Académique Documents

Professionnel Documents

Culture Documents

An Industrial Design Control Study For VAC Monomer Process PDF

Transféré par

PY YouTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

An Industrial Design Control Study For VAC Monomer Process PDF

Transféré par

PY YouDroits d'auteur :

Formats disponibles

Computers Chem. Engng Vol. 22, No. 78, pp.

867877, 1998

1998 Elsevier Science Ltd

All rights reserved. Printed in Great Britain

PII: S0098-1354(98)00030-1 00981354/98 $19.00#0.00

An industrial design/control study

for the vinyl acetate monomer process

Michael L. Luyben* and Bjo rn D. Tyre us

DuPont Central Research & Development, Experimental Station - Bldg 357, P.O. Box 80357,

Wilmington, DE 19880-0357, USA

(Received 23 April 1997; received in revised form 29 December 1997)

Abstract

This work presents design details of an industrial process for the manufacture of vinyl acetate monomer. Our

purpose is to oer a realistic example that is uniquely suited for academic researchers pursuing simulation,

design, and control studies. The vinyl acetate process has common, real chemical components. It contains many

standard unit operations in a realistic owsheet. And it illustrates the types of systems of industrial research

interest in the areas of process design, optimization, simulation, and control. Vapor-phase reactions convert

ethylene, oxygen, and acetic acid into vinyl acetate with water and carbon dioxide as byproducts. The process

contains a packed tubular reactor, a feed-euent heat exchanger, an absorber, a vaporizer, an azeotropic

distillation column with decanter, and both gas and liquid recycle streams. All physical property, kinetic, and

owsheet data have been compiled from sources in the open literature. We detail the owsheet information

required to construct rigorous steady state and dynamic mathematical models of the process and present the

process control requirements and objectives. Finally, we briey describe the rigorous nonlinear dynamic

simulation we have constructed for this process using TMODS, DuPonts in-house dynamic simulator. Models

of this process have also been developed by Aspen Technology and Hyprotech in their commercial simulators

and are available directly from the vendors. 1998 Elsevier Science Ltd. All rights reserved

Keywords: industrial design/control study; vinyl acetate monomer process

1. Introduction

Downs and Vogel (1993) published an industrial

plantwide control test problem that has proved to be

a benecial service to the academic process control

community. A number of researchers have utilized

this example to test their ideas and technical develop-

ments. Many publications have appeared about the

Eastman process, which was provided as a dynamic

simulation in Fortran code. The problem has usefully

served as a realistic check on the industrial and practi-

cal relevance of the ever-increasing amount of process

control publications in chemical engineering.

We have heard of continued interest among aca-

demic researchers within the process design and con-

trol areas to have additional industrial examples of

realistic processes that can be used in assessing new

technology. We also recognize the need in the litera-

ture for plantwide design, optimization, and control

studies that grapple with: (1) a realistically large

*Corresponding author. E-mail: luybenml@esvax.dnet.

dupont.com.

process owsheet containing standard chemical unit

operations; (2) a process with the typical industrial

characteristics of recycle streams and energy integra-

tion; and (3) real nonideal chemical components.

This paper presents design details of an industrial

process for the production of vinyl acetate monomer

and thus goes a step beyond the Eastman process

control challenge problem. The reaction loop section

of the vinyl acetate process contains a owsheet and

unit operations that are typical of many chemical

plants. It has both gas and liquid recycle streams with

real components.

We have chosen to convey this study as if we had

been assigned the task of designing the control system

for a proposed new vinyl acetate process that is to be

built. We have been given a particular preliminary

design that has not been optimized. The design could

potentially be improved with modications to the

owsheet or design parameters.

The data we provide in this paper are what would

typically be available or easily obtainable: (1) kinetic

reaction parameters and physical property data, (2)

a owsheet structure with stream and equipment

information, and (3) the location of control valves

867

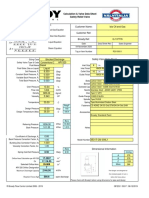

Fig. 1. Vinyl acetate monomer process owsheet.

included in the preliminary design. However, we

would not be given a linear transfer function model.

We certainly would not have a rigorous nonlinear

dynamic simulation. Steady state and dynamic mod-

els would have to be constructed by using a commer-

cial software simulation package or by writing the

code in some chosen programming language. As a re-

sult, unlike Downs and Vogel (1993), we do not make

available any code that simulates the vinyl acetate

process. Based upon the information provided in this

paper, models have been developed by Aspen Techno-

logy and Hyprotech in their commercial simulators.

We have ourselves built a rigorous nonlinear dy-

namic model of the process described in this paper

using TMODS, DuPonts in-house dynamic simula-

tor. This model has been used to verify the feasibility

of the simulation and to test the plantwide control

strategy proposed in Luyben et al. (1997). We believe

that this process should serve as a useful example for

researchers who are interested in working on indus-

trially relevant problems in simulation, design, and

control.

The industrial process for the vapor-phase manu-

facture of vinyl acetate monomer is quite common

(Daniels, 1989) and utilizes widely available raw ma-

terials. Vinyl acetate is used chiey as a monomer to

make polyvinyl acetate and other copolymers.

Hoechst-Celanese, Union Carbide, and Quantum

Chemical are reported US manufacturers. DuPont

also currently operates a vinyl acetate process at its

plant in LaPorte, Texas. To protect any proprietary

DuPont information, all of the physical property and

kinetic data, process owsheet information, and

modeling formulation in this work come from sources

in the open literature. We cite each source of data and

our process owsheet is based upon the description in

Report 15B by SRI International (1994). No relation,

either implied or intended, exists between this pub-

lished study and the DuPont process.

2. Vinyl acetate process

Figure 1 shows the eleven basic unit operations

proposed for the reaction section of the vinyl acetate

process, which is the focus of this study and the plant

we wish to design and operate. Three raw materials,

ethylene (C

`

H

"

), oxygen (O

`

), and acetic acid (HAc),

are converted into the vinyl acetate (VAc) product.

Water (H

`

O) and carbon dioxide (CO

`

) are byprod-

ucts. We assume that an inert component, ethane

(C

`

H

'

), enters with the fresh ethylene feed stream. We

consider the following two reactions:

C

`

H

"

#CH

`

COOH#1/2 O

`

PCH

`

"CHOCOCH

`

#H

`

O, (1)

C

`

H

"

#3O

`

P2CO

`

#2H

`

O. (2)

The exothermic reactions occur in a reactor contain-

ing tubes packed with a precious metal catalyst on

a silica support. Heat is removed from the reactor by

generating steam on the shell side of the tubes. Water

ows to the reactor from a steam drum, to which

make-up water (BFW) is supplied. The steam leaves

the drum as saturated vapor. The reactions are irre-

versible and the reaction rates have an Arrhenius-type

dependence on temperature.

