Académique Documents

Professionnel Documents

Culture Documents

ch55.1368 1388

Transféré par

alousteveDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ch55.1368 1388

Transféré par

alousteveDroits d'auteur :

Formats disponibles

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1368 # 1

CHAPTER FIFTY-FIVE

PROJECT MANAGEMENT IN THE AUTOMOTIVE INDUSTRY

Christophe Midler, and Christian Navarre

S N L

he automotive industry has always been a testing ground and a powerful specier for managerial innovationone need only think back to Fordism, Sloanism, and the Japanese Model of Manufacturing, which was in fact quite simply the Toyota Model. The success of the book The Machine That Changed the World is typical of this point of view (Womack, Jones, and Ross, 1990). The assimilation of managerial techniques by the auto industryTotal Quality Management (TQM) and just-in-time (JIT), for examplecertainly has transformed the way in which production is managed in car plants. However, much more than this, it completely goes beyond the dominant theories on the management of inventory and quality, and has radically changed perception of the relative importance of these disciplines throughout the various schools of thought on management. This chapter explains how and why the concept of the project gradually became formalized and deployed in car rms, and how this development generated, directly or indirectly, profound changes in (1) corporate structures and the professional practice in their technical disciplines and (2) the relationships between carmakers and their subcontractors. In short, it details how the development of project management transformed the automotive industry. Generally speaking, the strategic importance of project management methods is largely dependent on the importance both of product strategies and the competitive environment. The mass production of a small number of standardized, relatively undifferentiated products with a long life cycle does not require mastery of very sophisticated project management skills. Conversely, mass production of a large number of differentiated products has as a direct consequence the fact that the design and marketing of a large number of distinct products is hardly conceivable in the absence of the concomitant development of very so1368

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1369 # 2

Professional Associations and Global Initatives

1369

phisticated project management skills. The history of project management since World War II follows closely that of the markets (Morris, 1997). We will trace the evolution of project management in the auto industry through four stages: 1. From the postwar period up to the 1970s, there was no differentiation between the product strategies of carmakers in North America and Europe. Disciplined management of projects was not a core component in competitive strategy. 2. During the 1970s and 1980s, the gradual saturation of markets changed the competitive environment radically. Japanese carmakers succeeded in breaking into the North American market using (novel) product proliferation strategies, and the direct consequence of this business model was an explosive increase in the number of projects to be managed. The management of projects for new vehicles now assumed strategic importance. 3. In the late 1980s and early 1990s, manufacturers radically reorganized their approach to the management of projects for new products in order to develop more quickly and at lower cost a greater number of products of increasingly high quality. The management of projects for new vehicles was now at the heart of corporate strategy. 4. By the late 1990s, the limits of the reorganization of the beginning of the decade were becoming blatantly obvious. In addition, new challenges emerged. Manufacturers initiated a second wave of reorganization. New vehicle project management became more complex in order to cope with the new challenges, namely: alliances, market globalization, and innovation. In characterizing the specic position of the project function in rms at each stage, we will make use of the organizational diagrams of Clark and Wheelwright (1988). However, going beyond this framework, we shall show that the development of project-oriented logic was to bring about profound change in the permanent processes of companies, both internally and in their dealings with outside rms.

First Phase: From the Postwar Period to the 1960s

The product strategies of carmakers in North America and Europe were undifferentiated. Disciplined control of projects was not a core component in competitive strategy. The management of projects for new vehicles operated via functional structures, coordination was informal, and learning occurred within development projects. From a strategic point of view, the 1950s and 1960s were typied, in Europe and even more so in North America, by a conventional approach to mass production. The development of car manufacturing rms exhibited a gradual formation of product ranges, namely: a small number of models, long life cycles for models (as long as 12 to 14 years), little product diversication, competitiveness focused on cost reduction through standardization, and longer series (over 250,000 a year for a model).

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1370 # 3

1370

The Wiley Guide to Managing Projects

The design of these products was conducted using an organizational form of project craft in an essentially function-oriented corporate structure (see Figure 55.1). Firms were divided into powerful, compartmentalized, trade-focused entities: the product engineering ofce, the process engineering department, manufacturing, and so on. There was no direct linkage between functions. Projects passed in sequence from one function to the next, following a metaphorical relay race. Each project was handled on a case-by-case basis. The only player joining up functions and acting as arbiter between them was the senior management team and often the CEO himself or herself. Technical learning took place within the projects themselves, each project being a genuine locus for the development of new skill sets relating not only to products but also to production processes. The buildings of new bodies of expertise occurred in and through successive project development programs. Given this process, the consequences of the risks associated with major technical learning often became more visible in projects. The resulting level of performance in terms of duration, cost, and quality in the new products was mediocre: long development times (ve to seven years), often with delays of one or two years. Product launches were frequently beset with unforeseen problems of industrial feasibility. It often took several years before nominal production rates could be achieved in plants. And, nally, even in a context in which competition was weak because of lack of market availability of products, it is manifest that a large number of unsuitable products reached the market, a sign that upstream project targeting and evaluation processes had been relatively ineffective.

Second Phase: From 1970 to 1985

During the 1970s and 1980s, the gradual saturation of markets brought about radical change in the competitive environment. The management of new vehicle projects assumed strategic importance. Firms learned how to steer their projects strategically and centralize their coordination. The late 1960s saw, both in Europe and in the United States, the deployment of a new strategy that was to lead to the arrival of the modern, multiproduct vehicle model range, to the diversication of models (power trains, bodywork, and ttings), and to the international deployment of the companies. In such circumstances, the project craft of the preceding period was incapable of coping with the new complexity of product strategies. It is at this point that we see the beginnings of a professionalization of project management: The rst project functions were created in the early 1970s, along with periodic review systems involving corporate management. The careful guidance of projects to completion was gradually put in place, along with formalization of development timetables and the deployment of economic reporting tools integrating all the variables in the projects concerned.

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1371 # 4

Professional Associations and Global Initatives

1371

FIGURE 55.1. THE FUNCTIONAL STRUCTURE.

Departmental management Departmental project players

Contributors from outside the company (industrial market partners)

Source: Adapted from Clark, Hayes, and Wheelwright, 1988.

