Académique Documents

Professionnel Documents

Culture Documents

To Determine Compressive Strength of Cement

Transféré par

Anish OhriTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

To Determine Compressive Strength of Cement

Transféré par

Anish OhriDroits d'auteur :

Formats disponibles

EXPERIMENT To determine the compressive strength of cement. EQUIPMENTS REQUIRED 1. Vibration Machine - Vibration machine conforming to IS: 10080-1982.

2. 2. Poking Rod - Poking rod conforming to IS: 10080-1982. 3. Cube Mould- The mould shall be of 70.6 mm size conforming to IS: 10080-1982. 4. Gauging Trowel - Gauging trowel shall a steel blade 100 to 150 mm in length with straight edges weighing 210 10 g. 5. Balance - The balance shall conform to the following requirements: On balance in use, the permissible variation at a load of 1 000 g shall be 1.0 g. The permissible variation on new balance shall be one-half of this value. The sensibility reciprocal shall be not greater than twice the permissible variation. 6. Standard Weights - The permissible variation on weights in use in weighing the cement shall be as prescribed in Table 1. TABLE 1 PERMISSIBLE VARIATIONS ON WEIGHTS WEIGHT (g) PERMISSIBLE VARIATION ON WEIGHTS IN USE (g) 500 300 250 200 100 50 20 10 5 2 1 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.04 0.03 0.02 0.01

7. Graduated Glass Cylinders - Graduated glass cylinders of 150 to 200 ml capacity. The permissible variation on these cylinders shall be 1 ml. The main graduation lines of the cylinders shall be in circles and shall be numbered. The least graduations shall extend at least one-seventh of the way around, and intermediate graduations shall extend

at least one-fifth of the way around the cylinder. The graduation lines may be omitted for the lowest 5 ml.

THEORY - This manual covers the procedure for determining the strength of cement as represented by compressive strength tests on mortar cubes compacted by means of standard vibration machine. Sampling and selection of test samples - The samples of the cement shall be taken in accordance with the requirements of IS: 3535-1986 and the relevant standard specification for the type of cement being tested. The representative sample of the cement selected as above shall be thoroughly mixed before testing. Temperature and humidity - The temperature of moulding room, dry materials and water shall be maintained at 27 2C. The relative humidity of the laboratory shall be 65 5 percent. The moist closet or moist room shall be maintained at 27 2C and at a relative humidity of not less than 90 percent. General - The standard sand to be used in the test shall conform to IS : 650-1966. PROCEDURE 1. PREPARATION OF TEST SPECIMENS i) Mix proportions and mixing a) Clean appliances shall be used for mixing and the temperature of water and that of the test room at the time when the above operations are being performed shall be 27 2C. Potable/distilled water shall be used in preparing the cubes. b) The material for each cube shall be mixed separately and the quantity of cement, standard sand and water shall be as follows: Cement - 200 g Standard Sand - 600 g Water - (P/4 + 3) percent of combined mass of cement and sand, where P is the percentage of water required to produce a paste of standard consistency determined as described in IS : 4031 (Part 4)-1988. c) Place on a nonporous plate, a mixture of cement and standard sand. Mix it dry with a trowel for one minute and then with water until the mixture is of uniform colour. The time of mixing shall in any event be not less than 3 min and should the time taken to obtain a uniform colour exceed 4 min, the mixture shall be rejected and the operation repeated with a fresh quantity of cement, sand and water.