868 M.L. LUYBEN and B.D. TYRE US

We located plots of experimental kinetic data in

Samanos et al. (1971) for a particular vinyl acetate

catalyst. As summarized by Neurock et al. (1996),

various mechanisms have been proposed for the

formation of vinyl acetate (i.e. Samanos et al., 1971;

and Nakamura and Yasui, 1970, develop completely

dierent expressions). However, we derived the fol-

lowing rate expressions that provide the best t to the

experimental data.

r

"0.1036 exp(!3674/)

;

p

-

p

#

p

(1#1.7p

5

)

(1#0.583p

-

(1#1.7p

5

)) (1#6.8p

)

, (3)

r

`

"1.9365;10` exp(!10, 116/)

;

p

-

(1#0.68p

5

)

1#0.76p

-

(1#0.68p

5

)

, (4)

where r

has units of moles of vinyl acetate produced/

min/(g catalyst) and r

`

has units of moles of ethylene

consumed/min/(g catalyst). is the absolute temper-

ature in Kelvin and p

G

is the partial pressure of com-

ponent i (O is oxygen, E is ethylene, A is acetic acid,

and is water) in psia.

The standard state heat of reaction is

!42.1 kcal/mol of vinyl acetate for r

and !316

kcal/mol of ethylene for r

`

. These values are cal-

culated using heats of formation from the DIPPR

database. Thus the reactions are quite exothermic,

particularly the combustion reaction to carbon dioxi-

de, which also is more sensitive to temperature be-

cause of the higher activation energy.

The reactor euent ows through a process-to-

process heat exchanger, where the cold stream is the

gas recycle. The reactor euent is then cooled with

cooling water and the vapor (oxygen, ethylene, carbon

dioxide, ethane) and liquid (vinyl acetate, water, acetic

acid) are separated. The vapor stream from the separ-

ator goes to the compressor and the liquid stream

from the separator becomes a part of the feed to the

azeotropic distillation column. The gas from the com-

pressor enters the bottom of an absorber, where the

remaining vinyl acetate is recovered. A liquid stream

from the base is recirculated through a cooler and fed

to the middle of the absorber. Liquid acetic acid that

has been cooled is fed into the top of the absorber to

provide the nal scrubbing. The liquid bottoms prod-

uct from the absorber combines with the liquid from

the separator as the feed stream to the distillation

column.

Part of the overhead gas exiting the absorber enters

the carbon dioxide removal system. This could be one

of the several standard industrial CO

`

removal pro-

cesses. Here we simplify this system by treating it as

a component separator with a certain eciency that is

a function of rate and composition. The gas stream

minus carbon dioxide is split, with part going to the

purge for removal of the inert ethane fromthe process.

The rest combines with the large recycle gas stream

and goes to the feed-euent heat exchanger. The fresh

ethylene feed stream is added. The gas recycle stream,

the fresh acetic acid feed, and the recycle liquid acetic

acid stream enter the vaporizer, where steam is used to

vaporize the liquid. The gas stream from the vapori-

zer is further heated to the desired reactor inlet tem-

perature in a trim heater using steam. Fresh oxygen is

added to the gas stream from the vaporizer just prior

to the reactor to keep the oxygen composition in the

gas recycle loop outside the explosivity region.

The azeotropic distillation column separates the

vinyl acetate and water from the unconverted acetic

acid. The overhead product is condensed with cooling

water and the liquid goes to a decanter, where the

vinyl acetate and water phases separate. The organic

and aqueous products are sent for further rening to

another distillation section. Here we ignore the addi-

tional separation steps required to produce vinyl acet-

ate of sucient purity because there is no recycle from

the rening train back to the reaction loop. The bot-

tom product from the distillation column contains

acetic acid, which recycles back to the vaporizer along

with fresh make-up acetic acid. Part of this bottoms

stream is the wash acid used in the absorber after

being cooled.

3. Physical property data

The vaporliquid equilibrium (VLE) data for the

three nonideal component pairs are given in Table 1.

These data come from the vapor-liquid equilibrium

data collection in the Chemistry data series published

by DECHEMA. VLE calculations are performed as-

suming an ideal vapor phase and a standard Wilson

liquid activity coecient model. This takes the form

GH

"

G

exp(!a

GH

/R), (5)

where is the absolute temperature in K, R is the gas

constant (1.987 cal/mol K), and

G

is the molar vol-

ume of component i given in DECHEMA and listed

in Table 1.

The Wilson parameters we use for the VAcH

`

O

pair are assumed to be the same as the parameters for

ethyl acetate and water. The reason for this assump-

tion is that no VLE data are presented in DECHEMA

for vinyl acetate and water, but ethyl acetate and vinyl

acetate are quite similar species and should behave

essentially identically. The liquid-liquid equilibrium

solubility data for the VAcH

`

O pair in the column

decanter come from Smith (1942) extrapolated to the

decanter temperature of 40C.

Acetic acid dimerizes in the vapor phase. The Wil-

son parameters listed in DECHEMA for the

H

`

OHAc pair assume the eect of dimerization is

modeled. Without considering the vapor-phase asso-

ciation, the DECHEMA parameters predict the exist-

ence of an azeotrope close to pure water. Such an

Study for the vinyl acetate monomer process 869

Table 2. Pure component physical properties (c

N

in cal/(g C))

Component Molecular Specic Latent Liquid Vapor

weight gravity heat ht capacity ht capacity

(cal/mol) ab ab

O

`

32 0.5 2300 0.30 0.2180.0001

CO

`

44.01 1.18 2429 0.60 0.230

C

`

H

"

28.05 0.57 1260 0.60 0.370.0007

C

`

H

'

30.05 0.57 1260 0.60 0.370.0007

VAc 86.09 0.85 8600 0.440.0011 0.290.0006

H

`

O 18.02 1 10684 0.990.0002 0.56!0.0016

HAc 60.05 0.98 5486 0.460.0012 0.520.0007

Table 1. Wilson parameters a

GH

and molar volumes

G

a

GH

VAc H

`

O HAc

G

(ml/mol)

VAc 0 1384.6 !136.1 93.1

H

`

O 2266.4 0 670.7 18.07

HAc 726.7 230.6 0 57.54

From DECHEMA vaporliquid equilibrium data collection

Vol. 1.

VAcH

`

O: Part 1b, p. 236.

VAcHAc: Part 5, p. 90.

H

`

OHAc: Part 1, p. 127.

azeotrope does not exist for this system. The VLE

behavior close to pure acetic acid is acceptable with-

out a model of dimerization. Since we operate in the

process where the VLE behavior is acceptable, we

have used the parameters in Table 1 without special

provisions for vapor-phase association.

Table 2 shows the pure component physical prop-

erty data, which we obtained from the DIPPR

database. These data include the molecular weight

M, the liquid specic gravity (based on the density

of water at 0C), the latent heat of vaporization H

T

at

0C (in cal/mol), and the liquid cJ

N

and vapor cT

N

heat

capacity parameters. The heat capacity expressions

we use have the following temperature dependence:

c

N

"a#bt, (6)

where c

N

is in cal/(gC) and t is the temperature inC.

