Académique Documents

Professionnel Documents

Culture Documents

10Z 3

Transféré par

ZMCONTROLDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10Z 3

Transféré par

ZMCONTROLDroits d'auteur :

Formats disponibles

3

10Z3

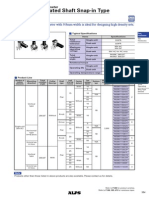

16 Small Air Cylinder/12

Further Compact With Adoption Of Band Type Small Switch.

With the adoption of stainless steel tube, the external shape has become simple. System improved type as it becomes switch-set cylinder only by mounting switch on cylinder body. For the switch mounting method, it can be mounted simply with the adoption of band type. The switch setting position can also be selected freely by mounting band. 6 types of mounting style are prepared so that the ideal mounting method can be selected. Stainless steel with Hard Chrome plating have been adopting for piston rod.

Cylinder Specifications

Structure Type Series Cylinder boremm Working fluid Lubrication Operating prssure Proof test pressure Speed range Temperature range Structure of cushioning Tolerance for thread Tolerance of stroke Basic type Mounting style Accessories Clevis cut type Post-port type 0.071MPa 1.5MPa 50500mm/s Note 1070 Do not use when frozen. With cushion pad JIS6g/6H

1.0 200mm or less 0

Double acting type/Single rod Single acting type Spring retum type Note When setting switch at the intermediate Fundamental type Switch set Fundamental type Switch set position, keep the cylinder maximum speed under 300mm/sec to preserve the 10Z-3 10Z-3SR switch detection capabilities. 12 16 Consult with us separately in case that Air the port position is modified. Unnecessay 0.151MPa

SD SD with B LB LS FA FB SK LK FK SP LP FP

Rod end attachment Rod end spherical eye S type Rod end clevis with pin Y type UnitN 50 4.94

Single Acting Type Cylinder Spring Force

Spr

Bore 12 Stroke

ing

forc

15

25 7.37 9.81

e

8.34

Initial load End load Initial load End load

16

10.28

9.32 11.76

6.88

Minimum Cylinder Stroke for Mounting Switch

Switch Bore 12 16 ZC201 10 ZC205 15 With 1 switch ZC230 10 ZC253 10 JR type 10 JS type 10 ZC201 15 ZC205 15 With 2 switches ZC230 10 ZC253 10 JR type 15

Unitmm

JS type 20

12 16/Small Air Cylinder

10Z3

Unitmm 12 16

Lines

Type Structure

Round rob type

Double Acting Single Rod

Fundamental Type 10Z-3 Switch Set 10Z-3 Fundamental Type 10Z-3SR Switch Set 10Z-3SR

End B angles oth side mount ing s End O angles ne s ides mountin g nting ting Cap

Unitg Mounting accessories weight Basic type LB 81 LS 35.5 FA 23 FB 23 Rod end attachment weight 24 20

Single Acting Type Single Rod Spring Return Type

mou

Bas ic brac type w ith ket

pe

nge

ic ty

Type Outline

Double Acting Type 10Z-3

Fundamental Type

Basic Type Clevis Cut Type Post-Port Type

Switch Set

Basic Type Clevis Cut Type Post-Port Type

Single Acting Type Spring Return Type 10Z-3SR

Fundamental Type

Basic Type Clevis Cut Type Post-Port Type

Switch Set

Basic Type Clevis Cut Type Post-Port Type

Weight Table

Additional Basic Clevis cut Post-port weight per stroke type type mm type SD with B 1mm SD SK SP Bore 12 16 65 67 55 57 55 57 87 86 77 76 77 76 0.38 0.42 58 Basic weight

Clevis cut type Post-port type Rod end Rod end clevis Y T LK FK LP FP eye with pin 35.5 23 35.5 23

NoteParenthesized are weight of single acting type.

