Académique Documents

Professionnel Documents

Culture Documents

1 s2.0 S1387181112002910 Main

Transféré par

Thao DophuongDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 s2.0 S1387181112002910 Main

Transféré par

Thao DophuongDroits d'auteur :

Formats disponibles

Microporous and Mesoporous Materials 165 (2013) 613

Contents lists available at SciVerse ScienceDirect

Microporous and Mesoporous Materials

journal homepage: www.elsevier.com/locate/micromeso

Post-synthesis of TiO2/MCM-41 from aqueous TiCl4 solution: Structure characteristics and epoxy catalytic activity

Lina Ma, Jianbing Ji , Fengwen Yu, Ning Ai, Hongtao Jiang

Zhejiang Province Key Laboratory of Biofuel, Zhejiang University of Technology, Hangzhou 310014, China

a r t i c l e

i n f o

a b s t r a c t

Titanium-containing mesoporous silica TiO2/MCM-41 (C) was prepared by impregnating MCM-41, pretreated by refrigeration at 278 K, with aqueous TiCl4 solution as titanium precursor. In addition, TiO2/ MCM-41 (H) was produced by same method but the support MCM-41 without refrigeration in order to investigate the inuence of unrefrigerated pretreatment on the structure of TiO2/MCM-41. The dispersion and nature of titanium species were characterized by inductively coupled plasma mass spectrometry (ICP-MS), powder X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), UVvisible diffuse reectance spectra (UV-vis DRS), standard BrunauerEmmnettTeller (BET), X-ray photoelectron spectra (XPS), scanning electron micrographs (SEM), transmission electron microscopy (TEM). The results indicate that TiO2/MCM-41 (C) showed better mesoscopic order, higher dispersion of titanium oxide species, stronger interaction with the MCM-41 support. But the pore size decreases from 3.4 to 2.4 nm when the titanium content increases to 76.6 mg/g. TiO2/MCM-41 (C2) exhibits more excellent catalytic performance than others, and the 97.6% conversion of methyl oleate (MO) and 93.1% selectivity to epoxidation methyl oleate (EMO) can be obtained at 353 K for 10 h. 2012 Elsevier Inc. All rights reserved.

Article history: Received 27 October 2011 Received in revised form 17 April 2012 Accepted 7 May 2012 Available online 3 August 2012 Keywords: TiO2/MCM-41 Mesoporous molecular sieves Post-synthesis Characterization Catalytic testing

1. Introduction Recently much attention has been paid on the olen epoxidation by various catalysis with various oxidants since epoxides are used in exible intermediates of many industrially signicant chemicals [14] such as drugs, agrochemicals, lubricants, biobased polymers, fuel additives, polymer stabilizer, and perfume materials. Several studies have been done to develop active catalytic systems for the epoxidation of different olens using a wide range of catalysts. Catalysts based on molybdenum [5], alumina [6], titanium [7] and tungsten [8,9] have been described for this reaction. Among them, Ti-containing catalysts enable many processes to be selectively, efciently, and environment-friendly conducted under mild condition. Usually Ti-containing catalyst is prepared by hydrothermal synthesis or post-synthesis. Post-synthesis has better industrialization prospect because its process is more easily to obtain than that of hydrothermal synthesis. Inumaru [10] prepared Ti/SiO2 catalysts by the chemical vapor deposition (CVD) method using TiCl4 as titanium source. And Lu and co-workers [11] optimized the CVD conditions and got the TiSBA-15 of Ti load of 4.62 wt.% with high epoxy selectivity and activity; Marchetti and co-workers [12] prepared Ti/MCM-41 samples by impregnation methods using Ti-tert Corresponding author. Tel./fax: +86 571 88320053.

E-mail address: jjb@zjut.edu.cn (J. Ji). 1387-1811/$ - see front matter 2012 Elsevier Inc. All rights reserved. http://dx.doi.org/10.1016/j.micromeso.2012.05.005

butoxide in isopropyl alcohol solution as titanium source and found that their catalytic activities were similar as that of the hydrothermal TiMCM-41. Yang and co-worker [13] investigated the synthesis of TiO2/SBA-15 materials via Ti-alkoxide hydrolysis in the support-isopropanol suspension; Stein and co-workers [14] and Sun and co-workers [15] used TiCl4 in hexane as titanium precursor to graft titania clusters into the pores of MCM-41. However, this process must be under nitrogen environment or TiCl4 hydrolyzes to TiO2 in an open atmosphere. In this work, we have investigated the post-synthesis of TiO2/ MCM-41 by grafting of titanium oxide onto the MCM-41 in air using an aqueous TiCl4 solution as precursor. And the comparison of the inuence of support with and without refrigerated pretreatment on the structure of TiO2/MCM-41 was investigated. The synthesized materials were characterized by various physical techniques. At the same time, their epoxy catalytic activities of MO were tested.

