Académique Documents

Professionnel Documents

Culture Documents

Aisc Member Dimensions and Properties Viewer

Transféré par

3cesDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aisc Member Dimensions and Properties Viewer

Transféré par

3cesDroits d'auteur :

Formats disponibles

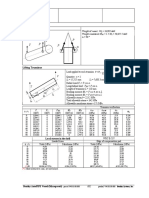

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes

C, MC Shapes

Single Angles

a=

Wno =

Sw =

Qf =

Qw =

wt. =

x=26.67

t=12.7

d=88.9

X

X

d=129.286

tw=5.588

d=127

mm

mm

mm

mm

in.

mm

mm

in.

cm

cm4

cm3

cm

cm4

cm3

cm

cm3

cm3

A=

d=

tw =

bf =

tf =

T=

k=

gage =

x(bar) =

eo =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

J=

Cw =

cm4

a=

cm6

ro(bar) =

H=

wt. =

cm

cm2

C8x11.5

21.7

203

5.6

57

9.9

1005840.0

23.8

1-3/8

14.5

17.7

9.08

1353

133

7.9

55

12.7

1.6

5.4

4430.8

117.0

8.7

0.862

17.1

d=203.2

y=26.67

tw=6.096

b=88.9

(0, 3/8, or 3/4

gap)

bf=57.404

cm2

t = 8.9

b=88.9

t=9.525

bf=146.05

y=27.178

tf=9.144

d=203.2

bf=146.05

W10x22

41.9

259.1

6.1

146.1

9.1

8-1/4

16.8

15.9

2-3/4

3.8

4.91

4912

380

10.8

475

65

3.4

426.1

100.0

9.95

73579

351.5

91.0

303.8

79.6

209.8

32.9

tf=9.906

tw=6.096

A=

d=

tw =

bf =

tf =

T=

k=

k1 =

gage =

rt =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

Cw =

Square & Rectangular HSS

Y

x(bar)=14.5288

d=259.08

Double Angles

Y

k1=15.875

tf=9.144

k=16.764

WT, ST, MT Shapes

cm2

mm

mm

mm

mm

mm

mm

in.

mm

mm

cm4

cm3

cm

cm4

cm3

cm

cm4

cm6

cm

cm

A=

d=

tw =

bf =

tf =

k=

d/tw =

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

J=

Cw =

a=

ro(bar) =

H=

wt. =

WT5x11

20.9

129.3

6.1

146.1

9.1

16.8

21.2

286

28.2

3.7

27.2

238

32.6

3.4

5.0

28.7

9.8

5.5

0.830

16.4

L3-1/2x3-1/2x1/2

cm2

mm

mm

mm

mm

mm

cm4

cm3

cm

mm

cm4

cm3

cm

cm4

cm6

cm

cm

d=

b=

t=

k=

wt. =

A=

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

x=

rz =

TAN(a) =

J=

Cw =

a=

kg/ml

ro(bar) =

H=

88.9

88.9

12.7

22.2

16.6

21.1

151.1

24.3

2.7

26.7

151.1

24.3

2.7

26.7

1.7

1.0

11.7

63.9

9.6

4.7

0.634

b=152.4

2L5x3-1/2x3/8LLBB

mm

mm

mm

mm

kg/ml

cm2

cm4

cm3

cm

mm

cm4

cm3

cm

mm

cm

d=

b=

t=

k=

wt. =

A=

Ix =

Sx =

rx =

y=

ry(0) =

ry(3/8) =

ry(3/4) =

ro(bar) =

H=

127.0

88.9

9.5

20.6

30.9

39.4

645.2

74.7

4.0

40.6

33.8

37.1

40.4

63.8

0.683

HSS8x6x3/8

d=

b=

t=

wt. =

A=

Ix =

Sx =

rx =

Zx =

Iy =

Sy =

ry =

Zy =

J=

mm

mm

mm

mm

kg/ml

cm2

cm4

cm3

cm

mm

mm

mm

mm

mm

203.2

152.4

8.9

17.9

22.8

3292.4

324.5

7.54

394.9

2106.1

276.9

6.0

324.5

4162

mm

mm

mm

kg/ml

cm2

cm4

cm3

cm

cm3

cm4

cm3

cm

cm3

cm4

Round HSS & Pipes

Y

cm4

6

t= 4.5

cm

cm

cm

O.D.= 33.5

I.D.=24.3078

kg/ml

cm4

3

cm

cm3

kg/ml

PIPE1XS

Reference:

