Académique Documents

Professionnel Documents

Culture Documents

High Impedance Sformer Differential

Transféré par

Hamayoun MurtazaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

High Impedance Sformer Differential

Transféré par

Hamayoun MurtazaDroits d'auteur :

Formats disponibles

HIGH IMPEDANCE BUS DIFFERENTIAL VS BIASED TRANSFORMER DIFFERENTIAL

Operating times for diff protection, excluding breaker tripping time are generally of the following order: Transformer diff - 10 cycles Busbar diff - 4 cycles Feeder diff - 5 cycles Modern relays act even faster These operating times are practically independent of magnitude of fault current. Trip time for transformer diff is a little longer to ensure that the relays do not operate incorrectly due to initial transients.

LOW IMPEDANCE DIFF SCHEMES Low impedance system (bias or unbias) current operated CTs are much cheaper (Compare prices of a 10P10 CT and a Class X CT).

HIGH IMPEDANCE DIFF SCHEMES High impedance system - voltage operated

low impedance refers to biased / percentage high impedance utilizes a series resistor differential relay. with the overcurrent differential element Main disadvantage of circulating current protection using low impedance relays is through fault instability due to CT saturation. and the low cost, if used on a simple bus system. However with the introduction of numerical relays and their low CT burden as well as their ability of measuring several feeder currents, a low impedance bus differential principal could be applied on simple busses also High impedance bus differential relays are used on most of the busses in North America. The popularity can be explained by the good performance of this scheme in relation to CT saturation and the low cost, if used on a simple bus system

Common advantages of all

low impedance bus protection

schemes are the ability to be able to use CT's of different ratios on respective branch inputs and the fact that the same CT used for the bus protection can be shared with the feeder protection relay

The metrosil is there to prevent very high voltages occuring under heavy fault conditions. These voltages would otherwise damage the CT, the relay, and the wiring. The stabilising resistor in principle converts the current operated relay into a voltage operated relay. Highly recommended. http://www.areva-td.com/servlet/ContentServer?page... For older type of schemes:

Transformators: Low impedance diff (bias or unbias) over the windings and high impedance diff (REF-protection) over the windings and the neutral CT. REF stands for restricted earth fault protection. Busbars: High impedance diff in all the zones which include different incomers and feeders. A typical zone can consist out of an incomer and 4 feeders (15 CTs), which make a low impedance diff circuit difficult.

Q:

Where to use High & Low impedance differential protection? I want to know, where should we use high impedance differential protection and where low impedance should be used? What are the advantages & disadvantages of both schemes? Please see thread 238-216247: High Impedance Differential protection

Ans:

High Impedance: Since it is having greater stability (during CT sat)for out of zone faults than low impedance version. Mainly used in Bus protection and Transformer (resistance grounded) REF protection schemes. Low cost, simple design, easy testing, needs accurate CT and wiring data to set the voltage setting. , there everything should be identical starting from turns ratio. knee point voltage, winding resistance and exciting current. Hi Z is traditionally used where there are numerous CT inputs to deal with, such as bus differential. Ct's designed for HI protection will have higher knee point voltage when compared to LI protection which will increase the cost of CT production. In my opinion for new substation where CTs are identical High Impedance 87B, is the best solution. However, in case of expansion or having different CTs low impedance should be use. Configuration, setup, and testing is much simpler with the Hi Z bus diff relaying. High impedance relay use for 87B, 87REF, 87 shunt reactor, etc. High impedance relays are much cheaper, simple design, and have been in service 10's of years. All other relays are Low impedance type. Diff low impedance is used for 87T. Low impedance: Low stability for out of zone faults. Mainly used in Bus Protection, Transformer, Generator and Motor Differential protection schemes. Also with present day microprocessor based relays, Transformer REF schemes can have low impedance version too. In LI we can use different ratio Ct's but not in HI Low Z was normally used for differential zones with two or three sets of CRTs, such as transformers, generators and motors. I don't think any problem in using LI protection scheme for bus bar, For multiple bus configuration we must go for LI protection, if we use HI protection, we have to switch the CT circuit, which may lead to mal operation of protection if there is any failure in switching, IF we use LI, only we have to give isolator input for bus selection, central unit

of BB protection will do the rest. I don't agree with the others who are saying that HI will be stable during external faults but not LI to counter this one we are using biased differential protection, how transformer biased differential protection works, it has to be stable for external faults, same way LI for bus bars also. A good reference on the principles of busbar protection can also be found at http://pm.geindustrial.com/FAQ/Documents/B30/GER-3984.pdf

Creepage Distance-Is it a Reliable Design Parameter?

