Académique Documents

Professionnel Documents

Culture Documents

BacComber System1

Transféré par

organicspolybondDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BacComber System1

Transféré par

organicspolybondDroits d'auteur :

Formats disponibles

By

Genesis Environment Services

Company Limited

The Common Cooling water problem The Common Cooling water problem

The Common Cooling water problem

Scaling

Corrosion

Bacteria (include Leginella)

Algae and Slime

Traditional approach : Chemical Water Treatment

Traditional approach : Chemical Water Treatment

The solution BacComber

Non chemical water treatment system

The solution BacComber

Non chemical water treatment system

Cyclic Problem of Chemical Treatment Cyclic Problem of Chemical Treatment

Cyclic Problem of Chemical Treatment

Add chlorine to

kill bacteria

created corrosion

problem

Add chlorine to

kill bacteria

created corrosion

problem

Add phosphate or

nitrate inhibitor

created bacteria

problem

Add phosphate or

nitrate inhibitor

created bacteria

problem

Additional

problems

Phosphate or

nitrite added is

also nutrient to

algae

Fouling

changed from

hard scale to

sticky calcium

phosphate film.

Additional

problems

Phosphate or

nitrite added is

also nutrient to

algae

Fouling

changed from

hard scale to

sticky calcium

phosphate film.

Cyclic Problem of Chemical Treatment Cyclic Problem of Chemical Treatment

Cyclic Problem of Chemical Treatment

Optimum chemical dosing concentration

Optimum chemical dosing concentration

Start of dosing cycle

End of dosing

cycle

Under Dose

Under Dose

Over Dose

Over Dose

The Common Cooling water problem The Common Cooling water problem

The Common Cooling water problem

-

- pH

-

-

-

-

pH

pH

TDS, Conductivity

TDS, Conductivity

TDS, Conductivity

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Foaming Foaming

Foaming

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Foaming Foaming

Foaming

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Corrosion : Chlorine added is corrosive Corrosion : Chlorine added is corrosive

Corrosion : Chlorine added is corrosive

Cooling Tower problem Cooling Tower problem

Cooling Tower problem

Scale & chemical deposits in the cooling system

Scale & chemical deposits in the cooling system

The Energy

and Water

Save Scale

and Hardness

Remover

No Chemical

The Energy

and Water

Save Scale

and Hardness

Remover

No Chemical

Descaler/Magnetite

Generator

Transformer Rectifier

Enclosure for ELCB/MCB

Inductor Coil unit Submersible pump

AC Power Supply

PVC pipe

Cables

BacComber

Descaler

Magnetite

Generator

BacComber Control

Enclosure

Electrode chamber

BacComber

Copper -

Silver

Ionizer

250 mm

142 mm

142 mm

205 mm

190 mm

147 mm

Descaler

ASAL2A530

Descaler

ASAL2A530

Transformer

Rectifier

ALD30V3A03

Transformer

Rectifier

ALD30V3A03

2

4

0

m

m

.

1250 mm.

8

0

m

m

.

Silver Electrode

Copper Electrode

Weight 2.5 Kg. approx without cable

300 mm.

118 m

m

.

Inductor Coil unit CU21CHN dimensions

Inductor Coil unit CU21CHN dimensions

(Electromagnetism)

(Electromagnetism)

(Ionization)

(Ionization)

Electromagnetic

water treatment

principle

Electromagnetic

water treatment

principle

Using electromagnetic

energy to change the water

molecular structures

including

hydrogen bonds,

polar bonds,

ions and ionic substances.