Other than this centralization of control, however, there was no change in the relationship between strategies for the building of technical skills occurring in engineering design ofces and central process planning departments, on the one hand, and development policies, on the other (see Figure 55.2). Project teams had neither the political weight nor the expertise to defend their own logic against the strategies of technical departments. This period can be characterized as that of the lightweight project manager, a notion given formal expression by Clark, Hayes, and Wheelwright (1988). These new forms of project organization and instrumentation certainly brought with them improvements in new vehicle projects, but the limits of this form of coordination became clear as early as the beginning of the 1980s. The failures that could be seen in projects became increasingly prejudicial: Control of project protability and lead times was often lost, signposting the limitations of the use of sequential input of trade-focused logic and an excessively hierarchical approach to the negotiation of compromises (Cabridain, 1988); Product quality at start-up was disappointing on occasion, reecting an organizational balance in which there was no powerful internal actor capable of measuring and managing the risks generated by technical innovation strategies. Last, despite a few hesitant attempts, there was no innovation in the area of project management on the part of American or European carmakers. The innovation, in fact, came from a small number of companies, Toyota and Honda in particular. Stalk and Hout (1990) have shown that by the end of the 1980s, certain Japanese rms were implementing highly

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1372 # 5

1372

The Wiley Guide to Managing Projects

FIGURE 55.2. THE PROJECT COORDINATION STRUCTURE.

Departmental management Project committees Departmental project players

Project Manager

Project Manager's scope

Departmental project supervisors

Contributors from outside the company (industrial market partners)

Source: Adapted from Clark, Hayes, and Wheelwright, 1988.

aggressive product proliferation strategies, the principle of which was to drown competitors in a ood of very rapidly replaced products. In such an environment, the products of slower competitors quickly go out of fashion. Stalk and Hout show how the use of such strategies by Honda and Yamaha won them dominance in the motorcycle market. A similar approach can be seen in the conquest of the North American market by Japanese carmakers. Table 55.1 (Womack, Jones, and Ross, 1990) shows that from 1955 to 1989 the number of vehicles offered to consumers was increased by a factor of ve; Japanese producers, absent from the market in 1955, were, by the late 1980s, offering a vehicle range equivalent in variety to, or even slightly more diverse than, their North American competitors. It is worth noting that European manufacturers did not penetrate the North American market with additional automobile models during this period. Moreover, the same study shows that in 1989 the models brought to market by Japanese car rms were more recent and superseded more quickly by new models than those of their North American competitors. Average sales per vehicle declined substantially. As a consequence, it became increasingly difcult to provide input for assembly plants designed for volumes greater than 250,000 vehicles per year. Such proliferation strategies were based on highly effective project management methods. Comparative studies (Clark and Fujimoto, 1987), updated in 1990 and published in 1995, highlight a signicant differential in relation to the development performance achieved by Japanese rms according to the three metrics chosen by the researchers: lead time, project

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1373 # 6

Professional Associations and Global Initatives

1373

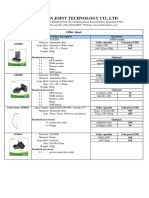

TABLE 55.1. FRAGMENTATION OF AMERICAN AUTO MARKET.

1955 American Products: Number on sale Sales/product (000s) European Products: Number on sale Sales/product (000s) Japanese Products: Number on sale Sales/product (000s) Total: Products on sale Sales/product (000s) Market share captured by six largest-selling products 25 309 1973 38 322 1986 47 238 1989 50 219

5 11

27 35

27 26

30 18

0 0

19 55

41 94

58 73

30 259 73

84 169 43

117 136 25

142 112 24

Source: Adapted from James P. Womack, Daniel T. Jones, Daniel Roos, 1990, Figure 5.6, p. 125.

team productivity as measured by the number of engineering hours required to develop the projects, and the quality of the vehicles placed on the market. This work was widely disseminated and analyzed by industry professionals. These studies stimulated intense reection among academics, researchers, and industry professionals. The conditions were in place for a radical change in the way projects were managed in North American and European auto rms in the late 1980s.

Third Phase: 19851995The Rise of Project Functions and the Deployment of Concurrent Engineering

At the end of the 1980s, a new template emerged: concurrent engineering, characterized by the spectacular rise of project functions and the deployment of new development methodologies. (See the chapter by Thamhain.) The most visible sign of this break with the past was the creation of project directors who were destined to become genuine entrepreneurs in automotive development. The time had come for the heavyweight project manager template described by Clark, Hayes, and Wheelwright (1988). The heavyweight project manager structure, under the label Susha, had existed for many years in the Japanese rm Toyota (The rst Susha was appointed at Toyota in 1953!). A Susha is an independent project director with wide-ranging powers, enjoying authority from the preliminary project stage right up to design and manufacture. As early as 1984, a

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1374 # 7

1374

The Wiley Guide to Managing Projects

TABLE 55.2. ADJUSTED LEAD TIME AND ENGINEERING HOURS.

Japan U.S. Europe Korea Total (w/o Korea) Total 2507 (1084) 2477 (755) 2493 (941) 53.5 (9.9) 54.7 (10.9) 54.1 (10.3) 52 (27) 56 (18) 54 (23)

Adjusted engineering hours (EHAD): 1980s 1703 3366 2915 2507 (843) (642) (950) (1084) 1990s 2093 2297 2777 2127 2438 (500) (947) (723) (926) (739) Total 1847 2880 2843 2127 2474 (745) (936) (822) (926) (926) Adjusted lead time (LTAD): 1980s 44.6 60.9 59.2 53.5 (7.4) (5.6) (6.1) (9.9) 1990s 54.5 51.6 56.1 54.5 54.7 (12.6) (3.8) (12.2) (3.6) (10.3) Total 48.6 56.7 57.6 54.5 54.1 (10.7) (6.7) (9.7) (3.6) (10.1) Total Product Quality (TPQ): 1980s 53 35 60 52 (29) (29) (21) (27) 1990s 61 42 59 21 52 (16) (18) (17) (1) (20) Total 56 38 60 21 52 (25) (24) (19) (1) (24)

Denitions: Adjusted engineering hours-The number of hours required to develop a project of average project complexity. See Appendix II for further details on the adjustment method, which is based on a multiple regression model. Adjusted lead time-The number of months required to develop a project of average project complexity. See Appendix II for further details on the adjustment method, which is based on a multiple regression model. Total product quality (TPQ)-The TPQ index presented in Table 2 makes quality comparisons relative to other vehicles in the same class. As a consequence, the TPQ index has already been adjusted for project quality and is presented here to allow comparisons across the three measures of development performance. Adapted from Ellison, David J., Kim B. Clark, Takahiro Fujimoto, and Young-suk Hyun. Product Development Performance in the Auto Industry: 1990s Update.. #w-0060a, IMVP 1995, p.11.

S N L

few perspicacious managers visiting Japan had discovered the Susha system and pointed, using the example of Toyota, to its strategic dimension for the management of new vehicle projects. In the United States, the company that took the heavyweight project manager template furthest was Chrysler. Early in the 1980s, Chrysler was close to bankruptcy and its project performance was poor: Development was taking 60 months with little or no cost control, and vehicles devoid of strong identity were being launched, which was undermining the companys commercial credibility. The team around Lee Iacocca pointed to the inability of vertical functional groups (trades) to cooperate and to soft compromises on policy. Vertical functional groups were clearly incompatible with innovation and audacious product policies.