The shapes contained in this database are a

compilation of those listed in the current AISC

"Shapes Database" CD-ROM Version 3.0 (June,

2001), as well as those listed in the AISC 9th

Edition Manual of Steel Construction (1989)

O.D. =

I.D. =

t=

wt. =

A=

I=

S=

r=

J=

33.5

24.3

4.5

3.2

4.1

1

3

1.0

9

mm.

mm.

mm.

kg/ml

cm2

cm4

cm3

cm.

cm4

k1=15.875

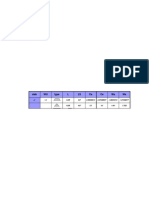

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes

C, MC Shapes

Single Angles

a=

Wno =

Sw =

Qf =

Qw =

x=0.854

t=0.375

d=5

X

X

d=5.09

tw=0.24

d=5

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.^4

in.^3

in.

in.^4

in.^3

in.

in.^3

in.^3

A=

d=

tw =

bf =

tf =

T=

k=

gage =

x(bar) =

eo =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

J=

Cw =

in.^4

a=

in.^6

ro(bar) =

H=

in.

C10x15.3

4.48

10.000

0.240

2.600

0.436

8

1.0000

1-1/2

0.634

0.796

8.81

67.30

13.50

3.870

2.27

1.15

0.711

0.21

45.5

23.74

4.19

0.884

d=8

y=1.6

tw=0.24

b=3.5

(0, 3/8, or 3/4

gap)

bf=2.6

in.^2

t=0.349

b=3.5

t=0.375

bf=5.75

y=1.07

tf=0.36

d=10

bf=5.75

W10x22

6.49

10.200

0.240

5.750

0.360

8-1/4

0.6600

0.6250

2-3/4

1.510

4.91

118.00

23.20

4.270

11.40

3.97

1.330

26.00

6.10

0.24

274

54.48

14.10

7.30

4.86

12.80

tf=0.436

tw=0.24

A=

d=

tw =

bf =

tf =

T=

k=

k1 =

gage =

rt =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

Cw =

Square & Rectangular HSS

Y

x(bar)=0.634

d=10.2

Double Angles

Y

k1=0.625

tf=0.36

k=0.66

WT, ST, MT Shapes

in.^2

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.^4

in.^3

in.

in.^4

in.^3

in.

in.^4

in.^6

in.

in.

A=

d=

tw =

bf =

tf =

k=

d/tw =

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

J=

Cw =

a=

ro(bar) =

H=

WT5x11

3.24

5.090

0.240

5.750

0.360

0.6600

21.20

6.88

1.72

1.460

1.070

5.71

1.99

1.330

0.119

0.107

1.53

2.16

0.830

L5x3-1/2x3/8

in.^2

in.

in.

in.

in.

in.

in.^4

in.^3

in.

in.

in.^4

in.^3

in.

in.^4

in.^6

in.

in.

d=

b=

t=

k=

wt./ft. =

A=

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

x=

rz =

TAN(a) =

J=

Cw =

a=

ro(bar) =

H=

5

3.5

0.375

0.8125

10.40

3.05

7.75

2.28

1.590

1.600

3.15

1.19

1.020

0.854

0.755

0.486

0.15

0.217

1.94

2.45

---

b=6

2L5x3-1/2x3/8LLBB

in.

in.

in.

in.

plf.

in.^2

in.^4

in.^3

in.

in.

in.^4

in.^3

in.

in.

in.

d=

b=

t=

k=

wt./ft. =

A=

Ix =

Sx =

rx =

y=

ry(0) =

ry(3/8) =

ry(3/4) =

ro(bar) =

H=

5

3.5

0.375

0.8125

20.80

6.10

15.50

4.56

1.590

1.600

1.330

1.460

1.590

2.51

0.683

HSS8x6x3/8

in.

in.

in.

in.

plf.

in.^2

in.^4

in.^3

in.

in.

in.

in.

in.

in.

d=

b=

t=

wt./ft. =

A=

Ix =

Sx =

rx =

Zx =

Iy =

Sy =

ry =

Zy =

J=

8

6

0.349

32.50

8.97

79.10

19.80

2.970

24.10

50.60

16.90

2.380

19.80

100.00

in.

in.

in.

plf.

in.^2

in.^4

in.^3

in.

in.^3

in.^4

in.^3

in.

in.^3

in.^4

Round HSS & Pipes

Y

in.^4

t=0.365

in.^6

in.

in.