Switch Additional Weight

Bore ZC type JRJS type

Unitg

mmCord length 1m Cord length 3m Cord length 1.5m Cord length 5m 12 16 25 55 35 98

NoteSwitch additional weight includes the weight of switch bracket. Calculation formula Calculation example Cylinder weight g Basic weight Cylinder stroke mm Additional weight per stroke 1mmSwitch additional weight Quantity of Switch Mounting accessories weight Rod end attachment weight 10Z-3 Double acting, clevis cut type LK Bore 12 Cylinder stroke 50mm ZC201A Cord length 1m 2 pieces Rod end clevis Y type 55 500.38 252 35.520179.5g

Hea

Bas

d fla

flang

em

oun

10Z3

Standard type Switch set

16 Small Air Cylinder/12

re

tit y

ke

t en hm d

bo

rie

ty p

bo

ty p

St ro

an

Se

nt in g

io n

er

sy

qu

itc h

ou

Cy

Cu

Sw

Sw

itc h

10Z3

SD

12

100 A

2 Y

Ro

10Z3 Double Acting Single Rod 10Z3SRSingle Acting Type Spring Return Type

With bracket Available mounting typeOnly for SD

S Rod end spherical eye S type Y Rod end clevis Y typewith pin

Mounting type Cylinder bore mm 12 16 With cushion pad Switch quantity 1, 2

Switch symbol Note Select applicable switches out of the Switch List

Notes on order for switch sets

If a switch set type is ordered, the switch will not be assembled onto the cylinder body at the time of shipment. Cylinder stroke mm Note Products are delivered without mounting switch, mounting accessories, rod end attachments.

Standard Stroke Double Acting Type

Stroke 15 25 30 50 75 100 Bore 12 16

Unitmm Max. stroke 200 200

Consult with us separately in case that stroke other than above standard stroke marked with is desired.

Single Acting Type(Spring Return Type)

Stroke 15 Bore 12 16 25 30 50

Unitmm

Max. stroke 50 50

Consult with us separately in case that stroke other than above standard stroke marked with is desired.

en

at ta c

lin d

sh

Br

ac

ke

12 16/Small Air Cylinder

10Z3

Wiring method Code length 1m Applicable load device

Switch List

Kind Switch symbol Load voltage Load current Maximum open/ Protective range range close capacity circuit None Indicating lamp None LED lights up during ON

JA ZC201A AC 115V or less AC 25mA or less 28V or less DC 40mA or less JB ZC201B DC Contact JC ZC205A JD ZC205B A JR101 B JR105 JJ ZC230A No contact JK ZC230B JL ZC253A JM ZC253B I JS211M O JS215M DC 1028V DC 540mA DC 550V DC 340mA AC 5120V AC 320mA DC 1028V 450mA

DC 1.5W AC 2VA

None

0.2mm2 2-core, outside diameter 3mm Rear wiring

3m 1m 3m 1.5m 5m 1m 3m 1m 3m 1.5m 5m

Small relay programmable controller

LED 0.3mm2 2-core, None red light lights outside diameter 3.4mm up during ON Rear wiring LED 0.2mm2 2-core, Present lights up outside diameter 3mm during ON Rear wiring LED 0.2mm2 3-core, outside diameter 3mm Present lights up during ON Rear wiring LED 0.3mm2 2-core, Present red light lights outside diameter 3.4mm up during ON Rear wiring

DC 28V or less 100mA or less

Small relay programmable controller

DC 1030V

670mA

Notes For the switches without a protective circuit, be sure to provide the protective circuit SK-100 with load devices when using induction load devices relay, etc. . For the handling of switches, be sure to refer to the switch specifications in the end of this catalogue.

ZC type switch

JR JS type switch

Mounting type Standard type Switch set Basic type

SD Basic type LB End angles mounting LS End angles mounting

FA Head rectangular flange mounting

FB Cap rectangular flange mounting

Clevis cut type

SK Basic type LK End angles mounting FK Head flange mounting

Post-port type

SP Basic type LP End angles mounting FP Head flange mounting

10Z3

SD

16 Small Air Cylinder/12

Unitmm

CAD/DATA is 10Z-3/TAZ3 Bore A, B available.