Component vapor pressures PQ in psia (Table 3) are

calculated using the Antoine equation, with the Anto-

ine coecients listed in the DECHEMA volumes.

ln PQ"A#B/(t#C), (7)

where t is the temperature in C. For the four gas

components, the A parameters of the Antoine equa-

tion were estimated based upon the vapor pressure at

the operating conditions in the absorber. We removed

the temperature dependence to facilitate the dynamic

simulation. However, in the case of ethylene and

ethane, we found that we needed to include a small

Table 3. Component vapor pressure antoine coecients

!ln PQ"A#B/(t#C), where PQ in psia and t in C

Component A B C

O

`

9.2 0 273

CO

`

7.937 0 273

C

`

H

"

9.497 !313 273

C

`

H

'

9.497 !313 273

VAc 12.6564 !2984.45 226.66

H

`

O 14.6394 !3984.92 233.426

HAc 14.5236 !4457.83 258.45

temperature dependence for the bubble point calcu-

lations to function properly.

4. Process data and constraints

4.1. Design requirements

The process design that we use is based upon the

owsheet shown in SRI Report 15B. We assume that

the production basis of our process with new catalyst

is 785 mol/min VAc and at the given conditions

85 mol/min CO

`

is also produced. For a plant with

90% operating utility, this corresponds to an annual

production rate of 32;10' kg/yr, if the VAc rate is

sustained over the life of the catalyst. We assume that

the catalyst lifetime is one year.

The ethylene and oxygen feed streams come from

supply headers. Acetic acid comes from a storage

tank. The carbon dioxide is released to the atmo-

sphere. The gas purge stream is sent to a thermal

converter. The vinyl acetate and water products from

the decanter are fed to other distillation columns in

a rening train. Available on the plant are the follow-

ing utilities: cooling tower water at a supply temper-

ature of 30C, steam at supply pressures of 50 and

200 psia, refrigeration at !25C, and electricity and

process water. Economic data for raw material and

energy costs are listed in Table 4. Any capital equip-

ment and vessel cost data can be found in Guthrie

(1969). The costs should be updated to current prices.

Also, the appropriate material of construction factors

should be used. Cost correlations for some equipment

are given in Douglas (1988).

870 M.L. LUYBEN and B.D. TYRE US

Table 5. Process stream data Table I

Reactor Reactor Absorber Absorber Absorber Purge

in out vapor in vapor out liquid out ow

Stream Number 1 2 3 4 5 6

Flow (mol/min) 19250 18850 16240 15790 1210 3

Temperature (C) 148.5 158.9 80 40.4 47.7 40.4

Pressure (psia) 128 90 128 128 128 128

O

`

(mol frac) 0.075 0.049 0.057 0.058 0.001 0.059

CO

`

0.007 0.011 0.013 0.014 0.001 68

C

`

H

"

0.583 0.551 0.642 0.658 0.025 0.667

C

`

H

'

0.216 0.221 0.256 0.263 0.010 0.266

VAc 0 0.043 0.021 0.002 0.255 0.002

H

`

O 0.009 0.055 0.007 0.001 0.129 0.001

HAc 0.110 0.070 0.004 0.004 0.579 0.005

moles/million.

Pressure drop in gas loop assumed to be in reactor.

Table 6. Process stream data Table II

Column Column Organic Aqueous Fresh

feed bottoms product product HAc feed

Stream number 7 8 9 10 11

Flow (mol/min) 3820 2160 826 831 785

Temperature (C) 42.5 137.2 40 40 30

Pressure (psia) 84 30 18 18 150

VAc (mol frac) 0.206 11 0.950 0.002 0

H

`

O 0.281 0.093 0.050 0.998 0

HAc 0.513 0.907 370 370 1

moles/million.

Table 4. Economic data for vinyl acetate process

Item Cost/price

Acetic acid $0.596/kg

Oxygen $0.044/kg

Ethylene $0.442/kg

Vinyl acetate $0.971/kg

200 psia steam $11/1000 kg

50 psia steam $8.8/1000 kg

Cooling tower water $0.02/1000 l

Process water $0.15/1000 l

!25C refrigeration $0.12/h, ton

Electricity $0.065/kwh

Tables 57 contain the ow, temperature, pressure,

and composition data for selected streams in the pro-

cess. The corresponding stream numbers are shown in

Fig. 1. In our simulation, all gas is removed in a com-

ponent separator prior to the distillation column. This

involves the liquid from the separator and the absorb-

er. The gas is sent back and combines with the vapor

product from the separator to form the vapor feed to

the absorber. Tables 810 contain certain vessel data

that are required to size the equipment and construct

the simulation. These data come from our TMODS

dynamic simulation and not from a commercial

steady-state simulation package.

The reactor contains 622 tubes packed with cata-

lyst. The tube diameter is 3.7 cm and length 10 m.

Steam is generated on the shell side of the reactor to

remove the heat of reaction. We have modeled the

reactor in 10 sections in the axial direction. The reac-

tor temperature prole is shown in Fig. 2. The ow-

sheet design conditions are for a new catalyst with an

activity of 1. However, the catalyst does deactivate

over the course of operation. This deactivation via

sintering is a nonlinear function of operating time (t

WP

)

and temperature, since higher temperatures within the

tubes (t

RS@C

) promote deactivation. We assume that the

activity (a) decays exponentially with time from 1.0 to

0.8 after 1 yr according to

a"f (t

RS@C

) exp(!t

WP

/0.621). (8)

Study for the vinyl acetate monomer process 871

Table 7. Process stream data Table III

Fresh Fresh CO

`

CO

`

C

`

H

"

feed O

`

feed purge Removal

in ow

Stream number 12 13 14 15

Flow (mol/min) 831 521 85 6411

Temperature (C) 30 30 40.4 40.4

Pressure (psia) 150 150 128 128

O

`

(mol frac) 0 1 0 Same

CO

`

0 0 1 as

C

`

H

"

0.999 0 0 stream

C

`

H

'

0.001 0 0 4

Table 8. Reactor and vaporizer equipment data

Catalyst weight 2590 kg

Catalyst porosity 0.8

Catalyst bulk density 0.385 kg/l

Catalyst heat capacity 0.23 cal/g C

Overall heat transfer coecient 150 kcal/h C m`

Number of tubes 622

Tube length 10 m

Tube diameter 3.7 cm

Circumferential heat transfer area 725 m`

Shell side temperature 133C

Reactor heat duty 2.8;10' kcal/h

Steam drum volume 2 m`

BFW to steam drum 79.5 kg/min

Reactor feed heater duty 5.3;10` kcal/h

Vaporizer duty 1.3;10' kcal/h

Vaporizer total volume 17 m`

Vaporizer working level volume 4 m`

Vaporizer temperature 119C

If the tube temperature has not exceeded 180C,

then f (t

RS@C

)"1. Above this temperature, then

f (t

RS@C

)"exp[!(t

RS@C

!180)/50], where t

RS@C

is in C.

