Académique Documents

Professionnel Documents

Culture Documents

Rolling Threads Details

Transféré par

fastenersworldTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rolling Threads Details

Transféré par

fastenersworldDroits d'auteur :

Formats disponibles

Rolled Threads

Tables of Dimensions

Thread rolling

State-of-the-art production methods, extensive

product expertise and access to more than

1000 machine tools, enable us to meet each

and every demand for rolled threads however exotic they may be:

What is thread rolling?

What materials are suitable?

Thread rolling (often also referred to as thread

all metals that feature an extension of at least

milling) is the cold forming of the surface of

6 % and do not exceed a tensile strength

round workpieces. The thread form is pro-

of 1300 N/mm2

duced by causing a radial dynamic force to

high-alloy, corrosion and acid-resistant

be exerted between the two rotating rolling

steel

dies that form the workpiece. As the roll die

special aluminium alloys

profile penetrates the workpiece surface, the

riveting-quality brass

material in cold state is pressed all the way

copper alloys

down into the root diameter of the thread

pitches up to 6 x diameter

threads can be rolled on hollow bodies and

roll die and is therefore rolled according to

spindle length up to 6 m

tubes only if wall thickness is sufficient; this

nominal value.

spindle diameter from 2 to 160 mm

wall thickness depends upon the type and

high-helix thread profiles

depth of intended profile as well as material

Advantages of thread rolling:

ball screw thread profiles

used.

significant increase in hardness through

all standard profiles

Please call or write for assistance.

cold forming

(M, Tr, UNC, UNF, UNEF, Whitworth)

excellent surface smoothness on thread

multiple start threads including

What materials are not suitable?

flanks and in ground radius

left-hand/right-hand threads

extremely brittle material such as Ms58,

reduced notch sensitivity

special profiles

cast iron, etc.

no interrupted swalfe as in machine-

worm gears

extremely soft materials such as lead

ground threads

(quality and price advantages)

synthetics

excellent dimensional accuracy

serrations and knurlings.

wood.

Quality Management ISO 9001:2000

We look forward to your challenge!

rational manufacturing process

extremely cost-effective especially in

large production batches

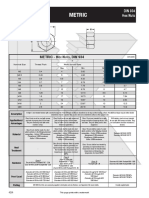

Tables of dimensions for:

page(s)

Metric threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4/5

UNC/UNF/UNEF threads (60) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Whitworth / Whitworth pipe thread (55) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Please note that these tables list dimensions, not available thread dies in stock.

Rolled threads

2

Eichenberger Gewinde AG V 07 11 30

Important notes for premachining

In order to ensure a perfect rolling process,

Threads over entire length

it is important for workpieces to be properly

(rolling diameter). Machining tolerance as

b

a

premachined. Please refer to the tables on the

Dimension a [mm]: Premachining diameter

following pages for dimensions a and b. The

per color code.

shaded green areas identify the four different

Dimension b [mm]: Chamfer, intake or pass

Conforming threads

d

Green 1

Tolerance

0

0.05 mm

Green 2

Tolerance

0

0.08 mm

Green 3

Tolerance

0

0.12 mm

Green 4

diameter (theoretical root diameter); without

prescribed tolerance.

c

Value in table = maximum dimension.

b

a

Tolerance

0

0.03 mm

tolerances for these dimensions.

Dimension c: Chamfer or intake angle

20 to 1000 N/mm2

approx. 15 over 1000 N/mm2

Non-conforming threads

e

Dimension d [mm]: Pass width

at least 1,5 x pitch

If no special tolerances are required, please

c

refer to tables for pre-machining and cham-

b

a

fer diameters and assign proper tolerance

Dimension e [mm]: Thread runout

(color-coded).

approx. 1,5 x pitch

Standard threads are shown in the black

(shorter runouts on request).

areas of the metric thread table.

Caution: If parts are scheduled for additional

Effects of non-compliance with premachining

Rolling diameter is below prescribed

surface or heat treatment after rolling, this may

measurements:

tolerance

If the rolling diameter is below the required

have to be taken into consideration when

Rolling diameter exceeds prescribed

tolerance, the flank diameter may be rolled

tolerance

true to tolerance but the outer diameter crest

Experience has shown that threads produced

When the die is filled with the engaged ma-

may be below the required tolerance.

in continuous operation, i.e. longer than ap-

terial of the blank during rolling (see cutout

prox. 120 mm, must be below listed values

Fig. 1), the flank diameter cannot be further

Chamfering

prior to rolling. Please take advantage of our

influenced in the minus range (not even by

Since the workpiece material exerts axial

experience and inquire about the appropriate

further feeding the rolling dies). The result is

flow properties in the areas of thread intake

premachining diameter.

that the flank diameter becomes too big, the

or runout, there is enough room to prevent

tolerance gauge will jam and the counterpart

any damage to the rolling die if chamfering

If new profiles are required, especially

will not fit on the thread.

has been done properly (Fig. 1). In the event

narrow tolerances or extreme pitches, tests

A massive oversize of the blank may en-

of non-compliance with prescribed intake

will be conducted to obtain premachining

danger the rolling die and often causes the

angle (chamfering), the material with axial

diameter.

workpiece to burst thus breaking the die.

flow will inevitably strain the dies to the

Therefore it is very important to premachine

breaking point (Fig. 2).

premachining the workpiece.

all parts of the same series with prescribed

tolerances.

