Académique Documents

Professionnel Documents

Culture Documents

Practical Motor Starting E161 PDF

Transféré par

micrefeeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Practical Motor Starting E161 PDF

Transféré par

micrefeeDroits d'auteur :

Formats disponibles

www.PDHcenter.com PDH Course E161 www.PDHonline.

org

Page 1 of 12

Practical Motor Starting

Richard W. Fruge, P.E. (Inactive)

Course Content

Motor acceleration time at various terminal voltage

levels must often be determined to evaluate

protective device performance or for power system

studies. This module presents a well-documented

methodology that is often used by engineers and

requires only published motor and load data. The

methodology presented here calculates a current

exponent ratio and a torque exponent ratio that

more accurately describes motor performance at

reduced voltage levels. In order to enhance the

utility of this methodology, a real world example

that includes a belt driven fan load is used. A

template that can be readily used in other motor

acceleration time calculations will be developed.

Equations describing motor performance will be

presented to demonstrate the relationship between

the various motor parameters used to calculate

motor acceleration time. Equations describing fan

performance will be presented to demonstrate the

relationship between the various fan parameters

and the impact of load performance on the motor

driving that load. An exercise using the motor and

load equations will then be presented to

demonstrate the motor starting time calculation

methodology.

Evaluation of the acceleration time at a different

motor terminal voltage requires re-calculation of the

motor torque and accelerating torque. Automating

the calculation can minimize the impact of this

requirement. A toolbox automating the motor

starting time calculation is presented in this module

to demonstrate the time saving and error reduction

potential. A general discussion of a calculation

automation process is also presented to detail the

resource requirements for implementing such a

process. A working copy of the toolbox is available

at no additional cost to the engineer using this

module.

I. MOTOR EQUATIONS

The general equation for motor acceleration time, t,

is:

n

2

T 308

N wk

t

= (Eq. 1)

where

load and motor the of Inertia wk

2

= (lb-ft

2

)

) RPM ( speed Motor N =

=

n

Accelerating torque (ft-lb)

Accelerating torque is the torque available to

accelerate the load. The load speed-torque curve

and the motor speed-torque curve are divided into

increments of at least 10% of motor speed ( N )

and the torque at the center of each increment

(

avg n

T for each N ) can be used to calculate the

acceleration time.

=

avg n

2

tot

T 308

N wk

t (Eq. 2)

Since our example uses a belt driven fan load, the

equivalent inertia of the load must be referred to

the prime mover. The inertia of driven equipment

(driven by pulleys) is referred to the motor shaft as

follows:

2

2

motor

2

load 2

eff

wk

RPM

RPM

wk = (Eq. 3)

Similarly, the torque of equipment driven by pulleys

can be referred to the motor shaft as follows:

load

motor

load

eff

T

RPM

RPM

T = (Eq. 4)

Motor nameplates generally contain the following

data:

1. Voltage

2. Horsepower rating

3. Rated speed

4. FLA - Full Load Amps

5. LRA Locked Rotor Amps

6. PF Power Factor

This data and motor performance curves are usually

provided in documentation supplied with the motor.

Data associated with motor performance at a

reduced terminal voltage is sometimes provided, if

required by the motor specification.

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 2 of 12

The relationship between horsepower and torque is

given by the equation:

ft lb

RPM

5250 hp

= (Eq. 5)

Motor manufacturers indicate the following

conditions are likely to occur with variations in

voltage:

1. An increase or decrease in voltage may

result in increased heating at rated

horsepower load. Extended operation at

other than nameplate voltage may

accelerate insulation deterioration and

shorten motor insulation life.

2. Increases in voltage will usually result in a

decrease in power factor, while a decrease

in voltage will result in an increase in power

factor.

3. Locked-rotor and breakdown torque will be

proportional to the square of the voltage.

Therefore, a decrease in voltage will result

in a decrease in available torque.

(Reference Equations 6 & 7 below).

4. An increase in voltage will result in a

reduction of slip. A voltage reduction would

increase slip.

IEEE Standard 112 (Reference 1) allows motor

performance to be determined based on tests made

at reduced voltage. The standard also states ..it

should be recognized that, because of saturation of

the leakage flux paths, the current may increase by

a ratio greater than the first power of the voltage;

and the torque may increase by a ratio greater than

the square of the voltage. The relationship varies

with design; however, as a first approximation, the

current is calculated as varying directly with voltage,

and torque with the square of the voltage.

Motor vendors using this method generally use a

more exact method, which is to determine the rate

of change of current and torque with voltage. The

reduced voltage test points are plotted on log-log

paper and corrected to rated voltage using a least

squares curve fit for maximum accuracy. This

results in the determination of a Torque Exponent

Ratio and a Current Exponent Ratio for the motor.

The Torque Exponent Ratio is calculated using the

corrected full voltage locked rotor torque and

reduced voltage locked rotor torque as follows:

( ) ( )

=

rv

fv

V

V

Log

lrrv

Log

lrfv

Log

1 K (Eq. 6)

Motor performance curves can be used to calculate

motor parameters at reduced terminal voltage

values as follows:

1 V

1 K

2 V

1 V

2 V

= (Eq. 7)

where:

2 voltage at Torque

2 V

=

1 voltage at Torque T

1 V

=

1 V

T and V1 are usually extrapolated from motor

performance data (i.e. read from the performance

curve).