Water Molecule Water Molecule

Water Molecule

Water Hydrogen

Bond Activated

Untreated Water

Electromagnetic

wave to inductor coil

1KHZ-50KHZ

Electromagnetic Water Treatment Electromagnetic Water Treatment

Electromagnetic Water Treatment

Water molecule in single

random molecule

before electro-magnetic

treatment

Water molecules orientated into larger water

clusters after electro-magnetic treatment

Electro-magnetic field

generated

Direction of water flow

A.C. input

Electronic

controller

Electro-magnetic descaler

Electromagnetic DescalerHow it works Electromagnetic DescalerHow it works

5.50 kcal/mol 17.10

48.60

49.60

76.01

122.39

37.70

Water Cluster Molecules Arrangement Illustration

Water Cluster Molecules Arrangement Illustration

How Water Cluster Trap Ions and Dissolved Gas

How Water Cluster Trap Ions and Dissolved Gas

Fe

Ca

Cl

O

O

CO2

Calcium Carbonate

Calcite

BacComber System

Calcium Carbonate

Aragonite

Pipe wall

Existing

hard Scale

Hard scale

spalled

off by electro-

magnetic treated

water

High frequency electro-magnetic treated cooling

water

Hard scale forming ions remain Hard scale forming ions remain

as ion form in water as ion form in water

High bi-polar energy of the electro-magnetic

treated water penetrates the hard scale

Hard scale calcite

Rhombohedron form

crystal

Powdery snow like soft

scale Aragonite

orthorhombic form crystal

Descaling effectiveness4 months after BacComber treatment

The cooling water pipe as shown by the arrow heat was cut off to

facilitate the addition of a new cooling tower. The cooling tower

was treated by chemical for the past 6 years and was changed to

BacComber treatment 4 months prior to the addition of the new

cooling tower.

The photos shows the various section of the pipe cut off from the

cooling tower. It can be seen in the photos that the scale and

chemical deposists in the pipeline are descale off from the pipe

wall. The formation of magnetite is also clearly seen forming on

the pipe wall.

There is also a swction of the pipe showing the thick chemical

deposits are cracking and spalling off from the pipe wall.

Scales

collected

at cooling

tower

strainer

Scales

collected

at cooling

tower

strainer

Condenser End Box

condition

8 months after

BacComber

treatment

This condenser was open up in

Feb 2003 for inspection, 8

months after the BacComber

treatment.

The photos were taken

immediately after the end cover

was open. The condition of the

end box shown in the photos was

before washing.

The photos clearly show that the

condenser was in excellent

condition and there were no sign

of scaling and corrosion problem

after treatment by BacComber

system.

Magnetite generating

effectiveness

4 months after BacComber

treatment on chilled water

pipe

F

e

i

o

n

p

p

m

Time

Cooling Tower Institute

guideline

max. control limit 3 ppm

Typical BacComber treatment

Fe ion level, below 0.08 ppm

when stabilized

Typical chemical

treatment

Fe ion range 1- 2 ppm

3

2

1

0

Cooling Water Fe Ion Content - Corrosion Indicator

Cooling Water Fe Ion Content - Corrosion Indicator

How BacComber control bacteria growth

Using Copper-Silver ionization to kill the

bacteria directly.

Using electromagnetic treatment to indirectly

kill and control bacteria growth.

Using Copper-Silver ionization to kill the

bacteria directly.

Using electromagnetic treatment to indirectly

kill and control bacteria growth.

Morphology changes Elongation of Bacteria

Bacteria behavior changes under BacComber

electromagnetic treatment

B

a

c

t

e

r

i

a

c

o

u

n

t

Resultant After Install

Resultant After Install

BacComber

BacComber

System

System

Time (month)

BacComber

BacComber

System

System

Applications

Applications

Check on-site iron readings

Check whether the magnetite

generator is working

Check any abnormal PH or TDS

reading.

Addition of unknown chemicals that causes corrosion

Accumulation of iron ion due to infrequent water change

Repair works on cooling system steel members

Rapid descaling is taking place.