2. Experimental 2.1. Catalyst preparation 2.1.1. Preparation of MCM-41 The pure mesoporous silica MCM-41 was synthesized according to the reported procedure [16] by using of cetyltrimethylammonium bromide (CTAB, 99%) as the cationic surfactant under alkaline

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

conditions. Briey, a solution of CTAB/NaOH/H2O/TEOS = 1/2.7/ 9820/8.7 (mole ratio) was prepared and stirred for 10 h at 353 K. The solid product was ltered off, and then dried overnight at 373 K. Mostly occluded surfactant was removed by calcinations at 853 K for 0.5 h in air, yielding the mesoporous molecular MCM-41 material. The MCM-41 (BET surface area: 1437 m2/g, average pore diameter: 3.41 nm, total pore volume: 1.35 cm3/g) was used in preparation of TiO2/MCM-41 samples support. 2.1.2. Preparation of TiO2/MCM-41 2.1.2.1. Aqueous TiCl4 solution. TiCl4 (above 99%) was used without any further purication. The aqueous TiCl4 solutions, the titanium precursor, were prepared by slowly adding, drop-wise, a given amount of water into a certain amount of TiCl4. When water contacts with TiCl4 excess heat explosively generating from the exothermic reaction was removed by constantly shaking in ice-water bath. And the white smoke was collected and absorbed by 2 N alkali liquor. The color of aqueous TiCl4 solution changed from pale yellow to lemon and then to colorless. The concentration of colorless aqueous TiCl4 solutions was 0.3 and 0.4 mol/L. And the aqueous TiCl4 solutions were kept in ice-water bath. 2.1.2.2. TiO2/MCM-41 (C). MCM-41 was dried at 373 K and then refrigerated in refrigerator at 278 K for overnight before impregnation. Following the simple impregnation to incipient wetness of 0.5 g MCM-41 with 2 ml above solutions at 278 K for two days in air the samples were dried at 373 K, separately. And then the samples were calcined in air at 823 K for 2 h at a heating rate of 2 K/ min to obtain TiO2/MCM-41 (C1), and TiO2/MCM-41 (C2) samples. 2.1.2.3. TiO2/MCM-41 (H). MCM-41 was dried at 373 K and cooled at room temperature for 2 h. With the same impregnation to incipient wetness and same nishing procedure as described above TiO2/MCM-41 (H1) and TiO2/MCM-41 (H2) samples were obtained. 2.2. Characterizations The titanium contents in TiO2/MCM-41 samples were determined by ICP-MS (PerkinElmer Elan DRC-e). For ICP-MS studied, 0.025 g of the samples was digested with 3 mL HNO3 and 1 mL of HF in digestion high-pressure tank at 333 K for 5 h, 25 ml boric acid neutralized after cooled down and then diluted to 250 mL, respectively. The titanium concentrations of samples were determined from a calibration plot made previously. XRD measurements were performed at room temperature using a PNAlytical XPert PRO powder diffractometer with Cu Ka (k = 1.5404 ) radiation. The diffractometer was operated at 40 kV and 40 mA and scanned between 1.5 and 8 (2h) with a step size of 0.0083 and between 10 and 70 (2h) using steps of 0.033. FT-IR spectra were recorded on a Nicolet 6700 FT-IR spectrometer using 0.5 mm KBr pellets containing 2.5 wt.% samples. The UVvis DRS in the UV vis range with BaSO4 as reference were recorded using a Shimadzu UV-2550 spectrometer equipped with an integration sphere attachment. XPS were acquired recorded on Kratos AXIS Ultra DLD spectrometer equipped with a dual X-ray source, of which the AlKa (1486.6 eV) anode and a hemispherical energy analyzer were used. The background pressure during data acquisition was kept below 7.4 107 Pa. Measurements were performed at pass energy of 160.0 eV to ensure sufcient sensitivity for the acquisition scan, while pass energy of 40.0 eV was used for the scanning of the narrow spectra of Ti 2p and C 1s to ensure sufcient resolution. All the binding energies were calibrated by referencing to the contaminant carbon (C 1s) 284.8 eV. The surface morphological details of catalysts were studied by SEM (Hitachi S-4700 II). The catalyst samples were mounted directly on the holders and covered with sputtered gold and then observed in SEM. TEM images were