O.D.=10.8

I.D.=10

in.^2

in.^4

in.^3

in.^3

PIPE10STD

Reference:

The shapes contained in this database are a

compilation of those listed in the current AISC

"Shapes Database" CD-ROM Version 3.0 (June,

2001), as well as those listed in the AISC 9th

Edition Manual of Steel Construction (1989)

O.D. =

I.D. =

t=

wt./ft. =

A=

I=

S=

r=

J=

10.8

10

0.365

40.50

11.90

161.00

29.90

3.670

321.00

in.

in.

in.

plf.

in.^2

in.^4

in.^3

in.

in.^4

NOMENCLATURE FOR MEMBER PROPERTIES AND DIMENSIONS:

A=

d=

tw =

bf =

tf =

T=

k=

k1 =

gage =

rt =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

Cw =

a=

E=

G=

W no =

Sw =

Qf =

Qw =

x(bar) =

eo =

xo =

yo =

ro(bar) =

H=

LLBB =

SLBB =

STD =

XS =

XXS =

Cross-sectional area of member (in.^2)

Overall depth of member, parallel to X-axis (in.)

Thickness of web of member (in.)

Width of flange of member (in.)

Thickness of flange of member (in.)

Distance between fillets for wide-flange or channel shape (in.) = d-2*k

Distance from outer face of flange to web toe of fillet (in.)

Distance from web centerline to flange toe of fillet (in.)

Standard gage (bolt spacing) for member (in.)

Radius of gyration of compression flange plus 1/3 of compression web area, taken about an axis in plane of web (in.)

Ratio of of total depth of member to area of compression flange of member = d/(bf*tf)

Moment of inertia of member taken about X-axis (in.^4)

Elastic section modulus of member taken about X-axis (in.^3)

Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A)

Moment of inertia of member taken about Y-axis (in.^4)

Elastic section modulus of member taken about Y-axis (in.^3)

Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Plastic section modulus of member taken about X-axis (in.^3)

Plastic section modulus of member taken about Y-axis (in.^3)

Torsional constant of member (in.^4)

Warping constant (in.^6)

Torsional property, a = SQRT(E*Cw/G*J)

Modulus of elasticity of steel = 29,000 ksi

Shear modulus of elasticity of steel = 11,200 ksi

Normalized warping function at a point at the flange edge (in.^2)

Warping statical moment at a point on the cross section (in.^4)

Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Statical moment at the mid-depth of the section (in.^3)

Distance from outside face of web of channel shape to Y-axis (in.)

Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

x-coordinate of shear center with respect to the centroid of the section (in.)

y-coordinate of shear center with respect to the centroid of the section (in.)

Polar radius of gyration about the shear center (in.) = SQRT(xo^2+yo^2+(Ix+Iy)/A)

Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

Long legs back-to-back for double angles

Short legs back-to-back for double angles

Standard weight (Schedule 40) pipe section

Extra strong (Schedule 80) pipe section

Double-extra strong pipe section

Vous aimerez peut-être aussi

- Profile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightDocument55 pagesProfile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightM Zahran KhairyPas encore d'évaluation

- KASTO 206 (인장 및 압축 시험기) PDFDocument28 pagesKASTO 206 (인장 및 압축 시험기) PDFTJPas encore d'évaluation

- Aisc Member Dimensions and Properties ViewerDocument23 pagesAisc Member Dimensions and Properties ViewerMadara Uchija100% (1)

- Brief Note PDFDocument37 pagesBrief Note PDFMoeenPas encore d'évaluation

- Perforated Thk. 2mmDocument99 pagesPerforated Thk. 2mmMuhamad Amar Hakimmie SuhaimiPas encore d'évaluation

- Super Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Document3 pagesSuper Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Omar RubioPas encore d'évaluation