< 1.0 Iron ion

(ppm)

Dilution followed by blow down is

recommended

Check on-site copper readings and

replace electrodes if required

Increase current output

(>2.0 ppm) Too high level

Too much copper ion discharge from the ionization

process

Accumulation of copper ions due to infrequent water

changes

Corrosion of copper pipes and fittings

(<0.2 ppm) Too low level

Fresh water has just recently been top up

Copper electrodes are consumed

Too low current output

0.2 - 5.0 Copper ion

(ppm)

Dilution followed by blow down is

recommended

Infrequent water changes

Chemical addition or other contamination

< 2500 TDS

(ppm)

Dilution followed by blow down is

recommended

Infrequent water changes

Chemical addition or other contamination

< 5000 Conductivity

(s/cm)

Dilution followed by blow down is

recommended

Unless the make up water exceeded the limit, otherwise there

could be addition of unknown chemical or substances

6.5 - 9.0 PH

Remedial action

( If limit is exceeded )

Causative reasons

( If limit is exceeded )

Recommended

limits

Parameter

Control Limits For Cooling Tower Water

Control Limits For Cooling Tower Water

* The above is just a guideline and common occurrences. Always compare with the previous months test results, It will give a better picture of the

trend and more conclusive reasoning may be arrived. This may be followed by remedial action if required.

BacComber Descaler-Magnetite Generator installation layout

diagram for boiler water treatment

Feedw

ater to

boiler

Boiler

Feedwater

tank

Condensate

return

Freshw

ater

supply

BacComber descaler-

magnetite generator

BacComber Descaler-Magnetite Generator installation layout

diagram for boiler water treatment

Chiller water pipe to building

Chiller water pipe to chiller

BacComber

Electromagnetic

Descaler /

Magnetite genrator

Approximate size:

256 mm height

196 mm width

160 mm depth

Weigh : 3 Kg approx.

Wall mounted

6 mm sq. PVC insulated cable

Approximately 30 cm pipe

length

insulation to be removed

for cable coil wrapping.

Reinstall the insulation

after cable wrapped.

Keep a min 5 m distance

from motors, pumps or

electrical driven machine.

Chiller

Typical BacComber installation inside the cooling tower

Typical BacComber installation inside the cooling tower

Typical BacComber installation inside the cooling tower

Typical BacComber installation inside the cooling tower

Changes in cooling tower corrosion condition after using

BacComber

Before

After

Typical BacComber Installation Layout for Chilled water

system

Chemical and Sludge BacComber

Dislodged chemical sludge

Dislodged chemical sludge

Dislodged chemical sludge

Vous aimerez peut-être aussi

- BacComber System1 PDFDocument59 pagesBacComber System1 PDFVenkates AdhinarayananPas encore d'évaluation

- Boiler Water Quality RecommendationsDocument7 pagesBoiler Water Quality Recommendationsnishanth930Pas encore d'évaluation

- Advanced Cooling Tower TreatmentDocument6 pagesAdvanced Cooling Tower TreatmentFawaaz KhurwolahPas encore d'évaluation

- Basic Guide To Boiler Water TreatmentDocument8 pagesBasic Guide To Boiler Water TreatmentjewettwaterPas encore d'évaluation

- Paper 2 Stator Water SystemDocument34 pagesPaper 2 Stator Water SystemLakshmi Narayan100% (1)

- Boiler WaterDocument70 pagesBoiler WaterDarius DsouzaPas encore d'évaluation

- Wkshop1 2.5GLEASONDocument44 pagesWkshop1 2.5GLEASONMohamed ImranPas encore d'évaluation

- Key Condenser Failure MechanismDocument8 pagesKey Condenser Failure MechanismdirgoramboPas encore d'évaluation

- C16-086K-R2 - Alfanar (Technical Offer)Document32 pagesC16-086K-R2 - Alfanar (Technical Offer)mominPas encore d'évaluation

- Cooling Water TreatmentDocument31 pagesCooling Water Treatmentpadmesh awasthiPas encore d'évaluation

- Stator Water System ChemistryDocument33 pagesStator Water System ChemistrySudhanshu Sekhar Dash100% (1)

- Thailand Power Workshop Grouping: Bangkok Office 29 & 30-Mar-2012Document29 pagesThailand Power Workshop Grouping: Bangkok Office 29 & 30-Mar-2012Prakasit JuangpanichPas encore d'évaluation

- Treated Water Quality: Combined Effluent Treatment PlantDocument7 pagesTreated Water Quality: Combined Effluent Treatment PlantTania Mery QuispePas encore d'évaluation