obtained on a Tecnai G2 F30 S-Twin microscope operated at 300 kV. The samples were dispersed in ethanol in an ultrasonic bath for several minutes, and then deposited on a Cu grid and dried by infrared heat lamp for the experiment. The specic surface area was calculated using the standard BET method. Nitrogen adsorption/desorption isotherms were measured at 77 K using micromeritics ASAP 2010 of samples. The total pores volume was estimated from the amount of nitrogen adsorbed at a relative pressure p/p0 of 0.99, assuming complete surface saturation with nitrogen, where p and p0 denote the adsorption size distribution curves were calculated from the adsorption branches of the isotherms using BarettJoynerHalenda (BJH) method. 2.3. Activity test 2.3.1. Materials Methyl oleate (MO), the substrate for catalytic tests, was a colorless liquid obtained from vegetable tallow by esterication, transesterication with methanol and following rectication. FAME mixture was qualitative analyzed by Agilent 9790A/5875C gas chromatographymass spectrometry (GCMS). And the composition is (wt.%) MO (84.5), methyl linoleate (2.5), methyl stearate (1.6), methyl palmitate (9.5), others (1.9) quantitative analyzed by Fuli GC 9790 with a HP-INNOWAX column (30 m 0.25 mm 0.25 lm) with a ame ionization detector (FID). 2.3.2. Catalytic tests The activity test was performed at 353 K for 10 h with magnetic stirring in a round bottomed ask with MO, aqueous tert-butylhydroperoxide (TBHP, 75%) as oxygen donor and ethyl acetate as solvent. The analysis method was same as above. 3. Results and discussion 3.1. Characterization of TiO2/MCM-41 The amount of titanium present on the support is determined by using ICP-MS. Table 1 shows the amounts of titanium, expressed in mg/g of product. Small-angle powder X-ray diffraction patterns of TiO2/MCM-41 (H1, H2), TiO2/MCM-41 (C1, C2) samples and pure MCM-41 are shown in Fig. 1. TiO2/MCM-41 (C1, C2) samples and pure MCM41 exhibit three well-resolved peaks indexed to d100, d110, and d200 Bragg reection, indicating that good microscopic order and the characteristic hexagonal features of MCM-41 are maintained (Fig. 1a, d, and e). However, the d110 and d200 reection peaks of TiO2/MCM-41 (H1, H2) samples become very weak and even disappear when the content of titanium reached 73.8 mg/g. Obviously, the incorporation process of using refrigerated pretreatment support does not lead to disorder the hexagonal structure. The intensity of the d100 reection diffraction peaks at 23 decrease moderately with the titanium content increasing as compared with the corresponding pure MCM-41. In addition, the reection positions of peaks shift in different level to larger diffraction angle and become slightly broader, especially for TiO2/MCM-41 (C1,

Table 1 Titanium content of TiO2/MCM-41 samples analyzed by ICP-MS. Samples TiO2/MCM-41 TiO2/MCM-41 TiO2/MCM-41 TiO2/MCM-41 (H1) (H2) (C1) (C2) Ti (mg/g) 62.2 73.8 63.3 76.6

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

Fig. 1. Small-angle powder XRD patterns of samples: (a) Pure MCM-41, (b) TiO2/ MCM-41 (H1), (c) TiO2/MCM-41 (H2), (d) TiO2/MCM-41 (C1), (e) TiO2/MCM-41 (C2).

Fig. 3. FT-IR spectra of samples: (a) Pure MCM-41, (b) TiO2/MCM-41 (H1), (c) TiO2/ MCM-41 (H2), (d) TiO2/MCM-41 (C1), (e) TiO2/MCM-41 (C2).

Fig. 2. Wide-angle powder XRD patterns of samples: (a) TiO2/MCM-41 (H2), (b) TiO2/MCM-41 (H1), (c) TiO2/MCM-41 (C2), (d) TiO2/MCM-41 (C1).

C2) samples, indicating narrowed unit cell. Wide-angle powder Xray diffraction patterns of various samples are shown in Fig. 2. None of the typical diffraction peaks form crystalline titanium oxide species are observed, only a broad peak resulting from amorphous silica centered at 2 = 23 for TiO2/MCM-41 (C1, C2) samples (Fig. 2c and d). While for TiO2/MCM-41 (H1, H2) samples which support without refrigerated pretreatment with very week characteristic peaks of crystalline anatase appear (Fig. 2a and b). Besides, the intensity of reection peaks strengthens and the number of peaks increases along with the increase of titanium content. This above result may be explained by the following two considerations: (i) titanium oxide species is totally incorporated into the lattice of the MCM-41 for TiO2/MCM-41 (C) samples and (ii)

