Académique Documents

Professionnel Documents

Culture Documents

Tension Control Systems

Transféré par

Sheik HassanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tension Control Systems

Transféré par

Sheik HassanDroits d'auteur :

Formats disponibles

Tension Control Systems

Application Examples

Dancer Control

The dancer control system consists of a power supply, dancer control, pivot point sensor, and controlling element, i.e., tension brake or clutch. Dancers provide the web tension while the control and controlling element stabilize dancer operation for unwind, intermediate zone or rewind tension.

Brake

Pivot Point Sensor

MCS 2000 PSDRV

MCS 2000 CTDA

Load Cell Control

Load cell control system consists of the load cell controller, power supply, load cells and controlling element, i.e., tension brake or clutch. Load cells measure the pull force on the web and compare that force to the set point tension in the control. The control increases or decreases the retarding force. Load cells are used for unwind, intermediate zone or rewind tension control.

Load Cell

ModEvo Transducer

MCS 2000 ECA

MCS 2000-PS

Analog Control

The analog system consists of a control module, power supply, and a controlling element, i.e., tension brake or clutch. The analog controller provides output proportional to the input signal for use in unwind, intermediate zone or rewind tensioning.

MTB II

TCS-167 TCS-220 Analog Signal

Electronic Control

Electronic control systems are very similar to analog control systems with the exception of using an electronic sensing element such as an ultrasonic or photoelectric sensor. The sensor monitors diameter change in either the unwind or rewind rolls, and provides a corresponding change in output.

Ultra-Sonic Sensor

Brake

Power Supply/Driver MCS-2000 PSDRV 6

Warner Electric 800-825-9050

Tension Control Systems

Application Examples

MTB II

TCS-168 TCS-320 AnalogSignal

Dual Brake Unwind

Dual brake unwind incorporates modular tension brakes and an analog control system. The brakes retard the unwind roll, creating tension in the web. An external, customer-provided signal adjusts the output current to the brakes to maintain the proper tension. The dual channel controller controls each brake independently or simultaneously.

Load Cell

Mistral Brake

Single Roll Pneumatic Brake Unwind

Pneumatic brake retards the rewind roll, providing the required tension. Tension is set by the loading force applied to the load cells, which send a signal to the controller. The controller signal to the electric/pneumatic transducer controls the air pressure to the brake.

Load Cell

MCS 2000 CTLC Transducer

Pivot Point Sensor

TCS-210 Magnetic Particle Brake TCS-167

Warner Electric 800-825-9050

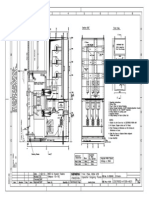

Single Roll Magnetic Particle Brake Unwind

The magnetic particle brake retards the unwind roll, maintaining tension provided by the dancer rolls weight. The pivot point sensor signals the controller to vary the current to the brake.

Vous aimerez peut-être aussi

- Application ExamplesDocument2 pagesApplication ExamplesSheik HassanPas encore d'évaluation

- BMW Transmission Specs 2004Document15 pagesBMW Transmission Specs 2004gabriela sanguinoPas encore d'évaluation

- BMW Transmission SpecificationsDocument15 pagesBMW Transmission SpecificationsDookie983Pas encore d'évaluation

- Caf Salidas ElectrónicasDocument6 pagesCaf Salidas ElectrónicasMiguel Angel Garrido CardenasPas encore d'évaluation

- Caterpillar 311b 330b Excavators Engine and Pump Electronic Control SystemDocument10 pagesCaterpillar 311b 330b Excavators Engine and Pump Electronic Control Systemjohn100% (47)

- Write Up On EHC - REV-01Document11 pagesWrite Up On EHC - REV-01jp mishra100% (2)

- General Engine Instrumentation-SumDocument13 pagesGeneral Engine Instrumentation-SumDaniel MkandawirePas encore d'évaluation

- Gland Steam Pressure For ReferenceDocument5 pagesGland Steam Pressure For ReferencebalajimechanicalPas encore d'évaluation

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetD'EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetÉvaluation : 2 sur 5 étoiles2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetD'EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetPas encore d'évaluation

- Wabco Brakes 3Document60 pagesWabco Brakes 3Shyam Srinivasan100% (5)

- Brake ControlDocument212 pagesBrake ControllogammicPas encore d'évaluation

- Chapter10 (Governors)Document10 pagesChapter10 (Governors)Zohaib Anser100% (1)

- Transmisión Inputs - CAT TH460Document10 pagesTransmisión Inputs - CAT TH460Daniel Aguirre100% (1)

- Brake - Control of Toyota Yaris 2007 US PDFDocument105 pagesBrake - Control of Toyota Yaris 2007 US PDFDavidTrevorPaul100% (2)