- Custom Fabricated Metal Cones FrustumsDocument6 pagesCustom Fabricated Metal Cones FrustumsWillie BalagotPas encore d'évaluation

- CAL-ST-070!17!01 Rev01 Shipping Saddles CalculationDocument11 pagesCAL-ST-070!17!01 Rev01 Shipping Saddles CalculationgiubelloPas encore d'évaluation

- AISC Properties-MmDocument86 pagesAISC Properties-MmAnghello Jeison Zavaleta De la CruzPas encore d'évaluation

- 3.equipment Nozzle Load Cal SYS - 623Document10 pages3.equipment Nozzle Load Cal SYS - 623Vaniya GoelPas encore d'évaluation

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJPas encore d'évaluation

- Setting Bolt CalculationDocument1 pageSetting Bolt Calculationrina2393Pas encore d'évaluation

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Document7 pagesLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonPas encore d'évaluation

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrPas encore d'évaluation

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195Pas encore d'évaluation

- Section DataDocument5 pagesSection Datamiteshpatel191Pas encore d'évaluation

- Auto PipeDocument18 pagesAuto PipeAdi Sutardi100% (1)

- OffCon Beta CanadaDocument11 pagesOffCon Beta CanadaHelmiPas encore d'évaluation

- Blind ThicknessDocument1 pageBlind ThicknessRizwan Waheed KhanPas encore d'évaluation

- Asce7 05 Earthquake F 7310 Sand Surge HopperDocument1 pageAsce7 05 Earthquake F 7310 Sand Surge HopperDeepmalaJayeshPas encore d'évaluation

- Design Wind Pressure: Aseana Bpo BuildingDocument5 pagesDesign Wind Pressure: Aseana Bpo BuildingRyan De Vera PagalPas encore d'évaluation

- Pin StressesDocument5 pagesPin Stressesprajakt_piePas encore d'évaluation

- #160 Lifting Fixture 38tons 020807Document14 pages#160 Lifting Fixture 38tons 020807halder_kalyan9216Pas encore d'évaluation

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarPas encore d'évaluation

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirPas encore d'évaluation

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonPas encore d'évaluation

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Padeye Shackle Sling Calculation r2Document7 pagesPadeye Shackle Sling Calculation r2Peja JusohPas encore d'évaluation

- Design of Face Mounted BracketDocument4 pagesDesign of Face Mounted Bracketvishal tomarPas encore d'évaluation

- Design Sheet: Overseas Technical Engineering and Construction Pte LTDDocument33 pagesDesign Sheet: Overseas Technical Engineering and Construction Pte LTDSasikumar JothiPas encore d'évaluation

- Comp 2Document9 pagesComp 2YYo YudiPas encore d'évaluation

- Lifting Lug Stress AnalysisDocument10 pagesLifting Lug Stress AnalysisChaitanya Sai TPas encore d'évaluation

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathPas encore d'évaluation

- Mech-Intro 13.0 AppB UserWkshopDocument4 pagesMech-Intro 13.0 AppB UserWkshopRichard HilsonPas encore d'évaluation

- Eq Base Shear CalculationsDocument9 pagesEq Base Shear Calculationsirshad313Pas encore d'évaluation

- Section Properties of Common ShapesDocument12 pagesSection Properties of Common Shapesdmaister1986Pas encore d'évaluation

- Crimp PLTDocument5 pagesCrimp PLTSai SushankPas encore d'évaluation

- Pin Connected Tension MemberDocument2 pagesPin Connected Tension MemberAUNGPSPas encore d'évaluation

- Hollow Sections PropertiesDocument20 pagesHollow Sections PropertiesHorace Prophetic DavisPas encore d'évaluation

- Engineering Mechanics Statics: Yousif J. BasDocument25 pagesEngineering Mechanics Statics: Yousif J. Basalnd azadPas encore d'évaluation

- Bolts,: Threaded Parts TensionDocument2 pagesBolts,: Threaded Parts TensionMary MarasiganPas encore d'évaluation

- Seismic Load Calculation of The Tank As Per IS 1893Document1 pageSeismic Load Calculation of The Tank As Per IS 1893ParthibanPas encore d'évaluation