Two parameters dene the performance of the cata-

lyst: selectivity (SEL) and space-time yield (STY).

Catalyst selectivity determines the fraction of the

ethylene consumed that makes the desired vinyl acet-

ate product.

SEL"100

mol/min VAc

mol/min VAc#0.5 mol/min CO

`

.

(9)

For conditions at the design basis with fresh catalyst,

the selectivity is 94.8%. At a catalyst activity of 0.8,

higher reactor temperatures are required to achieve

about the same VAc production rate, increasing the

production rate of CO

`

to 126 mol/min and reducing

the selectivity to 92.4%. The spacetime yield quan-

ties the activity of the catalyst by volume.

STY"g VAc/h/liter catalyst. (10)

Table 9. FEHE, separator, and absorber equipment data

FEHE duty 4.4;10` kcal/h

FEHE hot outlet temperature 134C

FEHE A 6800 kcal/h C

Separator cooler duty 2.7;10' kcal/h

Separator volume 15 m`

Separator working level volume 8 m`

Gas loop volume 170 m`

Approximate compressor size 350 kW

Absorber base volume 8 m`

Absorber bottom section 2 theoretical stages

Absorber top section 6 theoretical stages

Absorber stage eciency 50%

Absorber tray holdup 14 kmol

Absorber liquid recirculation 15 kmol/min

Absorber cooler duty 6.5;10` kcal/h

Absorber wash acid feed 756 mol/min

Absorber wash acid cooler duty 1.3;10` kcal/h

Table 10. Column and decanter equipment data

Theoretical stages 20

Feed stage 15 from bottom

Stage eciency 50%

Tray holdup 2.3 kmol

Reboiler duty 4.0;10' kcal/h

Condenser duty 3.9;10' kcal/h

Base working level volume 6 m`

Decanter working level volume 5 m`

For conditions at the design basis, the STY is 603

since the total volume of catalyst (tube volume) is

6724 l.

The CO

`

removal system is assumed to be a com-

ponent separator that removes just carbon dioxide at

a certain eciency, which is the fraction in the feed

leaving in the CO

`

purge. This eciency (E) is

a function of the feed rate (F

''`

in mol/min) and

composition (x

''`

in mole fraction). At the design

conditions, the eciency is 0.995 for a feed rate

of 6410 mol/min at 0.014 mol fraction CO

`

. The

872 M.L. LUYBEN and B.D. TYRE US

Fig. 2. Reactor temperature prole.

maximum allowable feed rate to the CO

`

removal

systemis 8000 mol/min set by its capacity. The follow-

ing correlation determines the system eciency

E"0.995!3.14;10'(F

''`

!6410)

!32.5(x

''`

!0.014), (11)

where the eciency must lie between 0 and 1.

Two key safety constraints exist in the process.

First, the oxygen composition must not exceed 8 mol

% anywhere in the gas recycle loop to remain outside

the explosivity envelope of ethylene (Coward and

Jones, 1952). Continuous and reliable O

`

analyzers

will be installed in the process at the inlet of the

reactor to monitor oxygen composition. Second, the

pressure in the gas recycle loop and distillation col-

umn cannot exceed 140 psia because of the mechanical

construction limit of the process vessels. Pressure

measurements are readily available and will be instal-

led at appropriate locations. Exceeding either the oxy-

gen concentration or pressure limits will shut down

the process via interlocks.

Several other operational constraints must also be

satised during process operation. The peak reactor

temperature along the length of the tube must remain

below 200C, otherwise mechanical damage occurs to

the catalyst requiring shutdown. Liquid levels in the

vaporizer, separator, absorber base, distillation col-

umn base, and decanter must operate within the limits

of 1090%. The vessel volumes listed have been pro-

posed for the working liquid inventories between the

level taps.

Reactor inlet temperature must exceed 130C to

prevent condensation of liquid in the reactor. The hot

side exit temperature from the feed-euent heat ex-

changer (FEHE) must remain above 130C to avoid

condensation in the exchanger, which has been

designed to handle only vapor-phase ow. In the

azeotropic distillation column, the acetic acid in the

decanter organic phase must not exceed 600 mol/mil-

lion to prevent product contamination. A decanter

composition analysis for acetic acid is available from

the laboratory every 4 h. Also, the vinyl acetate com-

position in the bottoms stream must remain below

100 mol/million to minimize polymerization and foul-

ing in the column reboiler and vaporizer. The column

temperature prole is plotted in Fig. 3.

4.2. Control requirements

Figure 4 shows the location of the 26 control valves

that have been proposed in the preliminary design.

Flow, temperature, pressure, and level measurements

are readily available and can be installed in any loca-

tion needed for control. The O

`

analyzers at the

reactor inlet are specialized instruments that are fast

and reliable. However, if additional composition

measurements are used, they must be conventional

chromatographic analyzer types that are character-

ized by sampling frequency and reliability problems.

It must be assumed that any chromatographic ana-

lyzer used in this process has a 10 min sampling fre-

quency and 10 min deadtime. Also, this analyzer has

a 90% utility. The remainder of the time the instru-

ment is o-line for maintenance or calibration. Hence,

when an analyzer is not on line, the plant must be able

to continue producing vinyl acetate. Further, it must

be demonstrated how the control system functions

when an analyzer is down and one of the disturbances

listed below occurs.

The control system which we are asked to design

for this process must be able to operate in the face of

several known disturbances and changes we antici-

pate a priori.

1. The process will operate at a catalyst activity of 0.8

(or lower based upon reactor temperature) at the

end of 1 yr. The control system must still function

for the changed conditions.

2. Process operation must be regulated automatically

to reect changes in raw material and operating

costs so that the process always runs close to the

ecomomic optimum.

Fig. 3. Azeotropic distillation column prole.

Study for the vinyl acetate monomer process 873

Fig. 4. Location of control valves.

3. The control system must be able to change produc-

tion rate (as measured by steady organic ow from

the decanter) by at least 20% (both up and down)

over the course of 6 h. This is due to limits on tank

storage.

4. The plant needs to run at half the VAc production

design rate but at maximum selectivity. This is the

result of an occasionally precipitous drop in the

price of vinyl acetate to a third its normal value.

5. In-line (but not operating) spare pumps will be

installed for the fresh acetic acid supply line and for

the distillation column feed stream. However, it

must be demonstrated what the control system

does during the course of a 5 min loss of either

fresh acetic acid or column feed pump.

6. The control system must handle a step change in

the composition of ethane in the fresh ethylene feed

stream from 0.001 to 0.003 mol fraction.

7. The control system must not shut down the pro-

cess due to the loss of fresh oxygen feed ow.

Instead, this should result in the process going into

hot recycle mode.

5. Nonlinear dynamic model

5.1. Background

In this section we provide a brief description of the

nonlinear dynamic modules used in TMODS. These

modules have been constructed following the practi-

cal philosophy toward dynamic simulation outlined

in Luyben (1990). Our purpose is to provide a

feel for the level of detail we use in our dynamic

simulations without divulging exactly how our simu-

lator is implemented.