for TiO2/MCM-41 (H1, H2) samples, the formation of partial anatase species causes destruction and partial blocking of the pore system. And this nding could be conrmed by SEM and TEM images and showed in context. In order to evaluate the formation of titanium oxide in the catalyst framework, FTIR, XPS and UVvis DRS were carried out. The FT-IR spectra of pure MCM-41 and TiO2/MCM-41 samples are shown in Fig. 3. Four characteristic absorption bands are observed. All the samples exhibit the symmetric stretching vibration band of SiOSi bridges at around 810 cm1, the anti-symmetric vibration band at around 1100 cm1 with a shoulder at 1220 cm1 for the tetrahedral SiO4 structure units. Finally, for Ti-containing molecular sieve the important band at 960 cm1 is to be regarded as a consequence of stretching vibrations of SiOTi bonds. And its increase in intensity along with the content is generally considered as a evidence of the incorporating of titanium into the framework [17,18] as the stretching SiO vibration mode perturbed by the neighboring metal ions. Pure MCM-41 shows very mild band (Fig. 3a). For TiO2/MCM-41 (C1, C2) samples, characteristic intensity band strengthens with the increase of titanium loading. While no typical intensity increase of IR band located at around 960 cm1 can be observed for TiO2/MCM-41 (H1, H2) samples. UVvis DRS is a very sensitive probe for the presence of extraframe Ti in molecular sieves. The UVvis DRS spectra of TiO2/ MCM-41 (C1, C2, H1, H2) samples and anatase are given in Fig. 4. There is no peak for pure MCM-41 (not show in gure). TiO2/ MCM-41 (C1, C2) (Fig. 4d and e) samples have an absorption maximum band at about 210240 nm, which is assigned to the ligandto-metal charge transfer involving isolated titanium atoms in tetrahedral coordination, in which two water molecules form part of the metal coordination sphere. Although there is not obvious peak at about 280 nm, the broad peak mean that there is probably a very weak shoulder at about 280 nm for TiO2/MCM-41 (C1, C2) samples. The shoulder at 280 nm probably corresponds to partially polymerized Ti species (ve- and six-coordinate) in small titania nanodomains [19]. While TiO2/MCM-41 (H1, H2) samples (Fig. 4b and c) show an intense band centered at 230260 nm, probably containing peaks at 210230 and 260270, together with a shoulder at 310 nm. The shoulder at 310 nm, being obvious for anatase

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

Fig. 6. Ti 2p photoelectron spectra of samples: (a) TiO2/MCM-41 (C2), (b) TiO2/ MCM-41 (H2). Fig. 4. UVvis DRS patterns of samples: (a) Anatase, (b) TiO2/MCM-41 (H2), (c) TiO2/MCM-41 (H1), (d) TiO2/MCM-41 (C2), (e) TiO2/MCM-41 (C1).

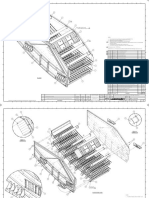

(shown in the Fig. 4a), indicates that bulk titania is formed [20]. Fig. 5 outlines the reaction scheme of potential structures resulting from the grafting procedure. Solution can reach internal pore (Fig. 5a) derived mainly by capillary force and titania is anchored to the silica framework via reaction with terminal SiOH groups on the pore surface (Fig. 5b) under the slow volatilization of HCl for TiO2/MCM-41 (C) samples. And the titanium species forming a smooth layer which coats the pore surface leads to narrow pore. Besides, with the increasing of content of titanium, polymerized Ti

Fig. 5. Schematic of the grafting procedure and potential results. Only a single pore is shown. The color darkens with the increase of concentration of titanium. (a) A single pore of pure MCM-41. (b) A smooth layer of titanium oxide species coats the pore surface. (c) Small polymerized titanium oxide species partially form. (d) (TiO2)n nanoclusters partially form. (e) Bulk (TiO2)n nanoclusters and isolated TiO2 unites form.

species form (Fig. 4c). While for TiO2/MCM-41 (H) samples, much of TiCl4 has formed (TiO2)n nanoclusters (Fig. 5d) or isolated TiO2 unites (Fig. 5e) when TiCl4 penetrates the pore in carrier and grafts onto pore surface because of the quick volatition of HCl. After obtaining information about the chemical nature and coordination states of the titanium species in the samples, we investigated the oxidation state of the species presents on their surface using XPS analysis. Fig. 6 shows the Ti 2p spectra of TiO2/ MCM-41 (C2, H2) samples. The deconvoluted XPS spectra of the two samples show the presence of three different Ti species with their Ti2p3/2 binding energies which can be tted with three symmetric cures which distinguish titanium oxide species in different chemical states according to published binding energy (BE) shifts for TiO2, SiO2, TiO2/SiO2mixed oxide systems, TS-1 and TiMCM41 [14,2124]. The rst species with the lowest binding energies arising at 457.8 0.2 eV is characteristic of octahedral titanium species. The proportion of peak at 457.8 0.2 eV of TiO2/MCM-41 (C2) sample is far less than that of TiO2/MCM-41 (H2) sample. The largest peak at 460.0 0.2 eV for TiO2/MCM-41 (C2) sample, as same as that observed on TS-1, is attributable to tetrahedral coordinated Ti species which is referred to titanium accommodated into the silica framework. TiO2/MCM-41 (H2) sample showing a maximum peak at 459 0.2 eV is consistent with titanium in the octahedral environment of anatase and probably originates from the anatase particles that are present on the external surface. The SEM and TEM micrographs of TiO2/MCM-41 (C) are shown in Figs. 7 and 8, respectively. The ball-rod-like structure of TiO2/ MCM-41 (C2) sample (Fig. 7a) is about 300 nm in diameter and about 650 nm in length. And each particle consists of well-ordered hexagonal nano-channels (Fig. 8a and b) of one-dimensional mesopores. Anatase crystallites are not present at external MCM-41 surfaces in sample, demonstrating titanium oxide species are well dispersed in MCM-41 channels. However, for the TiO2/MCM-41 (H2) sample, the scaly-like structure is shown in Fig. 7b. TEM images of TiO2/MCM-41 (H2) sample (Fig. 8c and d) show the degradation and rupture of the MCM-41 mesostructure, which are consistent with the small-angle XRD results. The amorphous zones and even anatase agglomerate species were blocked in the channels and formed on the external surface.