Fundamental Type 10Z3 SD Bore N Stroke

5

ZCStroke XCStroke 16 22 16 3.6 Lock nut for rod end attachment Width across flat 10 13 6 2M50.8 R8 6H9 9.5 6 M61 M161.5 K HStroke LLStroke K 9 R9 M161.5 5 PStroke 5

21

Lock nut for mounting accessories Width across flat 22

12 19

SK

Clevis cut Type 10Z3 SK Bore N Stroke

16 22 16 3.6 Lock nut for rod end attachment Width across flat 10 13 6 2M50.8

21

ZJStroke 5 PStroke 5

6 M61 M161.5 K HStroke LLStroke K

9.5

Lock nut for mounting accessories Width across flat 22

19

SP

Post-port Type 10Z3 SP Bore N Stroke

16 22 16 3.6 Lock nut for rod end attachment Width across flat 10 13 6 2M50.8

21

ZJStroke 5

6 M61 M161.5 K HStroke LLStroke K

9.5

Lock nut for mounting accessories Width across flat 22

19

Double acting type and single acting type are the same dimension. For single acting type, filter is mounted at head port.

Dimensional Table

Symbol H Bore 12 16 25 31 9.5 10 44 51 34 41 75 82 82 89 66 73 K LL P XC ZC ZJ

Unitmm

12 16/Small Air Cylinder

10Z3

CAD/DATA is 10Z-3/TAZ3 Bore A, B available.

SD with B

10Z3 SD Bore N Stroke B

XCStroke 16 Lock nut for rod end attachment Width across flat 10 22 16 13 6 5 PStroke 25 2M50.8

3.6

6 M61 M161.5 K HStroke K 12 KAStroke 36 24 225.5 12 6 3.2 25

Lock nut for mounting accessories Width across flat 22

43 55

6 17.8 15 21

LB

10Z3 LB Bore N Stroke

16 Lock nut for mounting accessories Width across flat 22 22 16 Lock nut for rod end attachment Width across flat 10 3.6 6 5

ZAStroke XAStroke PStroke

2M50.8

33 3.2 20

6 M61 M161.5

32 44

225.5 14 6

10.8 LLStroke SAStroke

10.8 14 6

LS

10Z3 LS Bore N Stroke

Lock nut for rod end attachment Width across flat 10 Lock nut for mounting accessories Width across flat 22 16 22 16 3.6 6 5

ZCStroke PStroke

2M50.8

33 3.2 20

6 M61 M161.5

32 44

25.5 32.8

14

For dimension other than the drawings, refer to SD type Basic type . Double acting type and single acting type are the same dimension. For single acting type, filter is mounted at head port.

Dimensional Table

Symbol H Bore 12 16 25 31 9.5 10 93 100 44 51 34 41 72 79 80 87 75 82 86 93 82 89 K KA LL P SA XA XC ZA ZC

10Z3

FA

10Z3 FA Bore N Stroke

16 Small Air Cylinder/12

Unitmm

CAD/DATA is 10Z-3/TAZ3 Bore A, B available.

16

22 16

PStroke

3.6 25.5

6 2M50.8

26

6 M61 Lock nut for rod end attachment Width across flat 10 Lock nut for mounting accessories Width across flat 22 M16 1.5 K 3.2 HStroke ZXStroke K

40 52

Relative ModelsCleves cut type FK type Post-port type FP type

FB

10Z3 FB Bore N Stroke

ZCStroke ZFStroke 16 3.6 22 16 13 2M50.8 25.5 5 PStroke 6

6 M61 Lock nut for rod end attachment Width across flat 10 M16 1.5 K HStroke K 12.8 3.2

26

Lock nut for mounting accessories Width across flat 22

40 52

For dimension other than the drawings, refer to SD type Basic type . Double acting type and single acting type are the same dimension. For single acting type, filter is mounted at head port.

Dimensional Table

Symbol H Bore 12 16 25 31 9.5 10 34 41 82 89 69.2 76.2 60 67 K P ZC ZF ZX

Unitmm

12 16/Small Air Cylinder

10Z3

10

CAD/DATA is 10Z-3/TAZ3 Bore A, B available.

Switch Set

10Z3 Mounting type Bore N Stroke Switch symbol Switch quantity ZC type switch

UX2 7

RG

UX1

JR JS type switch

UX1 UX2

33

0.3mm2 2Core Outer dia. 3.4 Cabtyre cord

For dimension other than this drawing, refer to the fundamental type. Double acting type and single acting type are the same dimension.