The Current Exponent Ratio is calculated using the

full voltage locked rotor current and reduced voltage

locked rotor current as follows:

( ) ( )

=

rv

fv

V

V

Log

lrrv

I Log

lrfv

I Log

2 K (Eq. 8)

Motor performance curves can be used to calculate

motor parameters at reduced terminal voltage

values as follows:

1 V

2 K

2 V

I

1 V

2 V

I

= (Eq. 9)

where:

2 voltage at Current I

2 V

=

1 voltage at Current I

1 V

=

1 V

I and V1 are usually extrapolated from motor

performance data (i.e. read from the performance

curve or from test data). Equations 8 & 9 are used

to calculate reduced voltage motor currents at

locked rotor, pull up, and break down points. This is

a direct result of the fact that a motor exhibits

characteristics of a "constant impedance" device

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 3 of 12

while starting and characteristics of a "constant

KVA" device while running. Using the equation for

calculating the KVA load of a running motor as

follows, one can readily see the "constant KVA"

characteristics:

Eff PF

hp

KW

746 . 0 bhp

KVA

=

An estimated Torque Exponent Ratio of 2.2 and

Current Exponent Ratio of 1.1 can be used when

test data is not available (Reference 2) for

calculating these values.

II. FAN EQUATIONS

Equations related to fan performance are presented

here to provide a means of evaluating effects on

motor loading. The equations provided can also be

used to evaluate the impact of motor terminal

voltage variations on fan performance.

Equations 10, 11, and 12 below are frequently

called the Fan Laws. Fan performance

parameters include Cubic Feet per Minute (CFM),

Static Pressure (SP), and Brake Horsepower (BHP).

Subscript 1 refers to existing conditions and

subscript 2 refers to new conditions.

1

1

2

2

CFM

RPM

RPM

CFM

= (Eq. 10)

1

2

1

2

2

SP

RPM

RPM

SP

= (Eq. 11)

1

3

1

2

2

BHP

RPM

RPM

BHP

= (Eq. 12)

Equation 5 and Equation 12 can be used to derive a

torque-speed relationship for the fan. This is useful

when a torque-speed curve for a motor is to include

the fan curve. The fan torque-speed relationship

shown in Figure 1 is given by:

1

2

1

2

2

T

RPM

RPM

T

= (Eq. 13)

Equations 10 through 13 demonstrate the effect that

a change in motor speed or gear/pulley ratio would

have on fan performance and motor requirements.

For example, any change that increases the fan

RPM would result in the following:

increased air flow (equation 10). This

change would be proportional to the speed

change.

increased static pressure (equation 11).

This change would be proportional to the

square of the speed change.

increased motor hp to drive the load

(equation 12).

increased motor torque requirement

(equation 13). This change would be

proportional to the square of the speed

change of the fan, then translated to the

motor shaft in accordance with equation 4.

III. Exercise for Motor Acceleration Time

Calculation

A motor starting time calculation at 80% rated

terminal voltage will be used to demonstrate the

concepts discussed above.

Load Data

Fan performance at 100% design speed are

specified as follows:

BHP =130 hp

wk

2

=450 lb-ft

2

RPM =960

Using the Torque-hp relationship given in Eq. 5:

ft lb 94 . 710

RPM

5250 hp

=

= .

This value can then be used to generate a fan

torque-speed curve using the Torque-speed

relationship given in Eq. 13 as follows:

2

1

2

1 2

RPM

RPM

=

The resulting fan torque-speed curve is shown on

Figure 1.

The fan is driven with a belt on a 16 sheave at the

fan and a 9 sheave at the motor. This results in

fan speed that is (9/16) x motor speed (i.e.

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 4 of 12

56.25%). The load torque referred to the motor

shaft is calculated using Eq. 4 as follows:

load

motor

load

eff

T

RPM

RPM

T =

load eff

T 5625 . T =

The fan inertia referred to the motor shaft is

calculated using Eq. 3 as follows:

2

2

motor

2

load 2

eff

wk

RPM

RPM

wk =

2 2 2

eff

ft lb 383 . 142 450 5625 . wk = =

Motor Data

The following motor parameters are provided:

Locked Rotor Current =920 A

Locked Rotor Torque =700 lb-ft

wk

2

=80 lb-ft

2

Torque Exponent Ratio =2.25

Current Exponent Ratio =1.15

Voltage Rating =460 V

Speed =1785 RPM

The motor speed-torque curve is provided in

Figure 2. This curve also contains the Figure 1 fan

speed-torque characteristics referred to the motor

shaft using Eq. 4. In order to demonstrate the

starting time calculation, Table 1 lists the motor

speed-torque values, Table 2 lists the fan (load)

speed-torque values, and Table 3 provides the

accelerating torque (T

n avg

) values.