10

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

Fig. 7. SEM images of samples: (a) TiO2/MCM-41 (C2), (b) TiO2/MCM-41 (H2).

Fig. 8. TEM images of samples: (a) and (b) TiO2/MCM-41 (C2); (c) and (d) TiO2/MCM-41 (H2).

The nitrogen adsorptiondesorption isotherms and typical pore size distributions for TiO2/MCM-41 (C2, H2) samples and ungrafted MCM-41 are shown in Fig. 9. And the average pore volume, diameter and BET surface area are listed in Table 2. Compared with MCM-41, TiO2/MCM-41 (C2, H2) samples have lower surface areas obviously caused by deposition of titanium oxide species. There is a noticeable difference in the shape of the isotherms and a significant decrease of pore size with Ti loading for the TiO2/MCM-41 (C2) sample compared to MCM-41, attributed to lling of pores with titanium oxide species. The nitrogen sorption isotherm for TiO2/MCM-41 (H2) sample exhibits the shape of type IV cures, typical of mesoporous material, but combined with above results it

can be seen that no signicant decrease of the pore size with Ti loading which suggest that mostly titanium oxide species located on external surface instead of incorporating with MCM-41. 3.2. Catalytic results The catalytic performance of TiO2/MCM-41 catalysts is shown in Fig. 10. For the purpose of comparison, the catalysts were used in these experiments containing the same amount of MO/Ti moral ratio. Furthermore, pure MCM-41 or TiO2 show no transformation toward the reaction (not shown here), while those grafted titanium species on the MCM-41 support show substantial activity and yield

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

11

Fig. 9. Nitrogen adsorption/desorption isotherms at 77 K and BJH pore size distribution of samples: h Calcined, pure MCM-41, 4 TiO2/MCM-41 (H2), O TiO2/MCM-41 (C2).

Table 2 Textural properties of TiO2/MCM-41 (C2, H2) samples. Sample TiO2/MCM-41 (C2) TiO2/MCM-41 (H2) BET surface area (m2/g) 882 840 Pore volume (cm3/g) 0.44 0.78 Average pore diameter (nm) 2.44 3.31

in the epoxidation reaction, which indicates that the titanium species loaded on the mesoporous MCM-41 act as active centers for the selective epoxidation of MO. Their catalytic selectivity of EMO is above 90%. This result suggests that the titanium species loaded on the mesoporous MCM-41 material act as active centers for the epoxidation of MO. As shown in Fig. 10, the TiO2/MCM-41 (C) catalysts show excellent catalytic activity as compared with the TiO2/MCM-41 (H) for this reaction. Furthermore, catalysts of

TiO2/MCM-41 (C2, H2) display better catalytic performance than that of TiO2/MCM-41 (C1, H1), which means that the catalytic performance is decided by the content and nature of titanium oxide species. To get more information on the activity of these two kinds catalysts, the effect of TBHP/MO and Ti/MO molar ratio have been carried out and results are shown in Figs. 11 and 12. The effect of TBHP/MO molar ratio (from 1.1/1 to 2.2/1) (Fig. 11) was investigated under 358 K, reaction time 10 h, MO/ Ti [TiO2/MCM-41 (H2)] = 8.8, mass ratio of ethyl acetate/MO = 20. We observe that the conversion of MO increases with the increasing of TBHP/MO molar ratio. And a maximum is obtained by using TBHP/MO molar ratio of 1.55 giving a conversion 78%. Then the effect of MO/Ti molar ratio was investigated under 358 K, reaction time 10 h, TBHP/ MO = 1.55, mass ratio of ethyl acetate/MO = 20 in Fig. 12. In aggregate TiO2/MCM-41 (C2) shows remarkable higher catalytic activity

12

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

Fig. 10. Epoxidation performance of the selective epoxidation of MO over catalysts: I. TiO2/MCM-41 (C2); II. TiO2/MCM-41 (C1); III. TiO2/MCM-41 (H2); IV. TiO2/MCM41 (H1). Reaction time 10 h, reaction temperature 358 K, mole ratio of MO/TBHP/ TiO2 = 100:160:6, mass ratio of ethyl acetate/MO = 20.