Rolling die

Rolling die

Fig. 1:

Fig. 2:

correct

chamfering

incorrect

chamfering

Rolled threads

Eichenberger Gewinde AG V 07 11 30

2

2,5

3

3,5

4

4,5

5

6

7

8

9

10

11

12

14

15

16

17

18

20

22

24

25

26

27

28

30

32

33

34

35

36

38

39

40

42

45

48

50

52

55

56

58

60

62

64

65

68

70

72

75

76

80

82

85

90

95

100

105

110

115

120

125

130

135

140

145

150

155

160

0,25

a

1,83

2,33

2,83

3,33

3,83

4,33

4,83

5,83

6,83

7,83

8,83

9,83

0,35

b

1,65

2,15

2,65

3,15

3,65

4,15

4,65

5,65

6,65

7,65

8,65

9,65

a

1,75

2,25

2,75

3,25

3,75

4,25

4,75

5,75

6,75

7,75

8,75

9,75

10,75

11,75

13,75

14,75

15,75

16,75

17,75

19,75

21,75

23,75

24,75

25,75

26,75

27,75

29,75

31,75

32,75

33,75

34,75

35,75

37,75

38,75

39,75

41,75

44,75

47,75

49,75

4 | Metric threads

0,4

b

1,45

1,95

2,45

2,95

3,45

3,95

4,45

5,45

6,45

7,45

8,45

9,45

10,45

11,45

13,45

14,45

15,45

16,45

17,45

19,45

21,45

23,45

24,45

25,45

26,45

27,45

29,45

31,45

32,45

33,45

34,45

35,45

37,45

38,45

39,45

41,45

44,45

47,45

49,45

a

1,72

0,45

b

1,35

0,5

2,18

1,80

2,64

3,14

3,64

4,14

4,64

5,64

6,64

7,64

8,64

9,64

10,64

11,64

13,64

14,64

15,64

16,64

17,64

19,64

21,64

23,64

24,64

25,64

26,64

27,64

29,64

31,64

32,64

33,64

34,64

35,64

37,64

38,64

39,64

41,64

44,64

47,64

49,64

Metric threads

0,6

b

a

b

2,25

2,75

3,25

3,75

4,25

5,25

6,25

7,25

8,25

9,25

10,25

11,25

13,25

14,25

15,25

16,25

17,25

19,25

21,25

23,25

24,25

25,25

26,25

27,25

29,25

31,25

32,25

33,25

34,25

35,25

37,25

38,25

39,25

41,25

44,25

47,25

49,25

3,08

0,7

0,75

3,51

2,95

0,8

3,98

4,48

5,48

6,48

7,48

8,48

9,48

10,48

11,48

13,48

14,48

15,48

16,48

17,48

19,48

21,48

23,48

24,48

25,48

26,48

27,48

29,48

31,48

32,48

33,48

34,48

35,48

37,48

38,48

39,48

41,48

44,48

47,48

49,48

51,48

54,48

55,48

57,48

59,48

61,48

63,48

64,48

67,48

69,48

71,48

74,48

75,48

79,48

3,40

3,90

4,90

5,90

6,90

7,90

8,90

9,90

10,90

12,90

13,90

14,90

15,90

16,90

18,90

20,90

22,90

23,90

24,90

25,90

26,90

28,90

30,90

31,90

32,90

33,90

34,90

36,90

37,90

38,90

40,90

43,90

46,90

48,90

50,90

53,90

54,90

56,90

58,90

60,90

62,90

63,90

66,90

68,90

70,90

73,90

74,90

78,90

1,0

4,44

3,80

1,25

5,31

6,31

7,31

8,31

9,31

10,31

11,31

13,31

14,31

15,31

16,31

17,31

19,31

21,31

23,31

24,31

25,31

26,31

27,31

29,31

31,31

32,31

33,31

34,31

35,31

37,31

38,31

39,31

41,31

44,31

47,31

49,31

51,31

54,31

55,31

57,31

59,31

61,31

63,31

64,31

67,31

69,31

71,31

74,31

75,31

79,31

4,55

5,55

6,55

7,55

8,55

9,55

10,55

12,55

13,55

14,55

15,55

16,55

18,55

20,55

22,55

23,55

24,55

25,55

26,55

28,55

30,55

31,55

32,55

33,55

34,55

36,55

37,55

38,55

40,55

43,55

46,55

48,55

50,55

53,55

54,55

56,55

58,55

60,55

62,55

63,55

66,55

68,55

70,55

73,55

74,55

78,55

1,5

7,15

8,15

9,15

6,20

7,20

8,20

11,15

10,20

1,75

8,98

9,98

10,98

12,98

13,98

14,98

15,98

16,98

18,98

20,98

22,98

23,98

24,98

25,98

26,98

28,98

30,98

31,98

32,98

33,98

34,98

36,98

37,98

38,98

40,98

43,98

46,98

48,98

50,98

53,98

54,98

56,98

58,98

60,98

62,98

63,98

66,98

68,98

70,98

73,98

74,98

78,98

7,85

8,85

9,85

11,85

12,85

13,85

14,85

