Académique Documents

Professionnel Documents

Culture Documents

TS 2

Transféré par

DGWTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TS 2

Transféré par

DGWDroits d'auteur :

Formats disponibles

TS-2 TELESCOPING VALVES

Brass, Stainless Steel or PVC Tubes Screw Type or Rack & Pinion Lifts

Telescoping valves are designed to control the height of liquid within a pond, reservoir, or other holding chamber. In modern sewage treatment facilities, one specific use is to control the level of effluent in settling basins. Also called Decanting Valves or Sludge Draw-off Valves, the assembly consists of a drain tube which can slip up and down inside a stationary vertical pipe. Through a lifting device, the tube is raised and lowered to maintain the desired level within the chamber.

CONSTRUCTION FEATURES TUBE:

Waterman manufactures telescoping valves in a range of sizes from 4" tube diameter to 36" tube diameter. Valve body material is brass, stainless steel, PVC plastic or fusion epoxy coated mild steel. Lifting straps (bails) for stainless or steel tubes are the same material as tube and rigidly welded to tube. When brass or PVC plastic tube is selected, a stainless steel bail is securely bolted to the tube using stainless steel hardware. V notches or flared tube tops can be provided when requested. Also nonrising stem tube design is available.

SEAL AND FLANGE:

At the point where the sliding tube enters the vertical stationary pipe a seal is effected by means of a wiper gasket retained by a holding flange. This retaining flange may be of cast iron or stainless steel. The wiper gasket is generally of Neoprene and is of such dimension as to provide a friction seal around the sliding tube.

STEM and OPERATOR:

Stems are manufactured from solid type 304 stainless steel rod and are available in rising or non-rising styles. The standard operator is the Waterman Threaded Stem Type Lift mounted on an upright or offset pedestal. Position indicators may be furnished for either model.

6" TS-2

BAFFLE STYLE BRASS/PVC

BAFFLE STYLE STEEL/STAINLESS STEEL

FLARED STYLE BRASS/PVC

FLARED STYLE STEEL/STAINLESS STEEL

INDUSTRIES, INC.

10

TS-2 TELESCOPING VALVES

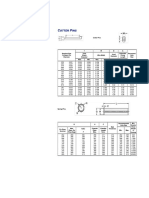

No. Name

PARTS

1 Valve Body - Commercial Brass.* 2 3 4 5 6 7 Lifting Strap - Stainless Steel ASTM A-276. Retainer Flange - Cast Iron ASTM A-126 Class B. Wiper Gasket - Neoprene ASTM D-2000. Lifting Stem - Stainless Steel ASTM A-276. Torque Nut -Manganese Bronze ASTM B-584 Al 865 Hex Bolt & Nut - Stainless Steel ASTM F-593

*Or 304 Stainless Steel *Or 316 Stainless Steel *Or PVC Pipe

TYPICAL INSTALLATION

NRS OPERATOR

PLAIN STYLE BRASS/PVC

PLAIN STYLE STEEL/STAINLESS STEEL

V NOTCH STYLE BRASS/PVC

V NOTCH STYLE STEEL/STAINLESS STEEL

INDUSTRIES, INC.

