak User GuideDocument939 pagesAir Pak User GuideGowtham MechPas encore d'évaluation

- Actuator Datasheet for Zone 2 Hazardous AreaDocument1 pageActuator Datasheet for Zone 2 Hazardous AreaJavad AmnianPas encore d'évaluation

- Dambreak: Volume of Fluid)Document12 pagesDambreak: Volume of Fluid)Javad AmnianPas encore d'évaluation

- Localized Dynamic Kinetic-Energy-based Models For Stochastic CoherentDocument14 pagesLocalized Dynamic Kinetic-Energy-based Models For Stochastic CoherentJavad AmnianPas encore d'évaluation

- E3 10 03 03Document0 pageE3 10 03 03elrajilPas encore d'évaluation

- FluidDocument3 pagesFluidJavad AmnianPas encore d'évaluation

- GRT Steam Turbines PDFDocument2 pagesGRT Steam Turbines PDFJavad AmnianPas encore d'évaluation

- Lars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Document5 pagesLars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Javad AmnianPas encore d'évaluation

- Cryostar Process Machinery PDFDocument0 pageCryostar Process Machinery PDFJavad AmnianPas encore d'évaluation

- E3 10 03 03Document0 pageE3 10 03 03elrajilPas encore d'évaluation

- Tutorial On Turbo ExpanderDocument0 pageTutorial On Turbo ExpanderMajid Sattar100% (1)

- Marine Steam Turbine Generator GuideDocument55 pagesMarine Steam Turbine Generator GuideDharmendra KumarPas encore d'évaluation

- HTTPDocument3 pagesHTTPJavad AmnianPas encore d'évaluation

- MersDocument22 pagesMersJavad AmnianPas encore d'évaluation

- E3 10 03 03Document0 pageE3 10 03 03elrajilPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Steam Nozzles and Turbines ConceptsDocument31 pagesSteam Nozzles and Turbines ConceptspaulaPas encore d'évaluation

- Engineer's Guide To Level Measurement For Power and Steam MeasurementDocument262 pagesEngineer's Guide To Level Measurement For Power and Steam Measurementvlcmstne04100% (1)

- Feedwater Heaters: Cost Effective & Environmentally Friendly SolutionsDocument5 pagesFeedwater Heaters: Cost Effective & Environmentally Friendly SolutionsrahulPas encore d'évaluation

- 014 PDFDocument12 pages014 PDFGrootPas encore d'évaluation

- ARGeo C7 Successful Commissioning ID 46811Document12 pagesARGeo C7 Successful Commissioning ID 46811Insan AzizPas encore d'évaluation

- PpeDocument7 pagesPpeChristopher YsitPas encore d'évaluation

- Jharkhand University of Technology 2nd Year UG Mechanical Engineering 4th Semester Course StructureDocument14 pagesJharkhand University of Technology 2nd Year UG Mechanical Engineering 4th Semester Course Structure507 20L SK DarainPas encore d'évaluation

- Turbines & Compressors Questionnaire GuideDocument3 pagesTurbines & Compressors Questionnaire Guidevaratharajan g rPas encore d'évaluation

- AE2203 - Propulsion and Power - 2011 PDFDocument142 pagesAE2203 - Propulsion and Power - 2011 PDFPythonraptor100% (1)

- Cooling BladesDocument35 pagesCooling BladesdbPas encore d'évaluation

- Material Turbine - 2 PDFDocument6 pagesMaterial Turbine - 2 PDFMonikaPas encore d'évaluation

- Steam Turbine Fact Sheet GEA31250Document3 pagesSteam Turbine Fact Sheet GEA31250Maycon FiorezePas encore d'évaluation

- Assignment 1Document4 pagesAssignment 1Ziyad Awali100% (1)

- 71559232Document11 pages71559232Nasr PooyaPas encore d'évaluation

- IP 0-0-2 Numerical IndexDocument4 pagesIP 0-0-2 Numerical IndexAtan B AtanPas encore d'évaluation

- Heat Balance For Steam Generator (Boiler) : Alarca, Braza, Gabriel, SebastianDocument43 pagesHeat Balance For Steam Generator (Boiler) : Alarca, Braza, Gabriel, SebastianCarlo SebastianPas encore d'évaluation

- Module 1: Energy Balance on Open SystemsDocument18 pagesModule 1: Energy Balance on Open SystemsKing Antonio AbellaPas encore d'évaluation

- ME8792 Power Plant Engineering: Department of Electrical and Electronics EngineeringDocument161 pagesME8792 Power Plant Engineering: Department of Electrical and Electronics EngineeringSushanth AlikepalliPas encore d'évaluation

- Parts of Geothermal Power PlantDocument6 pagesParts of Geothermal Power Plantpapanoggie50% (2)

- Working of DSTK-4101 Governing SystemDocument26 pagesWorking of DSTK-4101 Governing SystemSteve WanPas encore d'évaluation

- Benefits & Overview of Single-Shaft Combined Cycle Power PlantsDocument10 pagesBenefits & Overview of Single-Shaft Combined Cycle Power PlantsAhmed Abd El MoatiPas encore d'évaluation

- A New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured ParametersDocument8 pagesA New Calculation Approach To The Energy Balance of A Gas Turbine Including A Study of The Impact of The Uncertainty of Measured Parameters..........................Pas encore d'évaluation

- Determine Efficiency of Steam Turbine Power Plant LabDocument11 pagesDetermine Efficiency of Steam Turbine Power Plant LabCharlotte BPas encore d'évaluation

- Steam Turbine ExperimentDocument7 pagesSteam Turbine ExperimentEnriv YasiladPas encore d'évaluation

- ME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & RegenerationDocument7 pagesME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & RegenerationJesus Daniel QuispePas encore d'évaluation

- Bearing Isolator: Steam Turbine - High TempDocument1 pageBearing Isolator: Steam Turbine - High Tempbincoleto5536Pas encore d'évaluation

- Degradation of The Mechanical Integrity of Steam Turbine Steels Due To Stress-Corrosion Cracking in Acidic WaterDocument14 pagesDegradation of The Mechanical Integrity of Steam Turbine Steels Due To Stress-Corrosion Cracking in Acidic WaterLeila safiddinePas encore d'évaluation

- Electrical System Design GuidelinesDocument125 pagesElectrical System Design Guidelinescarlosmarciosfreitas100% (1)

- EPRI Journal 2016 No1 PDFDocument46 pagesEPRI Journal 2016 No1 PDFrichmondPas encore d'évaluation

- D2 - T2 - Chang Kwangpil Sang-Bong Lee - Hyundai Heavy IndustriesDocument18 pagesD2 - T2 - Chang Kwangpil Sang-Bong Lee - Hyundai Heavy IndustriesKarim Sowley DelgadoPas encore d'évaluation