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1375 # 8

Professional Associations and Global Initatives

1375

FIGURE 55.3. THE PROJECT DIRECTOR STRUCTURE.

Departmental management Departmental project players

Project manager

Project manager's scope

Departmental project supervisors

Contributors from outside the company (industrial market partners)

Source: Adapted from Clark, Hayes, and Wheelwright, 1988.

The new management redened how the development of new vehicles was to be organized on the basis of range segments functioning as autonomous enterprises in their own right. All engineering and project management resources, which previously had been conventionally organized by trade, were divided into ve platforms: Top of the Range (Large Car), Entry Range (Small Car), Jeep, Truck, and Minivan. The entire 10,000-strong workforce employed in the development of products and engineering design was split into medium-sized units comprising between 2,000 and 3,000 people and provided with clear leadership. In Europe, Renault was the rst manufacturer to put in place powerful project directors with a genuine entrepreneurial dimension in the late 1980s (Midler, 1993). These structural changes went on to drive profound modications in project communication and decision processes. We summarize these modications in ve broad categories in the text that follows. Overhaul of Project Control Processes The previous stage was characterized by the development of sophisticated control of planning and project costs. The limitations of this bureaucratic template have been thoroughly analyzed in the literature, namely: inertia and cost of control, lack of accountability, and lack of solidarity on shared general goals. In contrast, the new template emphasized the importance of adherence to an overall vision and the meaning of the projectof the personal involvement of individuals in seeking collectively to achieve objectives of a more general nature. There was a shift from burdensome controls that removed any sense of personal accountability to an encouragement for individual responsibility and self-regulation by proj-

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1376 # 9

1376

The Wiley Guide to Managing Projects

ect participants, within a framework dened by meta-rules guaranteeing minimum coherence (Jolivet and Navarre, 1993). At Chrysler, the new compact organization based on clear leadership created a new feeling of solidarity, favoring early resolution of problems, encouraging calculated risk taking, and reducing the inertia in decision making inherent in structures of the matrix type. In Europe, at Renault, followed by PSA Peugeot Citroe n, this logic of personal accountability for overall objectives, quality-cost-duration, was rolled out for all vehicle subassemblies: seats, engine, dashboard, and so on.

The Development of Concurrent Engineering The new project actors laid down new game rules for the coordination of project contributors. These changes were at three levels. First, they related to the timing of the contributions by the various specialists: Traditional sequential processes gave way to a planning logic aimed at maximum anticipation of problems through the early involvement of the trades involved in production: Plants were involved in the manufacture of prototypes in order to validate process feasibility, future products were tested with the sales networks, and so on. Next, they concerned communications between functions: Previously, intertrade dialogue had occurred largely at the top of the management tree. Project management departments now began to promote such dialogue at the bottom in decentralized work groups responsible for all aspects of the development of a given part of the vehicle (seats, dashboard, etc.). And last, the changes related to the spatial organization of work, with systematic use of colocation of participants in project ofce suites, and development of tools to accelerate intertrade communications. To point to the example of Chrysler once again, the construction of a single development center had the effect of locating transverse project communications within the workplace. Chryslers management realized that the companys conventional functional organization, which consisted of the usual design, engineering, manufacturing, marketing, and sales departments, was a prime culprit. Each functional group tended to operate as an independent efdom with its own goals . . . When there was a major decision to be made, it had to go up to the president, because each functional group had its own objectives, and it was difcult to get agreement among them. Chryslers president often ended up having to arbitrate among groups that should have been cooperating instead of competing. The implementation of integrated multifunctional platform design teams allowed Chrysler to replace the conventional sequential engineering with simultaneous engineering. To enhance communications among engineers and to make concurrent product development possible, it was seen as extremely important to have all platform teams members collocated. Despite limited nancial resources at the time of the turnaround, the costly decision to relocate all the people developing new cars under one roof was made. Lee Iacocca, then the company chairman, announced the new technical center in 1984. Construction began two years later. When an economic recession hit in 1989, Wall Street and a lot of others called for Chrysler to abandon the project to save money, but Iacocca refused, believing it was too important to Chryslers long-term health . . . The Chrysler Technical Center opened in 1991 and quickly became an important part of the enterprise.

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1377 # 10

Professional Associations and Global Initatives

1377

The architecture of the design center placed each platform/project physically on the buildings oors (horizontally), disposing trades vertically (along a vertical axis connected by escalators). The company implemented simultaneous engineering tools and, more generally, transverse communication systems (the center thus pioneered intranet and extranet development). Support programs were initiated to encourage cross-category culture and continuous learning processes: ongoing vocational training for staff and an aggressive policy of recruitment of young engineers, along with the overhaul of the system of personnel management and evaluation (notably by introducing coworker evaluation, etc.). The Dynamic of the Technical Trades Involved in Projects While project process efciency is a necessary condition of the new product innovation strategies, the excellence of the technical disciplines is just as essential. However, the new types of organization implemented profoundly destabilized the processes of capitalization and development of expertise in the various trades involved in vehicle engineering. One of the crucial problems facing carmakers in the 1990s was therefore the issue of how to create a project management capability without this being detrimental to the key disciplines expertise base. The example of Chrysler illustrates an extreme case in which trade-focused logic has manifestly been subordinated to project platform logic. However, the company set up expert clubs to maintain cross-platform solidarity learning on key technical skills. Initially informal, this system was consolidated and ofcially instituted in 1994, under the sponsorship of a general manager. In Europe, Renault preserved the trade-based structure of its vehicle engineering but thoroughly overhauled the boundaries between specialities to ensure their assimilation of product-process engineering logic by dividing up departments on the basis of vehicle subassemblies and functions. In Japan, the issue of how to organize corporate technical departments was at the heart of Toyotas engineering reorganization in 1992. A Change in Relations with the Outside World: From Subcontracting to Codevelopement The development of the project concept did not undermine internal corporate mechanisms alone. Automotive projects usually unfold in a space much wider than that of single company: Today, the proportion of production cost relating to parts bought in from suppliers is generally more than 70 percent. The new project actors have come to play a major role in the development of new types ofcodevelopment between carmakers and suppliers Calls for bids from and subsequent selection of suppliers operate from the outset of a project, on the basis of agreement on core project objectives. The chosen supplier is then associated closely with the engineering study process: co-location in the project ofce suite, participation in project progress meetings, and so on. Compared with the conventional template for competition between suppliers based around detailed project specications, this new template for the relationship involves, for those taking part in it, the need to modify their