Fig. 12. Effect of MO/Ti molar ratio on the epoxidation conversion of MO and yield of EMO. Reaction time 10 h, reaction temperature 358 K, mole ratio of TBHP/ MO = 1.5, mass ratio of ethyl acetate/MO = 20.

Fig. 11. Effect of TBHP/MO molar ratio on the reaction conversion using catalyst TiO2/MCM-41 (H2). Reaction time 10 h, reaction temperature 358 K, mole ratio of MO/ Ti = 8.8, mass ratio of ethyl acetate/MO = 20.

Fig. 13. Effect of MO/Ti molar ratio on the epoxidation conversion of MO with TiO2/ MCM-41 (C2) under solvent-free condition. Reaction time 10 h, reaction temperature 358 K, mole ratio of TBHP/MO = 1.6.

than TiO2/MCM-41 (H2). The range of conversion increases for TiO2/MCM-41 (H2) is bigger than that of TiO2/MCM-41 (C2) when the MO/Ti molar ratio changes from 15 to 7, but the maximum conversion of TiO2/MCM-41 (H2) still lower than that of TiO2/MCM-41 (C2). Besides, the solvent-free selective epoxidation of MO over TiO2/ MCM-41 (C2) was investigated. In Fig. 13, the conversion of MO for the high active catalyst TiO2/MCM-41 (C2) is below 70% even the MO/Ti reaching 8. As we could see, the activity of the catalyst at 358 K is strongly dependent upon the surface properties of the catalyst, MO/Ti molar ratio, as well as the solvent existing.

4. Conclusion TiO2/MCM-41 (C) and TiO2/MCM-41 (H) had been prepared by post-synthesis step via aqueous TiCl4 solution in the support with and without refrigeration pretreatment, respectively, and characterized by several physical techniques. The results show that using MCM-41 pretreated by refrigeration as the support is favor of reducing surface temperature, resulting in no anatase formation on the MCM-41 surface. TiO2/MCM-41 (C) show better mesoscopic order, higher dispersion of titanium oxide species, stronger interaction with the MCM-41 support. It is revealed that the refrigera-

L. Ma et al. / Microporous and Mesoporous Materials 165 (2013) 613

13

tion pretreatment is of crucial importance for the nature of catalyst. MO with highest loaded Ti retaining the ordered mesostructure showed 98% conversion with 92% selectivity for EMO, and even got 67% conversion of MO under solvent-free condition. References

[1] H.J. Nieschlag, J.A. Rothfus, V.E. Sohns, R. Beltron Perkins, Ind. Eng. Chem. Prod. Res. Dev. 16 (1977) 101107. [2] S. Warwel, F. Brse, C. Demes, M. Kunz, R.G. Klaas, Chemosphere 43 (2003) 39 48. [3] P. Czub, Macromol. Symp. 242 (2006) 6064. [4] F. Scholnick, H.A. MonROE Jr., E.J. Saggese, A.N. Wrigley, Urethane foams from animal fats. II. Reaction of propylene oxide with fatty acids, J. Am. Oil Chem. Soc. 44 (1967) 4042. [5] L. Barrio, J.M. Campos-Martn, M.P. de Frutos, J.L.G. Fierro, Ind. Eng. Chem. Res. 47 (2008) 80168024. [6] P.A.Z. Suarez, M.S.C. Pereira, K.M. Doll, B.K. Sharma, S.Z. Erhan, Ind. Eng. Chem. Res. 48 (2009) 32683270. [7] M. Guidotti, R. Psaro, N. Ravasio, M. Sgobba, E. Giamotti, S. Grinberg, Catal. Lett. 122 (2008) 5356. [8] E. Poli, J.M. Clacens, J. Barrault, Y. Pouilloux, Catal. Today. 140 (2009) 1922. [9] K. Sato, M. Aoki, M. Ogawa, T. Hashimoto, D. Panyella, R. Noyori, Bull. Chem. Soc. Jpn. 70 (1997) 905.