We would like to point out that the kind of dy-

namic models we use strike a balance between simula-

tion eciency and rigor of representation. We have

found that simulation speed is of vital importance and

we always strive to keep our user interactive simula-

tions running between 10 and 60 times real time.

There are basically two ways to meet this goal. We

can either limit the scope of the simulation to a few

process units that are rigorously simulated or limit the

complexity of most units within a plantwide scope.

Since we have found the plantwide perspective to be

most important for control simulations, we generally

opt for the second alternative.

This nonlinear dynamic model has been utilized to

conrm the feasibility of the simulation. It is the basis

for the data presented in the stream and equipment

tables. We also have used the simulation to test the

control strategy described in Luyben et al. (1997),

which was derived following the plantwide control

design procedure.

5.2. Physical property calculations

TMODS is implemented in an object-oriented

framework (Tyreus, 1992). It consists of a number of

generic classes that can be instantiated into objects in

the simulation. The objects are given appropriate

parameters to reect the actual piece of equipment

they represent. The objects are also connected to-

gether by the end user of the simulation to create

a owsheet. The most important aspect of the object-

oriented representation is the use of uid objects. The

874 M.L. LUYBEN and B.D. TYRE US

uid objects are instances of the uid system pertain-

ing to the simulation. The uid system contains all the

physical property constants described earlier includ-

ing the kinetic parameters. Each uid object is then

able to perform a number of services based upon these

parameters. For homogeneous (single phase) uids

these services amount to calculating thermodynamic

state variables from the knowledge of two intensive

state variables and the composition of the uid. In

TMODS these services are implemented to be explicit

functions of the known state variables. Examples are

"(P, , n

, n

`

,

2

),

h"h(P, , x

, x

`

,

2

),

"(P, u, x

, x

`

,

2

),

v"v(P, , x

, x

`

,

2

),

where P is the total pressure; is the temperature;

n

G

is the number of moles of component i; x

G

is the

mole fraction of component i (x

G

"n

G

/n

G

); is the

total internal energy; v is the specic volume, u is

the specic internal energy; and h is the specic

enthalpy.

In many cases the uid object represents a hetero-

geneous equilibrium system. Examples are the uid

objects in vaporizers, partial condensers, decanters,

and on the trays of a distillation column. Here the

thermodynamic state is completely specied by two

extensive state variables and the number of moles of

each component. The only dierence to a homogene-

ous system is that the unknown intensive state vari-

ables are no longer explicit functions of the known

entities. For example, to determine the pressure and

temperature of a uid in vaporliquid equilibrium, we

have to solve the following three nonlinear implicit

algebraic equations:

,

G

(K

G

!1)(n

G

/n)

1#(K

G

!1)

"0, (12)

/n!(1!) v*!v4"0, (13)

/n!(1!)u*!u4"0, (14)

where N is the number of components in the system,

n is the total number of moles in the uid object ( n

G

),

K

G

is the K-value for component i (K

G

"y

G

/x

G

), x

G

is the

mole fraction i in the liquid phase, y

G

is the mole

fraction i in the vapor phase, is the fraction of n in

the vapor phase; v is the specic volume; and u is the

specic internal energy.

The known state variables are total internal energy

and total volume that follow from the dynamic energy

balance and the equipment size. The total moles of

each component follow from the dynamic material

balances. The K-values are calculated from the equi-

librium requirement that the chemical potential of

each component is equal in both phases

4

G

"*

G

,

or equivalently that the partial fugacities of each com-

ponent are equal across the phases

f 4

G

"f *

G

.

In TMODS we assume that the vapor phase is ideal

such that

f 4

G

"y

G

P.

The liquid-phase partial fugacity is calculated with an

activity model according to

f *

G

"x

G

G

PQ

G

where

G

is the liquid-phase activity coecient of com-

ponent i and PQ

G

is the vapor pressure of component i.

To reduce the computational burden of iteratively

solving the three nonlinear equations, we frequently

make simplifying assumptions around two-phase sys-

tems. For example, in vaporliquid equilibria we of-

ten assume that the vapor holdup is negligible ("0).

This eliminates one of the three equations. The re-

maining variables can be solved for by making either

of the following assumptions. We can solve for and

P explicitly based on the fact that the n

G

s and the total

pertain to a single phase (the liquid). Or we can

assume that the pressure is known along with the n

G

s

of the liquid, and we can solve for temperature and

vapor compositions via a bubble point calculation.

The role of the unit operations is greatly simplied

by the use of uid objects. The unit operations contain

one uid object for each uid holdup in the equip-

ment. For example, a vaporizer contains one uid

object and a distillation tray section has a uid object

on each tray. The unit operation is responsible for

managing the accumulation of mass and energy into

the uid objects. With the knowledge of the total

internal energy, the total volume, and the number of

moles of each component, the thermodynamic state is

xed. The uid objects are then responsible for calcu-

lating all other relevant state variables pertaining to

the current state.

The equipment equations for accumulation of mass

and energy depend upon whether the system is lumped

or distributed.

5.3. Lumped equipment models

Material balances:

dn

G

dt

"FGLxGL

G

!FMSR xMSR

G

#R

G

. (15)

Energy balance:

d

dt

"FGLhGL!FMSRhMSR#Q#HR. (16)

Auxiliary relations:

FMSR"f (n

G

, P, , equipment conguration), (17)

where FGL is the molar ow of all streams entering the

vessel, xGL

G

is the mole fraction i in entering streams,

FMSR is the molar ow of exit streams, xMSR

G

is the mole

Study for the vinyl acetate monomer process 875

fraction i in exit streams, R

G

is the net production of

i from all chemical reactions, hGL is the specic en-

thalpy of entering streams, hMSR is the specic enthalpy

of exit streams, Q is the heat input to the vessel, and

HR is the total heat from reactions.

5.4. Distributed equipment models

Material balances:

*c

G

*t

"!

*J

G

*z

!

*(c

G

v)

*z

#

H

GH

r

H

!N

G

. (18)

Energy balance:

*(u

K

)

*t

"!

*J

O

*z

!

*(h

K

v)

*z

!

H

H

H

r

H

!

G

N

G

h

G

!q. (19)

Momentum balance:

*(v)

*t

"!

*P

*z

!

*(vv)

*z

#

G

G

FC

G

. (20)

Auxiliary relations:

N

G

"k

E

a(p

G

!p

*

G

), (21)

q"h

U

a(!

U

),

J

G

"!D

G

*c

G

*z

,

J

O

"!k

2

*

*z

,

where c

G

is the molar concentration of i; J

G

is the

diusion ux of component i; v is the bulk velocity of

uid; v

GH

is the stoichiometric coecient for compon-

ent i in reaction j; r

H

is the specic rate of reaction; N

G

is

the molar ux of component i; is the uid density;

u

K

is the specic internal energy (mass based); J

O

is the

heat ux due to conduction; h

K

is the specic enthalpy

(mass based); H

H

is the heat of reaction for reaction j;

q is the external heat ux per unit volume; FC

G

is the

external force acting on component i; k

E

is the overall

mass transfer coecient; a is the surface to volume

ratio for heat and mass transfer; p

G

is the partial

pressure for component i; p

*

G

is the interface partial

pressure for component i;

U

is the interface temper-

ature; D

G

is the molar diusivity coecient of compon-

ent i; and k

2

is the conductivity coecient.