ii) Moulding specimens a) In assembling the moulds ready for use, cover the joints between the halves of the mould with a thin film of petroleum jelly and apply a similar coating of petroleum jelly between the contact surfaces of the bottom of the mould and its base plate in order to ensure that no water escapes during vibration. Treat the interior faces of the mould with a thin coating of mould oil. b) Place the assembled mould on the table of the vibration machine and hold it firmly in position by means of a suitable clamp. Attach a hopper of suitable size and shape securely at the top of the mould to facilitate filling and this hopper shall not be removed until the completion of the vibration period. c) Immediately after mixing the mortar, place the mortar in the cube mould and prod with the rod. The mortar shall be prodded 20 times in about 8 s to ensure elimination of entrained air and honey-combing. Place the remaining quantity of mortar in the hopper of the cube mould and prod again as specified for the first layer and then compact the mortar by vibration. d) The period of vibration shall be two minutes at the specified speed of 12000 400 vibrations per minute. e) At the end of vibration, remove the mould together with the base plate from the machine and finish the top surface of the cube in the mould by smoothing the surface with the blade of a trowel. ii) Curing specimens Keep the filled moulds in moist closet or moist room for 241 hours after completion of vibration. At the end of that period, remove them from the moulds and immediately submerge in clean fresh water and keep there until taken out just prior to breaking. The water in which the cubes are submerged shall be renewed every 7 days and shall be maintained at a temperature of 27 2C. After they have been taken out and until they are broken, the cubes shall not be allowed to become dry. 2. TESTING i) Test three cubes for compressive strength for each period of curing mentioned under the relevant specifications for different hydraulic cements, the periods being reckoned from the completion of vibration. ii) The cubes shall be tested on their sides without any packing between the cube and the steel plattens of the testing machine. One of the plattens shall be carried on a base and shall be self-adjusting, and the load shall be steadily and uniformly applied, starting from zero at a rate of 35 N/mm/min.

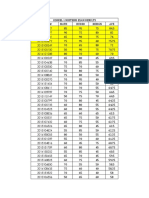

OBSERVATIONS a) For 3 days strength:

Sl.No. Length (L) in mm 1 2 3

Breadth (B) in mm

Load (P) in N

compressive strength in N/mm2

Average =

(b) For 7 days strength:

Sl.No. Length (L) in mm 1 2 3

Breadth (B) in mm

Load (P) in N

compressive strength in N/mm2

Average =

CALCULATION - The measured compressive strength of the cubes shall be calculated by dividing the maximum load applied to the cubes during the test by the cross-sectional area, calculated from the mean dimensions of the section and shall be expressed to the nearest 0.5 N/mm2. In determining the compressive strength, do not consider specimens that are manifestly faulty, or that give strengths differing by more than 10 percent from the average value of all the test specimens. After discarding specimens or strength values, if less than two strength values are left for determining the compressive strength at any given period, a retest shall be made. RESULT Compressive strength of cement at 3 days Compressive strength of cement at 7 days REFERENCES = = N/mm2. N/mm2

IS 4031-6 (1988): Methods of physical tests for hydraulic cement, Part 6: Determination of compressive strength of hydraulic cement (other than masonry cement)

Vous aimerez peut-être aussi

- Formwork 11Document77 pagesFormwork 11Anish OhriPas encore d'évaluation

- Fans Reference GuideDocument160 pagesFans Reference Guidekarthikraja21100% (13)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityD'EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityPas encore d'évaluation

- Determine Concrete Strength with Digital Compression TesterDocument57 pagesDetermine Concrete Strength with Digital Compression Testerneroshan1978100% (2)

- GX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Document64 pagesGX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Stasio80Pas encore d'évaluation

- Concrete &highway Lab New ManualDocument40 pagesConcrete &highway Lab New Manualshruthicivil100% (4)

- The Order of Historical Time: The Longue Durée and Micro-HistoryDocument17 pagesThe Order of Historical Time: The Longue Durée and Micro-HistoryGeorgia KoutaPas encore d'évaluation

- Aashto T 99-81Document7 pagesAashto T 99-81ORUSPas encore d'évaluation

- Test On Cement PDFDocument6 pagesTest On Cement PDFIrfan NazirPas encore d'évaluation

- Geotechnical Engineering: Testing ManualsD'EverandGeotechnical Engineering: Testing ManualsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Quality Control of Construction Testing of Concrete CubesDocument7 pagesQuality Control of Construction Testing of Concrete CubesHemanth KumarPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationJGD123Pas encore d'évaluation

- Wartsila CPP PaperDocument4 pagesWartsila CPP Papergatheringforgardner9550Pas encore d'évaluation

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- Astm C87Document3 pagesAstm C87avrajan100% (2)

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- Is 4031 Part 6 - Compressive StrengthDocument6 pagesIs 4031 Part 6 - Compressive Strengthbhustlero0o75% (4)

- Railway Handbook of Material Testing 1Document20 pagesRailway Handbook of Material Testing 1vpmohammedPas encore d'évaluation

- Astm C 185Document3 pagesAstm C 185cristian_agpPas encore d'évaluation

- Muddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsDocument15 pagesMuddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsAafaq Ur RehmanPas encore d'évaluation

