Académique Documents

Professionnel Documents

Culture Documents

MOM Piling Works WSH

Transféré par

hutuguoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MOM Piling Works WSH

Transféré par

hutuguoDroits d'auteur :

Formats disponibles

FACT SHEET OPERATION SANDPIPER Operation Sandpiper was part of MOM Occupational Safety and Health Department (OSHD)s

efforts to address the safety of crane/lifting operations at worksites, looking specifically at the use of cranes in bored piling activities 1 . 50 worksites were inspected between April and May this year. Background 2 In the last few years, piling works have contributed to both fatal incidents and dangerous occurrences. The table below shows the breakdown: 2011 2010 (Jan to June) 14 26 1 2 2 2 2 1 2009 21 1 10 0

Total number of Crane-Related Dangerous Occurrences (DOs) DOs due to piling works Crane-Related Workplace Fatalities Fatality due to piling works

3 In the first half of this year, both crane fatalities involved lifting activities carried out during piling works. One case involved a worker who died instantly after being struck by a fallen steel bar. A crane was lowering a steel cage into a borehole when the cage became dislodged from the crane hook and dropped into the borehole. As the cage fell, a piece of steel bar which was welded to the top of the cage struck the worker who had been standing near to the borehole. 4 During piling works, there are several critical areas that need to be properly managed. These include the method of bored piling and casing extraction 2 . Stakeholders must carry out proper risk assessments and implement the necessary safe work procedures. The development and implementation of proper Lifting Plans are critical in addressing issues such as: rigging of lifting gears to steel cages and pile casings; adequacy of the lifting gears used for the lifting operation; and assessment of ground conditions for the movement of cranes and piling rigs across the worksite.

Bored Piling is a process where steel circular casings are installed into the ground by the process of drilling and soil removal. This is then followed by placing of steel and concrete into the ground to form columns of bored piles. Bored piling activities relate to the activities done during installation of bored piles. 2 Casing extraction is the act of removing a steel casing that is installed in the ground for the purpose of installation of a bored pile.

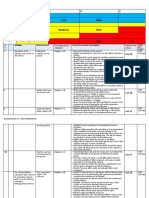

Results and Findings 5 Operation Sandpiper looked at these concerns at the 50 worksites inspected. Close to 80 contraventions were found, with $30,000 in compound fines (CFs) issued. The top 4 contraventions found were: i) ii) iii) iv) improper rigging methods; faulty safety devices; defective lifting gear; and failure to maintain lifting machines.

6 More information about these contraventions is in Annex. Follow-up checks by OSHD also showed that all 50 worksites had put proper measures in place to address these contraventions.

ANNEX OPERATION SANDPIPER - OVERVIEW Top 4 Contraventions No of contraventions Amount of CFs issued 1 Improper Rigging Methods 25 $12,500 2 Faulty Safety Devices 5 $2,500 3 Defective Lifting Gear 6 $3,000 4 Failure to Maintain Lifting Machines 4 $1,500

Total no. of contraventions = 79 Total amount of CFs issued = $30,000

NOTE: A Notice of non-compliance (NNC) serves as a warning for any breach of WSH regulations in the workplace. An Advisory letter is issued when there are safety and health concerns even though no part of the law had been breached. It advises Occupiers/employers to address the identified issues.

TOP FOUR CONTRAVENTIONS (1) IMPROPER RIGGING METHODS E.G. SINGLE LEGGED SLINGS FOR CASING INSTALLATION / EXTRACTION Improper rigging methods employed may cause damage to the slings being used e.g. crane hook used to fish the mid section of a sling often causes damage to the sling, which could subsequently lead to accidents e.g. collapse of loads lifted, toppling of cranes, etc.

Single legged sling The hook of the crane is used to fish this portion of the wire rope for casing extraction.

(2) DEFECTIVE LIFTING GEARS Lifting operations involving these defective lifting gears may lead to accidents causing serious injuries or even death e.g. collapse of loads lifted, toppling of cranes, etc. as a result of failure of the lifting gears during use. Hooks with safety latches and springs that are defective or damaged should not be used for lifting.

Twists and kinks on wire ropes indicate that wire ropes are damaged and should not be used.

Non-original pin, i.e. cotter pin, is used in place of original pins. The use of nonoriginal parts pose a danger as it may not be able to serve its function and may dislodge during operation.

(3) FAILURE TO MAINTAIN LIFTING MACHINE

This portion of the crane boom panel had broken off and was identified at the point of inspection.