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1378 # 11

1378

The Wiley Guide to Managing Projects

organizational and contractual frameworks (Banville and Chanaron, 1991; Lamming, 1993; Garel, Kesseler, and Midler, 1997; Kesseler, 1998). The purchasing process in particular is completely revolutionized. Once again, Chrysler can be seen to be, in North America, a precursor in its implementation of the extended enterprise concept, closely involving suppliers in projects. In Europe, Renault also consciously committed to codevelopment policies (Midler, 1993; Kesseler, 1998). Developing Project Management Professionalism within Automobile Firms The empowerment and generalization of project function called for institutionalization of project management professionalization processes. Beyond the variety of the programs and professional patterns that developed in the late 1980s and 1990s, we will pinpoint the following characteristic points (Boudes, Charue-Duboc, Midler, 1998): Project management was not generally developed into a specic professional pattern, as, for example, in construction. On the contrary, human relations rules organized transversal carrier trajectory, mixing skilled-based and project-based roles. Two ideas are behind that choice: (1) that a key difcult point is to maintain solidarity between project and functional populations and (2) that alternating the role will enhance the capitalization of inside project learning. Emphasizing the individual project management expertise appeared in that perspective not as important as developing a more collective project management competency. The maturity the project management approach of the rm can be correlated to the hard/soft orientation of project management learning programs: the deeper in organizational and strategic themes, the heavier the project management function. The more technical side of project management (planning tools, budgeting . . .) diffused through highly specialized staff people in the rm. Emphasizing on the entrepreneurial aspect of project function led to develop crosspractitioner learning and capitalizing programs. Such project managers exchanges not only occurred within each rm but also extensively in cross-sector clubs and associations. The Results: The Spectacular Success of Western Carmakers The implementation of these new project management modes led to signicant progress in the performance levels achieved by Western manufacturers in terms of new vehicle launches. Duplicating the study they had conducted in the 1980s, Ellison, Clark, Fujimoto, and Hun demonstrated that Western carmakers had very much caught up with the Japanese according to the various metrics they had dened as being most indicative of project management performance levels (see Table 52.2). At Chrysler, the results were initially impressive. The . . . Neon compact car model took 31 months to bring to market, while the current Dakota pickup truck made it in only 29 months. Over the rst ve years from the initial setting up of these new structures, Chrysler developed more new models than in the 20 previous years.

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1379 # 12

Professional Associations and Global Initatives

1379

Unquestionably, from the mid-1980s to the mid-1990s, Chrysler has been a exemplar company, especially for the development of new products. During the 1990s and up to the time of the merger with Daimler, Chrysler was generating by far the highest average prot per vehicle of any North American auto manufacturer (Harbour and Associates, from 1995 to 1999). In addition, its assembly plants also ranked, according to the same studies, among the non-Japanese plants with the highest productivity. In Europe during the rst half of the 1990s, Renault reaped the benets of its breakthrough in project management, bringing to market an innovative product range while also restoring its image in terms of product quality and improving its cost base. The success of vehicles such as the Twingo and the Megane Scenicwhich were to create new market niches as the Espace minivan had done in years pastwas the most spectacular result of the new project systems. New Difculties in the Late 1990s The 1990s ended less happily than they had begun. Surprisingly, the effectiveness of the new systems put in place a few years before seemed to run out of steam. Chrysler got into trouble and was taken over by Daimler-Benz. Unfortunately, excellence in new product development is not sufcient by itself to sustain protability and growth on a long-term basis. The inescapable turmoil induced by a merger, the disruptive effect of the 9-11 terrorist attack combined with a cutthroat competition made again Chrysler vulnerable. Since the end of 2001, Chrysler is again in crisis. In Europe, the most advanced carmakers evidenced slower product cycles, losses of control over lead times, and mismatches between vehicles and customer expectations. During this period, in Japan the landscape was very mixed. Toyota could do no wrong in any market around the world, while Nissan was mired in a profound crisis. This crisis ended only with its takeover by Renault, when the deep renewal was implemented triumphantly by the new managers of the company under the leadership of Carlos Ghosn.

Fourth Phase: 19952003

Project management faces new challenges in the automotive industry. Several factors serve to explain what might seem at rst sight to be a relapse, but that was in fact another stage in the intensication of innovation-based competition in the automotive industry; a stage described as one of intensive innovationinnovation that is both more radical in content and repeated at a faster rate (Hatchuel and Weil, 1999; Benghozi et al., 2000) and that has been increasingly deployed against the background of global alliances. The comparative benet of efcient project systems for the pioneers in the early 1990s tended to run out of steam as best practices spread rapidly to their competitors. To nd new values for differentiation, rms went down the road of innovation policies that were far more radical in terms of both engineering and styling. On the one hand, in doing so

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1380 # 13

1380

The Wiley Guide to Managing Projects

they were adding a source of higher risk; on the other, they were facing problems for which heavyweight types of automotive project organization were unsuited, since the most relevant context for the deployment of technical innovation is not vehicle development but transverse learning covering both the preliminary project stages and whole product ranges. No cross-functional and cross-product project existed to address, coordinate, and control these learning tracks on radical innovative features and technologies (a good example is car telematics; Lene and Midler, 2003). The increasing number of projects in rms clearly highlights problems associated with the heavyweight project management template, problems that were not burdensome when such forms of organization were the exception. As early as the beginning of the 1990s, Toyota had taken a critical look at its Susha system (Cusumano and Neoboka, 1998). By 1992 the number of platforms rose from 8 to 18, along with a decline in average production volume per platform. Communication and coordination problems became critical. In 1991, a Susha was communicating and working with 48 departments in 12 engineering divisions, plus the R&D division. Trade divisions were conducting concurrent dialogues with 15 projects. The relationship between Sushas and senior management in the plan-product division was all the more strained because detailed supervision of 15 Sushas was impossible without setting up an enormous project-focused bureaucracy. Staff in the plan-product division were nding it difcult to monitor all 15 projects and became disconnected from reality. R&D was perceived as being distantand its interfacing with projects became very problematic. The inuence and power enjoyed by Sushas were considerable and difcult to control because of the failings of the system. As crisis after crisis occurred, the powers of Sushas were strengthened, along with their responsibilities, which had the effect of locking them in to projects and encouraging the appearance of a blinkered silo mentalityalbeit transverse silos. The rapidly expanding number of projects led to the appointment of young, inexperienced Sushas. Coordination became increasingly difcult, or even impossible. The increased number of departments and divisions led to narrow specialization in the engineers, making it more and more difcult for them to understand cross-category logic and interfacing, and this in turn led to less wellthought-out, less integrated products. Capitalization and transfer of expertise from one project to another became extremely problematic. The same solutions were continually being reinvented. The total workforce assigned to development was not far from 15,000. The end of the 1990s was also a period of unprecedented strategic shifts in the auto industry. There were more and more alliances of all kinds. Projects needed to assimilate this new factor, which was a source of further difculty and new constraints compared with the previous stage. These strategic changes led eventually to new developments in automotive project management, which can be summarized in terms of ve interdependent trends: Deployment of the project function downstream of initial product development Implementation of systems better suited to steering radical innovations, both upstream and between product development programs