Table 1 (Motor)

% Speed N rpm T

avg

lb-ft

0 - 10 180 685

10 - 20 180 660

20 - 30 180 640

30 40 180 638

40 50 180 638

50 60 180 642

60 70 180 650

70 80 180 685

80 90 180 775

90 94 72 880

94 96 36 1080

96 98 36 1125

98 99.2 21.6 800

Table 2 (Fan T

eff

)

% Speed N rpm T

avg

lb-ft

0 - 10 180 1.11

10 - 20 180 10.01

20 - 30 180 27.8

30 40 180 54.49

40 50 180 90.08

50 60 180 134.56

60 70 180 187.94

70 80 180 250.22

80 90 180 321.4

90 94 72 376.51

94 96 36 401.47

96 98 36 418.55

98 99.2 21.6 432.47

Table 3 (Accel erating Torque)

% Speed N rpm T

n avg

lb-ft

0 - 10 180 683.89

10 - 20 180 649.99

20 - 30 180 612.20

30 40 180 583.51

40 50 180 547.92

50 60 180 507.44

60 70 180 462.06

70 80 180 434.78

80 90 180 453.60

90 94 72 503.49

94 96 36 678.53

96 98 36 706.45

98 99.2 21.6 367.53

Using Eq. 2 for each of the intervals in the tables to

calculate the time interval:

sec 19004 . 0

89 . 683 308

180 383 . 222

t

1

=

=

sec 19995 . 0

99 . 649 308

180 383 . 222

t

2

=

=

sec 21229 . 0

20 . 612 308

180 383 . 222

t

3

=

=

sec 22273 . 0

51 . 583 308

180 383 . 222

t

4

=

=

sec 23720 . 0

92 . 547 308

180 383 . 222

t

5

=

=

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 5 of 12

sec 25612 . 0

44 . 507 308

180 383 . 222

t

6

=

=

sec 28127 . 0

06 . 462 308

180 383 . 222

t

7

=

=

sec 29892 . 0

78 . 434 308

180 383 . 222

t

8

=

=

sec 28652 . 0

60 . 453 308

180 383 . 222

t

9

=

=

sec 10325 . 0

49 . 503 308

72 383 . 222

t

10

=

=

sec 03831 . 0

53 . 678 308

36 383 . 222

t

11

=

=

sec 03679 . 0

45 . 706 308

36 383 . 222

t

12

=

=

sec 04243 . 0

53 . 367 308

6 . 21 383 . 222

t

13

=

=

sec 40581 . 2 t t

13

1

start

= =

In order to demonstrate the starting time calculation

at 80% motor terminal voltage, Table 4 lists the

motor speed-torque values. The torque values are

calculated using the Table 1 torque values and Eq.

7. Table 2 is used for the fan (load) speed-torque

values, since the lower motor terminal voltage does

not affect the fan characteristics. Table 5 provides

the new (Table 4 minus Table 2) accelerating torque

(T

n avg

) values.

Table 4 (Motor 80% termi nal voltage)

% Speed N rpm T

avg

lb-ft

0 - 10 180 414.61

10 - 20 180 399.48

20 - 30 180 387.38

30 40 180 386.17

40 50 180 386.17

50 60 180 388.59

60 70 180 393.43

70 80 180 414.61

80 90 180 469.09

90 94 72 532.64

94 96 36 653.70

96 98 36 680.93

98 99.2 21.6 484.22

Table 5 (Accel erating Torque)

% Speed N rpm T

n avg

lb-ft

0 - 10 180 413.50

10 - 20 180 389.47

20 - 30 180 359.58

30 40 180 331.68

40 50 180 296.09

50 60 180 254.03

60 70 180 205.49

70 80 180 164.39

80 90 180 147.69

90 94 72 156.13

94 96 36 252.23

96 98 36 262.38

98 99.2 21.6 51.75

sec 31430 . 0

50 . 413 308

180 383 . 222

t

1

=

=

sec 33369 . 0

47 . 389 308

180 383 . 222

t

2

=

=

sec 36144 . 0

58 . 359 308

180 383 . 222

t

3

=

=

sec 39184 . 0

68 . 331 308

180 383 . 222

t

4

=

=

sec 43894 . 0

09 . 296 308

180 383 . 222

t

5

=

=

sec 51162 . 0

03 . 254 308

180 383 . 222

t

6

=

=

sec 63246 . 0

49 . 205 308

180 383 . 222

t

7

=

=

sec 79057 . 0

39 . 164 308

180 383 . 222

t

8

=

=

sec 87999 . 0

69 . 147 308

180 383 . 222

t

9

=

=

sec 33296 . 0

13 . 156 308

72 383 . 222

t

10

=

=

sec 10305 . 0

23 . 252 308

36 383 . 222

t

11

=

=

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 6 of 12

sec 09906 . 0

38 . 262 308

36 383 . 222

t

12

=

=

sec 30137 . 0

75 . 51 308

6 . 21 383 . 222

t

13

=

=

sec 49130 . 5 t t

13

1

start

= =

The starting time at 80% motor terminal voltage has

more than doubled the time calculated at rated

motor terminal voltage, as expected. It is interesting

to note here that the most widely used methodology

for calculating motor starting time "assumes" that

the torque varies with the square of the voltage

ratio. Using that methodology would have resulted

in a starting time of 4.85414 seconds in this

example exercise. It is obvious that the difference

resulting from that assumption would affect system

voltage studies using static motor starting models.