- Welded JointsDocument30 pagesWelded JointsOmkar Kumar JhaPas encore d'évaluation

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaPas encore d'évaluation

- Interaction-Diagram-Tied-Reinforced-Concrete-Column-with-High-Strength-Reinforcing-Bars - ACI318-19 PDFDocument32 pagesInteraction-Diagram-Tied-Reinforced-Concrete-Column-with-High-Strength-Reinforcing-Bars - ACI318-19 PDFDonny. B TampubolonPas encore d'évaluation

- Flowchart GirderDocument5 pagesFlowchart GirderkhoirunisaPas encore d'évaluation

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamPas encore d'évaluation

- Circular Section: C C AreaDocument7 pagesCircular Section: C C Areafoush bashaPas encore d'évaluation

- Ladder Rung Calc.Document1 pageLadder Rung Calc.Azwan ShahPas encore d'évaluation

- FRAME MetricDocument7 pagesFRAME MetricHernâniCruzPas encore d'évaluation

- PV Elite Transport A Vertical Vessel in The Horizontal Position PDFDocument3 pagesPV Elite Transport A Vertical Vessel in The Horizontal Position PDFlazy5Pas encore d'évaluation

- Vessel Data Sheet Process Specification Sheet FormDocument1 pageVessel Data Sheet Process Specification Sheet FormunitedmanticorePas encore d'évaluation

- Weldment Design and SimplificationsDocument9 pagesWeldment Design and SimplificationsEswaran RajamaniPas encore d'évaluation

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyPas encore d'évaluation

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Document5 pagesConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannPas encore d'évaluation

- Iv. Design Calculation of Rafter, Girder & ColumnDocument5 pagesIv. Design Calculation of Rafter, Girder & ColumnFaizal Sattu100% (1)

- Formula HandbookDocument80 pagesFormula HandbookElPerroMuerto100% (2)

- AISC Properties MMDocument31 pagesAISC Properties MMManuel JuanPas encore d'évaluation

- AISC (MM) PropertiesDocument7 pagesAISC (MM) PropertiesasrhaelPas encore d'évaluation

- AISC Properties ViewerDocument2 pagesAISC Properties ViewerLivian TeddyPas encore d'évaluation

- Exercises 5.5 and 5.6Document7 pagesExercises 5.5 and 5.63cesPas encore d'évaluation

- Working Load Concrete PropertyDocument2 pagesWorking Load Concrete Property3cesPas encore d'évaluation

- N & M (Int. Frame)Document2 pagesN & M (Int. Frame)3cesPas encore d'évaluation

- Working Load Concrete PropertyDocument4 pagesWorking Load Concrete Property3cesPas encore d'évaluation

- The Max Immediate & Long Term Deflection: Uncracked SecDocument8 pagesThe Max Immediate & Long Term Deflection: Uncracked Sec3cesPas encore d'évaluation

- Load DistrubutionDocument4 pagesLoad Distrubution3cesPas encore d'évaluation

- Load of BeamDocument3 pagesLoad of Beam3cesPas encore d'évaluation

- Load DistributionDocument1 pageLoad Distribution3cesPas encore d'évaluation

- Addational Moment To Slab From Linear LoadDocument2 pagesAddational Moment To Slab From Linear Load3cesPas encore d'évaluation

- C1 (Control) C3 (Angle 30) C4 (Angle 60) C2 (Control) C5 (Angle 30) C6 (Angle 60)Document5 pagesC1 (Control) C3 (Angle 30) C4 (Angle 60) C2 (Control) C5 (Angle 30) C6 (Angle 60)3cesPas encore d'évaluation

- 02.Are We Living in the Digital Dark Ages (교사용)Document7 pages02.Are We Living in the Digital Dark Ages (교사용)박은서Pas encore d'évaluation

- ASME Ch38 p001-018 11-8-08Document18 pagesASME Ch38 p001-018 11-8-08Dan MorganPas encore d'évaluation

- Astronaut Biosuit System To Enable Planetary Exploration 2004Document11 pagesAstronaut Biosuit System To Enable Planetary Exploration 2004Bao Hoang LePas encore d'évaluation

- Electric Charge, Force, and Field: Problem Solving LectureDocument27 pagesElectric Charge, Force, and Field: Problem Solving Lectureimane ibrahimiPas encore d'évaluation