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1381 # 14

Professional Associations and Global Initatives

1381

Increasing numbers of projects conducted by intermanufacturer partnerships Development of platform projects as a way of managing the plethora of multibrand product development programs Enlargement of supplier-manufacturer cooperation elds: modularization and colearning. Deployment of the Project Function in the Commercial Phases The intensication of innovation-based competition in the automotive industry had consequences. Downstream of development projects, it undermined the stability of the products commercial life cycles. This was because, since the mid-1970s, the initial development of new products was a key stage that allowed the introduction of innovations, whether in products or processes. Between product launches, there was room for minor modications. In the mid-1990s, the price war in the European and North American markets led to a new strategy involving more systematic deployment of development forces for products already in the market, in order to obtain immediately all the benets of the innovations introduced between new product cycles. Transverse integration, formerly restricted to the development phase, now spread to the entire product life cycle. This led in European car rms to a rise in importance of new actors, the series life project manager and the program director, with the task of coordinating the various trade components within a segment of the manufacturers range throughout the life cycle. The Management of Radical Innovation Projects: The Growing Importance of Predevelopment as a Base for Differentiation Strategies At the same time as this increase in the rate of appearance of innovations, the differentiation strategy increasingly included research activities in order to nd new competitive advantages. The quality-cost-lead time triangle no longer sufced. It was necessary to introduce more strikingly radical innovations in the services offered to customers: hence, recent changes in upstream development disciplines, which had until this point remained relatively aloof from ongoing changes. At Renault, by the end of the 1990s, the research division was totally overhauled, strengthened, and tightly interfaced with the preliminary project design departments. The logic of this reorganization was clearly expressed in the change of director: Previously led by a scientist with a past career in a French pure research body, the French National Research Council, the division was now led by a former vehicle project manager. The divisions activities, previously based around scientic disciplines, were now guided by programs focused on areas for innovation allying services and technology and that have clear importance for the evolution of automotive transport. Within vehicle development programs, the post of innovation project manager was created to manage the convergence of complex technical innovations (the keyless car, for example). At Peugeot-Citroe n Group, an Innovation Division provides a focus for all upstream specialists. By the early 2000s a new form of project organization was gradually being put in place to guide exploration upstream of vehicle projects (Lene and Midler, 2002). Although one

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1382 # 15

1382

The Wiley Guide to Managing Projects

can nd in this type of project some of the features of vehicle projects (specically the need to conduct such exploration by coordinating a plurality of forms of expertisetechnical, marketing, design, etc.), these projects also have novel characteristics. First, the level of risk is much higher because of the extent of the innovation in terms of both technology and product features. This leads projects to be conducted within exploration portfolios in which efforts are made to maximize synergy and offset risks, rather than mobilizing teams on oneshot operations, which is the principle underlying conventional projects. (See the chapter by Jamieson and Morris.) Second, the direct result of such a project is not a product placed on the market but a concept that is validated and knowledge that is acquired, which it will be necessary to exploit later in actual products. (See the chapters by Artto, Thiry and others.) This virtual, intangible character of the result is undoubtedly one of the difculties of this type of project: The tangible, practical nature of a new product launch is no longer present as a focus for the contributors to the project. The Development of Projects by Intermanufacturer Partnerships and the Interfacing of Project Management and Strategic Alliances The auto industry is one of the sectors that saw a spectacular wave of globalization and corporate restructuring in the 1990s (mergers, acquisitions, strategic alliances, industrial cooperation, as well as spin-offs and exit). Internationalization strategies and the importance of size are, of course, not new features of this sector, but the changes seen in the 1990s were unprecedented in their scale and generalized character, giving the impression of a fashion phenomenon that has swept all company strategies along in its wake. Such strategies for growth through alliances were reected in two ways in projects. First, manufacturers increased the number of one-off cooperative programs in joint projects, in order to round out their model ranges in niche markets and gain access to new markets by pooling with others the costs and risks involved in such developments. Second, where alliances were more global in character, projects for new products provided useful leverage for the exploitation of synergy between merged companies through the sharing of platforms, systematic exchange of mechanical subassemblies, and so on. Piron (2001) and Midler, Monnet, and Neffa (2002) have emphasized the importance of three problem sets that exist in cooperative projects, compared to the traditional automotive project culture: Mutual understanding within joint project teams. In single-manufacturer project teams, coordination is based on numerous unarticulated bodies of expertise forged throughout the companys past history. Once projects begin to be conducted as cooperative endeavors by more than one manufacturer, the risks of misunderstanding will be high if the participants do not make substantial efforts to make themselves clear. Such effort is costly and difcult to gauge correctly, since it runs counter to the participants need to protect their knowledge and expertise. S N L The management of fair and equal treatment of the partners. This becomes a prerequisite for cohesion and focus in joint project teams. Studying a joint project by General Motors and Renault,

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1383 # 16

Professional Associations and Global Initatives

1383

Midler, Neffa, and Monnet (2002), adapting Piron (2001), have demonstrated that the practical implementation of fair treatment in projects could take three forms: Distributive justice involves the search for a balanced proportionality between the partners, a fair return, in Pirons words. The point is, for the rms, to nd a fair distribution of goods and powers based on the goals sought and the resources committed by each. Procedural justice refers to the feeling that procedures have been fair. The point is for the participants to judge a decision-making process relative to a reference that is well known and considered legitimate. The factors that inuence this include a feeling of participation in decision making, an explanation of decisions, and clarity concerning expectations and the rules of the game, all of which inuence whether the participants feel they have been treated fairly and equitably. Finally, interactive justice refers to individual interactions based on fairness in behavior, which makes it possible for a decision to be considered doable. Hence, respect and courtesy between allies prove to have an important contribution to make in the fostering of a positive atmosphere for interpersonal relations during the cooperation process. Regulation of tensions between the project and the strategies of the parent companies. Cooperation projects are by their very nature unstable and vulnerable to exogenous events. In the case of the Renault-GM project, joint decisions have been upset by shocks coming from outside the project, such as the Renault-Nissan alliance in 1999 and the GM-Fiat alliance in 2000. However, the nomination of a project general manager representing the interests of both rms and the governance structures has strengthened the joint program and attenuated the impact of external events such as the Renault-Nissan and GME-Fiat Alliances or the high currency rate between the euro and sterling. The Growing Importance of the Platform Concept in Vehicle Design Strategies One of the core tensions in the automotive industry has always been the productstandardization/product-differentiation dilemma. In the 1980s, the myth of the global car was a subject much talked up by manufacturers, and a burden on the accounts of those American manufacturers who actually developed the concept. The development of highly entrepreneurial project managers allowed, in the early 1990s, the rapid launch of innovative products in market niches that conventional strategies were incapable of reaching. The successes achieved at that time by a rm like Renault can certainly be put down to this logic. However, with the advent of strategies for growth by merger and acquisition in the 1990s, the advantages of design strategies based on platforms common to different products took on new relevance. Firms such as the VAG group, PSA, and, less successfully, Fiat used such strategies to drive their development in Europe. Although the concept of the platform is an attractive one, putting it into practice involves, in project terms, a dual difculty in interfacing the platform-driven projects with product-driven projects. Specically, the issues are as follows: S N L The core issue is how to benet from covert standardization while nevertheless preserving differentiation in the nished products. The boundary is, however, far from obvious here.

