Académique Documents

Professionnel Documents

Culture Documents

TECS Water Cooled Chiller

Transféré par

ntt_121987Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TECS Water Cooled Chiller

Transféré par

ntt_121987Droits d'auteur :

Formats disponibles

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

R-410A

TECS

TM

R-134a

R-22

Series

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L Series 503-2008kW(143-571Rton)

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

High efficiency

The entire TECS range differs from chillers with screw compressor because of its high performance at partial loads, with an average increase of 60% in ESEER. This result is achieved by using an oilfree magnetic levitation centrifugal compressor combined with a dedicated flooded evaporator.

14 13 12

Comparison between TECS vs. traditional screw chiller Comparison between TECS vs. traditional screw chiller

13,21

Efficiency Efficiency

11 10 9 8 7 6 5 4

TECS-W

9,84

ESEER 9,52

+60%

6,93 5,97

ESEER 5,93

6,23 5,65 5,26 4,72 100%30

25%18

screw chiller Part Load (condenser inlet temp.) 50%22 75%26 Part Load (condenser inlet temp.)

Integrated part load value (ESEER)

TECS-W/L ESEER

Increasingly closer attention is being paid towards the power consumption of air-conditioning equipment. In air-conditioning systems, a chiller only works in full load conditions for a few hours a year. For this reason, seasonal efficiency is the truly determining consumption factor. The valuation indices have been adopted that consider usage in part load conditions as IPLV in the United States and ESEER in Europe. ESEER up to 9.58, and IPLV up to 10 ESEER(European Seasonal Energy Efficiency Ratio): 0.03A+ 0.33B+0.41C+0.23D Evaporator temp. leaving at 7 (constant), condenser water (inlet) at 30 (100% loadA), 26 (75% loadB), 22 (50% loadC), 18(25% loadD).

0511 1012 1453 1954

9.51 9.59 9.60 9.61

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Features and Benefits

A revolutionary heart

Centrifugal compressor with magnetic levitation

Soft start device / Inverter speed control

Synchronous brushless DC motor

2 stage, direct drive, hermetic centrifugal compressor

Pressure & temperature sensors

Inlet Guide Vanes

Motor & bearing control

Magnetic bearings

A leading-edge miniaturized compressor, featuring magnetic bearings and digital impeller speed control, partial load efficiency levels that have never been obtained up till now. Compression is obtained by two high-speed impellers, driven by a continuously variable frequency motor, which deliver the exact cooling capacity required by the system. Magnetic bearings keep the highspeed shaft suspended in the air and frictionless. This technology, derived from aerospace applications, has many advantages: Outstanding part load efficiency thanks to the inbuilt inverter speed control. Oil-free, offering improved performance of the heat exchangers thanks to the elimination of the film of oil which, in other types of compressor, lies between the coolant and the exchange surface. Low vibrations under all operating conditions, and super low operation noise. Centrifugal compressor with built-in continuous impeller speed adjustment up to 48000 rpm.

COP 12.00 10.00 8.00 6.00 4.00 2.00 0.00

Fixed frequency Variable frequency

1st stage impeller

2nd stage impeller

Condenser temp. decline

Thanks to their high speed, the impellers have been miniaturized, thereby reducing the size and weight of the compressor to just 120 kg. Very low current during starting (soft start), 2A instead of the 500-600 A of a screw compressor with the same cooling capacity.

0%

90

80

% 20

50

70

10

Part Load (%)

60

40

30

10

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Magnetic Bearings

Front Radial Bearing Motor Front Radial Bearing

Impellers

Axial Bearing Sensor Ring Sensor Ring

Magnetic bearings and sensors keep the shaft properly centered and positioned at all times.

The magnetic bearings have less than .2% the friction loss compared to conventional bearings Eliminates the ability of the oil to contaminate the refrigerant Eliminates cost of oil management systems (hardware and controls) Increases equipment life through elimination of wear surfaces

Does this Integrated Compressor Design handle a Power Outage?

Motor becomes a generator After the compressor comes to a complete stop, the rotor de-levitates normally onto touchdown bearings. Touchdown bearings are used as a back up bearing system

Yes.