5.5. Specic implementations

Catalytic plug ow reactor: The catalytic plug ow

reactor is modeled according to equations (18)(21)

on the tube side and equations (15) (17) on the shell

side. Simplifying assumptions are J

G

"0, J

O

"0, and

*(v)/*t"0. The time-independent momentum equa-

tion (20) sets the pressure prole in the reactor. We

assume that the entire gas loop pressure drop is repre-

sented by the reactor pressure drop. A simple back-

ward discretization scheme is used for the spatial

derivatives.

Gas Separator: This generic ash calculation can

be implemented in a number of dierent ways. In

TMODS this unit is implemented with two uid ob-

jects on the process side and a single-phase liquid

object on the shell side. In our implementation the

process side uid objects are not in equilibrium with

each other. The vapor object determines the system

pressure. The shell side uid determines the static

ash temperature. This allows us to use equation (12)

to solve for the partition of incoming feeds into the

vapor and liquid objects. The vapor object in the gas

separator denes the pressure level of the gas recycle

loop. As mentioned above, the reactor determines the

pressure drop in the loop.

Absorber: The gas absorber is implemented as two

countercurrent versions of equations (18), (19), and

(21). Each node, or stage, contains a liquid phase and

a vapor phase that are not in equilibrium with each

other. Instead, the single-phase state is determined by

the integration of equations (18) and (19). The auxili-

ary equations (21) then use the partial pressure and

temperature dierences between the two phases to

determine the mass and heat transfer rates.

aporizer: The vaporizer is implemented as a lum-

ped system with a single uid object. The vapor hold-

up is assumed negligible compared to the liquid

inventory.

Distillation Column: Each tray is a lumped system

and contains a uid object. The holdup in the vapor

phase is ignored. The pressure on each tray is assumed

known, which reduces the ash calculation to

a bubble point calculation. The energy balance deriv-

ative (16) is approximated numerically, which allows

us to solve for the vapor rate from stage to stage. This

is done to reduce system stiness.

Decanter: The TMODS decanter contains two

uid objects: one for the light phase and one for the

heavy phase. The partition coecients (K-values) are

assumed constant and independent of temperature.

This allows us to use equation (12) to determine the

distribution of the two liquid phases. Again, this is

done to save simulation time.

Heat Exchangers: Heat exchangers are calculated

statically with the eectiveness method. This allows

for an explicit calculation of the exit temperatures

based upon the exchanger eectiveness and the inlet

temperatures and heat capacities. The exchanger ef-

fectiveness depends on the eective A, the ratio

of stream heat capacities, and the exchanger cong-

uration. The exit temperatures are time-lagged to

introduce some realistic dynamics (usually very fast

compared to the overall recycle loop dynamics).

6. Conclusions

In this work we have presented design details of an

industrial process for the manufacture of vinyl acetate

876 M.L. LUYBEN and B.D. TYRE US

monomer. The design is preliminary and has not

been optimized. We have conveyed the study as if we

had been assigned the task of devising a control strat-

egy for this plant that is to be built. We have sum-

marized the design requirements for process opera-

tion and the control objectives that must be achieved

for various disturbances. A brief description was also

provided on the nonlinear dynamic modules in our

simulation. The purpose of this paper is to oer a real-

istic system that can be used by academic researchers

who are interested in working on an industrially rel-

evant study in the areas of design, simulation, and

control.

Complete models for this vinyl acetate process have

been made available by Aspen Technology and Hy-

protech. These models can be obtained electronically

from the following web sites:

(1) The application le for the vinyl acetate process

can be obtained from Aspen Technologys

example library Web site:

http://www.aspentec.com/tspsd/example/

example.htm

Search for Vinyl Acetate to nd and download

the application le.

(2) The case is made available at Hyprotech

www.hyprotech.com on the FTP site

(Papers/VinylAcetateProcess/VA

files.

zip). To download the le directly, users may

type the following into their Web browser:

ftp: //ftp.hyprotech.com/pub/Papers/

VinylAcetateProcess/VA

files.zip

Acknowledgements

We want to thank Dr W.D. Smith, Jr, DuPont, for

his support and help in making it possible to publish

this work. Also, we are grateful to Prof. W.L. Luyben,

Lehigh University, for his suggestions on the scope of

the paper and his careful review of the manuscript.

References

Coward, H.F. and Jones, G.W. (1952) Limits of ammability

of gases and vapors. Bulletin 503, Bureau of Mines.

Daniels, W.E. (1989) Vinyl ester polymers. In: Encyclopedia

of polymer science and engineering, 2nd ed. New York:

Wiley. Vol. 17, (pp. 393425).

Downs, J.J. and Vogel, E.F. (1993) A plant-wide industrial

process control problem. Computers in Chemical Engineer-

ing 17, 245255.

Douglas, J.M. (1988) Conceptual design of chemical processes.

New York: McGraw-Hill.

Guthrie, K.M. (1969) Capital cost estimating. Chemical En-

gineering 76, 114142. Mar. 24.

Luyben, M.L., Tyreus, B.D., and Luyben, W.L. (1997)

Plantwide control design procedure AIChE J. 43,

31613174.

Luyben, W.L. (1990) Process modeling, simulation and control

for chemical engineers, 2nd ed. New York: McGraw-Hill.

Nakamura, S. and Yasui, T. (1970) The mechanism of the

palladium-catalyzed synthesis of vinyl acetate from ethy-

lene in a heterogeneous gas reaction. Journal of Catalysis

17, 366374.

Neurock, M., Provine, W.D., Dixon, D.A., Coulston, G.W.,

Lerou, J.J. and van Santen, R.A. (1996). First principle analy-

sis of the catalytic reaction pathways in the synthesis of vinyl

acetate. Chemical Engineering Science 51, 16911699.

Samanos, B., Boutry, P. and Montarnal, R. (1971) The mech-

anism of vinyl acetate formation by gas-phase catalytic

ethylene acetoxidation. Journal of Catalysis 23, 1930.

Smith, J.C. (1942) The solubility diagrams for the systems

ethylidene diacetateacetic acidwater and vinyl acet-

ateacetonewater. Journal of Physical Chemistry 46,

229232.

Tyreus, B.D. (1992) Object-oriented simulation. In: W.L.

Luyben, (Ed.), Practical distillation control. chap. 5. New

York: Van Nostrand Reinhold.