Thomas Johansson, Robert Axelsson, Sven Nord Ceram Group Introduction

Creepage Distance(CD) has many advantages. It is easy to understand, visualise, calculate and measure. A disadvantage is that it does not accurately predicting the electrical performance of Insulators of various diameters. Even following IEC standards, the accuracy of the calculations are limited. The poorer performance, under polluted conditions, of lager diameter versus smaller diameter Insulators, both designed in accordance with IEC standards, similar profiles and located in the same position, indicates the need for more accurate design parameters than those offered by CD.

3.11. Creepage Distance The shortest distance, or the sum of the shortest distances, along the contours of the external surfaces of the insulating parts of the insulator between those parts which normally have the operating voltage between them. 3.12. Specific Creepage Distance The overall creepage distance of an insulator divided by the highest operating voltage across the insulator. It is generally expressed in mm/kV. CE to check 3.13. Dry Arcing Distance The shortest distance in air external to the insulator between those parts which normally have the operating voltage between them.

Vous aimerez peut-être aussi

- Shunt Reactor Outline DrawingDocument1 pageShunt Reactor Outline DrawingHamayoun MurtazaPas encore d'évaluation

- ElevationDocument1 pageElevationHamayoun MurtazaPas encore d'évaluation

- 变压器安装现场用的设备、工具及材料Document11 pages变压器安装现场用的设备、工具及材料Hamayoun MurtazaPas encore d'évaluation

- Bushing DesignDocument1 pageBushing DesignHamayoun MurtazaPas encore d'évaluation

- Imperial Units Length: Edmund GunterDocument2 pagesImperial Units Length: Edmund GunterHamayoun MurtazaPas encore d'évaluation

- Altitude or HeightDocument1 pageAltitude or HeightHamayoun MurtazaPas encore d'évaluation

- Quality of Vacuum: Quality Torr Pa Milli BarDocument1 pageQuality of Vacuum: Quality Torr Pa Milli BarHamayoun MurtazaPas encore d'évaluation

- Imperial Units MassDocument2 pagesImperial Units MassHamayoun MurtazaPas encore d'évaluation

- Thunderbird ConfigurationDocument2 pagesThunderbird ConfigurationHamayoun MurtazaPas encore d'évaluation

- 500KV Switch Yard DrawingDocument2 pages500KV Switch Yard DrawingHamayoun MurtazaPas encore d'évaluation

- Campus MapDocument1 pageCampus MapHamayoun MurtazaPas encore d'évaluation

- e-BD CardDocument2 pagese-BD CardHamayoun MurtazaPas encore d'évaluation

- Post Question Post Answer My Panel SearchDocument3 pagesPost Question Post Answer My Panel SearchHamayoun MurtazaPas encore d'évaluation

- Instrument Transformers 11010Document48 pagesInstrument Transformers 11010Hamayoun MurtazaPas encore d'évaluation

- Merlin GerinDocument2 pagesMerlin GerinHamayoun MurtazaPas encore d'évaluation

- MCBDocument2 pagesMCBHamayoun MurtazaPas encore d'évaluation

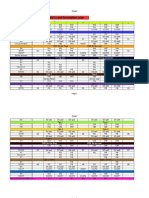

- Technical and Financial EvaluationDocument39 pagesTechnical and Financial EvaluationHamayoun MurtazaPas encore d'évaluation

- Symmetrical ComponentsDocument2 pagesSymmetrical ComponentsHamayoun Murtaza100% (1)

- Power Transformers: Your Partner in Energy SolutionsDocument24 pagesPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaPas encore d'évaluation

- Project Management Procedures4266Document27 pagesProject Management Procedures4266Hamayoun MurtazaPas encore d'évaluation

- Creepage DistanceDocument2 pagesCreepage DistanceHamayoun MurtazaPas encore d'évaluation

- Postgraduate Courses (PGD) : Sheet1Document1 pagePostgraduate Courses (PGD) : Sheet1Hamayoun MurtazaPas encore d'évaluation

- What Is Trip Circuit Supervision Relay How Does It Work in SwitchgearDocument7 pagesWhat Is Trip Circuit Supervision Relay How Does It Work in SwitchgearHamayoun MurtazaPas encore d'évaluation

- Open Circuit Test On TransformerDocument2 pagesOpen Circuit Test On TransformerHamayoun MurtazaPas encore d'évaluation

- LEcture 2 InstrumentationDocument54 pagesLEcture 2 InstrumentationHamayoun MurtazaPas encore d'évaluation

- Preventive Maintenance and Reliability of LV Overcurrent Protective DevicesDocument7 pagesPreventive Maintenance and Reliability of LV Overcurrent Protective DevicesHamayoun MurtazaPas encore d'évaluation

- High Frequency VCO Design and SchematicsDocument18 pagesHigh Frequency VCO Design and SchematicsHamayoun MurtazaPas encore d'évaluation

- Tan DeltaDocument1 pageTan DeltaHamayoun MurtazaPas encore d'évaluation

- Sab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsDocument2 pagesSab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsHamayoun MurtazaPas encore d'évaluation