Relative ModelsClevis cut type SK type Post-port type SP type

Dimensional Table

RG Bore mm 12 16 ZC type 15 17 JR JS type 17 19 ZC201 4.5 9 Contact ZC205 1 5.5 UX1 No contact ZC253 JS type JR type ZC230 0 4 3 7.5 3 5 ZC201 5.5 8 Contact ZC205 2 4.5 UX2 No contact ZC253 JS type JR type ZC230 1 3 4 6.5 3 5

NoteThe dimension UX indicates the optimum switch mounting position at the detection of the stroke end.

Working Range and Difference

Contact Bore mm 12 16 ZC201 ZC205 JR type ZC230 No contact ZC253 JS type

Working range Difference Working range Difference Working range Difference Working range Difference Working range Difference Working range Difference 36 49 1.5 or less 46 47 1.5 or less 46 2 or less 13 14 0.5 or less 13 23 0.5 or less 810 912 1 or less

11

10Z3

Rod End Attachment

16 Small Air Cylinder/12

Unitmm

Rod End Spherical Eye S type

CN

Rod End Clevis Y type With Pin

CD

CD

TA

Washer

Split pin

GW

TV

TW KK DK CN CM CA

PL CT CB PF CC CN CL CA W KK

ED

CF Oil port

CF

Dimensional Table/S Type

Symbol Parts code Bore 12 16 RSA06A 30 6H9 13 9 39 9 18 90.1

0

CA

CD

CF

CM

CN

DK

ED

GW

KK

TA

TV

TW

M61

14

6.750.1

11

Dimensional Table/Y Type

Symbol Parts code Bore 12 16 RYA06A 24 6 0.15

0.4

CA

CB

CC

CD

CF

CL

CN

CT

KK

PF

PL

12

H8 f7

10

31

12

M61

1.5

18.5

12

Rod End Lock Nut Parts Code

Bore 12 16 Code LNA06ZA LNA06ZA

Handling Instructions

Fastening Torque of Attachment

The respective nuts and bolts shall be fastened by clamp torque of the following tables.

M16 12, 16 Clamp torque of nut for mounting accessories 53.9Nm

M6 12, 16 Clamp torque of nut for fixing rod end attachment 4.81Nm

Unitmm

12 16/Small Air Cylinder

10Z3

12

Mounting Accessories

End Angles Mounting

3.2 16.5

Flange Mounting

33 20

16.5

26 25.5

25.5

40 52

3.2

20

14

32 44

Bracket

For SD Type

36 24

Pin

1 set of each 1 pcs

For SD Type With B

With 2 Retaining Rings-E type

6 0.05 0.10

6 25.5 3.2 6 0.15 0.05 15 21

20.6 25

25

31

18

36 24

6 21 15 3.2 6 0.15 0.05 25.5

Mounting Accessories Parts Code

25 31

Bore 12

LB

LS LK LP

FA FB

SD type bracket With pin

MAZ3LB012 MAZ3LS012 MAZ3FA012 MAZ3BK012PA MAZ3LB012 MAZ3LS012 MAZ3FA012 MAZ3BK012PA

18

16

13

10Z3

Small Air Cylinder

Further Compact With Adoption Of Band Type Small Switch.

The simple shape is available with the adoption of stainless steel tube. The system is improved as switch-set cylinder is available only by mounting a switch for cylinder body. For the switch mounting method, switch can be mounted simply with the adoption of band type. The switch setting position can also be selected freely with the movement of band. There are 17 types of mounting style so that the best mounting method can be chosen. Stainless steel with Hard Chrome plating have been adopting for standard piston rod of bore size 20mm to 30mm.