Dedicated Flooded Evaporator/Condenser

Flooded evaporator/condenser with integral rippled tube are modified to enhance the initiation of nucleate boiling sites and surface area, improving turbulent flow, resulting in increasingly overall heat transfer coefficient and high unit efficiency. The evaporator is characterized by low pressure drops on both the gas side and the water side. The level of refrigerant inside the flooded evaporator is guaranteed by dedicate sensor level and modulating electronic valve. Single circuit design even for multiple compressor improves unit part load efficiency.

Electronic Valve(EXV)

The electronic valve is adopted to grant the ideal operation of the evaporator in all conditions. The complete flooding of tubes is granted with a sophisticated detection of the refrigerant level in the heat exchangers. The fast processing of the acquired data allow a quick, fluctuation-free regulation, and therefore a highly accurate adjustment to the swings of load and ambient conditions.

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Touch Screen LCD

Full graphical interface, display all operating parameters. Full and effective control of the compressor and unit operation Comprehensive operation and alarm records, keeping the "black box" function. Compatible with the Climaveneta group controller such as Gr2000, Gr3000 and BMS.

Extremely silent operation

Thanks to the adoption of the centrifugal compressor with magnetic levitation, TECS sound power and pressure are the lowest on the market, without peaks in any of the sound frequency spectrum.

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Performance Data

Model TECS-W/L 0511 1012 1453 1954

Cooling capacity Power input Evaporator water flow Evaporator water pressure drop Condenser water flow Condenser water pressure drop

kW kW m3/h kPa m3/h kPa

502.9 93.2 86.5 44 102.5 57

1007.2 186.6 173.2 44 205.3 60

1504.8 277.1 258.8 43 306.4 45

2007.9 369.0 345.3 42 408.8 45

Number of compressors Refrigerating circuit Operating weight Dimensions Length Width Height

n n kg

1 1 1740

2 1 3160

3 1 4790

4 1 5970

mm mm mm

2990 950 1900

3490 1300 1800

4990 1300 1800

5450 1300 1990

1. Remarks: 2. Chilled water (in/out) 12/7 3. Condenser water (in/out) 30/35 4. Evaporator and condenser enduring waterside pressure is 1.0MPa.

Water-cooled Magnetic Levitation Variable Frequency Centrifugal Chiller

TECS-W/L

Over 300 projects all over the world

BARCLAYS Several server rooms and data centers in the Whole United Kingdom For over 10,000kW of total capacity provided by several TECS

European Parliament Strasbourg France Geothermal application total capacity 3,300kW Provided by 3 TECS water cooled chillers

Unilever Headquarters Hamburg - Germany Hydronic system, 3,000kW total capacity Provided by 2 TECS water cooled chillers

Glaxo Smith Kline Essex - U.K. Hydronic system, 1,000kW total capacity Provided by 2 TECS water cooled chillers

Sino-ltaly Ecological and Energy Efficient Building (SIEEB) Tsinghua University China Hydronic system, 800kW total capacity provided by 1 TECS water cooled chiller.

Climaveneta Italy: 36061 BASSANO DEL GRAPPA (VICENZA) ITALIA - VIA SARSON 57/c TEL. +39 / 0424 509 500 (r.a.) - TELEFAX +39 / 0424 509 509 E-mail:info@climaveneta.com http://www.climaveneta.com Climaveneta China: No,88 Baiyun Road Xinghuo Developing Zone ,Shanghai,China Post Code:201419 TEL: +86-21-57505566 FAX: +86-21-57505797 E-mail:info@climaveneta.com.cn http://www.climaveneta.com.cn Climaveneta Hongkong: Room 2003,CCT Telecom Building, 11 Wo Shing Street,Fotan,Shatin,N.T.,Hongkong TEL: +85-2-26871755 FAX: +85-2-26873078 E-mail:info@climaveneta.com.cn http://www.climaveneta.asia Climaveneta Vietnam: 381A1 Cong Hoa Street Ward 13 Tan Binh District, HCM City, Vietnam TEL: +84-8-38497529 FAX: +84-8-38124190 E-mail:info@climaveneta.com.cn http://www.climaveneta.asia

All specification and data are subject to change without notice

B219 CCU/01-01-2011EN-SH

Vous aimerez peut-être aussi

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideD'EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuidePas encore d'évaluation