15,85

17,85

19,85

21,85

22,85

23,85

24,85

25,85

27,85

29,85

30,85

31,85

32,85

33,85

35,85

36,85

37,85

39,85

42,85

45,85

47,85

49,85

52,85

53,85

55,85

57,85

59,85

61,85

62,85

65,85

67,85

69,85

72,85

73,85

77,85

2,0

b

2,5

12,65

11,20

14,65

15,65

16,65

18,65

20,65

22,65

23,65

24,65

25,65

26,65

28,65

30,65

31,65

32,65

33,65

34,65

36,65

37,65

38,65

40,65

43,65

46,65

48,65

50,65

53,65

54,65

56,65

58,65

60,65

62,65

63,65

66,65

68,65

70,65

73,65

74,65

78,65

80,65

83,65

88,65

93,65

98,65

103,65

108,65

113,65

118,65

123,65

128,65

133,65

138,65

143,65

148,65

13,20

14,20

15,20

17,20

19,20

21,20

22,20

23,20

24,20

25,20

27,20

29,20

30,20

31,20

32,20

33,20

35,20

36,20

37,20

39,20

42,20

45,20

47,20

49,20

52,20

53,20

55,20

57,20

59,20

61,20

62,20

65,20

67,20

69,20

72,20

73,20

77,20

79,20

82,20

87,20

92,20

97,20

102,20

107,20

112,20

117,20

122,20

127,20

132,20

137,20

142,20

147,20

3,0

16,32

18,32

20,32

14,50

16,50

18,50

3,5

21,98

19,80

Metric threads

4,0

b

a

b

4,5

5,0

38,98

41,98

35,80

38,80

5,5

44,65

41,10

48,65

45,10

6,0

52,32

48,40

56,32

52,40

8,0

59,98

55,70

63,98

65,98

67,98

59,70

61,70

63,70

71,98

75,98

67,70

71,70

80,98

85,98

90,98

95,98

100,98

105,98

110,98

115,98

120,98

125,98

130,98

135,98

140,98

145,98

150,98

155,98

Tolerance 0/0,12

76,70

81,70

86,70

91,70

96,70

101,70

106,70

111,70

116,70

121,70

126,70

131,70

136,70

141,70

146,70

151,70

2,60

10,81

Tolerance 0/0,03

Basic metric profile DIN 13

Applies to standard and fine threads

p = pitch [mm]

h3 = 0,61343 p

R = 0,14434 p

The metric threads we roll correspond to a tolerance of 6g.

Tolerance 0/0,05

Eichenberger Gewinde AG V 07 11 30

9,50

24,98 22,80

25,98 23,80

27,98 25,80 27,65 25,10

29,98 27,80

30,98 28,80 30,65 28,10

31,98 29,80

32,98 30,80

33,98 31,80

35,98 33,80

36,98 34,80

37,98 35,80

39,98 37,80

42,98 40,80

45,98 43,80

47,98 45,80

49,98 47,80

52,98 50,80

53,98 51,80

55,98 53,80

57,98 55,80

59,98 57,80

61,98 59,80

62,98 60,80

65,98 63,80

67,98 65,80

69,98 67,80

72,98 70,80

73,98 71,80

77,98 75,80

79,98 77,80

82,98 80,80

87,98 85,80

92,98 90,80

97,98 95,80

102,98 100,80

107,98 105,80

112,98 110,80

117,98 115,80

122,98 120,80

127,98 125,80

132,98 130,80

137,98 135,80

142,98 140,80

147,98 145,80

152,98 150,80

157,98 155,80

Tolerance 0/0,08

33,32

30,50

36,32

37,32

39,32

42,32

45,32

47,32

49,32

52,32

53,32

55,32

57,32

59,32

61,32

62,32

65,32

67,32

69,32

72,32

73,32

77,32

79,32

82,32

87,32

92,32

97,32

102,32

107,32

112,32

117,32

122,32

127,32

132,32

137,32

142,32

147,32

152,32

157,32

33,50

34,50

36,50

39,50

42,50

44,50

46,50

49,50

50,50

52,50

54,50

56,50

58,50

59,50

62,50

64,50

66,50

69,50

70,50

74,50

76,50

79,50

84,50

89,50

94,50

99,50

104,50

109,50

114,50

119,50

124,50

129,50

134,50

139,50

144,50

149,50

154,50

124,60 119,80

134,60 129,80

144,60 139,80

154,60 149,80

2

2,5

3

3,5

4

4,5

5

6

7

8

9

10

11

12

14

15

16

17

18

20

22

24

25

26

27

28

30

32

33

34

35

36

38

39

40

42

45

48

50

52

55

56

58

60

62

64

65

68

70

72

75

76

80

82

85

90

95

100

105

110

115

120

125

130

135

140

145

150

155

160

Metric threads | 5

UNC/UNF/UNEF threads (60)