- AN025-DC Motor Control With TMC4671Document11 pagesAN025-DC Motor Control With TMC4671Roland von KurnatowskiPas encore d'évaluation

- L2. Single Phase Ac Voltage ControllersDocument104 pagesL2. Single Phase Ac Voltage ControllersShivaram Vadla100% (2)

- Technical Service Information3Document4 pagesTechnical Service Information3JosePas encore d'évaluation

- 418000E4422 R0 Write Up On Electro Hydraulic ControllerDocument10 pages418000E4422 R0 Write Up On Electro Hydraulic ControllerkoinsuriPas encore d'évaluation

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetD'EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetPas encore d'évaluation

- Reporter: John Alvin B. SerenioDocument25 pagesReporter: John Alvin B. SerenioPrincess CutabPas encore d'évaluation

- Aygo MMT OpsDocument13 pagesAygo MMT OpsNick NickartPas encore d'évaluation

- Anti Skid SystemDocument9 pagesAnti Skid SystemBarkah Khoerun NissaPas encore d'évaluation

- VVC ControlDocument14 pagesVVC ControlRyte EchanoPas encore d'évaluation

- Sensors: Systems OperationDocument3 pagesSensors: Systems OperationSam SungPas encore d'évaluation

- Sensors 325CDocument3 pagesSensors 325CHAmir Alberto Mojica MojicaPas encore d'évaluation

- Topic 1 - Servo TechnologyDocument32 pagesTopic 1 - Servo TechnologyRakesh Karan SinghPas encore d'évaluation

- EHC NewDocument46 pagesEHC NewSam100% (6)

- 27 Appendix D Technical Reference & SpecificationsDocument17 pages27 Appendix D Technical Reference & SpecificationspapipapiiPas encore d'évaluation

- Governing System of Turbines (200 MW)Document18 pagesGoverning System of Turbines (200 MW)Debasish Dewan100% (2)

- Comparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveDocument8 pagesComparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveMatanAbutbulPas encore d'évaluation

- Assignment 4 Introduction ELWE Powder BrakeDocument20 pagesAssignment 4 Introduction ELWE Powder BrakeAditya PradiptaPas encore d'évaluation

- Speed Control of DC Motor Using Pulse Width ModulationDocument30 pagesSpeed Control of DC Motor Using Pulse Width ModulationRatul SarkarPas encore d'évaluation

- Giri 1Document18 pagesGiri 1GiridharPas encore d'évaluation

- Governor: BY Er. Tanuj Sharma Student of PGDC Hydro POWER PLANT (2010-11), NPTI NangalDocument24 pagesGovernor: BY Er. Tanuj Sharma Student of PGDC Hydro POWER PLANT (2010-11), NPTI NangalTanuj SharmaPas encore d'évaluation

- MIET/Department of Mechanical Engg: Case Studies of Mechatronics SystemsDocument9 pagesMIET/Department of Mechanical Engg: Case Studies of Mechatronics SystemsRaunak GuptaPas encore d'évaluation

- Mitigation of Voltage Sag and Voltage Swell by Using D-Statcom and PWM Switched Auto TransformerDocument11 pagesMitigation of Voltage Sag and Voltage Swell by Using D-Statcom and PWM Switched Auto TransformerGanesh KumarPas encore d'évaluation

- Novel Method PMDC Motor Speed ControlDocument15 pagesNovel Method PMDC Motor Speed ControlTravis WoodPas encore d'évaluation

- Modeling and Simulation of EHV (402034MJ) : Name of Author: Mr. Ravikant K. NanwatkarDocument64 pagesModeling and Simulation of EHV (402034MJ) : Name of Author: Mr. Ravikant K. Nanwatkarsagar kordePas encore d'évaluation

- Ijetae 0913 69Document6 pagesIjetae 0913 69Lucian Mihai BiltiuPas encore d'évaluation

- Ehc 500 MWDocument55 pagesEhc 500 MWSam100% (4)

- Servomechanism Presentation MCS 1Document38 pagesServomechanism Presentation MCS 1Vipin Ramachandran PillaiPas encore d'évaluation

- 545 ct100 INDEXcE1Document26 pages545 ct100 INDEXcE1Roberto FalconePas encore d'évaluation

- Servomotor: Types of Motor Used in ServomotorDocument4 pagesServomotor: Types of Motor Used in ServomotorJawad SandhuPas encore d'évaluation

- PrinciplesDocument5 pagesPrinciplesSachin RohillaPas encore d'évaluation

- Automaticclutch and Braking SystemDocument23 pagesAutomaticclutch and Braking SystemStartechnico TechnocratsPas encore d'évaluation

- Catalogo Thyripol Ingles - ExcitacaoDocument14 pagesCatalogo Thyripol Ingles - ExcitacaoErbil KeskinPas encore d'évaluation