- Three Winding Transformers and HarmonicsDocument2 pagesThree Winding Transformers and HarmonicsHamayoun MurtazaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- B450M DS3H: User's ManualDocument42 pagesB450M DS3H: User's ManualIsmael ZamoranoPas encore d'évaluation

- The ISO 30401 Knowledge Management Systems: A New Frame For Managing Knowledge. Conceptualisation and PracticeDocument14 pagesThe ISO 30401 Knowledge Management Systems: A New Frame For Managing Knowledge. Conceptualisation and PracticeGANIMEDES TRIMEGISTRO ROSALES REYESPas encore d'évaluation

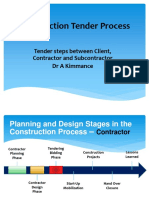

- Construction Tender ProcessDocument12 pagesConstruction Tender Processwidyo saptotoPas encore d'évaluation

- Analysis of Miss Call Issue V2 0Document8 pagesAnalysis of Miss Call Issue V2 0Armaghan AhmadPas encore d'évaluation

- Timeslots On The Abis InterfaceDocument18 pagesTimeslots On The Abis InterfaceHouss HoussiPas encore d'évaluation

- Polaris 1996 SLT780 Owner's Manual 02Document90 pagesPolaris 1996 SLT780 Owner's Manual 02Scott Spectra BritePas encore d'évaluation

- Cap Electrolitic 10-100V - 0.1 To 22000uf DatasheetDocument5 pagesCap Electrolitic 10-100V - 0.1 To 22000uf DatasheetHebert DennisPas encore d'évaluation

- Infoblox CLI Guide: NIOS 6.1 For Infoblox Network Core Services AppliancesDocument118 pagesInfoblox CLI Guide: NIOS 6.1 For Infoblox Network Core Services AppliancesPriyanto UkiPas encore d'évaluation

- A085hydraulicactuators PDFDocument2 pagesA085hydraulicactuators PDFCesar PomposoPas encore d'évaluation

- Compresor 10119 - 13 - 8 - 10 - Et DLT2101 100705 C210TS-9Document68 pagesCompresor 10119 - 13 - 8 - 10 - Et DLT2101 100705 C210TS-9Christian Andy H. Chavez100% (2)

- CESU Safe Practice in Power DistributionDocument26 pagesCESU Safe Practice in Power DistributionDevanand PallikuthPas encore d'évaluation

- Base Compensation - PeoplesoftDocument270 pagesBase Compensation - PeoplesoftkumarnujPas encore d'évaluation

- Fci Borivali ContractDocument3 pagesFci Borivali ContractnickPas encore d'évaluation

- Ansi Asabe D241.4 Oct1992 (R2008)Document4 pagesAnsi Asabe D241.4 Oct1992 (R2008)StephanPas encore d'évaluation

- Link Belt298 HSLTDocument36 pagesLink Belt298 HSLTIvan Sevillano Sanchez100% (1)

- Blackmagic 3G-SDI Arduino Shield PDFDocument262 pagesBlackmagic 3G-SDI Arduino Shield PDFTariq AngelPas encore d'évaluation

- Manual - iGO Primo 2.0Document134 pagesManual - iGO Primo 2.0emersonsfcPas encore d'évaluation

- Config WCMDocument22 pagesConfig WCMSUJAYPas encore d'évaluation

- Standoff AnodeDocument43 pagesStandoff Anodehendry_hdw100% (2)

- Motor Starting: Why Do The Calculation?Document13 pagesMotor Starting: Why Do The Calculation?carlos_eqnPas encore d'évaluation

- Acoustic AssignmentDocument19 pagesAcoustic AssignmentLaptuca Gabriel100% (1)

- Ccie Routing SwitchingDocument20 pagesCcie Routing SwitchingMusaib SyedPas encore d'évaluation

- Fire Protection and Safety FacilitiesDocument41 pagesFire Protection and Safety Facilitiesonur gunesPas encore d'évaluation

- Brochure Scania Irizar I8Document10 pagesBrochure Scania Irizar I8MioMaulenovoPas encore d'évaluation

- True Service ManualDocument121 pagesTrue Service ManualAnthony Manrique67% (3)

- Pt. Global Power Services: Section11-Piping SystemDocument18 pagesPt. Global Power Services: Section11-Piping SystemDangolPas encore d'évaluation

- Catalogue - LS-Titan Position SwitchesDocument33 pagesCatalogue - LS-Titan Position SwitchesRicardo CalmonPas encore d'évaluation

- Excavator Pe Senile HB365-3Document24 pagesExcavator Pe Senile HB365-3Cheta ElizaPas encore d'évaluation

- BS 6364-1984Document11 pagesBS 6364-1984harshithreemaPas encore d'évaluation