Designation

No 164

No 256

No 348

No 440

No 540

No 632

No 832

No 1024

No 1224

\ 20

\ 18

\ 16

\ 14

Z\ 13

\ 12

\ 11

\ 10

\ 9

1 8

1 \ 7

1 \ 7

1 \ 6

1 \ 6

1 \ 5

2 4 \

2 \ 4 \

2 \ 4

2 \ 4

3 4

3 \ 4

3 \ 4

3 \ 4

4 4

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC

UNC thread (60)

outer

a

1,83

1,57

2,16

1,86

2,49

2,14

2,82

2,40

3,15

2,73

3,48

2,95

4,14

3,61

4,80

4,09

5,46

4,75

6,32

5,47

7,90

6,97

9,49

8,44

11,07

9,87

12,66

11,37

14,24

12,85

15,83

14,31

19,00

17,33

22,17

20,32

25,34

23,25

28,51

26,13

31,69

29,30

34,86

32,08

38,03

35,25

44,38

41,05

50,72

47,03

57,07

53,38

63,42

59,25

69,76

65,60

76,11

71,95

82,46

78,30

88,81

84,65

95,16

90,99

101,51

97,34

b

1,30

1,60

1,80

2,00

2,30

2,50

3,10

3,50

4,10

4,70

6,10

7,50

8,80

10,20

11,60

13,00

15,80

18,70

21,40

24,00

27,20

29,60

32,80

38,10

43,80

50,10

55,60

61,90

68,30

74,60

81,00

87,30

93,70

p [mm]

0,39

0,45

0,52

0,63

0,63

0,79

0,79

1,05

1,05

1,27

1,41

1,58

1,81

1,95

2,11

2,30

2,54

2,82

3,17

3,62

3,62

4,23

4,23

5,08

5,64

5,64

6,35

6,35

6,35

6,35

6,35

6,35

6,35

Tolerance

0

0.03

0

0.05

0

0.08

0

0.12

UN thread profile

Basic profile corresponds to basic metric profile except that

diameter and pitch are in inch.

UN = thread with constant pitch

UNC = coarse thread

UNF = fine thread

UNEF = extra-fine thread

UNJF = thread with enlarged root radius (aviation application)

Designation

No 080

No 172

No 264

No 356

No 448

No 544

No 640

No 836

No 1032

No 1228

\ 28

\ 24

\ 24

\ 20

\ 20

\ 18

\ 18

\ 16

\ 14

1 12

1 \ 12

1 \ 12

1 \ 12

1 \ 12

Designation

No 1232

\ 32

\ 32

\ 32

\ 28

\ 28

\ 24

\ 24

\ 24

\ 20

\ 20

\ 20

\ 20

1 20

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

1 \ 18

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNEF

UNF thread (60)

outer

a

1,51

1,30

1,83

1,60

2,16

1,90

2,49

2,20

2,82

2,48

3,15

2,78

3,48

3,06

4,14

3,67

4,80

4,27

5,46

4,86

6,32

5,72

7,91

7,21

9,49

8,79

11,07

10,23

12,66

11,82

14,25

13,31

15,83

14,90

19,01

17,96

22,18

20,98

25,35

23,95

28,52

27,12

31,70

30,30

34,87

33,47

38,05

36,64

b

1,10

1,40

1,60

1,90

2,10

2,40

2,70

3,20

3,80

4,30

5,20

6,60

8,10

9,50

11,10

12,50

14,10

17,00

19,90

22,70

25,90

29,10

32,20

35,40

p [mm]

0,31

0,35

0,39

0,45

0,52

0,57

0,63

0,70

0,79

0,90

0,90

1,05

1,05

1,27

1,27

1,41

1,41

1,58

1,81

2,11

2,11

2,11

2,11

2,11

Tolerance

UNEF thread (60)

outer

a

5,46

4,93

6,32

5,79

7,91

7,38

9,50

8,97

11,08

10,48

12,67

12,07

14,25

13,55

15,84

15,14

17,43

16,73

19,01

18,17

20,60

19,75

22,19

21,34

23,77

22,93

25,36

24,51

26,95

26,00

28,53

27,59

30,12

29,17

31,71

30,76

33,29

32,35

34,88

33,94

36,47

35,52

38,06

37,11

39,64

38,70

41,23

40,29

42,82

41,87

b

4,40

5,30

6,90

8,50

9,90

11,50

12,90

14,50

16,10

17,40

19,00

20,60

22,20

23,80

25,20

26,80

28,30

29,90

31,50

33,10

34,70

36,30

37,90

39,50

41,00

p [mm]

