Académique Documents

Professionnel Documents

Culture Documents

Pile Design

Transféré par

peyostailDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pile Design

Transféré par

peyostailDroits d'auteur :

Formats disponibles

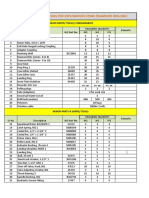

PILE DESIGN Reference: IS 2911(Part 1/Sec 3)-2010 ( Design for Bored cat in situ Pile) DATA: Type of Pile:

Bored cast in situ. Dia. Of pile =1.20m (Normally adopted for Bridge work) Length of Pile below pile cap=18.0m Depth of top of pilecap below ground level=45cm. Grade of Concrete: M35 Reinforcement Grade: Fe 500.clear cover to main reinforcement: 75mm Soil Parameters: Dry density of soil =18KN/m3 Submerged density of soil = 10 KN/m3 Angle of internal friction = 28 degree. Angle of wall friction between pile and soil =22.5 deg. (maximum as per code) Cohesion = Nil. DESIGN: Vertical Load Carrying capacity of pile : As per Appendix B.1 of Is2911(Part 1/Sec 2)-2010

= x 1.22/4= 1.131 m2

=1.20m

=unit weight (Submerged) =10KN/m3 =17.80 { for =28.0 deg as per IS 6403-1971}

=Pile length limit to 15 to 20 times pile dia =10x(0.45 + 1.8+20x1.2) or = 10 x( 0.45 +1.8+15 x 1.2) =202.5 KN/m2

=Bearing capacity factor( for =28.0 deg )=15.3 (From Fig. 1 of Appendix B of IS 2911 -2010)

= 1.5 as per Appendix B of IS2911(Part1/sec2)-2010 PD1=Effective overburden pressure at pile cap bottom. = 10x (0.45 +1.8) =22.5KN/m2 PD2=Effective overburden pressure at pile toe. = 10x (0.45 +1.8+18) =202.5KN/m2 = Angle of wall friction=22.5 deg. As1=Surface area of pile stem in the 1st layer = xDxL=3.14 x1.2x18=67.80m2 As2= Surface area of pile stem in the 2nd layer = x D x (L-20x Dia) =0 Q1= 1.131 x(0.5 x 1.20 x 10 x17.8 + 202.5 x 15.3) + [(22.5 x +202.5/2) x 67.80+ 202.5 x 0.000] x 1.50 tan 22.5 = 3625 +4740 =8365 KN Ultimate Bearing Capacity of pile =8365 KN

Factor of safety =2.50 Net Bearing Capacity = Qu/FOS = 8365/2.5= 3350KN. Horizontal Load carrying capacity of pile : The long flexible pile, fully or partially embedded, is treated as a cantilever fixed at some depth below the ground level. The maximum lateral load on any pile under normal condition should not exceed the value corresponding to 5 mm horizontal deflection (i.e at cutoff level). To find fixity depth: Referring to Appendix C given in Fig 3

LF= Depth of fixity L1= Height above ground level of lateral forces

E= Modulus of elasticity of concrete= 5000 sqrt 35 = 29580 MPa for M35 concrete. I=Moment of Inertia of pile in cm4 =3.14 x 1.24 x/64 = 0.1018 m4 =( For medium sand in submerged condition)=0.525kg/cm2

T= {( 29580 x 100) x 0.1018 x 108 }1/5 { 0.525 } =356 cm L1= 0 for fixity head piles. For fixed head piles in sand and normally loaded clays. From Fig 3 of Appendix C LF/T = Depth of fixity =2.18 LF = 2.18 x T =2.18 x 3.56 =7.76m Length of equivalent cantilever = L1+ Lf Pile head deflection y = Q (L1 +Lf)3 /12EI or Q= 12EI y/(L1+Lf)3 Where Q= Lateral load capacity of pile y= 5mm =0.5 cm Q= 12 x 29580 x 10 x 0.1018 x 108 x 0.5 / 7763 = 38664 kg or Q= 380KN Maximum moment on Pile: Fixed End moment in a fixed head pile is given by FEM= Q (L1+Lf)/2 Actual Maximum moment in pile M=m x Q(L1+Lf)/2 Where M= Maximum moment on pile M= Reduction factor For L1/T =0 and piles in sands and normally loaded clays, m= 0.82 ( from Fig 4 of Appendix C, corresponding to L1/R or L1/T) M= 0.82 x 380 x 7.76/2 =1200KN.m

Design of Pile Reinforcement: Under the governing seismic load case, if axial force and bending moment in a pile are 500KN and 1100 Kn.m design the reinforcement in the pile. Allowable stress in concrete =11.67 MPa for M35 concrete. Allowable stress in steel =240 MPa for Fe 500 steel. For seismic condtion the above stresses are increased by 50%.0 Reinforcement required is 1% that is 115 cm2 Mini. Steel required is 0.4%. Hence provide 15No.25 mm bars + 15 No. 20mm bars. These bars can be curtailed after the depth of fixity. i.e. 7.76m + Development length (40 times bar dia=7.76+40x25/1000= 9.0m below the pile cutoff level. Curtail 25mm bars, thus 15 No.20mm bars will continue up to the pile toe. SKETCH: Enclosed separately

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Section 06 - Hole CleaningDocument81 pagesSection 06 - Hole CleaningRicardo Villar100% (2)

- Project Management ProcessDocument23 pagesProject Management ProcessMuhammad Sajid Saeed100% (2)

- Principles of Failure AnalysisDocument2 pagesPrinciples of Failure AnalysisLuis Kike Licona DíazPas encore d'évaluation

- Round Hss DesignDocument2 pagesRound Hss DesignpeyostailPas encore d'évaluation

- FIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFDocument63 pagesFIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFamrefat77100% (1)

- CH - Mates PH II - Boiler QuestionsDocument13 pagesCH - Mates PH II - Boiler QuestionsArun GeorgePas encore d'évaluation

- Siemens Compressor PackageDocument8 pagesSiemens Compressor PackageMilos ObrenovicPas encore d'évaluation

- ACI 350-06 ExampleDocument1 pageACI 350-06 ExampleAhmed Ben Hmida100% (1)

- Waterproof Membrane SpecificationDocument4 pagesWaterproof Membrane SpecificationpeyostailPas encore d'évaluation

- Aisc360 - Single Plate Bolt Connection Column (Strong Axis) - To-Beam Rev. ADocument1 pageAisc360 - Single Plate Bolt Connection Column (Strong Axis) - To-Beam Rev. ApeyostailPas encore d'évaluation

- Asce - Natural Period Vertical Vessel Nonuniform PDFDocument1 pageAsce - Natural Period Vertical Vessel Nonuniform PDFpeyostailPas encore d'évaluation

- Vibration analysis of steel absorption towerDocument1 pageVibration analysis of steel absorption towerpeyostailPas encore d'évaluation

- Crane LoadsDocument2 pagesCrane LoadspeyostailPas encore d'évaluation

- Asce - Natural Period Vertical Vessel UniformDocument1 pageAsce - Natural Period Vertical Vessel UniformpeyostailPas encore d'évaluation

- Concreto en MasDocument1 pageConcreto en MaspeyostailPas encore d'évaluation

- Soil Bearing Pressure Coefficients Octagonal FootingsDocument1 pageSoil Bearing Pressure Coefficients Octagonal FootingspeyostailPas encore d'évaluation

- Steel Connection Design CalculationsDocument7 pagesSteel Connection Design CalculationspeyostailPas encore d'évaluation

- Ejercicio ConexionesDocument3 pagesEjercicio ConexionespeyostailPas encore d'évaluation

- Acer Aspire 5745p 5745pg 5820t Quanta Zr7 Rev 3b SCHDocument49 pagesAcer Aspire 5745p 5745pg 5820t Quanta Zr7 Rev 3b SCHWade DyerPas encore d'évaluation

- Labnet International 2011 International CatalogDocument60 pagesLabnet International 2011 International CataloglabnetinternationalPas encore d'évaluation

- DS150 Simon RO Service Manual EnglishDocument16 pagesDS150 Simon RO Service Manual EnglishJosé AdelinoPas encore d'évaluation

- Binary WorksheetDocument4 pagesBinary WorksheetMariell EllanoPas encore d'évaluation

- Pune University Simulation and Modeling Question PapersDocument2 pagesPune University Simulation and Modeling Question Paperspradeepkraj22Pas encore d'évaluation

- Wall-Mounting Speakers EN 54Document5 pagesWall-Mounting Speakers EN 54Mauricio Yañez PolloniPas encore d'évaluation

- Ramon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementDocument7 pagesRamon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementRam G. MorteraPas encore d'évaluation

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Kaung MyatToePas encore d'évaluation

- 14.H Out of Specification ResultsDocument10 pages14.H Out of Specification Resultsعبدالعزيز بدرPas encore d'évaluation

- Radiscreen-C Coarse Screen BR-ENDocument4 pagesRadiscreen-C Coarse Screen BR-ENmriosqPas encore d'évaluation

- 1SDA074199R1 Ekip Touch Lsig E1 2 E6 2Document2 pages1SDA074199R1 Ekip Touch Lsig E1 2 E6 2Vanderson Beltrão de CarvalhoPas encore d'évaluation

- Minimum drilling supplies stockDocument3 pagesMinimum drilling supplies stockAsif KhanzadaPas encore d'évaluation

- RT9173BDocument13 pagesRT9173BEletronica01 - BLUEVIXPas encore d'évaluation

- ISO 15589 1 2015, Petroleum andDocument21 pagesISO 15589 1 2015, Petroleum andamr s0% (1)

- B2-Embedded System DesignDocument20 pagesB2-Embedded System DesignSailesh KhandelwalPas encore d'évaluation

- Tiempos de entrega y actividades de aprendizajeDocument2 pagesTiempos de entrega y actividades de aprendizajejuanPas encore d'évaluation

- My Life - An Illustrated Biograp - A.P.J. Abdul KalamDocument76 pagesMy Life - An Illustrated Biograp - A.P.J. Abdul KalamAnonymous OJsGrxlx6100% (1)

- Coatings For Wind Power - Uk - 010213Document7 pagesCoatings For Wind Power - Uk - 010213King SabiPas encore d'évaluation

- Sample Code LmsDocument6 pagesSample Code LmsCharan TejaPas encore d'évaluation

- Mid Term Exam SolutionDocument7 pagesMid Term Exam SolutionBakhtiyar SuleimenovPas encore d'évaluation

- Keac 212Document17 pagesKeac 212Ias Aspirant AbhiPas encore d'évaluation

- TRINITY GCSL S2707 Quick Reference: J22 Front Panel ConnectorDocument1 pageTRINITY GCSL S2707 Quick Reference: J22 Front Panel Connectorrick krossPas encore d'évaluation

- Guidelines For Quality Control Testing For Digital CR DR Mammography V4Document62 pagesGuidelines For Quality Control Testing For Digital CR DR Mammography V4khaerul0% (1)

- Advanced S DOS Programming Microsoft Programmers PDF 9ededd7e1Document2 pagesAdvanced S DOS Programming Microsoft Programmers PDF 9ededd7e1Ojas Telwane100% (1)