- Branch Leaflet TECS-WDocument12 pagesBranch Leaflet TECS-WAlfin khoeril UmamPas encore d'évaluation

- CTV SLB041 en - 06292020Document2 pagesCTV SLB041 en - 06292020Nguyen ThuongPas encore d'évaluation

- BE YK Res SG PDFDocument12 pagesBE YK Res SG PDFAhmed GamalPas encore d'évaluation

- RLC PRC005 E4 - 0110Document60 pagesRLC PRC005 E4 - 0110jefhdez0% (1)

- Access and save files anywhere with OneDriveDocument5 pagesAccess and save files anywhere with OneDriveVeny WidyaPas encore d'évaluation

- Chiller RATINGREPORTDocument3 pagesChiller RATINGREPORTv6656Pas encore d'évaluation

- 160.49-PW14york Solid State StarterDocument4 pages160.49-PW14york Solid State StarterAwo Orumila Giraldolegra0% (1)

- Chiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingDocument7 pagesChiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingBogdan-iulian BalintPas encore d'évaluation

- Request For Quotation PartsDocument102 pagesRequest For Quotation PartsAli BeanPas encore d'évaluation

- Hrol - 19DVG41G43 700RTDocument5 pagesHrol - 19DVG41G43 700RTGohds100% (1)

- Field Connections Diagram For Ymc Model A Chiller With M1 CompressorDocument12 pagesField Connections Diagram For Ymc Model A Chiller With M1 CompressorJose CuevasPas encore d'évaluation

- De Lux Sistem PartsDocument58 pagesDe Lux Sistem PartsSaul acostaPas encore d'évaluation

- Presented By:-Bilal Kazmi Nilesh Kumar Nawnit Kumar Vivek Bhardwaj Sana Ullah Sahriff Saurabh KumarDocument13 pagesPresented By:-Bilal Kazmi Nilesh Kumar Nawnit Kumar Vivek Bhardwaj Sana Ullah Sahriff Saurabh KumarNawnit KumarPas encore d'évaluation

- Field Connections Model Yk Chillers (Style F and G) With Variable Speed DriveDocument10 pagesField Connections Model Yk Chillers (Style F and G) With Variable Speed DriveJose CuevasPas encore d'évaluation

- HydroBall Operational ManualDocument12 pagesHydroBall Operational ManualpostboxsgPas encore d'évaluation

- HTTP Cgproducts - Johnsoncontrols.com YorkDoc SI0261.PDF#XML HTTP Cgproducts - Johnsoncontrols.com Search Lit - Aspx CMD Pdfhits& DocId 12037& Index C Inetpub Wwwroot 72.3Document2 pagesHTTP Cgproducts - Johnsoncontrols.com YorkDoc SI0261.PDF#XML HTTP Cgproducts - Johnsoncontrols.com Search Lit - Aspx CMD Pdfhits& DocId 12037& Index C Inetpub Wwwroot 72.3danyelstoica100% (1)

- Rtaa SB 20Document5 pagesRtaa SB 20kulilin1100% (1)

- Active Magnetic BearingDocument7 pagesActive Magnetic BearingsomendratrivediPas encore d'évaluation

- Polyherbal Formulations Based On Indian Medicinal Plants As Antidiabetic PhytotherapeuticsDocument15 pagesPolyherbal Formulations Based On Indian Medicinal Plants As Antidiabetic PhytotherapeuticsJohnnPas encore d'évaluation

- Self-Contained Air Conditioners with Water-Cooled CondensersDocument19 pagesSelf-Contained Air Conditioners with Water-Cooled CondensersFadliPas encore d'évaluation

- 38HK 03 PD 60HZ 2011Document32 pages38HK 03 PD 60HZ 2011Ahmed Jabir100% (1)

- Starters For Centrifugal Chillers: Installation, Operation and Maintenance ManualDocument56 pagesStarters For Centrifugal Chillers: Installation, Operation and Maintenance ManualMuhammad Javed BhattiPas encore d'évaluation

- Climaveneta Installation Manuals Generale - enDocument20 pagesClimaveneta Installation Manuals Generale - enNhật Phong NguyễnPas encore d'évaluation