0,79

0,79

0,79

0,79

0,90

0,90

1,05

1,05

1,05

1,27

1,27

1,27

1,27

1,27

1,41

1,41

1,41

1,41

1,41

1,41

1,41

1,41

1,41

1,41

1,41

Tolerance

0

0.03

0

0.05

0

0.03

0

0.05

p = pitch [mm]

h3 = 0,61343 p

R = 0,14434 p

UN threads

6

Eichenberger Gewinde AG V 07 11 30

Whitworth / Whitworth pipe threads (55)

nominal [inch]

\

\

\

\

\

\

\

\

1

1 \

1 \

1 \

1 \

1 \

1 \

1 \

2

2 \

2 \

2 \

3

3 \

3 \

3 \

4

4 \

4 \

4 \

5

5 \

5 \

5 \

6

p

20

18

16

14

12

11

10

9

8

7

7

6

6

5

5

4 \

4 \

4

4

3 \

3 \

3 \

3 \

3

3

2 \

2 \

2 \

2 \

2 \

2 \

2 \

2 \

Whitworth (55)

outer

a

6,35

5,51

7,93

7,01

9,52

8,48

11,11

9,92

12,70

11,31

15,87

14,36

19,05

17,39

22,22

20,38

25,40

23,32

28,57

26,21

31,75

29,37

34,92

32,16

38,10

35,34

41,27

37,97

44,45

41,14

47,62

43,95

50,80

47,12

57,15

53,01

63,50

59,36

69,85

65,13

76,20

71,48

82,55

77,47

88,90

83,82

95,25

89,75

101,60

96,10

107,95

102,22

114,30

108,57

120,65

114,67

127,00

121,02

133,35

127,08

139,70

133,43

146,05

139,47

152,40

145,83

b

4,50

5,90

7,30

8,60

9,70

12,70

15,50

18,30

21,00

23,60

26,80

29,20

32,20

34,40

37,60

40,00

43,20

48,60

55,00

60,10

66,50

72,10

78,50

84,00

90,30

96,20

102,50

108,40

114,70

120,50

126,80

132,60

138,90

Tolerance

0

0.05

0

0.08

0

0.12

nominal [inch]

Whitworth pipe threads (55)

p

outer

a

R \

28

9,72

9,11

8,40

R \

R \

R \

R \

R \

R \

R 1

R 1 \

R 1 \

R 1 \

R 1 \

R 1 \

R 2

R 2 \

R 2 \

R 2 \

R 3

R 3 \

R 3 \

R 3 \

R 4

R 4 \

R 5

R 5 \

R 6

19

19

14

14

14

14

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

13,15

16,66

20,95

22,91

26,44

30,20

33,24

37,89

41,91

44,32

47,80

53,74

59,61

65,71

75,18

81,53

87,88

93,98

100,33

106,68

113,03

125,73

138,43

151,13

163,83

12,25

15,76

19,74

21,69

25,22

28,98

31,71

36,35

40,37

42,78

46,26

52,20

58,07

64,17

73,64

79,99

86,34

92,44

98,79

105,14

111,49

124,19

136,89

149,59

162,29

11,30

14,80

18,40

20,40

23,90

27,70

30,00

34,60

38,60

41,00

44,50

50,40

56,30

62,40

71,90

78,20

84,60

90,70

97,00

103,40

109,70

122,40

135,10

147,80

160,50

Tolerance

0

0.03

0

0.05

Basic Whitworth profile according to B.S. 84

W = Whitworth thread

BSF = Whitworth fine thread

R

= Whitworth pipe thread (gas pipe threads)

p = pitch [number of threads per inch]

t1 = 0,64033 p

R = 0,13733 p

Whitworth threads

Eichenberger Gewinde AG V 07 11 30

The examples below illustrate the range of

available cold-rolling applications. We may

even inspire you to investigate innovative solutions. Indeed, we are convinced that rational

cold-rolling solutions are available to solve

your particular threading problem. Why not

consider the benefits of cold rolling and profit

from our know-how?

Ball screw profile.

Trapezoidal thread as per

As a rule, ogival

ground profile DIN 103

threaded profiles

Flat trapezoidal thread

are used

as per DIN 380

Multiple trapezoidal thread,

incl. left/right

High-helix profiles

Special threads with

multiple threads

special profiles

with pitch up to

according to customer

6 x diameter

specifications

Eichenberger Gewinde AG

synthetic or brass

The contents of this publication is

nuts

protected by copyright held by the

publisher and may not be reproduced (even in part) unless permis-

Milled edges as per

Worm-gear profiles

sion is granted. Every care has

DIN 82

as per basic profile

been taken to ensure the accuracy

concentric

DIN 3976

of the information contained herein

left/right

single gears

but no liability shall be accepted

Serrations as per

multiple gears

for any loss or damage whether

DIN 5481

direct, indirect or consequential

resulting from or in connection

with the use of the information

Threads on awkward

contained herein. This catalogue

parts

supersedes previous catalogues in

which the data deviate from those

Conical threads

contained herein. Data subject to

change as required by technological developments.