Cylinder Specifications/Standard

Structure Type Series Cylinder bore mm Working fluid Lubrication Operating pressure Proof test pressure Note 1 Speed range Note 2 Temperature range 20700mm/s 1070 20500mm/s 1050 0.051MPa 2040 0.021MPa 50 63 0.151MPa Double acting type/Single rod Fundamental type Switch set 10Z3 20, 25, 32, 40, 50, 63 Val setSV set 10Z3V2 20, 25, 32, 40 Single acting type Single acting type Double acting type/ Spring retum type Spring push type Double rod Fundamental type Switch set 10Z3D 20, 25, 32, 40, 50, 63 Air Unnecessary 0.051MPa 2040 0.021MPa 5063 1.5MPa 50700mm/s 2040 20700mm/s 5063 1070 50700mm/s 1070 0.151MPa Fundamental type Switch set 10Z3SR Fundamental type Switch set 10Z3SH

20, 25, 32, 40

Structure of cushioning Standard With cushion pad 2040 , With both ends cushioned 50 63 , Semi-standard With cushion Only a part of types Tolerance for thread Tolerance of stroke JIS 6g/6H

1.0 250mm or less 251900mm1.5 0 0

Basic type Mounting Style

SDSD with B Only for20 40 LS Only for 20 25 LBFAFBTATA with BTBTB with BCA Only for 5063 CU Only for 2040 CU with B Only for 2040

SD LC FA TA TA with B TC TC with B AD BD

SD LB FA TA TA with B AD BD

SD SD with B LS Only for 20 25 LB FA FB TA TA with B TB TB with B CU CU with B

LK Only for 20 25 Clevis cut SK type FK TK TK with B AD BD Post-port SP LP Only for 20 25 type FP TP TP with B AP BP Accessories Boots

SK LK Only for 20 25 FK TK TK with B AD BD SP LP Only for 20 25 FP TP TP with B AP BP

Nylon tarpaulin

Rod end attachment Rod end eye T type Only for 50 63 Rod end spherical eye S type Rod end clevis with pin Y type F joint F type

Note 1. When setting switch at the intermediate, position keep the cylinder maximum speed under 300mm/sec to preserve the switch detection capabilities. 2. As to the temperature range, it shall be used on the unfrozen condition. In case that the port position and cushion needle position are modified, consult with us separately.

Small Air Cylinder

Cylinder Specifications/Non-Rotating Rod Type

Structure Type Series Cylinder bore mm Working fluid Lubrication Operating pressure Proof test pressure Note 1 Speed range Note 2 Temperature range 50700mm/s 1070 50500mm/s 1050 0.11MPa 25 40 0.051MPa 50 63 0.151MPa Double acting type/Single rod Fundamental type Switch set 10Z3G 25, 40, 50, 63 Val setSV set 10Z3V2G 25, 40 Air Unnecessary

10Z3

Fundamental type Switch set

14

Double acting type/Double rod Single Acting/Single Rod

10Z3GD 25, 40, 50, 63

10Z3GSR,10Z3GSH 25,40

0.11MPa 25 40 0.051MPa 50 63 1.5MPa 50700mm/s 1070

0.151MPa

Note 3 Structure of cushioning Standard With cushion pad 2040 , With both ends cushioned 50 63 , Semi-standard With cushion Only 40 Note 4 Telerauce rotating angle Allowable torque Tolerance for thread Tolerance of stroke Basic type Mounting Style Clevis cut type LB 25 1.5 40 1 50 63 0.8

With cushion pad

25 0.49N m or less 40 0.98N m or less 50 63 3.4N m or less JIS 6g/6H

4 250mm or less 251900mm

SD LC FA TA TA with B TC TC with B AD BD

SD LB FA TA TA with B AD BD

LB

SK LK Only for 25 FK TK TK with B SP LP Only for 25 FP TP TP with B AP BP

SK LK 25 only FK TK TK with B SP LP 25 only FP TP TP with B AP BP

Post-port type Boots Rod end attachment

Nylon tarpaulin

Accessories

Rod end eye T type Only for 50 63 Rod end spherical eye S type Rod end clevis with pin Y type

Note 1. When setting switch at the intermediate, position keep the cylinder maximum speed under 300mm/sec to preserve the switch detection capabilities. 2. As to the temperature range, it shall be used on the unfrozen condition. 3. Cylinder with cushion of non-rotating rod 25 /double rod/single acting type/Val set can not be manufactured. 4. The telerauce difference of rotation angle indicates the gap of piston rod rotation direction at stroke end. 5. In case of the joint use with other guide, round rod shall be used. In case that the port position and cushion needle position are modified, consult with us separately.

