Académique Documents

Professionnel Documents

Culture Documents

Brooks Trigger Kit 1st Set If Instructions

Transféré par

jimmywigglesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Brooks Trigger Kit 1st Set If Instructions

Transféré par

jimmywigglesDroits d'auteur :

Formats disponibles

Brooks trigger kit set if instructions READ ALL PAGES before attempting as a ballbearing is under the Sear pin

and if lost your in trouble? Ie. Do NOT remove Sear Pin

Step 1 -- take the stock off the rifle. To avoid marring up the screw slots, use a "proper" screw driver to do this. That means one with a hollow ground blade instead of the tapered blade found on normal screwdrivers. When you get the rifle out, you'll find the trigger's inner workings:

Step 2 - use a small screwdriver to lift the lock washer away from the adjusting nut on the trigger spring. That frees the nut so that you can use a small wrench (as I recall, it is 6mm) or a pair of pliers to turn the adjusting nut so that it moves down towards the trigger. Getting the nut all the way to the bottom of that rod gives you the lightest possible trigger pull with the spring currently installed in the rifle. Here is a close up of the spring and nut:

Step 3 - try the trigger to see if you are happy with it. You may want to put the stock back on to give it a proper try. Step 4 - If the trigger is not light enough, you can go a little bit further by removing the adjusting nut. That gives the spring a little more room to stretch out. To get the nut off, you first have to remove one of the pins from the trigger. In this pic, it is the pin at the top of the trigger, furthest to the left:

Use your pin punch and hammer to get that pin out. It will be a bit hard to get started but once it starts moving it should come out fairly easily. Put the rifle on a padded but solid surface (a towel on top of your work table) and support the trigger on something so you don't accidently bend it while hammering away. Something about the thickness of a deck of cards should do the trick in supporting the trigger. Once the pin starts moving you need to make sure it has room to get free on the back side. I just put it on my lap at that point. Step 5 - With the pin removed, you can pivot the trigger down and forward, allowing you to remove the adjusting rod from the hole where it goes up into the action. Slide the spring off the rod, then remove the washer and nut. Put the washer and nut away someplace safe in case you decide to reinstall them later. Now put the spring back on and reassemble everything. Step 6 - Try your trigger again. If still not happy with it, the next step is to replace the spring with a weaker one. Take it back apart (as in step 4), put the nut and washer back on, then put on your lighter spring and reassemble everything. If you find the new spring makes the trigger pull too light just turn the adjusting nut so it climbs away from the trigger and compresses the spring... that makes the pull harder.

http://cz452.com/springkit.html

CZ-452 Rifle Trigger Improvements

Although it is a relatively new arrival to the USA, this series of Czechoslovakian .22 calibre rimfire rifles has been around much of the world for close to 40 years. They have proven to be well-made and quite accurate rifles, and offer excellent value at a reasonable cost. Regardless of the specific model, they tend to have one major shortcoming. The trigger pull, although adjustable in theory, is far too heavy and exhibits too much creep and overtravel in its' operation to suit the tastes of most serious shooters. Over the years, one man . . . Dr. "Nick" Panisuan of Bangkok, Thailand . . . ( I almost showed my age and wrote Siam ! ) . . . has pioneered some simple techniques for minimising these shortcomings. Unfortunately the public website, on which he long exhibited photos of these modifications, has now disappeared in the ongoing turmoil of the Internet. Similarly, myself and others have taken his ideas and expanded or improved (?) them to suit our own needs. This project page will show some of the modifications that any owner of one of these fine guns can carry out with the simplest tools. Dismantling the barreled action - Separate it from the stock by removing the bedding screws to be found in the trigger guard. Take careful note of the arrangement of the various magazine and spacer pieces that are also "uncovered" when you do this. Some owners find it more convenient to handle the barreled receiver if the magazine fittings are also removed at this time. Be aware that the number and location of the bedding and trigger guard screws varies somewhat between different models in this series. The bolt should also be removed by holding the trigger all the way back while uncocking the bolt. To Lighten the Trigger Pull - You will find the trigger / sear sub-assembly held to the lower edge of the receiver by two small pins of approximately 4mm in diameter, (Ref. Figs. 1 and 2 ). Note the third, centre, pin located in the front trunnion of the trigger itself, is staked in position and should not, repeat not, be removed at any time ... ( I'll change that "opinion" later in the instructions for adjusting creep ). If all you want to do is lighten the trigger pull, then remove only the rear trigger pin using a suitably sized pin-punch, ( a #10 finish nail with the point removed works just fine), and light tack hammer. This will allow the rear of the assembly to swing down, thus enabling you to remove the trigger coil spring from its' support rod. ( Note the pull-weight adjustment nut at the lower end of this rod ! ). In his original version, "Nick" suggested replacing this spring with one half of a #150 stock spring available at that time from most larger Ace hardware stores. This pattern spring is rarely to be found nowadays, as Ace has changed suppliers . . . currently they are stocking springs made by Century Spring Corp. of Los Angeles, CA. (CSC).