Edition: V 07 11 30 e

Eichenberger Gewinde AG

Grenzstrasse 30

CH-5736 Burg

Switzerland

Phone +41 62 765 10 10

Fax +41 62 765 10 55

info@gewinde.ch

www.gewinde.ch

Vous aimerez peut-être aussi

- Thread Rolling SystemsDocument16 pagesThread Rolling SystemsAYOUB SOUIEDPas encore d'évaluation

- Inconel 82 (Austral-Wright)Document1 pageInconel 82 (Austral-Wright)Claudia MmsPas encore d'évaluation

- ArtificialDocument47 pagesArtificialShihabsirPas encore d'évaluation

- Customer Guide Vol18.1Document378 pagesCustomer Guide Vol18.1Arunan SivakumarPas encore d'évaluation

- Grinding MachinesDocument140 pagesGrinding MachinesyowiskiePas encore d'évaluation

- Moog-Ball Screws Planetary Roller Screws-DatasheetDocument2 pagesMoog-Ball Screws Planetary Roller Screws-DatasheetvaneaPas encore d'évaluation

- Ball BearingDocument15 pagesBall BearingArifSheriffPas encore d'évaluation

- Screw and BoltDocument31 pagesScrew and Boltyashar2500Pas encore d'évaluation

- Selection of Bearing ArrangementDocument2 pagesSelection of Bearing Arrangementprajakt_piePas encore d'évaluation

- NCS Liner HangersDocument5 pagesNCS Liner Hangerssmithyry2014Pas encore d'évaluation

- Using Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationDocument2 pagesUsing Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationLoganBohannonPas encore d'évaluation

- SKF Linear Ball BearingsDocument55 pagesSKF Linear Ball BearingsLLPas encore d'évaluation

- Deep Hole Drilling Tools: BotekDocument48 pagesDeep Hole Drilling Tools: Botekcarolina lopesPas encore d'évaluation

- Notes On Ball BearingsDocument10 pagesNotes On Ball BearingsSumit SinhaPas encore d'évaluation

- ESP Centrifugal PumpDocument7 pagesESP Centrifugal PumpRaidan AbdoPas encore d'évaluation

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5Pas encore d'évaluation

- Control Unit Model: WC-CUDocument3 pagesControl Unit Model: WC-CUmahsaPas encore d'évaluation

- Frequency Response Cylinder - EnglishDocument7 pagesFrequency Response Cylinder - Englishback1949Pas encore d'évaluation

- Vallorbs Guide Cut Vs Rolled ThreadsDocument3 pagesVallorbs Guide Cut Vs Rolled ThreadsOrlando AriasPas encore d'évaluation

- Bgi900 Manual 1.0.0Document70 pagesBgi900 Manual 1.0.0Andrea Liliana Moreno RiosPas encore d'évaluation

- MZ Alternate Path Multizone Packer: ApplicationsDocument3 pagesMZ Alternate Path Multizone Packer: ApplicationsRodolfo RiderPas encore d'évaluation

- Ball Screw PDFDocument30 pagesBall Screw PDFManoj SinghPas encore d'évaluation

- HoningDocument6 pagesHoningAnonymous 5AmJ13mLkPas encore d'évaluation

- G2 DiscBrakeDocument33 pagesG2 DiscBrakesiddout2006Pas encore d'évaluation

- Rotary Seal Design GuideDocument434 pagesRotary Seal Design GuideBhargav Suvagiya100% (3)

- How To Design With Precision BallscrewsDocument10 pagesHow To Design With Precision BallscrewsRichard CapewellPas encore d'évaluation

- Sealing Solutions For The Machine Tool Industry - Customized Machined Seals and Engineered Plastic PartsDocument22 pagesSealing Solutions For The Machine Tool Industry - Customized Machined Seals and Engineered Plastic PartsJurun_BidanshiPas encore d'évaluation

- FA25i FA5i FA5Ti Parts Information AirToolProDocument48 pagesFA25i FA5i FA5Ti Parts Information AirToolProEslam Saeed100% (1)

- Why Consider Roller Screw TechnologyDocument2 pagesWhy Consider Roller Screw Technologyryasa1Pas encore d'évaluation

- Gas Turbine Blade CoatingsDocument1 pageGas Turbine Blade CoatingsshamsPas encore d'évaluation

- LSP LowSpeedHighPressurePumps E00522Document7 pagesLSP LowSpeedHighPressurePumps E00522Sigit PramonoPas encore d'évaluation

- Bearings PDFDocument28 pagesBearings PDFKapil PudasainiPas encore d'évaluation

- Baker 2 Phase FlowDocument2 pagesBaker 2 Phase FlowLind D. QuiPas encore d'évaluation