(4) MODIFIED LIFTING GEARS

The safety latch is punctured through and attached with a string to enable the latch to be opened by pulling the string. This is a modification to the original safety latch and would pose a hazard of failure of the latch during lifting operations.

Vous aimerez peut-être aussi

- SCAL Construction Safety Seminar - Safe Work at Height (Howard How)Document28 pagesSCAL Construction Safety Seminar - Safe Work at Height (Howard How)ThanThansccPas encore d'évaluation

- Qcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFDocument124 pagesQcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFbryanpastor106100% (1)

- Wilhelmsen Wall Chart Safety Checklist For Welding Aug22Document1 pageWilhelmsen Wall Chart Safety Checklist For Welding Aug22Unitor ChrisPas encore d'évaluation

- Intel Construction EHS: Processes and Procedures ManualDocument127 pagesIntel Construction EHS: Processes and Procedures ManualRanjan BhaumikPas encore d'évaluation

- SS 679-2021 PreviewDocument6 pagesSS 679-2021 PreviewmasonPas encore d'évaluation

- CONQUAS StandardDocument9 pagesCONQUAS StandardBOYPas encore d'évaluation

- Cis 25 2018Document116 pagesCis 25 2018Megat Terawih100% (1)

- Garbage Chute Tender 2Document60 pagesGarbage Chute Tender 2Faizan100% (1)

- WSHC Bulletin - Accidents Involving Falling From HeightDocument3 pagesWSHC Bulletin - Accidents Involving Falling From HeightEric LimPas encore d'évaluation

- Basic Concepts of Occupational HealthDocument10 pagesBasic Concepts of Occupational Healthwakyereza derickPas encore d'évaluation

- WSH Awards 2018 Briefing (Auditors)Document58 pagesWSH Awards 2018 Briefing (Auditors)OnaFajardoPas encore d'évaluation

- LG - Hazards Identification (Level 5)Document64 pagesLG - Hazards Identification (Level 5)Ang Tze WeiPas encore d'évaluation

- Factories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Document46 pagesFactories and Machinery (Building Operations and Works of Engineering Construction) (Safety) Regulations, 1986 Ve - Pua328 - 1986Exsan Othman100% (1)

- Construction Industry Council: Development BureauDocument25 pagesConstruction Industry Council: Development BureauAlex Sandro Borges PereiraPas encore d'évaluation

- Ms Working PlatformDocument4 pagesMs Working Platformmohd solihin bin mohd hasan100% (1)

- SingaporeDocument162 pagesSingaporeabdirahmanPas encore d'évaluation

- Evaluation Criteria Table 1: Description of Likelihood (Probability)Document2 pagesEvaluation Criteria Table 1: Description of Likelihood (Probability)Rafee PiePas encore d'évaluation

- Injection Precast Concrete PileDocument18 pagesInjection Precast Concrete PileLee CwPas encore d'évaluation

- Crane Risk AssesmentDocument8 pagesCrane Risk AssesmentGilang ArdiPas encore d'évaluation

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- Hse-Cl-064. Scaffold Safety Inspection CertificateDocument2 pagesHse-Cl-064. Scaffold Safety Inspection CertificateZafira JamilPas encore d'évaluation

- Technical Note TN 073 Self Compacting ConcreteDocument4 pagesTechnical Note TN 073 Self Compacting ConcreteKhaja MohiddinPas encore d'évaluation

- Demolition Risk AssessmentDocument4 pagesDemolition Risk AssessmentNIJESHPas encore d'évaluation

- dc16 14Document24 pagesdc16 14Subramanian SaravananPas encore d'évaluation

- CHS Method StatementDocument3 pagesCHS Method StatementjatinPas encore d'évaluation

- Incipient Stage Fire Extinguisher Education OSHA 1910.157 (G)Document51 pagesIncipient Stage Fire Extinguisher Education OSHA 1910.157 (G)Azher AhmedPas encore d'évaluation

- Cis22 2021Document47 pagesCis22 2021MOHD AFIF BIN MOHD ZALIPas encore d'évaluation

- WSH Guide To Behavioural Observation InterventionDocument17 pagesWSH Guide To Behavioural Observation InterventionGading Diah Zahara PutriPas encore d'évaluation

- Cis10 Standard Industri PembinaanDocument47 pagesCis10 Standard Industri PembinaanWanie Maz100% (2)