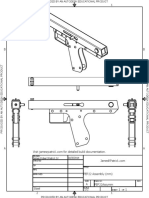

Fig. 1

Trigger and Sear Pin Locations

Fig. 2

Instead you have several options, depending upon the desired pull-weight range for your needs. Some owners have tried modifying the springs from retractable ball-point pens, but they tend to be too light and of inferior materials and workmanship. If you want a super-sensitive target-style pull-weight of a few ounces, then I would suggest replacing the original spring with the CSC #C-582 from your Ace store . . . this is 3/16" dia. x 13/8" long x 0.016" wire. For day-to-day hunting or plinking my recommendations would be for a heavier gauge spring wire. Unfortunately, the next-heavier, and available, CSC #C-580 springs . . . 3/16 dia x 1-3/8" long x 0.028" wire . . . are a slight interference fit on the locating rod. Therefore, if this is your preference, you will probably need to either change to one of the 7/32" diameter springs, or try your hand at "slightly untwisting" the #C-580 spring over a suitable nail or other mandrel to expand it in internal diameter . . . a tricky operation akin to wrestling a 20 foot anaconda with your finger tips . . . the spring should slide freely over the rod when finished. (See notes below on the availability of complete sets of replacement springs from Eric Brooks) Adjusting Trigger Creep - There are several basic methods for doing this. Regardless of which is used, you will need to remove the front sear attachment pin shown in Figs. 1 and 2 above . . . this separates the sear from the receiver. It also

presents you with a small problem ! In newer models of the CZ-452, the lower front of the sear contains a spring-loaded ball that bears against the receiver . . . the moment the pin is removed this ball tends to disappear forever into 'never-never land' unless restrained, ( Ref. Fig 3 ). I will discuss this problem further down ! Older versions of the rifle use a captive spring plunger.

Fig. 3 Sear Spring / Ball Arrangement Fig. 4 Trigger / Sear Engagement Fig. 4 shows the situation that we are seeking to control . . . the "overlapping" engagement of the trigger and sear. Creep is controlled by minimising that overlap to a point where the desired amount of trigger movement is obtained. Traditionally, a gunsmith would lock one or other of the two components in a special jig and carefully stone away material until the desired interaction is obtained. This involves much trial and error in re-assembling and dismantling of the sear / trigger unit to the receiver . . . very time consuming, not to mention wear and tear on the pins and trunnions. In general I would only recommend light stoning if there should be evidence of machining burrs at this point . . . just enough to remove the burrs, no more ! So how about alternatives ? If you have the equipment and experience it can be accomplished by removing the "centre staked-in pin" that I just told you never to remove . . . it is actually the front pin in the trigger trunnion. Then you will need to machine a slightly larger diameter pin, ream out the old holes in the front trunnion of the trigger, and press in and re-stake the new pin. Diameter of the new pin ? Ahah ! This will