[10] K. Inumaru, T. Okuhara, M. Misono, J. Phys. Chem. 95 (12) (1991) 48264832. [11] J.M. Yao, W.C. Zhan, X.H. Liu, Y.L. Guo, Y.Q. Wang, Y. Guo, G.Z. Lu, Microporous Mesoporous Mater. 15 (2012) 131136. [12] D. Marino, N.G. Gallrgos, J.F. Bengoa, A.M. Alvarez, M.V. Cagnoli, S.G. Casuscelli, E.R. Herrero, S.G. Marchetti, Catal. Today 133135 (2008) 632638. [13] J. Yang, J. Zhang, L.W. Zhu, S.Y. Chem, Y.M. Zhang, Y. Tang, T.T. Zhu, Y.W. Li, J. Hazard. Mater. B 137 (2006) 952958. [14] B.J. Aronson, C.F. Blanford, A. Stein, Chem. Mater. 9 (1997) 28422851. [15] X.C. Dong, Li Wang, J.F. Zhou, H.J. Yu, T.X. Sun, Catal. Commun. 7 (2006) 15. [16] Q. Cai, Z.S. Luo, W.Q. Pang, Y.W. Fan, X.H. Chen, F.Z. Cui, Chem. Mater. 13 (2001) 258263. [17] S. Che, S. Lim, M. Kaneda, H. Yoshitake, O. Terasaki, T. Tatsumi, J. Am. Chem. Soc. 124 (47) (2002) 1396213963. [18] M.S. Morey, S. OBrien, S. Schwarz, G.D. Stucky, Chem. Mater. 12 (4) (2000) 898911. [19] Y. Luo, G.Z. Lu, Y.L. Guo, Y.S. Wang, Catal. Commun. 3 (2002) 129134. [20] M. Rigutto. Vanadium and titanium-containing molecular sieves, Ph.D. thesis, Technische Universiteit Delft, 1996, 28. [21] A.O.T. Patrocnio, E.B. Paniago, R.M. Paniago, N.Y.M. Iha, Appl. Surf. Sci. 254 (2008) 18741879. [22] Y. Hasegawa, A. Ayame, Catal. Today 71 (2001) 177187. [23] A.Y. Stakheev, E.S. Shpiro, J. Apijok, J. Phys. Chem. 97 (21) (1993) 56685672. [24] O.D. Trong, M.P. Kapoor, E. Thibault, J.E. Gallot, G. Lemay, S. Kaliaguine, Microporous Mesoporous Mater. 20 (1998) 107118.

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- H-HS-0043 AP Abrasive Cream CleanerDocument1 pageH-HS-0043 AP Abrasive Cream CleanerDania UzairPas encore d'évaluation

- 100 Ways To Save The EnvironmentDocument3 pages100 Ways To Save The EnvironmentSarvesh JaiswalPas encore d'évaluation

- Flextronics Case AnalysisDocument31 pagesFlextronics Case AnalysisGauthamJayanPas encore d'évaluation

- Arvedi Brief Presentation Modernisation ProgrammeDocument30 pagesArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitPas encore d'évaluation

- Partition ManualDocument42 pagesPartition ManualAnonymous SblBDN0Pas encore d'évaluation

- Spent Caustic Treatment Options-Saudi AramcoDocument20 pagesSpent Caustic Treatment Options-Saudi Aramcoonizuka-t22630% (1)

- Sample Problem #22Document8 pagesSample Problem #22Dozdi0% (1)

- Refrigeration and Cooling ManualDocument15 pagesRefrigeration and Cooling ManualGrundfosEgyptPas encore d'évaluation

- Ueg 36Document2 pagesUeg 36PRADO_COMETA50% (2)

- 01CS1S02Document5 pages01CS1S02raobabar21Pas encore d'évaluation

- 11Document5 pages11Thao DophuongPas encore d'évaluation

- New Composite Membrane For Water SofteningDocument7 pagesNew Composite Membrane For Water SofteningThao DophuongPas encore d'évaluation

- công nghệ khử cặnDocument29 pagescông nghệ khử cặnThao Dophuong0% (1)

- Visa Application Form 2012Document2 pagesVisa Application Form 2012Honey OliverosPas encore d'évaluation

- Non Chemical DescalingDocument32 pagesNon Chemical DescalingKiran DuggarajuPas encore d'évaluation

- 12Document6 pages12Thao Dophuong0% (1)

- Softening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsDocument6 pagesSoftening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsThao DophuongPas encore d'évaluation

- 7Document13 pages7Thao DophuongPas encore d'évaluation

- 6Document7 pages6Thao DophuongPas encore d'évaluation

- Electrochemical Water Softening: Principle and ApplicationDocument14 pagesElectrochemical Water Softening: Principle and ApplicationThao DophuongPas encore d'évaluation

- Use of Nanofiltration For Partial Softening of Very Hard WaterDocument8 pagesUse of Nanofiltration For Partial Softening of Very Hard WaterThao DophuongPas encore d'évaluation

- 12Document6 pages12Thao Dophuong0% (1)

- 2Document7 pages2Thao DophuongPas encore d'évaluation

- Economic Feasibility Study of Polyelectrolyte-Enhanced Ultrafiltration (PEUF) For Water SofteningDocument15 pagesEconomic Feasibility Study of Polyelectrolyte-Enhanced Ultrafiltration (PEUF) For Water SofteningThao DophuongPas encore d'évaluation

- 15Document9 pages15Thao DophuongPas encore d'évaluation

- Water Softening Using A Generic Low Cost Nano-Filtration MembraneDocument6 pagesWater Softening Using A Generic Low Cost Nano-Filtration MembraneThao DophuongPas encore d'évaluation

- Desalination: Kristen S. Brastad, Zhen HeDocument6 pagesDesalination: Kristen S. Brastad, Zhen HeThao DophuongPas encore d'évaluation