- PCI - Precast Prestressed Concrete Parking StructuresDocument40 pagesPCI - Precast Prestressed Concrete Parking Structuresnap_carinoPas encore d'évaluation

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQuePas encore d'évaluation

- Blinding Concrete Works Contents Revised 19-04-16RDocument3 pagesBlinding Concrete Works Contents Revised 19-04-16RJoel Alcantara100% (1)

- Temporary Works RegisterDocument2 pagesTemporary Works Registerrachel banfieldPas encore d'évaluation

- Consass User GuideDocument13 pagesConsass User GuideAlfiPas encore d'évaluation

- Standard Industri Pembinaan: Construction Industry Development Board MalaysiaDocument24 pagesStandard Industri Pembinaan: Construction Industry Development Board MalaysiaTan Kang YaoPas encore d'évaluation

- Construction Design and Management RegulDocument39 pagesConstruction Design and Management Regulkhx2Pas encore d'évaluation

- Lo 2 - DemolitionDocument29 pagesLo 2 - DemolitionEng Stephen ArendePas encore d'évaluation

- Madda Walabu University: Construction Health and Safety Management COTM 5303Document47 pagesMadda Walabu University: Construction Health and Safety Management COTM 5303ABU BEBEK AhmPas encore d'évaluation

- STD Specificatioins - CE - 2011Document176 pagesSTD Specificatioins - CE - 2011ကိုနေဝင်းPas encore d'évaluation

- Safety MS SingaporeDocument2 pagesSafety MS SingaporeRaymondGomezBlancoPas encore d'évaluation

- Based On The UK Construction Industry Key Performance IndicatorsDocument30 pagesBased On The UK Construction Industry Key Performance Indicatorsahtin618Pas encore d'évaluation

- WSH Guidelines Design For SafetyDocument33 pagesWSH Guidelines Design For SafetyCyndi01Pas encore d'évaluation

- Effective Implementation of Site Layout On Construction Site A Review PaperDocument5 pagesEffective Implementation of Site Layout On Construction Site A Review PaperIJRASETPublicationsPas encore d'évaluation

- MOM - WSH (Design For Safety) RegulationsDocument36 pagesMOM - WSH (Design For Safety) RegulationsEdmund YoongPas encore d'évaluation

- Method Statement For Block Works - Rev01Document19 pagesMethod Statement For Block Works - Rev01rayPas encore d'évaluation

- CP-09-F1-KTS-Incident Investigation ReportDocument7 pagesCP-09-F1-KTS-Incident Investigation ReportArjel SagadPas encore d'évaluation

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223Pas encore d'évaluation

- BR PDFs FiresafetyDocument42 pagesBR PDFs FiresafetyWan SyaPas encore d'évaluation

- Paper 2 - Design For Safety of Formwork by DR N Krishnamurthy PDFDocument29 pagesPaper 2 - Design For Safety of Formwork by DR N Krishnamurthy PDFTSGohPas encore d'évaluation

- ESMP Revised Road No 7Document144 pagesESMP Revised Road No 7Nisanth ThulasidasPas encore d'évaluation

- 5 Step CultureSAFE CycleDocument1 page5 Step CultureSAFE CycleKhuda BukshPas encore d'évaluation

- Bangladesh RailwayDocument67 pagesBangladesh RailwaytakoPas encore d'évaluation

- General Health and Safety Information For PillingDocument8 pagesGeneral Health and Safety Information For PillingiwansalmaPas encore d'évaluation

- All American ScaffoldDocument50 pagesAll American ScaffoldCalvin SzetoPas encore d'évaluation

- BRE Screed TesterDocument1 pageBRE Screed TesterdantranzPas encore d'évaluation

- Internship Interim Report: Andrew Hao Jie AbisheganadenDocument2 pagesInternship Interim Report: Andrew Hao Jie AbisheganadenAnonymous 32vj2LXxwhPas encore d'évaluation

- English ProjectDocument19 pagesEnglish ProjectSalim Abdul HakimPas encore d'évaluation

- Safe - Operation - of - Lifting - EquipmentDocument26 pagesSafe - Operation - of - Lifting - EquipmentVepxvia NadiradzePas encore d'évaluation

- Safe Operation of Lifting Equipment: Technical Advisory ForDocument24 pagesSafe Operation of Lifting Equipment: Technical Advisory Fors_bharathkumarPas encore d'évaluation

- Tower Crane DiscussionsDocument18 pagesTower Crane DiscussionsGelbert SilotPas encore d'évaluation