- Brochure For York ChillerDocument8 pagesBrochure For York ChillervenkatearPas encore d'évaluation

- Turbocor Compressor - Service - HireDocument4 pagesTurbocor Compressor - Service - Hireinfo3903Pas encore d'évaluation

- Crystalization Temp of Lithium BromideDocument11 pagesCrystalization Temp of Lithium BromideVictor PPas encore d'évaluation

- Part Load 10% - Ymc 450 TR Paralelo KW - TRDocument3 pagesPart Load 10% - Ymc 450 TR Paralelo KW - TRAdler LinharesPas encore d'évaluation

- C0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFDocument20 pagesC0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFNhật Phong NguyễnPas encore d'évaluation

- Carrier ISM VersioSoftwaren 06Document3 pagesCarrier ISM VersioSoftwaren 06Mbayat167% (3)

- Technical YKDocument16 pagesTechnical YKnairam2003Pas encore d'évaluation

- Exhaust Water CondensationDocument9 pagesExhaust Water CondensationDeepa PujariPas encore d'évaluation

- Waste Heat Recovery Steam Generator in Sponge Iron PlantDocument6 pagesWaste Heat Recovery Steam Generator in Sponge Iron PlantthesijPas encore d'évaluation

- YcivDocument334 pagesYcivrodrigomalvon100% (2)

- SB0018: Adding Line Inductor to Variable Speed Oil Pump DriveDocument2 pagesSB0018: Adding Line Inductor to Variable Speed Oil Pump DrivemikenilsonPas encore d'évaluation

- Pit Installations - Restricted Airflow SituationsDocument16 pagesPit Installations - Restricted Airflow Situationsfarshan296015Pas encore d'évaluation

- 40LX040 060 (Malaysia)Document8 pages40LX040 060 (Malaysia)Leed ENPas encore d'évaluation

- MVSSS Gate Driver CardDocument1 pageMVSSS Gate Driver CardMohammad yasinPas encore d'évaluation

- W3000TE User ManualDocument65 pagesW3000TE User ManualmodussarPas encore d'évaluation

- High Efficiency High AmbientGeneral Sales BrochureDocument30 pagesHigh Efficiency High AmbientGeneral Sales BrochureJosue Alvarez GomezPas encore d'évaluation

- AERCO Boiler Benchmark 3.0Document129 pagesAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Controls Operation and TroubleshootingDocument138 pagesControls Operation and TroubleshootingAnup SurendranPas encore d'évaluation

- KS Vertical Split Coupled CatalogDocument20 pagesKS Vertical Split Coupled CatalogAugusto Alcaraz UgartePas encore d'évaluation

- Rtxa 209 - 212 Iom E30im001-Gb - 1098Document32 pagesRtxa 209 - 212 Iom E30im001-Gb - 1098DianaPas encore d'évaluation

- RLC Svu01b E4 - 06012006Document60 pagesRLC Svu01b E4 - 06012006YAIR ANDRES BARON PEÑAPas encore d'évaluation

- Multiaqua Products CatalogDocument418 pagesMultiaqua Products Cataloge-ComfortUSAPas encore d'évaluation

- 19DV CLT 4SS PDFDocument96 pages19DV CLT 4SS PDFramakrishnanPas encore d'évaluation

- Electronic Anti-Scale System Reference BookDocument94 pagesElectronic Anti-Scale System Reference BookTadej SevšekPas encore d'évaluation

- Product Data: Features/BenefitsDocument60 pagesProduct Data: Features/BenefitsBJNE01Pas encore d'évaluation

- Iom Enfriador CgakDocument32 pagesIom Enfriador CgakDaniel Carretero100% (1)

- Rcu2e Ag2 & Rhu2e Ag2 PDFDocument192 pagesRcu2e Ag2 & Rhu2e Ag2 PDFKostas AstrinisPas encore d'évaluation

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Document32 pagesTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehPas encore d'évaluation

- Quick Setup GuideDocument145 pagesQuick Setup Guidevampiro_yiyo0% (1)

- HFCC D Iom 03Document16 pagesHFCC D Iom 03geovany_villagraPas encore d'évaluation

- CRANE BS&U Proportional Balancing GuideDocument37 pagesCRANE BS&U Proportional Balancing GuideAhmed MostafaPas encore d'évaluation