- U 340Document19 pagesU 340yosergey100% (2)

- KWU Electro Hydraulic Governing Final1Document41 pagesKWU Electro Hydraulic Governing Final1Sam80% (5)

- Mechatronics CEP 2 Designing Control System For Suspension SystemDocument12 pagesMechatronics CEP 2 Designing Control System For Suspension SystemFaizan SamdaniPas encore d'évaluation

- Tension Control System MCS-166, MCS-203, MCS-204: Installation & Operation InstructionsDocument24 pagesTension Control System MCS-166, MCS-203, MCS-204: Installation & Operation Instructionsesau hernandezPas encore d'évaluation

- Four-Quadrant Single-Phase Rectifier DC DriveDocument14 pagesFour-Quadrant Single-Phase Rectifier DC DriveBivolaru AndreiPas encore d'évaluation

- FGDocument54 pagesFGJulio C. SalinasPas encore d'évaluation

- Basic Motor ControlDocument17 pagesBasic Motor ControlHeizen BulanPas encore d'évaluation

- DR20Document136 pagesDR20Daryl Asto MercadoPas encore d'évaluation

- Adaptive Braking System Using LabviewDocument10 pagesAdaptive Braking System Using Labviewsurajgurnani24Pas encore d'évaluation

- DST2600 Is A Compact and Rugged Automatic Gen-Set Control Panel For Engines With Power Up To 40kVA MaxDocument4 pagesDST2600 Is A Compact and Rugged Automatic Gen-Set Control Panel For Engines With Power Up To 40kVA Maxmuhammad arifPas encore d'évaluation

- 777e BNMDocument10 pages777e BNMJACOB MUDONHIPas encore d'évaluation

- U 340Document19 pagesU 340ruslan1580Pas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Idap QueryDocument1 pageIdap QuerySheik HassanPas encore d'évaluation

- CTDocument5 pagesCTRachit KhannaPas encore d'évaluation

- Salary Slip Format in Excel With Formulas 1Document1 pageSalary Slip Format in Excel With Formulas 1Sheik HassanPas encore d'évaluation

- Kitchens Edition 1 Mov 05-11-2020Document76 pagesKitchens Edition 1 Mov 05-11-2020Sheik HassanPas encore d'évaluation

- LHC - Updated QuotationDocument4 pagesLHC - Updated QuotationSheik HassanPas encore d'évaluation

- Master Offisys Quotation For Infrastructure Development Authority Punjab 18-07-2022Document17 pagesMaster Offisys Quotation For Infrastructure Development Authority Punjab 18-07-2022Sheik HassanPas encore d'évaluation

- L630 CogDocument3 pagesL630 CogSheik HassanPas encore d'évaluation

- Capacity 1.5 To 1.85 Components 3-5-21Document8 pagesCapacity 1.5 To 1.85 Components 3-5-21Sheik HassanPas encore d'évaluation

- CM DevelopersDocument1 pageCM DevelopersSheik HassanPas encore d'évaluation

- 02 Technical Guide EU Council DirectivesDocument64 pages02 Technical Guide EU Council DirectivesAlejandro MárquezPas encore d'évaluation

- Furniture Catalog For IDAp ProjectsDocument13 pagesFurniture Catalog For IDAp ProjectsSheik HassanPas encore d'évaluation

- TP48300B (48V 30A 300A) High Frequency Switch-Mode Power Supply Inspection Report 20091228Document23 pagesTP48300B (48V 30A 300A) High Frequency Switch-Mode Power Supply Inspection Report 20091228Sheik HassanPas encore d'évaluation

- Legno Home Catalogue WardrobeDocument64 pagesLegno Home Catalogue WardrobeSheik HassanPas encore d'évaluation

- Electrical Thumb Rules You MUST Follow Part 1Document4 pagesElectrical Thumb Rules You MUST Follow Part 1Sheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- L630 CogDocument3 pagesL630 CogSheik HassanPas encore d'évaluation

- L630 CogDocument3 pagesL630 CogSheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- L21Document1 pageL21Sheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- Dalian Insulator Technical DataDocument2 pagesDalian Insulator Technical DataSheik Hassan75% (8)

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- PakistanDocument1 pagePakistanSheik HassanPas encore d'évaluation

- Pakistan Shikarpur Substation 500kV 200MVA Auto-Transformer AVR Drawings For Final Approval (Revised in 20130313)Document29 pagesPakistan Shikarpur Substation 500kV 200MVA Auto-Transformer AVR Drawings For Final Approval (Revised in 20130313)Sheik HassanPas encore d'évaluation

- 132kv Bus and Line IsolatorDocument1 page132kv Bus and Line IsolatorSheik HassanPas encore d'évaluation