- ElectrocoagulationDocument31 pagesElectrocoagulationMarineil Gomez100% (1)

- 243 Poster 2021 A4Document12 pages243 Poster 2021 A4kyrillos wahbaPas encore d'évaluation

- NETRA Corrosion Control Dec 2016Document132 pagesNETRA Corrosion Control Dec 2016ankitgarg13100% (1)

- Cooling Water Chemistry 101: Opportunities For Water Savings, Energy Savings, Maintenance SavingsDocument35 pagesCooling Water Chemistry 101: Opportunities For Water Savings, Energy Savings, Maintenance SavingsMahmoud ElsherbenyPas encore d'évaluation

- Steam Generation in Power - DOC043.53.30251.Mar17Document9 pagesSteam Generation in Power - DOC043.53.30251.Mar17NO BOTHERPas encore d'évaluation

- Power Plant ChemistryDocument136 pagesPower Plant ChemistryGajender Singh RajputPas encore d'évaluation

- Scale Remover PresentationDocument18 pagesScale Remover PresentationRaja Pathamuthu.G100% (1)

- Water Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidDocument27 pagesWater Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidAmarendra Mani TiwariPas encore d'évaluation

- Benamir Cooling System MarE1-ADocument6 pagesBenamir Cooling System MarE1-AbenamirbrentyuridPas encore d'évaluation

- Basic Knowledge To Cooling Water SystemDocument60 pagesBasic Knowledge To Cooling Water Systempavanchem61Pas encore d'évaluation

- The Fundamentals of Water Treatment Technology: A Training Workshop For STASMODocument39 pagesThe Fundamentals of Water Treatment Technology: A Training Workshop For STASMOSushanta K BeheraPas encore d'évaluation

- PPE - Feed Water Treatment SystemDocument6 pagesPPE - Feed Water Treatment SystemSandeep ChhabraPas encore d'évaluation

- Steam Generation in Power PlantsDocument13 pagesSteam Generation in Power PlantsAurenio RibeiroPas encore d'évaluation

- Electrochlorination Basic Process TrainingDocument40 pagesElectrochlorination Basic Process Trainingraghuvarma50% (2)

- Electrochlorination Basic Process Training PDFDocument40 pagesElectrochlorination Basic Process Training PDFraghuvarma100% (4)

- Good Nalco Document For High Pressue Boiler ChemistryDocument79 pagesGood Nalco Document For High Pressue Boiler ChemistryJayanath Nuwan Sameera100% (1)

- Boiler Water AnalysisDocument44 pagesBoiler Water AnalysisDileep MishraPas encore d'évaluation

- Condenser Failure MechanismDocument7 pagesCondenser Failure MechanismprakashPas encore d'évaluation

- Crying Up and Down A SmileDocument8 pagesCrying Up and Down A SmileMr SinghPas encore d'évaluation

- Boiler Water TreatmentDocument5 pagesBoiler Water TreatmentUsamaPas encore d'évaluation

- Boiler Water TreatmentDocument13 pagesBoiler Water TreatmentAisyah M YahyaPas encore d'évaluation

- High Pressure Boiler ChemistryDocument67 pagesHigh Pressure Boiler ChemistryJayanath Nuwan SameeraPas encore d'évaluation

- Power Plant Chemistry For BoeDocument22 pagesPower Plant Chemistry For BoeRamakrishna ChiliveryPas encore d'évaluation

- Presentation 2b WhittakerDocument27 pagesPresentation 2b Whittakermoorthymtps_54120305Pas encore d'évaluation

- PowerChem Scaling and Corrosion Article (Revised 9.02)Document7 pagesPowerChem Scaling and Corrosion Article (Revised 9.02)Pujo SatrioPas encore d'évaluation

- Chemical Dozing System in HVACDocument9 pagesChemical Dozing System in HVACAlex OrodePas encore d'évaluation

- UNIT-III ChemistryDocument12 pagesUNIT-III ChemistrySivaprasad GanjiPas encore d'évaluation