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1384 # 17

1384

The Wiley Guide to Managing Projects

In multibrand groups, it usually leads to the de facto domination of one brand identity over the others, which must t in with the constraints imposed by the initial designer of the platform. The second issue is how to link up the replacement cycles for platform and products. If a requirement to use a platform is imposed on a product, it will often mean that recent innovations cannot be introduced, with the consequence that a risk is taken in a market characterized by swift obsolescence. But if the platform evolves at the same speed as the products derived from it, there is no longer much of a distinction between the concept and the conventional notion of carry-over. The New Boundaries of Manufacturer/Supplier Relationships and Vehicle Programs: Toward Colearning and Modular Codesign? In the 1990s, the successes achieved in efforts at codevelopment led rst-rank suppliers to gradually broaden their eld of competence and learn trades that had in the past been the reserved domain of carmakers. Major value shifts were observed as subcontracting was generalized. How far should one go in this new allocation of the roles of the manufacturer of the vehicle as a whole and the suppliers of its components? The issue of extension of supplier responsibilities and involvement is apparent today in two main areas. The rst area relates to timing. In the 1980s, suppliers provided input in the later stages of projects, in the context of relationships that were precisely governed by detailed technical specications laid down by the car manufacturer. In the 1990s, it became gradually possible to dene effective arrangements for codevelopment (Garel and Midler, 2000; Kesseler, 1998)that is to say, cooperation between the carmaker and its suppliers on the basis of overall functional objectives. However, with the increasing importance of innovation policies, carmaker/supplier cooperation sought to extend itself upstream within development projects, in colearning arrangements (Lene and Midler, 2001) for the design of innovative concepts for product features in which more effective coordination of the partners respective roadmaps was sought. The expanding importance of concept competition phases compared with the more traditional competitive bid processes was the visible sign of this strong trend, which raises several questions: For example, how should one allocate the costs and risks involved in such upstream explorative programs, whose outcome is highly uncertain? What type of regulation of intellectual property issues might encourage the partners to provide the transparency imperative to the success of the partnership? The second relates to the spatial and functional boundaries of supply. The last two decades have been ones in which the functional and spatial scope of the suppliers role has expanded: There has been a shift from the individual part to the component, followed, in the 1990s, by entire systems (complete functional assemblies) and modules (an assembly whose boundaries can be geographically isolated). The principle is to dene interface standards to enable the producers of components (whether modules or systems) to develop items that are simultaneously less expensive (volume effects), more versatile (offering greater variety), and compatible with open-architecture interiors. Suppliers delivering similar or homogeneous items

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1385 # 18

Professional Associations and Global Initatives

1385

to more than one manufacturer are in a position to gradually dene commonalities in the components they offer. They are also in a position to dene the best ways to differentiate them at low cost and to contain, or even to eliminate, the extra cost because of variety. Volume also allows R&D costs to be spread over a number of client manufacturers. This approach, summed up in the black box sourcing concept, suggested by Clark, forms part of a particularly active ow of work on modular design (Henderson and Clark, 1990; Ulrich, 1995; Baldwin and Clark, 2000). The area that has been revolutionized by the modular architecture concept is that of telecommunications and information technology. Is the auto industry ready to be rethought in terms of combinations of interchangeable components whose interaction can be predetermined through the adoption of common standards and integrated into platforms with a strong and sharply dened architecture? A highly futuristic concept car, Autonomy, presented by GM in 2002, is a step in this direction. However, many authors rightly emphasize the integrity that is characteristic of the car as object: It is very difcult to uncouple components without penalizing overall performance, given that its functions are split between a number of component parts (vehicle behavior, weight, compactness, noiseall these are examples of highly distributed functions). On the other hand, industrial vehicles do allow much more advantageous use of modularity. Finally, one of the original features of the car as product is that while this dual evolution toward platforms and modular black box design provides a rich mine of inspiration, it cannot be applied literally as it has been in information technology. (There is, in fact, a need to specify this area more precisely: Portable computers, like mobile telephones, have integrity characteristics associated with their compact dimensions, which place tight constraints on the deployment of modularity.) This observation is of major importance where project management is concerned because it forces partners to interact during the design phase in order to arrive at compromises on distributed functions. Given that fact, a template for contractualized coordination capable of handling black box logic in terms of functional performance is inadequate. It must be overlaid with procedures for interaction enabling the detection of problems and the negotiation of compromises aimed at resolving them. Limits of Performance in New Product Development Are Constantly Surpassed Today, in a nutshell, the performance envelope for new vehicle project management can probably be located in the following ranges in North America: 1. Cost of development of a new vehicle: between USD1bn and USD1.5bn (compared with USD3bn to USD5bn ten or so years ago). 2. Accelerating fragmentation of market supply and creation of innovative new product lines (Mini Rover, Beetle, Crossover, Hybrids, Nissan Cube, SUVs, etc.). In addition, some manufacturers, with Renault in the forefront, are taking the risk of introducing radical styling that breaks with the past, staking the visual identity of their products. 3. Development duration is of the order of 24 months or less (with a mean of around 36 months), compared to 60 months (and a years delay) at the beginning of the decade. Lead times are shortening between concept cars and serial production. 4. Carmakers in North America are now generally close together in terms of measured

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1386 # 19

1386

The Wiley Guide to Managing Projects

quality, which, however, does not preclude wide variations in quality as perceived by the consumer. In addition, quality is no longer a competitive advantage but a prerequisite. However, a worrying rise in the cost of vehicle recalls can be seen. 5. A continuous decline is apparent in the costs of assembly and processes (productivity gains estimated in the region of 7 percent per yearcf. Harbour Report) as well as components (on the order of 20 percent to 30 percent for each new vehicle). In addition, manufacturers have included systematic annual volume-linked price reductions in their contracts with suppliers. 6. These savings are passed on to the consumer through constant enrichment of the features offered by vehicles at a constant price level. Moreover, for the last three years the beginnings of further reductions in prices targeted on certain model ranges have been observed. In short, there are now more features for a given price in constant, declining money terms. 7. Architecture is controlled in terms of platforms and modules in order to take advantage of scale effects on common portions while nevertheless preserving the diversity and identity of the vehicles. For example, Toyota sells, on the basis of the same platform, vehicles as different as a sedan, a van, a Lexus, and an SUV.