Study for the vinyl acetate monomer process 877

Vous aimerez peut-être aussi

- Lab Report R3 Batch ReactorDocument9 pagesLab Report R3 Batch Reactorzy_yf0% (1)

- SaponificationDocument35 pagesSaponificationsemanasemana80% (5)

- First Order SystemDocument21 pagesFirst Order SystemNiranjan BeheraPas encore d'évaluation

- Distillation 3Document36 pagesDistillation 3Renu SekaranPas encore d'évaluation

- Report Compiled 1Document14 pagesReport Compiled 1Opeyemi KehindePas encore d'évaluation

- Report TemplateDocument9 pagesReport Templatedmscott10Pas encore d'évaluation

- Liquid Diffusion Coefficient Apparatus BP09Document4 pagesLiquid Diffusion Coefficient Apparatus BP09Ahmed AliPas encore d'évaluation

- LleDocument30 pagesLlefirstlove_492_736373Pas encore d'évaluation

- Lab 3Document16 pagesLab 3Paen Zulkifli100% (1)

- Solved Problem Question (Gas Ab)Document2 pagesSolved Problem Question (Gas Ab)Seruzna IshxPas encore d'évaluation

- Thermal Processing of Ready-to-Eat Meat ProductsD'EverandThermal Processing of Ready-to-Eat Meat ProductsC. Lynn KnipePas encore d'évaluation

- Gas Diffusion UnitDocument20 pagesGas Diffusion Unitsolehah misniPas encore d'évaluation

- Distillation ReportDocument17 pagesDistillation ReportSebastian PinzonPas encore d'évaluation

- Plug Flow ReactorDocument28 pagesPlug Flow ReactorNurul AinPas encore d'évaluation

- CBB3024 Flowsheeting 1Document93 pagesCBB3024 Flowsheeting 1Yunaida YusoffPas encore d'évaluation

- Water Treatment BasicsDocument62 pagesWater Treatment Basicsanac_mathPas encore d'évaluation

- Pinch Technology by ShubhamDocument29 pagesPinch Technology by Shubhamapi-381283580% (5)

- Ion Exchange TechnologyD'EverandIon Exchange TechnologyF. C. NachodPas encore d'évaluation

- Measurement of Transference Numbers in H2SO4Document112 pagesMeasurement of Transference Numbers in H2SO4mojakovichPas encore d'évaluation

- An Industrial Wastewater Contains 10 MG L ChlorophenolDocument5 pagesAn Industrial Wastewater Contains 10 MG L ChlorophenolsumitPas encore d'évaluation

- Laboratory Scale Water Circuit Including A Photocatalytic ReactorDocument8 pagesLaboratory Scale Water Circuit Including A Photocatalytic ReactorPatrick_NickelsPas encore d'évaluation

- Lab 3 Plug FlowDocument29 pagesLab 3 Plug FlowHikaru MokaPas encore d'évaluation

- Packed Bed FermentersDocument20 pagesPacked Bed FermentersGerald Owen FranzaPas encore d'évaluation

- Gas AbsorptionDocument19 pagesGas AbsorptionAnonymous NyvKBW100% (3)

- 333 Manual 11 T2 Armfield ManualDocument45 pages333 Manual 11 T2 Armfield ManualSyamim AsyrafPas encore d'évaluation

- Chapter 4 - StudentDocument69 pagesChapter 4 - Studenteja70Pas encore d'évaluation

- 14 EquilibriumDocument6 pages14 EquilibriumAgam HanasichulaPas encore d'évaluation

- Adverse Vapour Flow ConditionsDocument3 pagesAdverse Vapour Flow ConditionsSana HajriPas encore d'évaluation

- Ethyl Acetate Kinetics 2011Document9 pagesEthyl Acetate Kinetics 2011Paola moreno100% (1)

- Energy Transport Notes 2Document102 pagesEnergy Transport Notes 2Faisal MumtazPas encore d'évaluation

- Carbon Dioxide Scrubber RPDocument5 pagesCarbon Dioxide Scrubber RPpassionPas encore d'évaluation

- Intro CSTRDocument6 pagesIntro CSTREmmanuel PlazaPas encore d'évaluation

- Water TreatmentDocument19 pagesWater TreatmentAnonymous 8ooQmMoNs1Pas encore d'évaluation

- Rr410802 Chemical Reaction Engineering IIDocument8 pagesRr410802 Chemical Reaction Engineering IISrinivasa Rao G100% (3)

- CHE201ch12Document25 pagesCHE201ch12chandro57Pas encore d'évaluation

- 3 - Vle in A Binary Mixture - 2Document22 pages3 - Vle in A Binary Mixture - 2Faisal El HakimPas encore d'évaluation

- Experiment No 18Document4 pagesExperiment No 18Suvrasoumya Mohanty100% (2)

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziPas encore d'évaluation

- Pressure Drop in Water Gas Shift Reactor (Jason Keith)Document6 pagesPressure Drop in Water Gas Shift Reactor (Jason Keith)ahmadliePas encore d'évaluation

- Aldol Notes PDFDocument8 pagesAldol Notes PDFAna100% (1)

- Exp-40 Part2Document22 pagesExp-40 Part2Ahmet Samet ÖzdilekPas encore d'évaluation

- Control of An Isomerization Column/Reactor Process: William L. LuybenDocument8 pagesControl of An Isomerization Column/Reactor Process: William L. LuybenMirko SusichPas encore d'évaluation

- Open-Ended Problems: A Future Chemical Engineering Education ApproachD'EverandOpen-Ended Problems: A Future Chemical Engineering Education ApproachPas encore d'évaluation

- Kgs KGS: Gujarat Alkalies and Chemicals LimitedDocument1 pageKgs KGS: Gujarat Alkalies and Chemicals LimitedChetan Solanki100% (1)

- Balance On Reactive Systems LECTURE 5Document28 pagesBalance On Reactive Systems LECTURE 5OZIS AcademyPas encore d'évaluation

- Mass and Energy Balances in Materials Engineering by Mark A. Schlesinger PDFDocument9 pagesMass and Energy Balances in Materials Engineering by Mark A. Schlesinger PDFsgPas encore d'évaluation

- Chapter 4Document43 pagesChapter 4aliPas encore d'évaluation

- Glucose To Acrylic AcidDocument2 pagesGlucose To Acrylic AcidRachel FrenchPas encore d'évaluation

- Effux Time EquationsDocument7 pagesEffux Time EquationsDhananjay KadamPas encore d'évaluation

- Gas Absorption Theory, Apparatus, ProcedureDocument16 pagesGas Absorption Theory, Apparatus, Proceduresolehah misni100% (1)

- Cyclohexane PDFDocument14 pagesCyclohexane PDFsushant kadamPas encore d'évaluation

- Design of HEDocument35 pagesDesign of HESaurabh SengarPas encore d'évaluation

- Analysis of Culturable Microorganisms in WaterDocument9 pagesAnalysis of Culturable Microorganisms in WaterPalaysma AmrahsPas encore d'évaluation