- Direct Fired Vapor Absorption ChillerDocument40 pagesDirect Fired Vapor Absorption ChillerObayomi KennyPas encore d'évaluation

- RtadDocument60 pagesRtadBlondu AlexPas encore d'évaluation

- Dunham Bush - IntroductionDocument3 pagesDunham Bush - Introductionchris110Pas encore d'évaluation

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963D'EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Pas encore d'évaluation

- 1Document3 pages1ntt_121987Pas encore d'évaluation

- 0712 Boiler Rev. 1Document8 pages0712 Boiler Rev. 1ntt_121987Pas encore d'évaluation

- SVTT-140831-930 Bitzer Quotation SumaryDocument5 pagesSVTT-140831-930 Bitzer Quotation Sumaryntt_121987Pas encore d'évaluation

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Pas encore d'évaluation

- 0703 Mechanical InsulationDocument11 pages0703 Mechanical Insulationntt_121987Pas encore d'évaluation

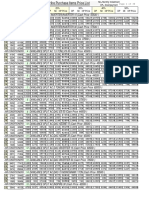

- No. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 BarsDocument1 pageNo. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 Barsntt_121987Pas encore d'évaluation

- 0702 Sound and Vibration ControlDocument7 pages0702 Sound and Vibration Controlntt_121987Pas encore d'évaluation

- 0711 Pachage Chiller - Scroll and ScrewDocument9 pages0711 Pachage Chiller - Scroll and Screwntt_121987Pas encore d'évaluation

- 0704 Mechanical IdentificationDocument6 pages0704 Mechanical Identificationntt_121987Pas encore d'évaluation

- 0701 Mechanical General ProvisionDocument13 pages0701 Mechanical General Provisionntt_121987Pas encore d'évaluation

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Pas encore d'évaluation

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Pas encore d'évaluation

- VAV Design GuideDocument326 pagesVAV Design GuideHESuarez100% (3)

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Pas encore d'évaluation

- Thu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNDocument2 pagesThu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNntt_121987Pas encore d'évaluation

- Thu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNDocument2 pagesThu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNntt_121987Pas encore d'évaluation

- Stair Pressurization Requirements CalculatorDocument8 pagesStair Pressurization Requirements Calculatorntt_121987Pas encore d'évaluation

- SdasdDocument9 pagesSdasdntt_121987Pas encore d'évaluation

- VAV Design GuideDocument326 pagesVAV Design GuideHESuarez100% (3)

- Thu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNDocument2 pagesThu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNntt_121987Pas encore d'évaluation

- 3.MECH Duct11Document2 pages3.MECH Duct11ntt_121987Pas encore d'évaluation

- 19xr DataDocument3 pages19xr Datantt_121987Pas encore d'évaluation

- Pressure Relief DamperDocument1 pagePressure Relief Damperntt_121987Pas encore d'évaluation

- FVG FVPG FD R22Document154 pagesFVG FVPG FD R22thanhlong2005Pas encore d'évaluation

- Water and drainage system diagramsDocument56 pagesWater and drainage system diagramsntt_121987Pas encore d'évaluation

- 14.1 Round Volume - ControlDocument1 page14.1 Round Volume - Controlntt_121987Pas encore d'évaluation

- 1 Steam Training TerumoDocument39 pages1 Steam Training Terumontt_121987Pas encore d'évaluation

- 2 Fire DamperDocument28 pages2 Fire Damperntt_121987Pas encore d'évaluation

- Non Return DamperDocument3 pagesNon Return Damperntt_121987Pas encore d'évaluation

- Motorised DamperDocument3 pagesMotorised Damperntt_121987Pas encore d'évaluation

- Rooftop Packaged Air Conditioners: CatalogDocument212 pagesRooftop Packaged Air Conditioners: CatalogRicardo Molina SánchezPas encore d'évaluation

- Iction Stir WeldingDocument16 pagesIction Stir WeldingNeeraj MishraPas encore d'évaluation

- Fire Fighting Equipment LayoutDocument1 pageFire Fighting Equipment LayoutAditya PranotoPas encore d'évaluation