prove to be a trial and error operation, but the size increase will vary from gun to gun, probably in the range of .010 to .030 ". Again, much trial and error re-assembly effort to find the right diameter. Obviously we need something simpler ? Dr "Nick" has come up with a very simple technique for enlarging the pin diameter without all that fuss . . . ! I use it myself and it works just fine. First, get a roll of adhesive-backed aluminium foil furnace tape at the hardware store. Then separate the sear from the trigger, and clean the surface of that front pin in the trigger trunnion using Acetone or MEK. Cut a short strip of the aluminium tape. This strip should be trimmed in width with a sharp knife or scissors to slightly less than the inside length of the pin. Now carefully wrap and stick the tape strip around that front trigger pin . . . three complete wraps works best if the rifle is to be used for competitive target shooting in conjunction with the C-582 spring, and two complete wraps for the hunting rifle conversion. This wrapping is a little tricky, but if you only "stick down" the tape on the accessible rear, upper and front surfaces of the pin, then carefully feed the loose end of the tape through the gap between the pin and the trigger . . . a little push with a screwdriver helps here . . . before attempting to pull it tight around the pin, it is not too difficult. See Fig. 5 for details of a "wrapped" pin.

Fig. 5 Tape-wrapped Front Trigger Pin If you're not confident about the resulting amount of creep that this gives, go ahead and do a trial re-assembly to the receiver . . . ! Personally, I have found by actual usage that this checking is really not necessary. Reducing Overtravel - With pull-weight and creep now adjusted to our liking, there remains the problem of trigger overtravel after sear release. Again there are several methods of reducing this. As the amount of overtravel is controlled in the original design by linear motion of the trigger spring support rod in the matching pocket in the receiver, Dr "Nick" originally suggested light hammering, ( "cold forging" ), of the surfaces of the trigger spring support rod . . . this has the effect of reducing it in

diameter and slightly increasing its' length. My preferred methods involve building up the height of the upper surface of the sear in the area where the wrapped trigger pin contacts it. This can be accomplished by depositing braze spelter, silver solder or soft solder on the upper surface of the sear . . . problem here is heat ! It can destroy the hardness of that heat-treated sear. Instead try one of these methods. Thoroughly clean the upper and side surfaces of the sear with Acetone or MEK. Now add small strips of the aluminium furnace tape to the upper surface to build up the height, and finish up with a strip wrapped over them and down each side of the sear to minimise peeling in use. An even better method, and the one I now use, is to again fall back on the old reliable 5-Minute Epoxy resin. Rough up the upper surface of the sear with a fine file or emery cloth and again thoroughly clean with Acetone or MEK. Mix up a small quantity of the epoxy resin and build up a blob on that upper surface. After the resin thoroughly hardens, dress down the upper surface of the blob to the desired height with a detail sander tool or fine file. Like many tasks in the gunsmithing world this is unfortunately a trial and error operation. If you have reservations about the durability of the resin in long-term use, then cover it with a strip of the aluminium tape from side to side of the sear. Earlier I mentioned the "disappearing ball" problem. A suitable replacement ball can be found at Ace in their specialty hardware section . . . get some of the 5/32" diameter variety, (the original ball size is 4mm but these replacements are only 0.001" off ). The real problem is getting the trigger / sear sub-assembly back in the receiver without again losing the ball and spring. Try putting a small dab of gap-filling Crazy glue on one end of the spring and fastening the ball to it with light pressure . . . be careful not to bond your fingers in place during this process ! Then using finish nails smaller than the actual sear and rear trigger pins as temporary holding devices, carefully re-assemble the unit to the receiver. Now re-insert the sear pin, pushing out the "nail" pin as you do it. Finally tap in the rear trigger pin, knocking out that temporary "nail pin" in the process. If, like me, you only have three hands it is tricky but achievable . . . supporting the barreled action in a padded vise helps at this point . . . using the "nail" pins as levers also helps to get the real pins aligned with the holes. One last item . . . if, like me, you prefer the "American" scope-sights-only version of the CZ-452, either the Sporter or the Varmint variety, I would recommend that you check the fit of the barrel in the forearm of the stock. Make sure that the barrel is fullyfloated back to within an inch or so of the receiver . . . light sanding of the barrel groove is all that is necessary, although a light coating of MinWax Wipe-on Poly varnish will minimise future moisture absorbtion. Glass bedding the action will really finish off these modifications, but that's another story !!! Now go out and play in the yard ! ( NB - All photos edited from Dr. Panisuan's originals)