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasPas encore d'évaluation

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasPas encore d'évaluation

- Compressive Strength of Cement: 1. ObjectiveDocument7 pagesCompressive Strength of Cement: 1. ObjectiveAhmad FarooqPas encore d'évaluation

- Compressive Strength of CementDocument2 pagesCompressive Strength of CementMastani BajiraoPas encore d'évaluation

- Compressive Strength of CementDocument3 pagesCompressive Strength of CementRama shankarPas encore d'évaluation

- Method B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.Document5 pagesMethod B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.GUO LEIPas encore d'évaluation

- Portland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Document3 pagesPortland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Anuradha RumeshPas encore d'évaluation

- Concrete Technology Lab ManualDocument32 pagesConcrete Technology Lab ManualaddayesudasPas encore d'évaluation

- CMT FINALS Compiled ExercisesDocument17 pagesCMT FINALS Compiled ExercisesRaymund SuanPas encore d'évaluation

- Stas 2634 1980 enDocument25 pagesStas 2634 1980 enCheran Florin TiberiuPas encore d'évaluation

- Determine cement properties using Vicat apparatusDocument7 pagesDetermine cement properties using Vicat apparatusNavneet SinghPas encore d'évaluation

- Laboratory Manual of Concrete TechnologyDocument50 pagesLaboratory Manual of Concrete TechnologyYogeshwar singhPas encore d'évaluation

- تقرير السمنتDocument20 pagesتقرير السمنتسجاد علي جابر حبيب DPas encore d'évaluation

- Soundness of CementDocument3 pagesSoundness of CementKrishnaChaitanya100% (1)

- BS 598-Part 108-90Document10 pagesBS 598-Part 108-90anish_am2005Pas encore d'évaluation

- Various Lab Test On CementDocument4 pagesVarious Lab Test On Cementhncc ghazniPas encore d'évaluation

- Cycle 2 Som LabDocument10 pagesCycle 2 Som LabAnonymous SEDun6PWPas encore d'évaluation

- خرسانة عملي الفصل الاول والثانيDocument58 pagesخرسانة عملي الفصل الاول والثانيAhmed AlyasPas encore d'évaluation

- AS 1012.6-1999 For The Determination of Bleeding of ConcreteDocument9 pagesAS 1012.6-1999 For The Determination of Bleeding of Concreteheyh jdjPas encore d'évaluation

- CONCRETE LAB MANUALDocument20 pagesCONCRETE LAB MANUALsidPas encore d'évaluation

- Tests of Cement - SOPDocument13 pagesTests of Cement - SOPElegant PrincePas encore d'évaluation

- 3 (D) Workability of Concrete - Flow Table TestDocument11 pages3 (D) Workability of Concrete - Flow Table TestFrank JohnPas encore d'évaluation

- Cemetn TestingDocument20 pagesCemetn TestingKrishnan SubramaniamPas encore d'évaluation

- Soil mechanics relative densityDocument5 pagesSoil mechanics relative densitytusopulaPas encore d'évaluation

- Testing Procedures Adopted For Cement and SteelDocument6 pagesTesting Procedures Adopted For Cement and Steelp.v.n. lakshmanPas encore d'évaluation

- CT Lab ManualDocument26 pagesCT Lab ManualJagathChandraPas encore d'évaluation

- High Strength Prestressed Concrete Cube Test ResultsDocument5 pagesHigh Strength Prestressed Concrete Cube Test ResultsKumar Narmadeshwar Gupta0% (1)

- Cement Test eDocument10 pagesCement Test esajjad.ghazai2001Pas encore d'évaluation

- Concrete Tech. ManualDocument31 pagesConcrete Tech. ManualAnkesh ShrivastavaPas encore d'évaluation

- Compressive Strength of Hydraulic CementDocument3 pagesCompressive Strength of Hydraulic CementEr Mansoor HussainPas encore d'évaluation

- CMT Laboratory ExperimentsDocument4 pagesCMT Laboratory ExperimentsErvi Soriano FabrosPas encore d'évaluation

- M4 Lab.6 MaglintemarkandykennDocument10 pagesM4 Lab.6 MaglintemarkandykennMark Andykenn Liaga MaglintePas encore d'évaluation

- تخرج 3Document6 pagesتخرج 3احمد ابو جودPas encore d'évaluation

- Cube TestDocument7 pagesCube TestAmritpal Singh50% (2)