If the torque exponent ratio was not known to be

2.25 as specified in this exercise, and using the

assumption that K =2.2 (Reference 2) yields a

starting time of 5.34772 seconds. The difference

resulting from this assumption would have a much

less severe impact on system studies.

IV. AUTOMATION

The discussion presented in the previous sections

of this module provides an excellent case for

automating a calculation process. The same

equations are solved for multiple data points.

Therefore, development of a program to store the

data and solve the equations for all the data would

appear to be a reasonable endeavor. Automation of

this process not only simplifies the calculation, but

also reduces the possibility of errors.

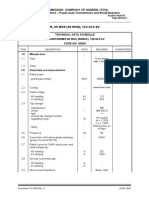

Figures 3 & 4 show the output of a motor start time

program developed using Microsoft Access 97. The

output represents the results of the example

exercise at 100% and 80% motor terminal voltage.

The program implements the motor starting time

calculation described in equations 1 & 2. Use of a

database eliminates the need for specially formatted

data files and provides an intuitive user interface

(input forms). Additionally, use of a database allows

for storage of motor and load performance data for

reuse in many motor case studies.

Forms are designed to perform and store the results

of the torque exponent ratio and current exponent

ratio calculations described in equations 6 & 8. All

the attributes and properties of a relational database

are used to minimize required input. The capability

to calculate reduced voltage locked rotor torque for

an assumed torque exponent ratio is also included.

The program uses the stored performance data to

generate a report that contains the starting time

calculation results in a tabular format. The

computations are made inside the report,

eliminating the requirement to store the results in

the database. Motor starting time can be evaluated

at a different voltage level by entering the new

voltage, selecting "UPDATE", then printing the

results.

Development of programs of this type eliminates the

computational aspects of motor starting calculations

and would require an investment of 40 to 50 man

hours. The possibilities for automation are endless,

and customization to meet specific requirements is

easily achieved by engineers with minimal

programming skills.

Students using this module for PDH credit may

request a free copy of the program described

above. This will enable them to explore the benefits

that could be realized by automating repetitive

tasks, as well as provide them with a sense of what

is involved in the application of an automated

approach to calculation systems. Email the author

to request your free copy of the tool at

rwfruge@yahoo.com.

The flexibility of this automated calculation tool will

now be demonstrated by analyzing a what if

example using the program described above.

What if the motor vendor rating for the motor was

changed to include a torque exponent ratio (K1) of

2.15 and the minimum motor terminal voltage was

90%. Compare the results with Figure 4.

You would copy the Figure 3 performance data and

paste to a new record (Figure 5). Select the Torque

Exponent Ratio tab, enter the full voltage torque,

enter 90 % for the voltage ratio, enter 2.15 for the

Torque Exponent Ratio, and then press

CALCULATE T2. Return to the Motor Data tab and

observe that TEST VOLTS is 90% and the reduced

voltage locked rotor torque value is 558.110. Use

HEADERS to prepare the desired report header,

then press PRINT RESULTS. When compared to

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 7 of 12

the results in Figure 4, observe that the reduce

voltage motor torque values and the net

(accelerating) torque values have increased and the

resulting starting time has been reduced to 3.3184

seconds. As expected, the new starting time is

greater than the full voltage starting time and less

than the 80% voltage starting time.

V. SUMMARY

Methods are described to analyze motor starting

time with reduced motor terminal voltage. The

methods described include the generally accepted

assumption that the torque varies with the square

of the voltage ratio, as well as use of reduced

voltage test data to more precisely calculate the

impact of voltage on the motor torque. Equations

for "translating" belt driven load data to the motor

shaft are presented. The Fan Laws are also

provided to demonstrate the impact that motor

RPM changes would have on fan performance.

The practice exercise demonstrates the repetitive

calculations required to evaluate the motor

accelerating time and the impact of reduced motor

terminal voltage on those calculations. Examples

included full voltage and 80% voltage cases.

An automated calculation tool is presented and an

analysis of motor starting time with different

terminal voltage and motor torque characteristics

demonstrates the benefits of "automating"

calculations. The program is provided to users of

this module to demonstrate automation

possibilities.

References

1. IEEE Standard 112, 1991

2. EPRI Power Plant Electrical Reference Series,

Volume 6, Motors, Dated 1987.