- Butterfly ValveDocument25 pagesButterfly ValveRahul JadhavPas encore d'évaluation

- Backlash For Planetary GearboxDocument8 pagesBacklash For Planetary GearboxSerkanPas encore d'évaluation

- Seal Self Study Guide PDFDocument114 pagesSeal Self Study Guide PDFhalder_kalyan9216Pas encore d'évaluation

- Catalog: Servo TechnologyDocument180 pagesCatalog: Servo Technologyhagh_mostafa2787Pas encore d'évaluation

- Rollvis Roller Screws EnglishDocument36 pagesRollvis Roller Screws EnglishrayamsPas encore d'évaluation

- S-Wall™ Sidewall Conveyor Belting: Technical ManualDocument44 pagesS-Wall™ Sidewall Conveyor Belting: Technical ManualVasant HiremathPas encore d'évaluation

- OMC Roller Catalog PDFDocument77 pagesOMC Roller Catalog PDFMarco ViniciusPas encore d'évaluation

- Rohm Lathe ChucksDocument91 pagesRohm Lathe ChucksNebojša ObradovićPas encore d'évaluation

- SKF PriceDocument156 pagesSKF Priceparesh singhalPas encore d'évaluation

- Super Finishing ProcessDocument14 pagesSuper Finishing ProcessKumarChirraPas encore d'évaluation

- SKF Thrust Ball BearingDocument28 pagesSKF Thrust Ball Bearingsalmonsilalahi100% (1)

- Gears - Engineering InformationDocument138 pagesGears - Engineering InformationGiang T LePas encore d'évaluation

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- Wadkin AGSP SawbenchDocument6 pagesWadkin AGSP SawbenchmarkandersonsaPas encore d'évaluation

- SIERRADocument6 pagesSIERRAMario PerezPas encore d'évaluation

- Arcfix Arc StudDocument21 pagesArcfix Arc StudKiran Kumar KondapalliPas encore d'évaluation

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Product Catalogue: Your Specialist in Flow DrillingDocument64 pagesProduct Catalogue: Your Specialist in Flow DrillingВасяPas encore d'évaluation

- Gun Drill PriceDocument15 pagesGun Drill Price1mmahoneyPas encore d'évaluation

- Am ItDocument27 pagesAm Itakalbhor90Pas encore d'évaluation

- Hot Forge UpsetDocument13 pagesHot Forge UpsetAnonymous QiMB2lBCJLPas encore d'évaluation

- Sheet Metal Design HandbookDocument9 pagesSheet Metal Design Handbooktrujillo4769Pas encore d'évaluation

- Dme CatalogDocument28 pagesDme Cataloggalici2002Pas encore d'évaluation

- BCP Technical ConstructionDocument22 pagesBCP Technical ConstructionKarthik KarthikPas encore d'évaluation

- Sheet Metal BasicsDocument16 pagesSheet Metal BasicsvittlevishnuPas encore d'évaluation

- Investment Casting: Expendable Mould and PatternDocument44 pagesInvestment Casting: Expendable Mould and PatternRajumhaveri HaveriPas encore d'évaluation

- Di Gi Tal Si Gnature Certi Fi Cate Subscri Pti On FormDocument3 pagesDi Gi Tal Si Gnature Certi Fi Cate Subscri Pti On FormfastenersworldPas encore d'évaluation

- 16 - 1 - 1 - Health Advt. 2015Document10 pages16 - 1 - 1 - Health Advt. 2015Manu KhodPas encore d'évaluation

- Logistic GoalDocument1 pageLogistic GoalfastenersworldPas encore d'évaluation

- DIN 934 Hex NutDocument1 pageDIN 934 Hex NutfastenersworldPas encore d'évaluation

- Din 933-87 PDFDocument9 pagesDin 933-87 PDFEdson.Serejo100% (4)

- Iso TS 16949 2009Document30 pagesIso TS 16949 2009AndroidFlaghipPas encore d'évaluation

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroPas encore d'évaluation

- Time TAbleDocument3 pagesTime TAblefastenersworldPas encore d'évaluation

- 2315155054Document2 pages2315155054fastenersworldPas encore d'évaluation

- f436 Flat WasherDocument1 pagef436 Flat Washerbabis1980Pas encore d'évaluation

- Full Page PhotoDocument1 pageFull Page PhotofastenersworldPas encore d'évaluation

- 1 4 1 Application FormDocument1 page1 4 1 Application FormfastenersworldPas encore d'évaluation

- Abacus: Mystery of The BeadDocument37 pagesAbacus: Mystery of The BeadUsama AlsoofiPas encore d'évaluation

- Automotive CompaniesDocument12 pagesAutomotive CompaniesfastenersworldPas encore d'évaluation

- Astm A182Document2 pagesAstm A182fastenersworldPas encore d'évaluation

- Trivalent Chromates FAQDocument3 pagesTrivalent Chromates FAQfastenersworldPas encore d'évaluation