- Quality Control Of Concrete TestingDocument7 pagesQuality Control Of Concrete TestinganmoljassalPas encore d'évaluation

- WI 15 Cement TestingDocument6 pagesWI 15 Cement TestingRaja Varshney100% (1)

- Compressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109Document4 pagesCompressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109YasirPas encore d'évaluation

- Lab Manual.1pdfDocument31 pagesLab Manual.1pdfAshish KumarPas encore d'évaluation

- Marshal TestDocument8 pagesMarshal TestodainsaratPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IID'EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiPas encore d'évaluation

- Analysis of TrussesDocument33 pagesAnalysis of TrussesJames ChiomaPas encore d'évaluation

- Admixture TypesDocument25 pagesAdmixture TypesAnish OhriPas encore d'évaluation

- Aggregates On Site Lec 30Document11 pagesAggregates On Site Lec 30Anish OhriPas encore d'évaluation

- 2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMDocument3 pages2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMTropic BazarPas encore d'évaluation

- The Machining of Brake DiscsDocument8 pagesThe Machining of Brake DiscsBusu Cyp100% (1)

- Inferential Statistics: Estimation and Confidence IntervalsDocument19 pagesInferential Statistics: Estimation and Confidence IntervalsHasan HubailPas encore d'évaluation

- Die Science - Developing Forming Dies - Part I - The FabricatorDocument6 pagesDie Science - Developing Forming Dies - Part I - The FabricatorSIMONEPas encore d'évaluation

- 02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0Document5 pages02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0QQPas encore d'évaluation

- Development of A Highway Performance Index For Upgrading Decision Making - Case Study For A Provincial Road Network in A Developing CountryDocument6 pagesDevelopment of A Highway Performance Index For Upgrading Decision Making - Case Study For A Provincial Road Network in A Developing CountryAshen MinolPas encore d'évaluation

- General 04 Fixed Flow Pump To Three TanksDocument13 pagesGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemPas encore d'évaluation

- Public Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityDocument7 pagesPublic Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityAbrasaxEimi370Pas encore d'évaluation

- Velocity profiles and incompressible flow field equationsDocument2 pagesVelocity profiles and incompressible flow field equationsAbdul ArifPas encore d'évaluation

- 4495 10088 1 PBDocument7 pages4495 10088 1 PBGeorgius Kent DiantoroPas encore d'évaluation

- Javascript Api: Requirements Concepts Tutorial Api ReferenceDocument88 pagesJavascript Api: Requirements Concepts Tutorial Api ReferenceAshish BansalPas encore d'évaluation

- Classification of Differential Equations For Finding Their SolutionsDocument2 pagesClassification of Differential Equations For Finding Their SolutionsakhileshPas encore d'évaluation

- HER107 DatasheetDocument4 pagesHER107 DatasheetPeter Yvan Ramos PeñaPas encore d'évaluation

- Power Theft Identification Using GSM TechnologyDocument3 pagesPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioPas encore d'évaluation

- Spesifikasi ACER Travelmate P2-P245Document12 pagesSpesifikasi ACER Travelmate P2-P245Sebastian Fykri AlmuktiPas encore d'évaluation

- Lab Manual MCSE 101Document35 pagesLab Manual MCSE 101Juan JacksonPas encore d'évaluation

- Pipeline Corrosion Assessment MethodsDocument21 pagesPipeline Corrosion Assessment MethodsGilletPas encore d'évaluation

- PDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressDocument7 pagesPDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressErickson Brayner MarBerPas encore d'évaluation

- Notifier Battery Calculations-ReadmeDocument11 pagesNotifier Battery Calculations-ReadmeJeanCarlosRiveroPas encore d'évaluation

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDocument16 pagesGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelPas encore d'évaluation

- Crystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledDocument33 pagesCrystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledArkodip MandalPas encore d'évaluation

- RelativedensityipgDocument2 pagesRelativedensityipgapi-310625232Pas encore d'évaluation

- Mathematics of Finance: Simple and Compound Interest FormulasDocument11 pagesMathematics of Finance: Simple and Compound Interest FormulasAshekin MahadiPas encore d'évaluation

- SubNetting Practice LabDocument3 pagesSubNetting Practice LabOdoch HerbertPas encore d'évaluation