POSTSCRIPT ! Since the above was written, there have been several "commercial" developments to aid

in the above trigger improvements. First and foremost, Eric Brooks, "Brookie" of Oneonta, NY has put together a kit of assorted springs that can be used to obtain various trigger pull weights to suit the individual owner. The kit also includes several tubular sleeves of differeing wall thicknesses, that can be used to replace the foil tape wrap described in my article for controlling creep. An excellent kit value for $9.00 including shipping . . . saves hunting for them in your local Ace Hardware. His website contains answers to many CZ-452 questions, and descriptions of other products of interest to the CZ-452 owner. These include his new low-profile Weaver adapters for both 11mm and 3/8 inch dovetail bases, and "ghost ring" rear sight blades for those with open-sighted variants of this rifle. So . . . . visit his Website: or E-mail him at : ebrooks77@hotmail.com Another item of interest . . . an adjustable sear, made by Automated Solutions, is now obtainable from Brownells . . . check their latest catalogue. Finally, the Timney folk have developed complete replacement trigger units for the CZ452 .... one that fits the regular .22 and .17Mach2, and another that fits the .22WMR and .17HMR rifles.

Vous aimerez peut-être aussi

- P90X Workout SheetsDocument7 pagesP90X Workout SheetsEric Pelz50% (2)

- Build Lower ReceiverDocument27 pagesBuild Lower ReceiverBrian ButePas encore d'évaluation

- Building a Home Defense Remington 870 ShotgunD'EverandBuilding a Home Defense Remington 870 ShotgunÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Threading A Barrel For A Muzzle Brake or orDocument4 pagesThreading A Barrel For A Muzzle Brake or orJohnn SchroederPas encore d'évaluation

- Building Firearms - HoffmanDocument81 pagesBuilding Firearms - HoffmanWilliam Owers100% (2)

- Saxophone SoundDocument10 pagesSaxophone SoundMia Lesaca-Medina67% (9)

- Low Calorie Food Calories List for Weight LossDocument9 pagesLow Calorie Food Calories List for Weight Losshammoudeh13Pas encore d'évaluation

- The AK-47 Full Auto Conversion For DummiesDocument6 pagesThe AK-47 Full Auto Conversion For Dummiesjaroslav100% (1)

- Blueprints To Build A Mark II Sten GunDocument25 pagesBlueprints To Build A Mark II Sten GunKawchhar AhammedPas encore d'évaluation

- OBAS-12 Updated v2Document89 pagesOBAS-12 Updated v2Professor100% (2)

- PM 01 CarbineDocument9 pagesPM 01 CarbineK Scott Wyatt100% (2)

- IPG223Silencer Assembly GuideDocument10 pagesIPG223Silencer Assembly GuideTimPas encore d'évaluation

- Sextant User's GuideDocument24 pagesSextant User's GuideHenrik Lindqvist100% (1)

- Us 3722358Document9 pagesUs 3722358awe234Pas encore d'évaluation

- Correct Trigger Slap and Doubling in AK RiflesDocument8 pagesCorrect Trigger Slap and Doubling in AK RiflesAdam Hemsley100% (2)

- AR15 Parts AssemblyDocument10 pagesAR15 Parts Assemblykolas hernandezPas encore d'évaluation

- Build TutorialDocument9 pagesBuild Tutorialohsweet jeremyPas encore d'évaluation

- Crosman 2011 Product CatalogDocument36 pagesCrosman 2011 Product CatalogAmmoLand Shooting Sports News100% (1)

- Body Beast Food ListsDocument5 pagesBody Beast Food ListsSthefany Almanzar100% (1)

- Armalite AR-7 RifleDocument6 pagesArmalite AR-7 Rifleblowmeasshole1911Pas encore d'évaluation

- Practical Guide to the Operational Use of the PPS-43 Submachine GunD'EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunPas encore d'évaluation

- PG22 Maverick 22 Short Revolver Build GuideDocument6 pagesPG22 Maverick 22 Short Revolver Build GuideTimPas encore d'évaluation

- Sten Plans The Sten MkiiDocument28 pagesSten Plans The Sten MkiiJohn FindleyPas encore d'évaluation

- Manual Colt 1911 22 Rimfire GoldDocument28 pagesManual Colt 1911 22 Rimfire Goldtostes_brPas encore d'évaluation