- International Journal of Heat and Mass TransferDocument12 pagesInternational Journal of Heat and Mass TransferThao DophuongPas encore d'évaluation

- 16Document9 pages16Thao DophuongPas encore d'évaluation

- Electrochemical Water Softening: Principle and ApplicationDocument14 pagesElectrochemical Water Softening: Principle and ApplicationThao DophuongPas encore d'évaluation

- 11Document5 pages11Thao DophuongPas encore d'évaluation

- 13Document7 pages13Thao DophuongPas encore d'évaluation

- New Composite Membrane For Water SofteningDocument7 pagesNew Composite Membrane For Water SofteningThao DophuongPas encore d'évaluation

- Softening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsDocument6 pagesSoftening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsThao DophuongPas encore d'évaluation

- 6Document7 pages6Thao DophuongPas encore d'évaluation

- 7Document13 pages7Thao DophuongPas encore d'évaluation

- 2Document7 pages2Thao DophuongPas encore d'évaluation

- Water Softening Using A Generic Low Cost Nano-Filtration MembraneDocument6 pagesWater Softening Using A Generic Low Cost Nano-Filtration MembraneThao DophuongPas encore d'évaluation

- Use of Nanofiltration For Partial Softening of Very Hard WaterDocument8 pagesUse of Nanofiltration For Partial Softening of Very Hard WaterThao DophuongPas encore d'évaluation

- Desalination: Kristen S. Brastad, Zhen HeDocument6 pagesDesalination: Kristen S. Brastad, Zhen HeThao DophuongPas encore d'évaluation

- 3 M Conductive TapeDocument12 pages3 M Conductive TapebabaranddPas encore d'évaluation

- Industrial Training Report 18se02ch014Document9 pagesIndustrial Training Report 18se02ch014Alis Navadiya0% (1)

- Long Life Bearing Series: CAT - NO.199EDocument5 pagesLong Life Bearing Series: CAT - NO.199EJhefferson FreitasPas encore d'évaluation

- Catalysis: Submitted By: Ahsan Misbah Ul Hadi Submitted ToDocument10 pagesCatalysis: Submitted By: Ahsan Misbah Ul Hadi Submitted ToAsim AliPas encore d'évaluation

- Crouse Hinds Rs RSM Rss Junction Boxes Catalog PageDocument1 pageCrouse Hinds Rs RSM Rss Junction Boxes Catalog Pagejose luisPas encore d'évaluation

- Siemens PLM NX CAM 2 5 Axis Milling Add On Fs Tcm1023 118151Document2 pagesSiemens PLM NX CAM 2 5 Axis Milling Add On Fs Tcm1023 118151rasgeetsinghPas encore d'évaluation

- Capstone Report On Wheel Chair Cum StretcherDocument40 pagesCapstone Report On Wheel Chair Cum StretcherRakesh Moparthi100% (1)

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- Epoxy CuringDocument8 pagesEpoxy CuringUrban Renewal Development100% (1)

- Analisis Sikap Good Faith Non-Compliance Indonesia Dalam Upaya Implementasi Konvensi Basel Nehru AnggitaDocument9 pagesAnalisis Sikap Good Faith Non-Compliance Indonesia Dalam Upaya Implementasi Konvensi Basel Nehru AnggitaMuhammad IqbalPas encore d'évaluation

- Seamless VS Welded TubesDocument1 pageSeamless VS Welded Tubeshirenkumar patelPas encore d'évaluation

- High Voltage Motors: in Power GenerationDocument8 pagesHigh Voltage Motors: in Power GenerationKarim IsmailPas encore d'évaluation

- Conceptual Design: Thulhiriya Textile City Comprehensive Design ProjectDocument14 pagesConceptual Design: Thulhiriya Textile City Comprehensive Design ProjectAmila DayarathnaPas encore d'évaluation

- Product Catalogue Camfil FarrDocument61 pagesProduct Catalogue Camfil FarrTrần Hữu DũngPas encore d'évaluation

- Rock Cycle Crayon LabDocument4 pagesRock Cycle Crayon Labapi-251355123Pas encore d'évaluation

- Samalkot Lab - (16-17 SSR) (Final)Document161 pagesSamalkot Lab - (16-17 SSR) (Final)Phani PitchikaPas encore d'évaluation

- RI 4 Defect CausesDocument50 pagesRI 4 Defect CausesSathishkumar Srinivasan100% (1)

- 1301A01422 Zaranda 3500Document2 pages1301A01422 Zaranda 3500Edgar FloresPas encore d'évaluation

- Bulletin 446 - 1/06 - Alumina Loading Problems - Western AustraliaDocument2 pagesBulletin 446 - 1/06 - Alumina Loading Problems - Western Australialevent364Pas encore d'évaluation

- Analysis of Ink by TLCDocument7 pagesAnalysis of Ink by TLCkeshavPas encore d'évaluation