11

TYPICAL SPECIFICATIONS TS-2 TELESCOPING (SLIP-SEAL) VALVES

General Telescoping valves are used primarily for sludge removal, or liquid level control, and are considered to be fully open when in the lowermost position. The valve tube travels inside a cast iron or ductile iron riser pipe as shown in the plan drawings. The nominal riser pipe diameter determines the valve tube diameter. Vee notch, flared, or baffled tube tops shall be provided when required by the plan drawings. Tube (metal) Brass tubes for 10 inch nominal diameter and smaller valves shall be manufactured from seamless tube or pipe. For 12 inch and larger brass valves the tube shall be of rolled plate construction with the weld seam ground smooth. The finish O.D. of the tube is to be .04 inches, cylindrical within .100 TIR and have a smooth, 125 micro inch or better surface. Stainless steel or steel tubes up through 24 size shall be manufactured from seamless pipe or tube. Steel tubes are to be fusion epoxy coated. Tube lengths shall be as shown or noted on the drawings and must be of sufficient length to facilitate valve travel and maintain an appropriate insert depth. Valve tubes are to be a minimum 1/8" thick and are attached to connecting stems by use of a lifting bail. Tube (PVC) Valve tubes shall be of PVC plastic pipe. Tube lengths shall be as shown or noted on the plan drawings and must be of sufficient length to facilitate valve travel and maintain an appropriate insert depth. Valve tubes are to be attached to connecting stems by use of a lifting bail and must include bushings or an inner reinforcing ring of stainless steel, to prevent bolt hole enlargement on tube. Seal Flange A cast iron or stainless steel companion flange and neoprene slip seal gasket shall be provided by the valve manufacturer. The gasket must be a minimum 1/4" thick. The inside diameter of the gasket is to be 1/8" smaller than the outside diameter of the valve tube to provide a friction seal. The gasket is to be sandwiched between the riser pipe flange and the companion flange. The gasket and companion flange shall include a 125# standard drilling pattern to match the riser pipe. Lifting Bail On brass and PVC tubes the lifting bail shall be stainless steel construction and be fastened to the valve body with stainless steel attaching bolts. On stainless steel and steel tubes, the bail shall be the same material as the tube and be rigidly welded to the tube. Lift and Stems (Rising) Lifts shall be handwheel type, with UHMW polyethylene thrust bearings along with a stub acme threaded type 304 stainless steel stem to provide automatic self-locking, infinite valve positioning. The standard rising stem lift shall use a galvanized steel square tube with torque nut design to prevent telescoping valve tube rotation. Alternately, where conditions require, a vee keyed shaft, with torque plate, shall be used to prevent valve tube rotation. Handwheels shall be a minimum of 12" in diameter and shall include a clear plastic Butyrate stem cover with a mylar strip type position indicator, calibrated in inch increments to illustrate valve position. The mylar strip, provided by the manufacturer, will be affixed by the contractor after installation to provide a true and accurate indication of the tube elevation by comparing it to the top of the rising stem. Stainless steel anchor bolts shall be provided for all pedestals. Cleaning and shop prime coat of lift housing and handwheel will be (as specified elsewhere in this specification) (manufacturers standard). Lift (Non-Rising Stem) Lifts shall be ball bearing supported handwheel type with dial position indicator, mounted to a fabricated galvanized steel non-rising stem pedestal. The pedestal shall be manufactured with a square, main vertical member and a telescoping type torque tube. The torque tube must incorporate a square thrust pocket at the top to house a square thrust nut, to prevent rotation of the valve tube assembly. The bottom of the torque tube is attached to the lifting bail with bolts & nuts, same as rising stem lift. Non-Rising Stem Where mounting conditions do not permit standard rising or non-rising stem lifts, a non-rising stem telescoping valve shall be provided. The valve bail design shall include nut pocket for NRS thrust nut and guides to prevent tube rotation. Stems shall be stub acme threaded type 304 stainless steel non-rising stem, threaded and keyed to either ball bearing supported lift, or floor box type lift. Lift shall have dial position indicator and 2 square nut to be operated by T-handle. Telescoping valve shall be Model TS-2 as manufactured by Waterman Industries, Inc. or equal.

INDUSTRIES, INC.

12

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Sbi Afi 2012Document48 pagesSbi Afi 2012Moneylife FoundationPas encore d'évaluation

- Massey Ferguson MF7600 Technician Workshop ManualDocument798 pagesMassey Ferguson MF7600 Technician Workshop Manualgavcin100% (5)

- Wood Finishing Basics: Application Techniques & Product SelectionDocument13 pagesWood Finishing Basics: Application Techniques & Product SelectionDGWPas encore d'évaluation

- Review of Related Literature and Related StudiesDocument23 pagesReview of Related Literature and Related StudiesReynhard Dale100% (3)

- Electric Machinery and Transformers - I. L. Kosow PDFDocument413 pagesElectric Machinery and Transformers - I. L. Kosow PDFzcjswordPas encore d'évaluation

- He130 - Driveway Asphalt Coating: Physical PropertiesDocument2 pagesHe130 - Driveway Asphalt Coating: Physical PropertiesDGWPas encore d'évaluation

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Document2 pagesMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWPas encore d'évaluation

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDocument2 pagesWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWPas encore d'évaluation

- Lee Spring CatalogDocument391 pagesLee Spring CatalogDGWPas encore d'évaluation

- Overkote Asphalt Pavement Coating: DescriptionDocument1 pageOverkote Asphalt Pavement Coating: DescriptionDGWPas encore d'évaluation

- D-01 7041 Flange-ANSI 125,150-RevlDocument4 pagesD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasPas encore d'évaluation

- Flat Washer and FastenersDocument49 pagesFlat Washer and FastenersDGWPas encore d'évaluation

- 01 04tocDocument428 pages01 04tocFaltooPas encore d'évaluation

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdPas encore d'évaluation

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdPas encore d'évaluation

- Tap Drill ChartDocument2 pagesTap Drill ChartDGWPas encore d'évaluation

- Nord-Lock Washers: The Original Wedge-Locking SolutionDocument16 pagesNord-Lock Washers: The Original Wedge-Locking SolutionDGWPas encore d'évaluation

- Schedule 80 Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 Pipe Dimensions & Pressure RatingsDGWPas encore d'évaluation

- Thrust Restraint For Expansion JointDocument2 pagesThrust Restraint For Expansion JointDGWPas encore d'évaluation

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDocument2 pagesTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWPas encore d'évaluation

- The First Hillside Washer That Eliminated Back-Up Plates!Document1 pageThe First Hillside Washer That Eliminated Back-Up Plates!DGWPas encore d'évaluation

- Rubber Expansion JointsDocument9 pagesRubber Expansion JointsDGWPas encore d'évaluation