Summary

From the postwar period until the present time, the development of project management has radically changed structures and processes within car manufacturing companies. But on the reverse, we can say that project management had been changed by its implementation within the automotive context: from technique and tool orientation to more strategic and organizational approaches, from highly precise contractualized relation patterns to procedural open learning meta-rules. The auto industry was a latecomer to project management, compared to military equipment or construction business. But these sectors are now trying to transform there project management tradition and adopt the project management practices that were developed in the late 1980s and 1990s in the auto sector. We can see various reasons behind such a dragging effect: the economic importance and symbolic notoriety of the auto sector, of course, but also the importance of researches in management science and economics in the eld, that happened to evaluate the performances of various project patters and to trace the transformations round the world. This process is not yet complete, since performance limits are constantly increasing.

References

Ashley, S. (1997). Keys to Chryslers comeback, Mechanical Engineering Online, The American Society of Mechanical Engineers. Ayas, K. 1997. Design for learning for innovation. Delft, Netherlands: Eburon Publishers. Banville E. de et Chanaron, J. J. (1991). Vers un syste `me automobile europe en, Economica, Paris.

S N L

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1387 # 20

Professional Associations and Global Initatives

1387

S N L

Bayart, D., Y. Bonhomme, and C. Midler. 1999. Management tools for R&D project portfolios in complex organizations: The case of an international pharmaceutical rm. In 6th International Product Development Management Conference. Cambridge, UK. Benghozi, P. J., F. Charue-Duboc, and C. Midler. 2000. Innovation based competition and design systems dynamics. paris: LHarmattan. Ben Mammoud-Jouini, S. 1998. Strate gies doffre innovantes et dynamiques des processus de conception: Le cas des grandes entreprises franc aises de ba timent. Universite Paris IX Dauphine, The ` se de doctorat de gestion, Paris. Boudes, T., F. Charue-Duboc, and C. Midler. 1998. Project management learning: A contingent approach. In Projects as arenas for renewal and learning processes, ed. R. A. Lundin and C. Midler. 61 71. Norwell, MA: Kluwer Academic Publishers. Brown, S. L., and K. M. Eisenhardt. 1997. The art of continuous change: Linking complexity theory and time-paced evolution in relentlessly shifting organizations. Administrative Science Quarterly 42 (1, March). Chapel, V. 1996. La croissance par linnovation: de la dynamique dapprentissage a ` la re ve lation dun cole Nationale mode ` le industriel. Le cas Tefal. The ` se de doctorat spe cialite Inge nierie et Gestion, E Supe rieure des Mines de Paris, Paris. Charue-Duboc, F. 1997. Ma trise doeuvre, ma trise douvrage et direction de projet: des cate gories pour comprendre le volution des fonctionnements en projet dans le secteur chimie de Rho ne Poulenc. Ge rer et Comprendre (September): 5464. . 1998. The role of research departments in focusing innovative projects and understanding customer usage and needs. In International Research Network on Project Management and Temporary Organization (IRNOP Conference). Calgary, Canada. . 2001. What are the organizational artefacts implemented to foster learning processes in a context of intensive innovation? In 17th EGOS Colloquium: The Odyssey of Organizing. Lyon. Charue-Duboc, F., and C. Midler. 1999. Impact of the development of integrated project structures on the management of research and development. In 6th International Product Development Management Conference. Cambridge, UK. Ciavaldini, B. 1996. Des projets a ` lavant projet: lincessante que ` te de la re activite . The ` se de doctorat spe cialite Inge nierie et Gestion, Ecole des Mines de Paris, Paris. Clark, K. B., and T. Fujimoto. 1991. Product development performance: Strategy, organization and management in the world auto industry. Cambridge, MA: Harvard Business School Press. Clark, K. B., and S. C. Wheelwright. 1992. Revolutionizing product development. New York: Free Press. Cooper, R. G., S. J. Edgett, and E. J. Kleinschmidt. 1998. Best practices for managing R&D portfolios. Research Technology Management ( JulyAugust). Cusumano, M., and K. Nebeoka. 1998. Thinking beyond lean. New York: Free Press. Ellison, D. J., K. B. Clark, T. Fujimoto, and Y. S. Hyun. 1995. Product development performance in the auto industry: 1990s Update. #w-0060a, IMVP. Garel, G. and C. Midler. 2001. Front-loading problem-solving in co-development: Managing the contractual, organizational and cognitive dimensions. Journal of Automotive Technology and Management. no. 3. Hatchuel, A., V. Chapel, X. Deroy, and P. Le Masson. 1998. Innovation re pe te e et croissance de la rme. Paris: Rapport de recherche CNRS. Hatchuel, A., and B. Weil. 1999. Design oriented organisations. Towards a unied theory of design activities. In 6th New Product Development Conference. Cambridge, UK. Jolivet, F., and C. Navarre. 1996. Large-scale projects, self-organizing and meta-rules: towards new forms of management. International Journal of Project Management 14(5):265271 Harbour and Associates. The Harbour Report North America 1995, 1996, 1997, 1998, 1999. Harbour and Associates Publication.

Name /8830/ch55

07/19/2004 03:35PM

Plate # 0

Morris (Wiley)