- CSTRDocument12 pagesCSTRsamueloPas encore d'évaluation

- SO2 Removal Using Packed Column Scrubber TowerDocument60 pagesSO2 Removal Using Packed Column Scrubber TowerAbrahamChongPas encore d'évaluation

- Plug Flow ReactorDocument16 pagesPlug Flow ReactorN Afiqah RazakPas encore d'évaluation

- P4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperatureDocument7 pagesP4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperaturejayaprinaPas encore d'évaluation

- Residence - Time DistributionDocument9 pagesResidence - Time DistributionNik Nur Izzatul IkmalPas encore d'évaluation

- Recent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004D'EverandRecent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004Pas encore d'évaluation

- My WayDocument2 pagesMy WayArtūras AnusauskasPas encore d'évaluation

- Welcome To ASUS WebStorageDocument8 pagesWelcome To ASUS WebStorageAia BarrettoPas encore d'évaluation

- Data GC - MSDocument12 pagesData GC - MSPY YouPas encore d'évaluation

- 陛下饶命GLDocument186 pages陛下饶命GLPY YouPas encore d'évaluation

- Attrage Brochure PricelistDocument8 pagesAttrage Brochure PricelistPY YouPas encore d'évaluation

- GEBENGDocument5 pagesGEBENGPY YouPas encore d'évaluation

- NanofiltrationDocument3 pagesNanofiltrationPY YouPas encore d'évaluation

- Study Case 1Document2 pagesStudy Case 1PY YouPas encore d'évaluation

- Environmental Quality (Industrial Effluent) Regulations 2009 - P.U. (A) 434-2009Document50 pagesEnvironmental Quality (Industrial Effluent) Regulations 2009 - P.U. (A) 434-2009PY YouPas encore d'évaluation

- INtroduction of Ren EnerDocument49 pagesINtroduction of Ren EnerPY YouPas encore d'évaluation

- Eastin MenuDocument4 pagesEastin MenuPY YouPas encore d'évaluation

- GTA GameboyDocument2 pagesGTA GameboyPY YouPas encore d'évaluation

- NanofiltrationDocument2 pagesNanofiltrationPY YouPas encore d'évaluation

- NanofiltrationDocument2 pagesNanofiltrationPY YouPas encore d'évaluation

- PZZDocument1 pagePZZPY YouPas encore d'évaluation

- Excerpt For Process Modeling (EKC 361)Document9 pagesExcerpt For Process Modeling (EKC 361)PY YouPas encore d'évaluation

- Rangka Kursus (Course Outline) : (Process Dynamics and Control)Document3 pagesRangka Kursus (Course Outline) : (Process Dynamics and Control)PY YouPas encore d'évaluation

- Maurice Nicoll The Mark PDFDocument4 pagesMaurice Nicoll The Mark PDFErwin KroonPas encore d'évaluation

- Dr. Soleh 013515104X - Pp9a Dimensioning 23.9.13.Document36 pagesDr. Soleh 013515104X - Pp9a Dimensioning 23.9.13.PY YouPas encore d'évaluation

- Impeller BioprocessDocument4 pagesImpeller BioprocessPY YouPas encore d'évaluation

- BeeDocument20 pagesBeeAnudeep ChittluriPas encore d'évaluation

- 5 CorrosionDocument67 pages5 CorrosiongnanasekarPas encore d'évaluation

- Industrial Process Calculations CHE 341Document145 pagesIndustrial Process Calculations CHE 341ZanyboiPas encore d'évaluation

- Indrakanty Surya ShashankDocument10 pagesIndrakanty Surya ShashankINDRAKANTY SURYA SHASHANKPas encore d'évaluation

- Thermodynamics - Lesson 2Document12 pagesThermodynamics - Lesson 2Raymond AbesamisPas encore d'évaluation

- Reinforced Concrete I Midterm Exam: C20 - S420 D 4cmDocument1 pageReinforced Concrete I Midterm Exam: C20 - S420 D 4cmAhmad ThaherPas encore d'évaluation

- Cehdra 1 Obe Syllabus T2 2019 2020Document6 pagesCehdra 1 Obe Syllabus T2 2019 2020Jemina SamsonPas encore d'évaluation

- CFF RegularDocument2 pagesCFF RegularAmal SPas encore d'évaluation

- Simulation of Vars Component (Evaporator) Using Ansys SoftwareDocument22 pagesSimulation of Vars Component (Evaporator) Using Ansys SoftwareSanket BhilarePas encore d'évaluation

- Combined FootingDocument4 pagesCombined FootingSakar ShresthaPas encore d'évaluation

- Fourier's Law: A T T (LDocument8 pagesFourier's Law: A T T (LEzioSilvestrePas encore d'évaluation

- AccumulatorDocument44 pagesAccumulatoradi JuliantoPas encore d'évaluation

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuPas encore d'évaluation

- Chap9 NPT Grand Canonical Ensemble v04Document12 pagesChap9 NPT Grand Canonical Ensemble v04Paramita HaldarPas encore d'évaluation

- Mechanics of Materials - Poisson's RatioDocument11 pagesMechanics of Materials - Poisson's RatioDavid Clark100% (5)

- Capilary Rise PDFDocument4 pagesCapilary Rise PDFradhakanta_phy8453100% (1)

- ASTM D7760 - Permeability of TDADocument6 pagesASTM D7760 - Permeability of TDASarangi M PPas encore d'évaluation

- Bolted Connections LectureDocument65 pagesBolted Connections Lecturerghazzaoui1793100% (1)

- Lab 8Document3 pagesLab 8Nadia NasirPas encore d'évaluation

- PT 2023 Past QuestionDocument7 pagesPT 2023 Past QuestionTSOG MHPas encore d'évaluation

- Chapter 3Document24 pagesChapter 3Nesi HafilaPas encore d'évaluation

- Lecture - Combined LoadingsDocument22 pagesLecture - Combined LoadingsSharvinPas encore d'évaluation

- A NoteDocument106 pagesA NoteKenneth SantiagoPas encore d'évaluation

- Advance Heat Transfer - 2Document2 pagesAdvance Heat Transfer - 2Himansu BisoiPas encore d'évaluation

- 0st HTD Calculating Z and EOSDocument65 pages0st HTD Calculating Z and EOSHua Tien DungPas encore d'évaluation

- Yorulma 1 PDFDocument36 pagesYorulma 1 PDFAnonymous KzJcjGCJb100% (1)

- Answerkey FullTest2 SankalpEducationDocument16 pagesAnswerkey FullTest2 SankalpEducationDkPas encore d'évaluation

- Activities Term 2Document6 pagesActivities Term 2studies for sundarPas encore d'évaluation

- Serrano y Olalla - Linearization of The Hoek y BrownDocument11 pagesSerrano y Olalla - Linearization of The Hoek y BrownEsteban JamettPas encore d'évaluation

- Acceptance Criteria For Welds by AUT - Mohamed Amro Aly TorabDocument12 pagesAcceptance Criteria For Welds by AUT - Mohamed Amro Aly Torabidir AMOKRANEPas encore d'évaluation