- Glock Generation PDFDocument18 pagesGlock Generation PDFสุรา ไทประดิษฐ์100% (1)

- Service Manual: WashingDocument37 pagesService Manual: WashingjimmywigglesPas encore d'évaluation

- Handi Instr OneDocument9 pagesHandi Instr OnenotjustsomeonePas encore d'évaluation

- Workoutsheet PDFDocument1 pageWorkoutsheet PDFwaseem1986Pas encore d'évaluation

- 9mm PistolDocument24 pages9mm PistolGeorg WolfPas encore d'évaluation

- The Armalite AR-7 Survival RifleDocument6 pagesThe Armalite AR-7 Survival Rifleblowmeasshole1911Pas encore d'évaluation

- Sample Essay #1 - Accepted by Harvard: Admissions Committee CommentsDocument3 pagesSample Essay #1 - Accepted by Harvard: Admissions Committee CommentsKepher OnukoPas encore d'évaluation

- Sterling Build V2Document16 pagesSterling Build V2Nester Tovar100% (2)

- The Fit Test P90X: Start With The Heart DateDocument5 pagesThe Fit Test P90X: Start With The Heart DatejimmywigglesPas encore d'évaluation

- Gunpower TalonDocument4 pagesGunpower TalonolhodeboiPas encore d'évaluation

- Jaco DerringerDocument4 pagesJaco DerringerFunkpiratPas encore d'évaluation

- Polymer80: Phoenix Version - G150 80% Lower Receiver InstructionsDocument13 pagesPolymer80: Phoenix Version - G150 80% Lower Receiver InstructionsTimothy ScottPas encore d'évaluation

- PEP22 Assembly DrawingDocument1 pagePEP22 Assembly Drawingkolas hernandezPas encore d'évaluation

- Cetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsDocument7 pagesCetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsRon WalshPas encore d'évaluation

- Chimera ManualDocument12 pagesChimera ManualticocrazyPas encore d'évaluation

- AMT LightningDocument9 pagesAMT LightningJustinPas encore d'évaluation

- Converting A Saiga To Pistol Grip ConfigurationDocument57 pagesConverting A Saiga To Pistol Grip ConfigurationEric Rumfelt100% (1)

- DP Series Build SheetDocument49 pagesDP Series Build SheetJoe CreolePas encore d'évaluation

- Build blueprints for gunsDocument2 pagesBuild blueprints for gunsZehBrzPas encore d'évaluation

- Checkmate II .22lr Manual.Document2 pagesCheckmate II .22lr Manual.Griffin Armament SuppressorsPas encore d'évaluation

- 2016catalogweb PDFDocument108 pages2016catalogweb PDFCamilo JustinianoPas encore d'évaluation

- 12 Gauge Pistol Breech Block Machining DimensionsDocument3 pages12 Gauge Pistol Breech Block Machining DimensionsDavid Hoffman100% (1)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsD'EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsPas encore d'évaluation

- RShooter - June 2016Document76 pagesRShooter - June 2016Dennis ShongiPas encore d'évaluation

- Sten mk2 Complete Machine Instructions PDFDocument24 pagesSten mk2 Complete Machine Instructions PDFTristan Jones100% (2)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesD'EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesPas encore d'évaluation

- GRT-III Trigger Blade InstructionsDocument5 pagesGRT-III Trigger Blade InstructionsPatrik Avlo100% (1)

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsD'EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsÉvaluation : 5 sur 5 étoiles5/5 (3)

- MPA 22 ManualDocument16 pagesMPA 22 ManualChris Choat100% (1)

- Assembling Your Own Stripped AR - 1Document103 pagesAssembling Your Own Stripped AR - 1bigwhiteguy100% (1)

- Us 20060101695Document11 pagesUs 20060101695galak12001Pas encore d'évaluation

- l5r RPG 4th Ed - Homebrew Unofficial PathsDocument1 pagel5r RPG 4th Ed - Homebrew Unofficial PathsLuca CherstichPas encore d'évaluation

- Lyman Hollow Point BulletsDocument5 pagesLyman Hollow Point BulletsTactic Otd ArgPas encore d'évaluation