pg 1388 # 21

1388

The Wiley Guide to Managing Projects

Kesseler, A. 1998. The creative supplier: A new model for strategy, innovation, and customer relationships in concurrent design and engineering processes: The case of the automotive industry. The ` se de Doctorat, spe c. Gestion, Ecole Polytechnique, Paris. Kogut, B., and Kulatilaka, N. 1994. Options thinking and platform investments: Investing in opportunity. California Management Review (Winter): 5271. Lamming, R. (1993). Beyond Partnership: Strategies for Innovation and Lean Supply. Englewood Cliffs, NJ: Prentice Hall. Lemasson, P., and B. Weil. 1999. Nature de linnovation et pilotage de la recherche industrielle. Cahiers de recherche du CGS, Ecole des Mines de Paris. Lene, S., and C. Midler. 2002. Innovation-based competition and the dynamics of design in upstream suppliers. International Journal of Automotive Technology and Management. vol 2, n5. . 2003. Innovation in automotive telematics services: Characteristics of the eld and management principles. International Journal of Automotive Technology & Management 3(1/2):144,159. Lundin, R. A., and A. So derholm. 1995. A theory of the temporary organization. Scandinavian Journal of Management 11(4):437455. Lundin, R. A., and C. Midler. 1998. Projects as arenas for renewal and learning processes. Norwell, MA: Kluwer Academic Publishers. Midler, C. 1993. Lauto qui nexistait pas; management des projets et transformation de lentreprise. Paris: Dunod. . 1995. Projectication of the rm: The Renault case. Scandinavian Journal of Management 11(4): 363375. Midler, C., J. C. Monnet, P. Neffa. 2002. Globalizing the rm through projects: The Case of Renault. International Journal of Automotive Technology & Management Vol 2, n1, pp 24, 46. Morris, P. W. G. The management of projects. 1997 London: Thomas Telford. Navarre C. 1992. De la bataille pour mieux produire a ` la bataille pour mieux concevoir. Gestion 2000 6:1330. Piron, P. (2001). Lalliance en convergence. De velopper conjointement dans lindustrie europe ene des missiles tactiques. Ph.D Thesis, Ecole Polytechnique, Paris. Ponssard, J. P., and H. Tanguy. 1992. Planning in rms: An interactive approach. Theory and Decision 34:139159. Scho n, D. A. 1983. The reective practitioner: How professionals think in action. New York: Basic Books. Sharpe, P., and T. Keelin. 1998,. How SmithKline Beecham makes better resource-allocation decisions. Harvard Business Review (MarchApril). Simon, H. A. 1969. The sciences of the articial. Cambridge, MA: MIT Press. So derlund, J., and N. Andersson. 1998. A framework for analyzing project dyads: The case of discontinuity, uncertainty and trust. In Projects as arenas for renewal and learning processes, ed. R.A. Lundin and C. Midler. 181189. Norwell, MA: Kluwer Academic Publishers. Stalk, G., T. M. Hout. 1990. Competing against time: How time-based competition is reshaping global markets New York: Free Press. Weil, B. 1999. Conception collective, coordination et savoirs. Les rationalisations de la conception cole Nationale Supe automobile. The ` se de doctorat spe cialite inge nierie et gestion, E rieure des Mines de Paris, Paris. Womack, P. J. P., D. T. Jones, and D. Ross. 1990, The machine that changed the world. New York: Rawson Associates.

S N L

Vous aimerez peut-être aussi

- (Roger A. Bruns) Billy Graham A BiographyDocument178 pages(Roger A. Bruns) Billy Graham A BiographyMarks AcostaPas encore d'évaluation

- C-WF WiMAX 16e Principle-20070528-A-2.0Document79 pagesC-WF WiMAX 16e Principle-20070528-A-2.0aloustevePas encore d'évaluation

- Energy Shelters V2 (1) .1Document57 pagesEnergy Shelters V2 (1) .1aloustevePas encore d'évaluation

- ZVH OperatingManual en FW140Document195 pagesZVH OperatingManual en FW140aloustevePas encore d'évaluation

- Tek Y400 SpecDocument4 pagesTek Y400 SpecaloustevePas encore d'évaluation

- ZVH OperatingManual en FW140Document195 pagesZVH OperatingManual en FW140aloustevePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- QY25K5-I Technical Specifications (SC8DK280Q3)Document11 pagesQY25K5-I Technical Specifications (SC8DK280Q3)Everton Rai Pereira Feireira100% (1)

- DodupukegakobemavasevuDocument3 pagesDodupukegakobemavasevuMartian SamaanPas encore d'évaluation

- +GF+ Pressure Retaining Valve Type 586Document4 pages+GF+ Pressure Retaining Valve Type 586ROMNAPas encore d'évaluation

- Cartoon Network, Boomerang & TCM TV Rate Card July - SeptemberDocument11 pagesCartoon Network, Boomerang & TCM TV Rate Card July - SeptemberR RizalPas encore d'évaluation

- Vehicle Tracker Offer SheetDocument1 pageVehicle Tracker Offer SheetBihun PandaPas encore d'évaluation

- Mineral Processing Course: ThickeningDocument50 pagesMineral Processing Course: ThickeningAdham Elbrawy100% (1)

- Obeid Specialized Hospital - Riyadh: Inpatient DeptsDocument4 pagesObeid Specialized Hospital - Riyadh: Inpatient DeptsLovelydePerioPas encore d'évaluation

- Module II Lecture 4Document19 pagesModule II Lecture 4Prateek NayakPas encore d'évaluation

- Delivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsDocument20 pagesDelivered Voided Application (Surrender Instrument) Returned To at - Sik - Hata Nation of Yamasee MoorsMARK MENO©™Pas encore d'évaluation

- Ethics in ResearchDocument21 pagesEthics in Researchmukku_raviPas encore d'évaluation

- Topic 3Document28 pagesTopic 3Ashraf YusofPas encore d'évaluation

- Five Sheets For Technology PlanDocument16 pagesFive Sheets For Technology Planapi-200984070Pas encore d'évaluation

- Strategic Investment Plan ForDocument78 pagesStrategic Investment Plan Forapi-3833112Pas encore d'évaluation

- DUPLICATE BILL TITLEDocument8 pagesDUPLICATE BILL TITLEMohammed AhmedPas encore d'évaluation

- PC 4 Product List 2019 - Pc4Document28 pagesPC 4 Product List 2019 - Pc4ShPas encore d'évaluation

- Mascot LD series hydraulic motor specsDocument6 pagesMascot LD series hydraulic motor specsM S GokulPas encore d'évaluation

- Soft Computing Techniques Assignment1 PDFDocument14 pagesSoft Computing Techniques Assignment1 PDFshadan alamPas encore d'évaluation

- Vaje 3 - Macionis in PlummerDocument2 pagesVaje 3 - Macionis in PlummerLazar DjondricPas encore d'évaluation

- Handy 2010 Case StudyDocument6 pagesHandy 2010 Case Studycancer6Pas encore d'évaluation

- Tiger AnddragonDocument61 pagesTiger AnddragonAdil SiddiquiPas encore d'évaluation

- MD SHAFIUL ISLAM 沙菲 ID;20183290290Document23 pagesMD SHAFIUL ISLAM 沙菲 ID;20183290290SHAFIUL SETUPas encore d'évaluation

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- Nature vs Nurture DebateDocument3 pagesNature vs Nurture DebateSam GoldbergPas encore d'évaluation

- Audi A3 Injeção DiretaDocument109 pagesAudi A3 Injeção Diretawesley candido100% (1)

- Teodora Sarkizova: Certificate of AchievementDocument2 pagesTeodora Sarkizova: Certificate of AchievementAbd El-RahmanPas encore d'évaluation

- 3.0 Wrap Up and SummaryDocument4 pages3.0 Wrap Up and SummaryGian SanchezPas encore d'évaluation

- American With Disabilities Act AdaDocument16 pagesAmerican With Disabilities Act Adaapi-376186426Pas encore d'évaluation

- Methanol Technical Data Sheet FactsDocument1 pageMethanol Technical Data Sheet FactsmkgmotleyPas encore d'évaluation

- Renal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaDocument9 pagesRenal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaFarhanPas encore d'évaluation

- Green Screen Background Remover Using CV SystemDocument20 pagesGreen Screen Background Remover Using CV SystemSubhamPas encore d'évaluation