- Water ChemistryDocument13 pagesWater ChemistrynivasssvPas encore d'évaluation

- Water Chemistry Aspects of Supercritical Thermal Power PlantsDocument72 pagesWater Chemistry Aspects of Supercritical Thermal Power PlantsdstpschemlabPas encore d'évaluation

- Boiler-Water Treatment-Why, What and HowDocument7 pagesBoiler-Water Treatment-Why, What and How陳0鴻Pas encore d'évaluation

- SteamDocument9 pagesSteamNESAEIDARYOUSHPas encore d'évaluation

- What Is Boiler Corrosion?Document4 pagesWhat Is Boiler Corrosion?Viola ZakariaPas encore d'évaluation

- Boiler Water Treatment Basics - Common Issues and Their Modern SDocument12 pagesBoiler Water Treatment Basics - Common Issues and Their Modern Sedos izedonmwenPas encore d'évaluation

- Condenser Tube Leakage2Document10 pagesCondenser Tube Leakage2prakashPas encore d'évaluation

- TP1174ENDocument16 pagesTP1174ENTran Khac TruongPas encore d'évaluation

- Common Boiler Water ProblemsDocument6 pagesCommon Boiler Water ProblemsEge CPas encore d'évaluation

- Steam Systems Basics, Challenges and TroubleshootingDocument31 pagesSteam Systems Basics, Challenges and TroubleshootingLutfi NugrahaPas encore d'évaluation

- Water Treatment ProcessesDocument7 pagesWater Treatment ProcessesgondeathPas encore d'évaluation

- Corrosion Control Class For As, BS, AW, & BWDocument79 pagesCorrosion Control Class For As, BS, AW, & BWTuanPas encore d'évaluation

- Descaler Presentation EN1Document60 pagesDescaler Presentation EN1Amar BenAmarPas encore d'évaluation

- Microsoft PowerPoint - WatertreatmentDocument37 pagesMicrosoft PowerPoint - WatertreatmentGOBLIN XXXPas encore d'évaluation

- Dmptfe!Sfdjsdvmbujoh!Tztufnt : Common Operating ProblemsDocument4 pagesDmptfe!Sfdjsdvmbujoh!Tztufnt : Common Operating Problemsgunduboss1985Pas encore d'évaluation

- Case Study On Corrosion Water Tube BoilersDocument3 pagesCase Study On Corrosion Water Tube BoilersSalem Garrab100% (2)

- What's Bugging Your Pipes: How Microorganisms Affect Plumbing SystemsD'EverandWhat's Bugging Your Pipes: How Microorganisms Affect Plumbing SystemsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Water Level Indicator Circuit Using Bipolar Junction TransistorD'EverandWater Level Indicator Circuit Using Bipolar Junction TransistorÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Electrochemical and Electrocatalytic Reactions of Carbon DioxideD'EverandElectrochemical and Electrocatalytic Reactions of Carbon DioxideB.P. SullivanÉvaluation : 5 sur 5 étoiles5/5 (1)

- Autocad Tutorial 6Document25 pagesAutocad Tutorial 6Selman EL HogPas encore d'évaluation

- Autocad Tutorial 4Document24 pagesAutocad Tutorial 4Selman EL Hog100% (1)

- Refrigeration CycleDocument1 pageRefrigeration CycleorganicspolybondPas encore d'évaluation

- Utocad Tutorial 3:: or EleaseDocument18 pagesUtocad Tutorial 3:: or EleaseorganicspolybondPas encore d'évaluation

- Utocad Tutorial 2:: or EleaseDocument24 pagesUtocad Tutorial 2:: or EleaseorganicspolybondPas encore d'évaluation

- Utocad Tutorial 5:: or EleaseDocument13 pagesUtocad Tutorial 5:: or EleaseorganicspolybondPas encore d'évaluation

- WT FormualeDocument1 pageWT FormualeorganicspolybondPas encore d'évaluation

- Ansi Fci 70 2 2006pdfDocument6 pagesAnsi Fci 70 2 2006pdforganicspolybondPas encore d'évaluation