- Changing The Face of Concrete: Avinash Shaw Department of Civil Engineering NIT Durgapur Prof. A. K. SamantaDocument26 pagesChanging The Face of Concrete: Avinash Shaw Department of Civil Engineering NIT Durgapur Prof. A. K. SamantahutuguoPas encore d'évaluation

- Guidelines On NRM 2: Detailed Measurement of Building Works: 1st EditionDocument22 pagesGuidelines On NRM 2: Detailed Measurement of Building Works: 1st EditionhutuguoPas encore d'évaluation

- Impounding Gates For Marina & HarbourDocument10 pagesImpounding Gates For Marina & HarbourhutuguoPas encore d'évaluation

- Components and Connections - Principles of Construction PDFDocument134 pagesComponents and Connections - Principles of Construction PDFSam Uriarte100% (1)

- Surface Runoff - The Water Cycle, From USGS Water-Science SchoolDocument3 pagesSurface Runoff - The Water Cycle, From USGS Water-Science SchoolhutuguoPas encore d'évaluation

- Economic Base Analysis Notes Fall 2014Document2 pagesEconomic Base Analysis Notes Fall 2014hutuguoPas encore d'évaluation

- M-25 Report-Rev. 2016-03-16Document57 pagesM-25 Report-Rev. 2016-03-16hutuguoPas encore d'évaluation

- ManholeDocument8 pagesManholehutuguoPas encore d'évaluation

- Struttest PDFDocument49 pagesStruttest PDFhutuguoPas encore d'évaluation

- R 271Document90 pagesR 271hutuguoPas encore d'évaluation

- Quiz 3 SoltnDocument4 pagesQuiz 3 SoltnhutuguoPas encore d'évaluation

- Unit HydrographDocument27 pagesUnit Hydrographmrs_minalPas encore d'évaluation

- Peb Noise Barrier New Brochure 2016Document41 pagesPeb Noise Barrier New Brochure 2016hutuguoPas encore d'évaluation

- 01 HYI HS16 Introduction Lecture CompleteDocument59 pages01 HYI HS16 Introduction Lecture CompletehutuguoPas encore d'évaluation

- 2008 - 09 IFI Transmission Annual Report Gas TransmissionDocument83 pages2008 - 09 IFI Transmission Annual Report Gas TransmissionhutuguoPas encore d'évaluation

- 2016 Sgca 07 PDFDocument63 pages2016 Sgca 07 PDFhutuguo0% (1)

- Modern Delay Analysis TechniquesDocument40 pagesModern Delay Analysis TechniqueshutuguoPas encore d'évaluation

- Ove Arup V Mirant 2005Document14 pagesOve Arup V Mirant 2005hutuguoPas encore d'évaluation

- Fidic Letters by ConsultantDocument48 pagesFidic Letters by ConsultantAbdelateef Samy97% (37)

- Burger Slurry Hybrid Large TbmsDocument52 pagesBurger Slurry Hybrid Large TbmshutuguoPas encore d'évaluation

- Simple Guide On Used Water, Sewerage System and Related ApplicationDocument18 pagesSimple Guide On Used Water, Sewerage System and Related ApplicationhutuguoPas encore d'évaluation

- Construction Delay Analysis TechniquesDocument26 pagesConstruction Delay Analysis Techniquesengmts1986Pas encore d'évaluation

- Pipeline Consultation PlanDocument37 pagesPipeline Consultation PlanhutuguoPas encore d'évaluation

- Model Specification For The Purchase of Structural Bolting Assemblies and Holding Down Bolts - Revision 1 PDFDocument8 pagesModel Specification For The Purchase of Structural Bolting Assemblies and Holding Down Bolts - Revision 1 PDFhutuguoPas encore d'évaluation

- Reinforcing Bar Couplers: For The Construction IndustryDocument32 pagesReinforcing Bar Couplers: For The Construction IndustryhutuguoPas encore d'évaluation

- Long Intl Construction Contract Notice LettersDocument21 pagesLong Intl Construction Contract Notice Lettersjose miguel lagumbayPas encore d'évaluation

- 2016 Sgca 07 PDFDocument63 pages2016 Sgca 07 PDFhutuguoPas encore d'évaluation

- 74309Document6 pages74309hutuguoPas encore d'évaluation

- Complete List of Licensable Chemicals 2014 - 2Document17 pagesComplete List of Licensable Chemicals 2014 - 2hutuguoPas encore d'évaluation