- viewNitPdf 1136048Document2 pagesviewNitPdf 1136048fastenersworldPas encore d'évaluation

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- Indian RDSO-Guidelines For HSFG Bolts On India RailDocument16 pagesIndian RDSO-Guidelines For HSFG Bolts On India RailUpaliFernando100% (1)

- Bolt HangarDocument1 pageBolt HangarfastenersworldPas encore d'évaluation

- 1 3 1 Fees-challan-FormDocument1 page1 3 1 Fees-challan-FormfastenersworldPas encore d'évaluation

- VacanciesDocument6 pagesVacanciesfastenersworldPas encore d'évaluation

- Flange Bolt DifferenceDocument1 pageFlange Bolt Differencefastenersworld100% (1)

- Cr6 Geomat DetailsDocument27 pagesCr6 Geomat DetailsfastenersworldPas encore d'évaluation

- List of Companies PDFDocument106 pagesList of Companies PDFfastenersworldPas encore d'évaluation

- Chemical Comp PDFDocument1 pageChemical Comp PDFfastenersworldPas encore d'évaluation

- Bolt Grade Cross RefDocument3 pagesBolt Grade Cross Refsamnm1971Pas encore d'évaluation

- PronounciationDocument4 pagesPronounciationfastenersworldPas encore d'évaluation

- Tpi Whitworth BSW BSFDocument2 pagesTpi Whitworth BSW BSFfastenersworldPas encore d'évaluation

- DecarbDocument2 pagesDecarbfastenersworldPas encore d'évaluation

- Technical Data Sheet TR24-3-T USDocument2 pagesTechnical Data Sheet TR24-3-T USDiogo CPas encore d'évaluation

- Bluestar Annual Report 2021-22Document302 pagesBluestar Annual Report 2021-22Kunal PohaniPas encore d'évaluation

- Brochure International ConferenceDocument6 pagesBrochure International ConferenceAnubhav Sharma sf 12Pas encore d'évaluation

- Settlement Report - 14feb17Document10 pagesSettlement Report - 14feb17Abdul SalamPas encore d'évaluation

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenPas encore d'évaluation

- Final Prmy Gr4 Math Ph1 HWSHDocument55 pagesFinal Prmy Gr4 Math Ph1 HWSHKarthik KumarPas encore d'évaluation

- Flying ColorsDocument100 pagesFlying ColorsAgnieszkaAgayo20% (5)

- Lec. 2Document22 pagesLec. 2محمدPas encore d'évaluation

- Suspend and Resume Calls: Exit PlugDocument4 pagesSuspend and Resume Calls: Exit PlugrajuPas encore d'évaluation

- Karthik ResumeDocument2 pagesKarthik ResumeArun Raj APas encore d'évaluation

- IIM L: 111iiiiiiiDocument54 pagesIIM L: 111iiiiiiiJavier GonzalezPas encore d'évaluation

- Session4 Automotive Front End DesignDocument76 pagesSession4 Automotive Front End DesignShivprasad SavadattiPas encore d'évaluation

- P. E. and Health ReportDocument20 pagesP. E. and Health ReportLESSLY ABRENCILLOPas encore d'évaluation

- Better Photography - April 2018 PDFDocument100 pagesBetter Photography - April 2018 PDFPeter100% (1)

- Life in The Ancient WorldDocument48 pagesLife in The Ancient Worldjmagil6092100% (1)

- Biblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFDocument400 pagesBiblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFSourav SircarPas encore d'évaluation

- Test Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen DownloadDocument74 pagesTest Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen Downloadmichaelmarshallmiwqxteyjb100% (28)

- Kidney Stone Diet 508Document8 pagesKidney Stone Diet 508aprilPas encore d'évaluation

- Bag Technique and Benedict ToolDocument2 pagesBag Technique and Benedict ToolAriel Delos Reyes100% (1)

- Advent Wreath Lesson PlanDocument2 pagesAdvent Wreath Lesson Planapi-359764398100% (1)

- Oral ComDocument2 pagesOral ComChristian OwlzPas encore d'évaluation

- Chap9 PDFDocument144 pagesChap9 PDFSwe Zin Zaw MyintPas encore d'évaluation

- 0 BA Design ENDocument12 pages0 BA Design ENFilho AiltonPas encore d'évaluation

- CV ChristianDocument2 pagesCV ChristianAlya ForeferPas encore d'évaluation

- DIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Document2 pagesDIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Laurice Carmel AgsoyPas encore d'évaluation

- Le Chatelier's Principle Virtual LabDocument8 pagesLe Chatelier's Principle Virtual Lab2018dgscmtPas encore d'évaluation

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinPas encore d'évaluation

- Asus Test ReportDocument4 pagesAsus Test ReportFerry RiantoPas encore d'évaluation

- Ac221 and Ac211 CourseoutlineDocument10 pagesAc221 and Ac211 CourseoutlineLouis Maps MapangaPas encore d'évaluation