- Refrigerant Piping 20Document1 pageRefrigerant Piping 20organicspolybondPas encore d'évaluation

- HydroTest JHADocument14 pagesHydroTest JHAorganicspolybond100% (2)

- Refrigerant-Piping 55 PDFDocument1 pageRefrigerant-Piping 55 PDForganicspolybondPas encore d'évaluation

- Pipeline DryingDocument2 pagesPipeline DryingAriel Anasco100% (2)

- Refrigerant-Piping 55 PDFDocument1 pageRefrigerant-Piping 55 PDForganicspolybondPas encore d'évaluation

- Ansi Asme b16.5 Class 900 Forged FlangesDocument1 pageAnsi Asme b16.5 Class 900 Forged FlangesorganicspolybondPas encore d'évaluation

- Utocad Tutorial 1:: or EleaseDocument23 pagesUtocad Tutorial 1:: or EleaseorganicspolybondPas encore d'évaluation

- FLexible Duct SizingDocument1 pageFLexible Duct Sizingorganicspolybond100% (1)

- GASA SANITARYtDocument1 pageGASA SANITARYtorganicspolybondPas encore d'évaluation

- As Per The GSAS Requirements Faucet: Flow Rate:1.7 L/M Flush Tank: 3L or 2.9L To 4.5LDocument1 pageAs Per The GSAS Requirements Faucet: Flow Rate:1.7 L/M Flush Tank: 3L or 2.9L To 4.5LorganicspolybondPas encore d'évaluation

- Autocad Command List and Explanations Act. 6Document9 pagesAutocad Command List and Explanations Act. 6organicspolybondPas encore d'évaluation

- FLexible Duct SizingDocument1 pageFLexible Duct Sizingorganicspolybond100% (1)

- Autocad Command List and Explanations Act. 5Document8 pagesAutocad Command List and Explanations Act. 5organicspolybondPas encore d'évaluation

- Autocad Tutorial 4Document24 pagesAutocad Tutorial 4Selman EL Hog100% (1)

- Autocad Commands - Act 3Document17 pagesAutocad Commands - Act 3organicspolybondPas encore d'évaluation

- Autocad Commands - Act 3Document17 pagesAutocad Commands - Act 3organicspolybondPas encore d'évaluation

- Utocad Tutorial 1:: or EleaseDocument23 pagesUtocad Tutorial 1:: or EleaseorganicspolybondPas encore d'évaluation

- Autocad Tutorial 4Document24 pagesAutocad Tutorial 4Selman EL Hog100% (1)

- Autocad Commands - Act 1Document16 pagesAutocad Commands - Act 1organicspolybondPas encore d'évaluation

- Autocad Commands - Act 2Document31 pagesAutocad Commands - Act 2organicspolybondPas encore d'évaluation

- Autocad Tutorial 6Document25 pagesAutocad Tutorial 6Selman EL HogPas encore d'évaluation

- Autocad Act - 5Document14 pagesAutocad Act - 5organicspolybondPas encore d'évaluation

- 5th Grade Water Lesson Plan (FINAL)Document10 pages5th Grade Water Lesson Plan (FINAL)2022ee363Pas encore d'évaluation

- Summer Training Report NTPC BARHDocument33 pagesSummer Training Report NTPC BARHAyush SinghPas encore d'évaluation

- Pump Station in WTPDocument42 pagesPump Station in WTPJoe Mari CapaPas encore d'évaluation

- Jalmani: Guidelines On Installation of Stand Alone Drinking Water Purification Systems in Rural IndiaDocument9 pagesJalmani: Guidelines On Installation of Stand Alone Drinking Water Purification Systems in Rural IndiaSaswat NayakPas encore d'évaluation

- Ict500 Individual AssignmentDocument35 pagesIct500 Individual AssignmentSITI NURHIDAYAH BINTI AZMEEPas encore d'évaluation

- Eureka Forbes ProDocument18 pagesEureka Forbes ProRakesh SinghPas encore d'évaluation