- Adult ListDocument3 pagesAdult ListhutuguoPas encore d'évaluation

- Sop PDFDocument308 pagesSop PDFNamrata PaiPas encore d'évaluation

- FINA Facilities Rules 2017 - 2021Document54 pagesFINA Facilities Rules 2017 - 2021Ivan Andrae Esperanza PesebrePas encore d'évaluation

- Design of Stuctures For The Mining Industry - Part 3 - Comementary On SANS 10208-2005 PDFDocument135 pagesDesign of Stuctures For The Mining Industry - Part 3 - Comementary On SANS 10208-2005 PDFNhlakanipho NkwanyanaPas encore d'évaluation

- Crane Hoist Safety PresentationDocument13 pagesCrane Hoist Safety PresentationMAHEBOOB PASHAPas encore d'évaluation

- Is 3696.part1 .1987 Safety Regulations For ScaffoldingDocument36 pagesIs 3696.part1 .1987 Safety Regulations For ScaffoldingBalkishan DyavanapellyPas encore d'évaluation

- (MOORINGS) Otc17789 - Predicting The Torsional Response of Large Mooring Chains PDFDocument0 page(MOORINGS) Otc17789 - Predicting The Torsional Response of Large Mooring Chains PDFAndrew EdwardPas encore d'évaluation

- PDFDocument129 pagesPDFPedro ArangoPas encore d'évaluation

- 2016 Catalogue Vol 2 PDFDocument19 pages2016 Catalogue Vol 2 PDFTimSmithPas encore d'évaluation

- SGS Lifting Work Instruction1 PDFDocument99 pagesSGS Lifting Work Instruction1 PDFashrafasdPas encore d'évaluation

- Atlas Davit 2500 PDFDocument14 pagesAtlas Davit 2500 PDFChief EngineerPas encore d'évaluation

- Carl Stahl UAE CatalogDocument64 pagesCarl Stahl UAE CatalogsuhailpmPas encore d'évaluation

- Department of Education: Batangas City South Senior High SchoolDocument5 pagesDepartment of Education: Batangas City South Senior High Schoolmarinella borbonPas encore d'évaluation

- Rigging EquipmentDocument23 pagesRigging EquipmentAldi SetiadiPas encore d'évaluation

- Rope Making (1) AaaDocument7 pagesRope Making (1) Aaaalefe gebriePas encore d'évaluation

- Load Chart-Wire RopeDocument2 pagesLoad Chart-Wire RopeRajmohan Babu100% (1)

- BTS3900E GSM Installation Guide - (V300R008&R009 - 06)Document54 pagesBTS3900E GSM Installation Guide - (V300R008&R009 - 06)seringh100% (1)

- Me-605 ADocument7 pagesMe-605 AEmperorPas encore d'évaluation

- 320B All PDFDocument43 pages320B All PDFahmed_merzban9153Pas encore d'évaluation

- Tms474 OperationDocument483 pagesTms474 Operationrjan7pe100% (1)

- Bullivants WireRope - SpecificationsDocument20 pagesBullivants WireRope - SpecificationsAndrew PeterPas encore d'évaluation

- 2019 Catalog PDFDocument196 pages2019 Catalog PDFMohamed HadjkacemPas encore d'évaluation

- Hoisting Rigging FundamentalsDocument89 pagesHoisting Rigging FundamentalsRoger Loomis100% (2)

- DSR Cables de AceroDocument36 pagesDSR Cables de Acerojhon rodriguezPas encore d'évaluation

- Manual For Laying 110-500 KV XLPE Power CablesDocument84 pagesManual For Laying 110-500 KV XLPE Power CablesZoran PetrovićPas encore d'évaluation

- Catalogo CMCDocument145 pagesCatalogo CMCalyboscanPas encore d'évaluation

- Rope TensionerDocument4 pagesRope TensionerblizanacPas encore d'évaluation

- Ship Vetting Questionnaire FormDocument2 pagesShip Vetting Questionnaire Formmika yapPas encore d'évaluation

- Safety and Health Checklist For Monitoring Transmission Line Construction WorksDocument6 pagesSafety and Health Checklist For Monitoring Transmission Line Construction WorksWinstone Audi100% (3)

- BLU Code - Ship Shore Safety ChecklistDocument8 pagesBLU Code - Ship Shore Safety Checklistsouvik halder100% (2)

- User's Manual - Synthetic Μooring RopesDocument32 pagesUser's Manual - Synthetic Μooring RopesNikos StratisPas encore d'évaluation