PDH Course E161 Practical Motor Starting

Figure 1

Page 8 of 12

FAN 1

0

100

200

300

400

500

600

700

800

900

0 100 200 300 400 500 600 700 800 900 1000

RPM

l

b

-

f

t

PDH Course E161 Practical Motor Starting

Figure 2

Page 9 of 12

Torque Vs. Speed

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

% RPM

l

b

-

f

t

Motor 1

Fan 1

FLT

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 10 of 12

Practical Motor Starting Figure 3

Motor Starting Time Example Page 1 of 1

Motor 1

Voltage 460 V Terminal Voltage 100 %

Speed 1800 RPM Torque Exponent 2.2500

Inertia 222.383 lb-ft^2

Speed Speed Motor Torque Load Net

Increment Incremen (lb-ft) Torque Torque Time

(%) t (RPM) FV RV (lb-ft) (lb-ft) (Sec)

0.00 - 10.00 180.00 685.00 685.00 1.11 683.89 0.19004

10.00 - 20.00 180.00 660.00 660.00 10.01 649.99 0.19995

20.00 - 30.00 180.00 640.00 640.00 27.80 612.20 0.21229

30.00 - 40.00 180.00 638.00 638.00 54.49 583.51 0.22273

40.00 - 50.00 180.00 638.00 638.00 90.08 547.92 0.23720

50.00 - 60.00 180.00 642.00 642.00 134.56 507.44 0.25612

60.00 - 70.00 180.00 650.00 650.00 187.94 462.06 0.28127

70.00 - 80.00 180.00 685.00 685.00 250.22 434.78 0.29892

80.00 - 90.00 180.00 775.00 775.00 321.40 453.60 0.28652

90.00 - 94.00 72.00 880.00 880.00 376.51 503.49 0.10325

94.00 - 96.00 36.00 1080.00 1080.00 401.47 678.53 0.03831

96.00 - 98.00 36.00 1125.00 1125.00 418.55 706.45 0.03679

98.00 - 99.20 21.60 800.00 800.00 432.47 367.53 0.04243

Total Starting Time 2.40581

NOTES:

Fan wk^2 =450 lb-ft^2

Motor wk^2 =80 lb-ft^2

Total wk^2 =222.383 lb-ft^2

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 11 of 12

Practical Motor Starting Figure 4

Motor Starting Time Example Page 1 of 1

Motor 1

Voltage 460 V Terminal Voltage 80 %

Speed 1800 RPM Torque Exponent 2.2500

Inertia 222.383 lb-ft^2

Speed Speed Motor Torque Load Net

Increment Incremen (lb-ft) Torque Torque Time

(%) t (RPM) FV RV (lb-ft) (lb-ft) (Sec)

0.00 - 10.00 180.00 685.00 414.61 1.11 413.50 0.31430

10.00 - 20.00 180.00 660.00 399.48 10.01 389.47 0.33369

20.00 - 30.00 180.00 640.00 387.38 27.80 359.58 0.36144

30.00 - 40.00 180.00 638.00 386.17 54.49 331.68 0.39184

40.00 - 50.00 180.00 638.00 386.17 90.08 296.09 0.43894

50.00 - 60.00 180.00 642.00 388.59 134.56 254.03 0.51162

60.00 - 70.00 180.00 650.00 393.43 187.94 205.49 0.63246

70.00 - 80.00 180.00 685.00 414.61 250.22 164.39 0.79057

80.00 - 90.00 180.00 775.00 469.09 321.40 147.69 0.87999

90.00 - 94.00 72.00 880.00 532.64 376.51 156.13 0.33296

94.00 - 96.00 36.00 1080.00 653.70 401.47 252.23 0.10305

96.00 - 98.00 36.00 1125.00 680.93 418.55 262.38 0.09906

98.00 - 99.20 21.60 800.00 484.22 432.47 51.75 0.30137

Total Starting Time 5.49130

NOTES:

Fan wk^2 =450 lb-ft^2

Motor wk^2 =80 lb-ft^2

Total wk^2 =222.383 lb-ft^2

www.PDHcenter.com PDH Course E161 www.PDHonline.org

Page 12 of 12

Practical Motor Starting Figure 5

Motor Starting Time @ 90 % Page 1 of 1

Motor 1

Voltage 460 V Terminal Voltage 90 %

Speed 1800 RPM Torque Exponent 2.1500

Inertia 222.383 lb-ft^2

Speed Speed Motor Torque Load Net

Increment Incremen (lb-ft) Torque Torque Time

(%) t (RPM) FV RV (lb-ft) (lb-ft) (Sec)

0.00 - 10.00 180.00 685.00 546.15 1.11 545.04 0.23845

10.00 - 20.00 180.00 660.00 526.22 10.01 516.21 0.25177

20.00 - 30.00 180.00 640.00 510.27 27.80 482.47 0.26937

30.00 - 40.00 180.00 638.00 508.68 54.49 454.19 0.28615

40.00 - 50.00 180.00 638.00 508.68 90.08 418.60 0.31048

50.00 - 60.00 180.00 642.00 511.87 134.56 377.31 0.34445

60.00 - 70.00 180.00 650.00 518.24 187.94 330.30 0.39347

70.00 - 80.00 180.00 685.00 546.15 250.22 295.93 0.43917

80.00 - 90.00 180.00 775.00 617.91 321.40 296.51 0.43832

90.00 - 94.00 72.00 880.00 701.62 376.51 325.11 0.15990

94.00 - 96.00 36.00 1080.00 861.08 401.47 459.61 0.05655

96.00 - 98.00 36.00 1125.00 896.96 418.55 478.41 0.05433

98.00 - 99.20 21.60 800.00 637.84 432.47 205.37 0.07594

Total Starting Time 3.31834

NOTES:

Fan wk^2 =450 lb-ft^2

Motor wk^2 =80 lb-ft^2

Total wk^2 =222.383 lb-ft^2

Vous aimerez peut-être aussi

- Load Flow Analysis PDFDocument33 pagesLoad Flow Analysis PDFRakshitha VPas encore d'évaluation

- Transformer Protection 1594577509 PDFDocument63 pagesTransformer Protection 1594577509 PDFAdrián RomeroPas encore d'évaluation

- HV Winding Phase Overcurrent ProtectionDocument5 pagesHV Winding Phase Overcurrent Protection386Pas encore d'évaluation

- Motor Starting CasestudyDocument2 pagesMotor Starting Casestudykajale_shrikant2325Pas encore d'évaluation

- Motor Starting - Open ElectricalDocument12 pagesMotor Starting - Open ElectricalHoangPas encore d'évaluation

- Motor Starting Dynamic AccelerationDocument63 pagesMotor Starting Dynamic Accelerationashraf-84Pas encore d'évaluation

- Overcurrent and Overload Protection Using Protective Relays: Electricity and New EnergyDocument73 pagesOvercurrent and Overload Protection Using Protective Relays: Electricity and New EnergyKaisar PrimaPas encore d'évaluation

- IDMT Relay SettingDocument1 pageIDMT Relay SettingJeya KannanPas encore d'évaluation

- KVMRT MMJV SBK SS05 Sysw Rep PDS 000089Document349 pagesKVMRT MMJV SBK SS05 Sysw Rep PDS 000089syafiqishamuddinPas encore d'évaluation

- Slip Ring PresentationDocument12 pagesSlip Ring PresentationMynampati Sai SrinivasPas encore d'évaluation

- Fe-10 2e-7641-105 Short-Circuit Current CalculationDocument28 pagesFe-10 2e-7641-105 Short-Circuit Current CalculationNarayanaPas encore d'évaluation

- Electrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTDocument28 pagesElectrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTStefano FavaroPas encore d'évaluation

- Medium Voltage Variable Frequency DriveDocument39 pagesMedium Voltage Variable Frequency Drivekajale.shrikantPas encore d'évaluation

- 03 Directional OvercurrentDocument10 pages03 Directional OvercurrentM Kumar MarimuthuPas encore d'évaluation

- 07a Backup OCEF Relay - Tech. Data Check List CompletedDocument6 pages07a Backup OCEF Relay - Tech. Data Check List CompletedAnupam0103Pas encore d'évaluation

- E02C3112E (Power Socket Terminal Direction and Fixing Methode)Document6 pagesE02C3112E (Power Socket Terminal Direction and Fixing Methode)Heru AwanzPas encore d'évaluation

- Areva P443 Protection by Areva PaperDocument6 pagesAreva P443 Protection by Areva PaperRajesh BoddunaPas encore d'évaluation

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoPas encore d'évaluation

- Safelink CB: Gas Insulated Ring Main UnitDocument2 pagesSafelink CB: Gas Insulated Ring Main UnitABCDPas encore d'évaluation

- 7SJ61 As High Impedance RelayDocument36 pages7SJ61 As High Impedance Relayzarun1Pas encore d'évaluation

- Motor ProtectionDocument7 pagesMotor ProtectionAbhijit KumarPas encore d'évaluation

- Relay CoordinationDocument30 pagesRelay CoordinationMohamed MeeranPas encore d'évaluation

- CT Polarity On SIPROTEC Quick StartDocument5 pagesCT Polarity On SIPROTEC Quick StartedgardPas encore d'évaluation

- 11 KV Bay EquipmentDocument22 pages11 KV Bay EquipmentSudhir ShindePas encore d'évaluation

- 132kv Ss Vestas Test ReportDocument77 pages132kv Ss Vestas Test ReportdaminhvienPas encore d'évaluation

- Difference Between Vacuum Circuit Breaker & Vacuum ContactorDocument2 pagesDifference Between Vacuum Circuit Breaker & Vacuum ContactorMohan K67% (3)

- Tech Con 2011 Kruger New Experience With Diagn Meas On PTDocument15 pagesTech Con 2011 Kruger New Experience With Diagn Meas On PTMichael KrügerPas encore d'évaluation

- 100 STATOR EF P345 With 20HZ INJECTION Apr 09Document6 pages100 STATOR EF P345 With 20HZ INJECTION Apr 09Amaresh NayakPas encore d'évaluation

- 11kV SPBD General TechnicalDocument12 pages11kV SPBD General TechnicalNihar SenapatiPas encore d'évaluation

- CLPS - UAT Protection CT Sizing Calculations Rev ADocument5 pagesCLPS - UAT Protection CT Sizing Calculations Rev ATosikur RahmanPas encore d'évaluation