- Pakistan 500kV Shikarpur Project 11kV 200kVA Auxiliary Transformer Layout Drawing For Final Approval (Revised in 20130308)Document1 pagePakistan 500kV Shikarpur Project 11kV 200kVA Auxiliary Transformer Layout Drawing For Final Approval (Revised in 20130308)Sheik HassanPas encore d'évaluation

- Pakistan 500kV Shikarpur Project Three Phase Tertiary Winding Connection PDF Drawing For ApprovalDocument1 pagePakistan 500kV Shikarpur Project Three Phase Tertiary Winding Connection PDF Drawing For ApprovalSheik HassanPas encore d'évaluation

- Pakistan 500kV Shikarpur Project 11kV 200kVA Auxiliary Transformer Prefabricated Substation Foundation Drawing For Final ApprovalDocument1 pagePakistan 500kV Shikarpur Project 11kV 200kVA Auxiliary Transformer Prefabricated Substation Foundation Drawing For Final ApprovalSheik HassanPas encore d'évaluation

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocument1 pageConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelPas encore d'évaluation

- Periodic Table Lab AnswersDocument3 pagesPeriodic Table Lab AnswersIdan LevyPas encore d'évaluation

- CHAPTER I Lesson II Seven Environmental PrinciplesDocument17 pagesCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotPas encore d'évaluation

- Bullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceDocument174 pagesBullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceAlexandre AndréPas encore d'évaluation

- Science9 Q4 Week2Document16 pagesScience9 Q4 Week2Maria Josie Lopez TumlosPas encore d'évaluation

- Final LUS EvaluationDocument36 pagesFinal LUS EvaluationNextgenPas encore d'évaluation

- UpdateJul2007 3julDocument10 pagesUpdateJul2007 3julAnshul SinghPas encore d'évaluation

- SANDWICH Elisa (Procedure) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabDocument2 pagesSANDWICH Elisa (Procedure) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabsantonuPas encore d'évaluation

- Macros and DirectiveDocument7 pagesMacros and DirectiveAbdul MoeedPas encore d'évaluation

- EDAG0007Document5 pagesEDAG0007krunalPas encore d'évaluation

- Nationalism, Feminism, and Modernity in PalestineDocument26 pagesNationalism, Feminism, and Modernity in PalestinebobandjoerockPas encore d'évaluation

- Sub-Wings of YuvanjaliDocument2 pagesSub-Wings of Yuvanjalin_tapovan987100% (1)

- Unilever PakistanDocument26 pagesUnilever PakistanElie Mints100% (3)

- Pipe Freezing StudyDocument8 pagesPipe Freezing StudymirekwaznyPas encore d'évaluation

- Teaching PowerPoint Slides - Chapter 5Document19 pagesTeaching PowerPoint Slides - Chapter 5Azril ShazwanPas encore d'évaluation

- 12 Logarithm Approximate FloatingDocument6 pages12 Logarithm Approximate FloatingPhilippe Englert VelhaPas encore d'évaluation

- Cella Di Carico Sartorius MP77 eDocument3 pagesCella Di Carico Sartorius MP77 eNCPas encore d'évaluation

- GR 9 Eng CodebDocument6 pagesGR 9 Eng CodebSharmista WalterPas encore d'évaluation

- Aex-Kissan KeralaDocument25 pagesAex-Kissan Keralabsh08070Pas encore d'évaluation

- ING C1 CO JUN2016 CorrectorDocument6 pagesING C1 CO JUN2016 CorrectoraciamePas encore d'évaluation

- TCGRX BullsEye Tablet SplitterDocument2 pagesTCGRX BullsEye Tablet SplittermalucPas encore d'évaluation

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocument10 pagesFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaPas encore d'évaluation

- An Introduction To Routine and Special StainingDocument13 pagesAn Introduction To Routine and Special StainingBadiu ElenaPas encore d'évaluation

- Group Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanDocument18 pagesGroup Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanNurul Hana BalqisPas encore d'évaluation

- Anykycaccount Com Product Payoneer Bank Account PDFDocument2 pagesAnykycaccount Com Product Payoneer Bank Account PDFAnykycaccountPas encore d'évaluation

- MCFKTP G3 S2 SC Number Pattern PuzzlesDocument5 pagesMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoPas encore d'évaluation

- Installation of Submarine PE PipesDocument84 pagesInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- The Ethics of Peacebuilding PDFDocument201 pagesThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- 3.0 Series and Parallel DC CircuitsDocument29 pages3.0 Series and Parallel DC CircuitsJinky Loyce RaymundoPas encore d'évaluation

- 3-A Y 3-B Brenda Franco DíazDocument4 pages3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZPas encore d'évaluation