- Adya Filtration SysDocument3 pagesAdya Filtration SyscolostgrpPas encore d'évaluation

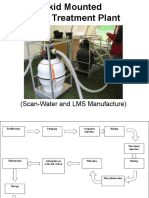

- Scan-Water and LMS ManufactureDocument19 pagesScan-Water and LMS Manufactureshivani guptaPas encore d'évaluation

- Libro Edgar 1 PDFDocument321 pagesLibro Edgar 1 PDFAnonymous 9P9foQlV100% (1)

- Note Taking Water TreatmentDocument3 pagesNote Taking Water TreatmentHiro ExalionPas encore d'évaluation

- A Prototype Recirculating Aquaculture-Hydroponic SystemDocument10 pagesA Prototype Recirculating Aquaculture-Hydroponic Systemkriskee13100% (1)

- Or Purge) Bring Up Mucus and Other Material From The Lungs, Bronchi, and Trachea)Document34 pagesOr Purge) Bring Up Mucus and Other Material From The Lungs, Bronchi, and Trachea)Danica BondocPas encore d'évaluation

- Marketing Plan Aquaboss Water Refilling Station PDFDocument13 pagesMarketing Plan Aquaboss Water Refilling Station PDFNoel Carbos100% (3)

- 442-670 PDFDocument10 pages442-670 PDFNermeen ElmelegaePas encore d'évaluation

- Midterm ExamDocument5 pagesMidterm ExamRaphael CajucomPas encore d'évaluation

- Sitar ADocument35 pagesSitar Asaeedr337100% (1)

- USP41 - 71 - Sterility TestsDocument8 pagesUSP41 - 71 - Sterility TestsGiang Hanh LePas encore d'évaluation

- International Pharmacopeia - Purified WaterDocument2 pagesInternational Pharmacopeia - Purified WaterFatma AbdelaalPas encore d'évaluation

- Orange and Banana Peel Waste As Natural Coagulant in Treating Wastewater - Yom KiroDocument8 pagesOrange and Banana Peel Waste As Natural Coagulant in Treating Wastewater - Yom KiroBenedicta UncianoPas encore d'évaluation

- Reprocessing of Zinc Galvanic Waste Sludge by Selective PrecipitationDocument4 pagesReprocessing of Zinc Galvanic Waste Sludge by Selective PrecipitationAli AddiePas encore d'évaluation

- Red Recruitment Kit 2016 Basic Product IntroDocument11 pagesRed Recruitment Kit 2016 Basic Product IntroEzry samadPas encore d'évaluation

- Waste Water TreatmentDocument35 pagesWaste Water TreatmentNaveen Meena100% (1)

- An Assignment On Biosecurity in Parent Stock Layer FarmDocument37 pagesAn Assignment On Biosecurity in Parent Stock Layer FarmAvskilt MazidPas encore d'évaluation

- Role of Chemical EngineerDocument5 pagesRole of Chemical EngineerRichard MamonePas encore d'évaluation

- Activated Carbon and Its ApplicationDocument16 pagesActivated Carbon and Its ApplicationErik Weeks100% (2)

- AeroBath SF-230 Shower FilterDocument4 pagesAeroBath SF-230 Shower FilterFabian DeePas encore d'évaluation

- Lecture 2 General Water Supply Design ConsiderationsDocument9 pagesLecture 2 General Water Supply Design ConsiderationsSharif Gushgar0% (1)

- Lyq 型过滤器 Lyq Type Filter: 四川新海润泵业有限公司 Sichuan Newhrun Pump Co.,LtdDocument9 pagesLyq 型过滤器 Lyq Type Filter: 四川新海润泵业有限公司 Sichuan Newhrun Pump Co.,Ltdrahmat budi hartanto100% (1)

- Assignment - SDGDocument2 pagesAssignment - SDGNur Fatihah ZulkifliPas encore d'évaluation

- 1 s2.0 S0048969722084431 Main 1Document14 pages1 s2.0 S0048969722084431 Main 1Ram PrasathPas encore d'évaluation