Valve Specifications

Code Rated voltage Voltage fluctuation range Current consumption Coil Assy With DIN socket code NAS8221D RB512V1SA1D RB512V1SA1DW RB512V1SA2D RB512V1SA2DW RB512V1SA8D RB512V1SA8DW AC100V 50/60Hz AC200V 50/60Hz Rated voltage of 10 50Hz6.0VA/60Hz4.9VA NAS8221DW With lanp protective circuit NAS8222D NAS8222DW With lanp protective circuit 2.5W NAS8228D NAS8228DW With lanp protective circuit DC24V

If using a different voltage from above one, please do not hesitate to contact us.

15

10Z3

Lines

Type

Small Air Cylinder

Unitmm

Structure Standard type/Switch set 10Z3

20

25

32

40

50

63

Double Acting Single Rod Val set/SV set 10Z3V2 Double Acting Double Rod Single Acting Type Single Rod Spring Return Type Single Acting Type Single Rod Spring Push Type With stroke adjustment pull side With stroke adjustment push side Standard type/Switch set 10Z3D Standard type/Switch set 10Z3SR Standard type/Switch set 10Z3SH Standard type/Switch set 10Z3A2 Standard type/Switch set 10Z3A1 Single Rod 10Z3Q1 Dual stroke Made-to-order Double Rod 10Z3Q2 Standard type/Switch set 10Z3G Double Acting Single Rod Val set/SV set 10Z3V2G Standard type/Switch set 10Z3GD Standard type/Switch set 10Z3GSR Standard type/Switch set 10Z3GSH Standard type/Switch set 10Z3GA2 Standard type/Switch set 10Z3GA1

Round rob type

Non-rotating rob type

Double Acting Double Rod Single Acting Type Single Rod Spring Return Type Single Acting Type Single Rod Spring Push Type With stroke adjustment pull side With stroke adjustment push side

Small Air Cylinder

Single Acting Type SR type SH typeSpring Force

Bore mm 20 Load Initial load End load Initial load End load Initial load End load Initial load End load 80.4 50.6 80.4 125.2 51.3 32.3 51.3 79.9 50.6 32.5 20.4 32.5 50.7 32.3 Strokemm 15 20.6 25 12.9 30 20.6 32.2 20.4 50 75 100 125 12.9 150 175

10Z3

UnitN 200

16

25

32

40

Minimum Cylinder Stroke for Mounting Switch

With 1 switch Bore mm AX 20 25 32 40 50 63 10 10 15 10 10 Contact ZC201 ZC205 JR SR 15 AX No contact ZC230 ZC253 JS AX Contact ZC201 ZC205 JR SR AX With 2 switches

Unitmm

No contact ZC230 ZC253 JS

10 10 10 10 15 15 15 15 35 20 10 10 20

15 10

NoteDimensions of Non-rotating rod type switch set and SV set are the same.

Cushion Stroke

Bore 50 63 Cushion stroke 14mm

17

10Z3

Standard type Switch set

s rie

Small Air Cylinder

The items in broken lines in the codes below need not to be entered, if unnecessary.

Semi-standard specification

re

tit y

ke

t Br ac ke ity

St ro

Se

nt in g

io n

er

sy

qu

lin d

itc h

sh

ou

Cu

itc h

Cy

Sw

Sw

10Z3

Round rod type 10Z3 10Z3D 10Z3SR 10Z3SH 10Z3G 10Z3GD 10Z3GSR 10Z3GSH Double Acting Single Rod Double Acting Double Rod Single Acting Type Spring Return Type Single Acting Type Spring Push Type Double Acting Single Rod Double Acting Double Rod Single Acting Type Spring Return Type Single Acting Type Spring Push Type

SD

25

100 AH

2 Y

Ro

de

nd

att

B J

Boots Nylon tarpaulin Note Boot for cylinder is not available for AD,BD,and BP Mounting type conforming to cylinder with bracket SD type, TA type, TB type, TK type, CU type 2040 , TA type, TB type 50 40

Non-rotating rod type

Mounting type Note For Non-rotating rod type, Basic type with clevis is not available.