- Blower Air Room HeaterDocument18 pagesBlower Air Room HeaterPrashant SrivastavaPas encore d'évaluation

- 2000 Performance PDFDocument12 pages2000 Performance PDFMehdi HasanPas encore d'évaluation

- Earth's Internal Heat - LectureDocument15 pagesEarth's Internal Heat - LectureMARIA LOURDES MENDOZA100% (1)

- SCI 7 3 3 Force Energy and MotionDocument4 pagesSCI 7 3 3 Force Energy and MotionShanna RainePas encore d'évaluation

- Quick Installation Guide: RTH2300/RTH221Document40 pagesQuick Installation Guide: RTH2300/RTH221IBJSC.comPas encore d'évaluation

- ATD Module 4Document23 pagesATD Module 4kannanPas encore d'évaluation

- Alexandre Dijoux 2017 Working Fluid Selection General Method and Sensitivity Analysis of An ORC Application To OTECDocument21 pagesAlexandre Dijoux 2017 Working Fluid Selection General Method and Sensitivity Analysis of An ORC Application To OTECASET Soru ÇözümPas encore d'évaluation

- Heat Transfer Study of Helically Coiled Heat ExchangersDocument3 pagesHeat Transfer Study of Helically Coiled Heat ExchangersRahul JaganPas encore d'évaluation

- Tutorial - Conduction Heat TransferDocument3 pagesTutorial - Conduction Heat TransferDayanidiPas encore d'évaluation

- Refrigerator Cooling and Storage EssentialsDocument20 pagesRefrigerator Cooling and Storage EssentialsSanjay VermaPas encore d'évaluation

- 5 Stage Reciprocating CompressorDocument10 pages5 Stage Reciprocating CompressorJhay-Pee QueliopePas encore d'évaluation

- Advanced Refrigeration Cycles and Systems OverviewDocument8 pagesAdvanced Refrigeration Cycles and Systems OverviewAde FandiPas encore d'évaluation

- RTWD Series-CatalogueDocument40 pagesRTWD Series-CatalogueRobecal GeneralPas encore d'évaluation

- Mechanical Engineering PDFDocument153 pagesMechanical Engineering PDFkylealamangoPas encore d'évaluation

- Introduction of Air CoolerDocument2 pagesIntroduction of Air CoolerHarshal Madgulkar (Harsh)100% (1)

- Last Updated CSD Hire Purchase Items Price ListDocument38 pagesLast Updated CSD Hire Purchase Items Price ListPak Land0% (1)

- Carrier-Ducted-Brochure-QSM QSH v3 LRDocument8 pagesCarrier-Ducted-Brochure-QSM QSH v3 LRbilal.alshafiPas encore d'évaluation

- Baknor Cold Plates Liquid and BrazedDocument2 pagesBaknor Cold Plates Liquid and Brazedthemike03Pas encore d'évaluation

- 314 ch1Document70 pages314 ch1Bilal AhmadPas encore d'évaluation

- Principle of Electrostatic Chuck PDFDocument7 pagesPrinciple of Electrostatic Chuck PDFkamaveriyan100% (1)

- VRV System of Air ConditionDocument15 pagesVRV System of Air ConditionRushabh Rajendra YerunkarPas encore d'évaluation

- Lamina Brasado Bphe Produto GBHDocument2 pagesLamina Brasado Bphe Produto GBH伊藤 哲ウンベルト(Tabibito)Pas encore d'évaluation

- Modeling and Simulation of Natural Ventilation of Building Using Solar ChimneyDocument6 pagesModeling and Simulation of Natural Ventilation of Building Using Solar ChimneyLinh Nam NguyenPas encore d'évaluation

- Deepa ParekhDocument53 pagesDeepa ParekhKrutika DongrePas encore d'évaluation

- Fundamentals of Microwave Extraction: 2.1 Basic PrinciplesDocument39 pagesFundamentals of Microwave Extraction: 2.1 Basic PrinciplesJollana Dianne GuillermoPas encore d'évaluation

- Green Buildings 2019 MG C9Document514 pagesGreen Buildings 2019 MG C9Tấn Nguyễn VănPas encore d'évaluation

- Ansys Solved TutorialsDocument162 pagesAnsys Solved TutorialsUmesh Vishwakarma86% (7)