- B 0 Be 3 NDocument2 pagesB 0 Be 3 NAlvaro GustavoPas encore d'évaluation

- (Andrei Bourchtein, Ludmila Bourchtein) CounterExa PDFDocument358 pages(Andrei Bourchtein, Ludmila Bourchtein) CounterExa PDFAmjed Far100% (1)

- 1 Graded Problems: PHY 5246: Theoretical Dynamics, Fall 2015 Assignment # 2, SolutionsDocument8 pages1 Graded Problems: PHY 5246: Theoretical Dynamics, Fall 2015 Assignment # 2, SolutionsJennifer RibeiroPas encore d'évaluation

- Coordinate Geometry: Coordinate Geometry Is Considered To Be One of The MostDocument5 pagesCoordinate Geometry: Coordinate Geometry Is Considered To Be One of The MostSyed M HassanPas encore d'évaluation

- CMTI Final ReportDocument23 pagesCMTI Final ReportN BHUSHANPas encore d'évaluation

- Ppcatalogue 2 PDFDocument527 pagesPpcatalogue 2 PDFrutwickPas encore d'évaluation

- Basic Principle of Chemical EngineeringDocument47 pagesBasic Principle of Chemical EngineeringEmre KOÇPas encore d'évaluation

- Example-40: Active Site Edutech - 9844532971 (For Customized Printed Books With Logo & Name)Document27 pagesExample-40: Active Site Edutech - 9844532971 (For Customized Printed Books With Logo & Name)Mayuri chatpalliwarPas encore d'évaluation

- Movement Joints in Steel BuildingsDocument10 pagesMovement Joints in Steel Buildingsfloi dPas encore d'évaluation

- How The Three Phase System Voltages Are Derived With Respect To ABC and CBA SequenceDocument13 pagesHow The Three Phase System Voltages Are Derived With Respect To ABC and CBA SequenceRyan CortesPas encore d'évaluation

- ToR Upper Chameliya Geophysical Tests DraftDocument17 pagesToR Upper Chameliya Geophysical Tests DraftMani PathakPas encore d'évaluation

- Kobelco SK 200-9 Shop ManualDocument135 pagesKobelco SK 200-9 Shop ManualGogot Yuliyanto50% (2)

- SJI Bridging Webinar For-Participants 021516Document131 pagesSJI Bridging Webinar For-Participants 021516Dan VPas encore d'évaluation

- Word RootsDocument3 pagesWord RootsJASPER DELLPas encore d'évaluation

- FEA Simulation 2020: Smart NonlinearDocument32 pagesFEA Simulation 2020: Smart NonlinearAmr EmadPas encore d'évaluation

- 3 Hours / 70 Marks: Seat NoDocument5 pages3 Hours / 70 Marks: Seat NoMadao111Pas encore d'évaluation

- Gate Syllabus Civil Engineering PDFDocument3 pagesGate Syllabus Civil Engineering PDFsagar kolhePas encore d'évaluation

- Brahma GuptaDocument9 pagesBrahma Guptadroy21Pas encore d'évaluation

- Fluid Mechanics Chapter 1-Basic ConceptsDocument29 pagesFluid Mechanics Chapter 1-Basic ConceptsAmine JaouharyPas encore d'évaluation

- Thru-Hull: Compact and Budget-Minded!Document2 pagesThru-Hull: Compact and Budget-Minded!argodumilahPas encore d'évaluation

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofMina RemonPas encore d'évaluation

- Euclidean Geometry - WikipediaDocument18 pagesEuclidean Geometry - WikipediakamaalPas encore d'évaluation

- CH 8Document20 pagesCH 8Zahim HarkiPas encore d'évaluation

- ME3100 Solution Tut-1Document10 pagesME3100 Solution Tut-1B V V HANUMA GAYATHRIPas encore d'évaluation

- Lesson 3: Definition and Equation of A ParabolaDocument4 pagesLesson 3: Definition and Equation of A ParabolaJan RobertsPas encore d'évaluation

- Displacement Based Seismic Design of RC Bridge PiersDocument6 pagesDisplacement Based Seismic Design of RC Bridge PiersBhaskar KumarPas encore d'évaluation