- E Pipe Restraint ROMAC 612 CDocument1 pageE Pipe Restraint ROMAC 612 CDGWPas encore d'évaluation

- Countersinking Drill Bit ReamerDocument1 pageCountersinking Drill Bit ReamerDGWPas encore d'évaluation

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDocument2 pagesJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWPas encore d'évaluation

- Tap Drill DataDocument1 pageTap Drill DataDGWPas encore d'évaluation

- PVC Gravity Sewer PipeDocument1 pagePVC Gravity Sewer PipeDGWPas encore d'évaluation

- Threaded RodDocument1 pageThreaded RodDGWPas encore d'évaluation

- Steel Rebar SizesDocument1 pageSteel Rebar SizesDGWPas encore d'évaluation

- Bolt - Astm A449Document2 pagesBolt - Astm A449DGWPas encore d'évaluation

- Screw Threads DesignDocument1 pageScrew Threads DesignDGWPas encore d'évaluation

- Cotter Pins and Spring PinsDocument1 pageCotter Pins and Spring PinsDGWPas encore d'évaluation

- Standard Pipe Schedules and Sizes ChartDocument1 pageStandard Pipe Schedules and Sizes ChartDGWPas encore d'évaluation

- Proposed 4way D54 Proposed 2way D56: Issue Date DescriptionDocument3 pagesProposed 4way D54 Proposed 2way D56: Issue Date DescriptionADIL BASHIRPas encore d'évaluation

- UNIT 4 Digital Integrated CircuitsDocument161 pagesUNIT 4 Digital Integrated CircuitssimhadriPas encore d'évaluation

- RCD ManagementDocument6 pagesRCD ManagementPindoterOPas encore d'évaluation

- Tyler & Wheeler Curriculum ModelDocument8 pagesTyler & Wheeler Curriculum Modelliliyayanono100% (1)

- T10 - PointersDocument3 pagesT10 - PointersGlory of Billy's Empire Jorton KnightPas encore d'évaluation

- Teccrs 3800Document431 pagesTeccrs 3800Genus SumPas encore d'évaluation

- Bill - AKIJDocument3 pagesBill - AKIJm.tanjil2005Pas encore d'évaluation

- DRUGPDocument371 pagesDRUGPPolarogramaPas encore d'évaluation

- Paper Format IJRDTDocument3 pagesPaper Format IJRDTrock starPas encore d'évaluation

- General Information Exhibition Guide Lines - 3P 2022Document6 pagesGeneral Information Exhibition Guide Lines - 3P 2022muhammad khanPas encore d'évaluation

- Statement of Cash Flows AnswerDocument3 pagesStatement of Cash Flows Answeranber mohammadPas encore d'évaluation

- College Invitation Letter - Managedia 2023Document2 pagesCollege Invitation Letter - Managedia 2023Sandeep DeyPas encore d'évaluation

- In Other Words RE Increased by P250,000 (Income Less Dividends)Document6 pagesIn Other Words RE Increased by P250,000 (Income Less Dividends)Agatha de CastroPas encore d'évaluation

- Exam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)Document10 pagesExam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)SadishPas encore d'évaluation

- I - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsDocument6 pagesI - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsHaPas encore d'évaluation

- EPA NCP Technical Notebook PDFDocument191 pagesEPA NCP Technical Notebook PDFlavrikPas encore d'évaluation

- Presentation 1Document22 pagesPresentation 1AILYN PECASALESPas encore d'évaluation

- José Guadalupe PosadaDocument19 pagesJosé Guadalupe PosadaJudy Baca100% (1)

- Automatic Coconut Dehusking MachineDocument12 pagesAutomatic Coconut Dehusking MachineKumaresh Salem0% (1)

- AR Financial StatementsDocument281 pagesAR Financial StatementsISHA AGGARWALPas encore d'évaluation

- Case Study Presentation - CGDocument37 pagesCase Study Presentation - CGapi-290866384Pas encore d'évaluation

- H I Ôn Thi Aptis & Vstep - Tài Liệu - Anna MaiDocument4 pagesH I Ôn Thi Aptis & Vstep - Tài Liệu - Anna Maihanh.mt2022Pas encore d'évaluation

- Haldex Valve Catalog: Quality Parts For Vehicles at Any Life StageDocument108 pagesHaldex Valve Catalog: Quality Parts For Vehicles at Any Life Stagehoussem houssemPas encore d'évaluation

- Lesson Plan Defining and Non Relative Clauses XII (I)Document3 pagesLesson Plan Defining and Non Relative Clauses XII (I)mariaalexeli0% (1)

- Autodesk Design Review: About DWF and DWFXDocument7 pagesAutodesk Design Review: About DWF and DWFXNesrePas encore d'évaluation

- Et200sp Im 155 6 PN ST Manual en-US en-USDocument47 pagesEt200sp Im 155 6 PN ST Manual en-US en-USayaz officePas encore d'évaluation