S T Y F

S type Rod end spherical eye T-end rod end eye Only for 50 63 Y-end rod end clevis F-end F-joint for 7 MPa

Cylinder bore mm Switch quantity 1, 2, to n

20 25 32 40 50 63 Round rod type 40 50 63 Non-rotating rod type 25

N With cushion pad B With cushion

Note Uncushioned type of 50 63 is semi-standard. not standard Cylinder stroke mm

Switch symbol Note Select applicable switches out of the Switch List

Notes on order for switch sets

Switches are not mounted to cylinders at delivery.

VAL setSV set

eth od ta ge pe or e ty pe bo l t ro ke ie s t Br a ck e qu an t Se r in g vo l sy m rb nm St n de io tio h Va lve Cy lin Cu sh op era tc att nt h ac hm Bo ots ty en

M ou

itc

ac

hm

an

Sw i

Sw

lve

10Z3V2

Round rod type 10Z3V2 Double Acting Single Rod Non-rotating rod type 10Z3V2G Double Acting Double Rod

SD

25

100 A

AH

2 Y

Ro

Va

de

1 AC100V 50/60Hz 2 AC200V 50/60Hz 8 DC24V

Note Application for exceptional voltage needs consultation with us.

Mounting type Cylinder bore mm 20 25 32 40 Note Non-rotating rod type is only for 25, 40.

With cushion pad

A B G H

Energieized push type with lamp, protective circuit Energieized pull type with lamp, protective circuit Energieized push type no lamp Energieized pull type no lamp

Cylinder stroke mm NoteFor the details of types other than the above, refer to the specifications of the standard type, switch set.

nd

B J

Bo ots

bo

ty p

bo

ty p

en

Small Air Cylinder

Mounting type Standard typeSwitch set Basic type

SD Basic type LB End angles mounting

10Z3

18

LS End angles mounting Note FA Head flange mounting

FB Cap flange mounting

TA Head trunnion type

TB Cap trunnion type

CA Eye mounting only for 5063

CU Cap spherical eye mounting

Clevis cut type

SK Basic type LK End angles mounting Note FK Head flange mounting TK Head trunnion type

AD Block type foot mounting

BD Block type flange mounting

Post-port type

SP Basic type LP End angles mounting Note FP Head flange mounting TP Head trunnion type

AP Block type foot mounting

BP Block type flange mounting

Mounting type Valve mounted type

SD Basic type LC End angles mounting FA Head flange mounting TA Cap trunnion type

TC Cap trunnion type

AD Block type foot mounting

BD Block type flange mounting

NoteOnly bore 20, 25 for LS type, LK type, LP type. LK,LP with non-rotating rod are only for 25.

19

10Z3

Switch List

Kind Switch symbol

Small Air Cylinder

Semi-standard specification

Load voltage Load current Maxmum open/ Protective close capacity circuit range range None

Indicating lamp

Wiring Method

Code length

Applicable load device

AF AX101 AG AX105 AH AX111 AJ AX115 AE AX125 AK AX11A

Contact DC 30V or less DC 40mA or less AC 120V or less AC 20mA or less AC 5120V DC 530V 520mA 540mA

1.5 5 1.5 5 5 0.5 0.5 1

None Small relay programmable controller

DC 530V DC 540mA AC 5120V AC 520mA

DC 1.5W AC 2VA

LED red light lights up during ON 0.3mm2 2-core, Present outside diameter 4mm Rear wiring None None

2VA 1.5W

AL AX11B

4-pin LED Present red light lights connector type up during ON Rear wiring None 0.2mm2 2-core, outside diameter LED None red light lights 3mm Rear wiring up during ON 0.3mm2 2-core, LED None red light lights outside diameter 3.4mm Rear wiring up during ON 0.5mm2 2-core, Neon lamp Present red light lights outside diameter 6mm Rear wiring up during OFF LED red light lights 0.3mm2 2-core, Present up during ON outside diameter LED 2-lamp type 4mm Rear wiring in red/green 2-core, LED Present lights up outside diameter during ON3mm Rear wiring 3-core, LED Present lights up outside diameter during ON3mm Rear wiring 0.3mm2 2-core, LED Present lights up outside diameter during ON3.4mm Rear wiring 0.2mm2 0.2mm2