- GE-Guide To Instantaneous SelectivityDocument19 pagesGE-Guide To Instantaneous SelectivityJOSE LUIS FALCON CHAVEZPas encore d'évaluation

- Earthing Cal - Rev-01 - As Per Mecon Comnt.Document9 pagesEarthing Cal - Rev-01 - As Per Mecon Comnt.Prateek SinghPas encore d'évaluation

- Protection Directional OC & EFDocument54 pagesProtection Directional OC & EFbrijalPas encore d'évaluation

- Ansi CodesDocument6 pagesAnsi CodesAlbert Sekar0% (1)

- Technical Rules For The Assessment of Network Disturbances (HV) 2012Document47 pagesTechnical Rules For The Assessment of Network Disturbances (HV) 2012Fikret VelagicPas encore d'évaluation

- PGCIL ET Salary in Hand, Structure & Allowances - OlxamDocument3 pagesPGCIL ET Salary in Hand, Structure & Allowances - OlxamAravindanPas encore d'évaluation

- 1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsDocument14 pages1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsjmohammadrezaPas encore d'évaluation

- One Case Study-Practical Protection Engineering BasicDocument4 pagesOne Case Study-Practical Protection Engineering BasicarsalanhamidPas encore d'évaluation

- 04 - Transformer SizingDocument19 pages04 - Transformer Sizingashraf-84Pas encore d'évaluation

- 7714-U0bk8-00 (RD Yl BL BK)Document3 pages7714-U0bk8-00 (RD Yl BL BK)vsswami_82Pas encore d'évaluation

- Overall Understanding of Voltage Transformer 1683194716Document4 pagesOverall Understanding of Voltage Transformer 1683194716rupali patilPas encore d'évaluation

- Voltage Drop Calculation of 11kV H.V. Motor at Starting: ST STDocument2 pagesVoltage Drop Calculation of 11kV H.V. Motor at Starting: ST STdpkfatnani05Pas encore d'évaluation

- Single Line To Ground FaultDocument12 pagesSingle Line To Ground Faultluhusapa-1Pas encore d'évaluation

- Outline ETAP PDFDocument1 pageOutline ETAP PDFSiddarthan AnnamalaiPas encore d'évaluation

- Arc Flash Analysis and Mitigation Solutions - IIEE WCCDocument155 pagesArc Flash Analysis and Mitigation Solutions - IIEE WCCJake LozantaPas encore d'évaluation

- 50smss1 (Specification For Current Transformer Up To 380kv)Document21 pages50smss1 (Specification For Current Transformer Up To 380kv)engrandyPas encore d'évaluation

- NTPC CW - 3006600303 - Sec - C - Rev - BDocument93 pagesNTPC CW - 3006600303 - Sec - C - Rev - BGautamupadhyay100% (1)

- CYMTCC For Windows: User's Guide and Reference ManualDocument290 pagesCYMTCC For Windows: User's Guide and Reference ManualJosselynGalloMuñozPas encore d'évaluation

- Transformer Details ReportDocument1 pageTransformer Details Reportwaseem kausarPas encore d'évaluation

- Power Systems Relays Relion 670Document43 pagesPower Systems Relays Relion 670kass_ecsPas encore d'évaluation

- Cap P13Document5 pagesCap P13Siva NandhamPas encore d'évaluation

- Directional OverDocument28 pagesDirectional OverEdinson Milton Gaona BarbozaPas encore d'évaluation

- 14 Voltage Regulation and Per Unit SystemDocument13 pages14 Voltage Regulation and Per Unit SystemAlfredo Brumnić FredoPas encore d'évaluation

- Transient Stability 2Document29 pagesTransient Stability 2Carlos Ortiz de ZevallosPas encore d'évaluation

- Harmonic Analysis Hand Calculation For THDDocument3 pagesHarmonic Analysis Hand Calculation For THDFabian Andres Calderon HernandezPas encore d'évaluation

- 4202A, PowerTransformerDocument13 pages4202A, PowerTransformerkuttrPas encore d'évaluation

- IEEE CTs and PTs 6 10Document99 pagesIEEE CTs and PTs 6 10brianwg2100% (1)

- TechRef 3-W-Transformer 3phaseDocument40 pagesTechRef 3-W-Transformer 3phaseTorrez JeanPas encore d'évaluation

- Motor CalculationsDocument8 pagesMotor CalculationssmhbPas encore d'évaluation

- The Role of The Praise and Worship Leader: A Model For Preparing The Singer For Leadership in Contemporary WorshipDocument142 pagesThe Role of The Praise and Worship Leader: A Model For Preparing The Singer For Leadership in Contemporary WorshipmicrefeePas encore d'évaluation

- Quick Chilled Water EstimationDocument2 pagesQuick Chilled Water EstimationSami Khoury100% (5)

- R-407c by KevinDocument2 pagesR-407c by KevinmicrefeePas encore d'évaluation

- Carrier - Handbook of Air Conditioning System Design (Part 1)Document162 pagesCarrier - Handbook of Air Conditioning System Design (Part 1)Jonathan Castro96% (93)