- Build a semi-auto RPD rifle from a parts kitDocument6 pagesBuild a semi-auto RPD rifle from a parts kitDale Wade50% (2)

- 9mm BSP Machine Gun: Legal NoteDocument29 pages9mm BSP Machine Gun: Legal NoteLeonBackupsPas encore d'évaluation

- 2014 Bear Adult Bow ManualDocument40 pages2014 Bear Adult Bow Manualjohn0% (1)

- Spring RatingDocument6 pagesSpring Ratingbrowar444Pas encore d'évaluation

- Build Your Own Tow DollyDocument58 pagesBuild Your Own Tow DollyjimmywigglesPas encore d'évaluation

- CZ 452 Benchrest Custom TriggerDocument9 pagesCZ 452 Benchrest Custom Triggerernst1978Pas encore d'évaluation

- Tanfoglio Thor Single Shot PistolDocument20 pagesTanfoglio Thor Single Shot PistolAndrew Gates100% (1)

- CZ Usa - 2016 Product Catalog PDFDocument73 pagesCZ Usa - 2016 Product Catalog PDFGabriel Lee100% (1)

- GSG MP40 - 9x19 - America PDFDocument20 pagesGSG MP40 - 9x19 - America PDFeric100% (1)

- Tuning The Pietta Part OneDocument19 pagesTuning The Pietta Part Oneack67194771100% (2)

- Age of TrebuchetDocument17 pagesAge of Trebuchettheonetrickponymikkel1100% (1)

- Target Shooter NovemberDocument96 pagesTarget Shooter NovemberTarget Shooter75% (4)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.D'EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Évaluation : 5 sur 5 étoiles5/5 (1)

- Martini-Enfield MK I and MK II RiflesDocument5 pagesMartini-Enfield MK I and MK II Riflesblowmeasshole1911Pas encore d'évaluation

- D-Bit Chambering Reamer MakingDocument5 pagesD-Bit Chambering Reamer MakingEadPas encore d'évaluation

- Dec. 22, 1953 R. T. Catlin Etal: AmmunitionDocument4 pagesDec. 22, 1953 R. T. Catlin Etal: Ammunitionkahj juliPas encore d'évaluation

- RSTA Muzzle Brake / Flash Suppressor Mount Installation ManualDocument2 pagesRSTA Muzzle Brake / Flash Suppressor Mount Installation ManualGriffin Armament Suppressors0% (1)

- DR Bob's Quick Fill InstructionsDocument3 pagesDR Bob's Quick Fill Instructionsgraham4877100% (1)

- ST Albans Campus Map Oaklands CollegeDocument1 pageST Albans Campus Map Oaklands CollegejimmywigglesPas encore d'évaluation

- Thermal Inspection Code of PracticesDocument17 pagesThermal Inspection Code of PracticesjimmywigglesPas encore d'évaluation

- ESST CE190 Guide For Developers and Planners PDFDocument24 pagesESST CE190 Guide For Developers and Planners PDFjimmywigglesPas encore d'évaluation

- Heating CatalogueDocument15 pagesHeating CataloguejimmywigglesPas encore d'évaluation

- Sacred Heart Church Ware Parish Newsletter May 15th 2016Document6 pagesSacred Heart Church Ware Parish Newsletter May 15th 2016jimmywigglesPas encore d'évaluation

- Site Pass & Safety Induction Application Form: Trade Contractor Details (Please Print All Details Clearly)Document1 pageSite Pass & Safety Induction Application Form: Trade Contractor Details (Please Print All Details Clearly)jimmywigglesPas encore d'évaluation

- Osteoarthritis Thumb Joint 9 PDFDocument16 pagesOsteoarthritis Thumb Joint 9 PDFjimmywigglesPas encore d'évaluation

- AC Heating Heat Pumps - Installation EngineerDocument1 pageAC Heating Heat Pumps - Installation EngineerjimmywigglesPas encore d'évaluation

- How To Make ParallettesDocument4 pagesHow To Make ParallettesTomas BenadikPas encore d'évaluation

- Alto Flash CardsDocument6 pagesAlto Flash Cardsjimmywiggles100% (1)

- Inner Warrior WorkoutDocument1 pageInner Warrior WorkoutjimmywigglesPas encore d'évaluation

- Brute Abs WorkoutDocument1 pageBrute Abs WorkoutjimmywigglesPas encore d'évaluation

- Alto Flash CardsDocument6 pagesAlto Flash CardsjimmywigglesPas encore d'évaluation

- ... Muscle Chart Front PDFDocument1 page... Muscle Chart Front PDFjimmywigglesPas encore d'évaluation

- Sax FingeringsDocument4 pagesSax FingeringsjimmywigglesPas encore d'évaluation

- Sightreading Rules PDFDocument2 pagesSightreading Rules PDFjimmywigglesPas encore d'évaluation

- Sightreading Rules PDFDocument2 pagesSightreading Rules PDFjimmywigglesPas encore d'évaluation

- Sax FingeringsDocument4 pagesSax FingeringsjimmywigglesPas encore d'évaluation

- Hercules Muscle Chart Front PDFDocument1 pageHercules Muscle Chart Front PDFjimmywigglesPas encore d'évaluation

- YogaDocument77 pagesYogajimmywigglesPas encore d'évaluation

- 8 Sets of 8 The Way Vince Gironda InstructedDocument18 pages8 Sets of 8 The Way Vince Gironda InstructedjimmywigglesPas encore d'évaluation

- Gamo Export 18Document67 pagesGamo Export 18magatsu2099Pas encore d'évaluation

- WRABF and ERABSF Rulebook 2012 - 2013Document30 pagesWRABF and ERABSF Rulebook 2012 - 2013wwbr22adminPas encore d'évaluation

- Archery Safety RulesDocument6 pagesArchery Safety RulesToan NguyenPas encore d'évaluation

- USA Archery Bab 8 PDFDocument22 pagesUSA Archery Bab 8 PDFAgus IsdiyantoPas encore d'évaluation

- Lancaster PistolDocument5 pagesLancaster Pistolblowmeasshole1911Pas encore d'évaluation

- Firefight Cheat Sheet: Firearms Difficulty Levels Using FirearmsDocument1 pageFirefight Cheat Sheet: Firearms Difficulty Levels Using FirearmsDiego Amaya0% (1)

- Sniper LevelzingDocument1 pageSniper LevelzingEmiya KiritsuguPas encore d'évaluation

- Crosman 2015 CatalogDocument39 pagesCrosman 2015 CatalogjemoqccaPas encore d'évaluation

- UZI Action Arms .22 Conversion ManualDocument5 pagesUZI Action Arms .22 Conversion Manualgreaternorthroad8820Pas encore d'évaluation

- Marksmage: Master of Magic and ArcheryDocument4 pagesMarksmage: Master of Magic and ArcheryYipyiohPas encore d'évaluation

- Titan HLX ManualDocument3 pagesTitan HLX Manualhockeyfans46Pas encore d'évaluation

- Hasil Kualifikasi Sore Sabtu (11 Maret 2023)Document2 pagesHasil Kualifikasi Sore Sabtu (11 Maret 2023)Andi ZhafiraPas encore d'évaluation

- October 13th 2012 CatalogDocument114 pagesOctober 13th 2012 Catalogewood1999Pas encore d'évaluation

- Howa m1500 243winDocument5 pagesHowa m1500 243winxcfbgrthwyPas encore d'évaluation

- 2015 Browning Catalog FirearmsDocument73 pages2015 Browning Catalog Firearmsqcqapgh7748Pas encore d'évaluation

- Guide to Shotguns A-ZDocument8 pagesGuide to Shotguns A-ZYorgos KordoniasPas encore d'évaluation

- Stoeger Airguns 2018 CatalogueDocument18 pagesStoeger Airguns 2018 CatalogueJennifer EstradaPas encore d'évaluation

- Perazzi 2011-2012Document136 pagesPerazzi 2011-2012Peter DavidsonPas encore d'évaluation

- Eagle Imports 2015 Firearms CatalogDocument25 pagesEagle Imports 2015 Firearms CatalogAmmoLand Shooting Sports NewsPas encore d'évaluation