- HAP44 ManualDocument148 pagesHAP44 ManualmicrefeePas encore d'évaluation

- ASMA BuildingDocument5 pagesASMA BuildingmicrefeePas encore d'évaluation

- Modified BitumenDocument2 pagesModified BitumenmicrefeePas encore d'évaluation

- GBI NREB Non-Residential Existing Building Tool V1.1 FinalDocument19 pagesGBI NREB Non-Residential Existing Building Tool V1.1 FinalIvan WongPas encore d'évaluation

- KeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiaDocument22 pagesKeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiamicrefeePas encore d'évaluation

- Apache ConfDocument19 pagesApache ConfAlexandra AguiarPas encore d'évaluation

- Java Applets and Awt ProgramsDocument48 pagesJava Applets and Awt Programsreddyksridhar880Pas encore d'évaluation

- UNIQUE Specifications VEO 1050I 0316 2 PDFDocument12 pagesUNIQUE Specifications VEO 1050I 0316 2 PDFAndrian Dede HandikaPas encore d'évaluation

- SE Experiment 5Document9 pagesSE Experiment 5Anurag ChorghePas encore d'évaluation

- OpenDesign Specification For .DWG Files PDFDocument262 pagesOpenDesign Specification For .DWG Files PDFBrainReaktorPas encore d'évaluation

- Support Device ListDocument60 pagesSupport Device Listfox7878Pas encore d'évaluation

- EM 13c2 LifeCycle Management LCMDocument1 276 pagesEM 13c2 LifeCycle Management LCMvikPas encore d'évaluation

- Vulkan Tutorial PDFDocument281 pagesVulkan Tutorial PDFabhijay25Pas encore d'évaluation

- BSCS Action PlanDocument2 pagesBSCS Action PlanAlvin CaragdagPas encore d'évaluation

- COMPLETEDVector BQ ASSGDocument25 pagesCOMPLETEDVector BQ ASSGAsyraf HakeemPas encore d'évaluation

- Delete Blank Rows in Excel - Easy Excel TutorialDocument5 pagesDelete Blank Rows in Excel - Easy Excel TutorialJamalodeen MohammadPas encore d'évaluation

- Pega CLSA Office Hour Note 1651953783Document21 pagesPega CLSA Office Hour Note 1651953783Chinmayee ParijaPas encore d'évaluation

- Manufacturing Execution System (MES) : Web AccessDocument42 pagesManufacturing Execution System (MES) : Web AccessNhat Tan MaiPas encore d'évaluation

- MS Excel Level 2 2010Document85 pagesMS Excel Level 2 2010Harshad DharodPas encore d'évaluation

- Enterprise StructureDocument16 pagesEnterprise StructureOfek DahariPas encore d'évaluation

- 7 13presentationDocument46 pages7 13presentationJagan Mohan RamanPas encore d'évaluation

- CAPTAIN-i Installation Manual (ENG) Rev J (05-2005)Document72 pagesCAPTAIN-i Installation Manual (ENG) Rev J (05-2005)JuanCarpizoPas encore d'évaluation

- Report Sem 3Document24 pagesReport Sem 3theycallmealwinPas encore d'évaluation

- SSRN Id3851056Document7 pagesSSRN Id3851056Isha MarlechaPas encore d'évaluation

- EAGLE Controller: Third-Party LicensesDocument20 pagesEAGLE Controller: Third-Party LicensesErmiasPas encore d'évaluation

- CAD ViewersDocument24 pagesCAD Viewersjohnaustin1Pas encore d'évaluation

- Ahe Iepf1 2010-11Document194 pagesAhe Iepf1 2010-11rajeshyoyo1993Pas encore d'évaluation

- Commandcalc: Instructions For Use GeneralDocument10 pagesCommandcalc: Instructions For Use Generalminhtutran1983Pas encore d'évaluation

- List of Vacancies FO September 07 2021Document25 pagesList of Vacancies FO September 07 2021Geronette PascuaPas encore d'évaluation

- Design and Development of Condition Monitoring and Control System For Distribution TransformerDocument48 pagesDesign and Development of Condition Monitoring and Control System For Distribution TransformerAddis Goshiye100% (2)

- Cognex Deep Learning: Textile Inspection Industry OverviewDocument7 pagesCognex Deep Learning: Textile Inspection Industry OverviewPrabhuti ChauhanPas encore d'évaluation

- CwcheatDocument6 pagesCwcheatFaqih Nabawi RamadhanPas encore d'évaluation

- Introduction To Solana - Grayscale-Building-Blocks-Solana-1Document18 pagesIntroduction To Solana - Grayscale-Building-Blocks-Solana-1openteknologiePas encore d'évaluation

- NCA 2 Instruction Manual 52482Document128 pagesNCA 2 Instruction Manual 52482Juan Lorenzo Martin100% (1)

- Manufacturing Engineer Laser Optical in Portland OR San Jose CA Resume John LafrentzDocument2 pagesManufacturing Engineer Laser Optical in Portland OR San Jose CA Resume John LafrentzJohnLafrentzPas encore d'évaluation