JA ZC201A AC 115V or less AC 25mA or less JB ZC201B DC 28V or less DC 40mA or less JC ZC205A JD ZC205B A JR101 B JR105 DC 1028V DC 540mA DC 550V DC 340mA AC 5120V AC 320mA

3 1 3 1.5 5 5 1.5 5 1.5 5 1 3 1 3 1.5 5

Small relay programmable controller

DC 1.5W AC 2VA 30VA

80220V 2300mA S SR405 AC BE AX201 BF AX205 CE AX211

No contact

DC 530V

540mA

CF AX215 JJ ZC230A JK ZC230B JL ZC253A JM ZC253B I JS211M DC 1028V 450mA

DC 28V or less 100mA or less

0.3mm2 2-core, 1.5 outside diameter 5 CU AX215CE 4mm Rear wiring 4-pin connector 0.5 CV AX21BCE LED type Rear wiring 540mA DC 530V Present 2-lamp type 2 2-core, 0.3mm 1.5 CW AZ211CE in red/green outside diameter 5 CX AZ215CE 4mm Upper wiring 4-pin connector 0.5 CY AZ21BCE type Upper wiring Notes For the switches without a protective circuit, be sure to provide the protective circuitSK-100with load devices when using induction load divicesrelay, etc. For the handling of switches, be sure to refer to the switch specifications in the end of this catalogue. All the AX type switches can be mounted. For the types other than the above, refer to the switch specifications in the end of this catalogue. We recommend AND UNITAU seriesfor multiple switches connected in series.

No contact Corresponding CE marking

O JS215M CT AX211CE

DC 1030V

670mA

AX type switch Code type Connector type

ZC type switch

JR JS type switch

SR type switch

Small Air Cylinder

Standard Stroke Fabrication Range

Structure Type Bore 20 25 Standard type 32 Double Acting Switch set Single Rod 40 10Z3 50 63 Round rod type 20 25 Standard type 32 Double Acting Switch set Double Rod 40 10Z3D 50 63 Standard type Single Acting Type Single Rod Switch set 10Z3SR 10Z3SH 20 25 32 40 Cylinder strokemm 15 25 30 50 75

10Z3

Unitmm MAX

20

100 125 150 175 200 250 300 350 400 450 500 Stroke 900 900 900 900 900 900 450 450 450 450 450 450 150 200 200 200 500 500 500 500 450 450 450 450 200 200

Non-rotating rod type

25 Standard type 40 Double Acting Switch set Single Rod 50 10Z3G 63 25 Standard type 40 Double Acting Switch set Double Rod 50 10Z3GD 63 Single Acting Standard type 25 Switch set Type 10Z3GSR Single Rod 10Z3GSH 40

Please refer to the chart of minimum stroke for the switch set type. Page 16

21

10Z3

20 LB type LC type LS type LK type LP type FA type FB type FK type FP type TA type TB type TK type TP type TC type CU type

Small Air Cylinder

Mounting Accessories Parts Code

25 MAZ3LB020 MAZ3LC020 32 MAZ3LB032 MAZ3LC032 40 MAZ3LB040 MAZ3LC040 50 MAZ3LB050 63 MAZ3LB063

MAZ3LS020

MAZ3FA020

MAZ3FA032

MAZ3FA040

MAZ3FA050

MAZ3FA063

MAZ3TA020

MAZ3TA032

MAZ3TA040

MAZ3TA050

MAZ3TC020 MAZ3CU020 MAZ3CU025

MAZ3TC032 MAZ3CU032

MAZ3TC040 MAZ3CU040

Bracket Parts Code

20 For SD With pin 9EJD FE MAZ3BK020PB For S +7 25 32 40 50 MAZ3BK050 63 MAZ3BK063 MAZ3BK020PA MAZ3BK032PA MAZ3BK040PA MAZ3BK032PB MAZ3BK032 MAZ3BK040PB MAZ3BK040

. H 6)6*6+

MAZ3BK020

Rod End Lock Nut Parts Code

Bore 20 25 32 40 50 63 Round rod type LNA08ZA LNA10ZA LNA12ZA LNA16ZA Non-rotating rod type LNA08ZA LNA12ZA LNA16ZA

Made-to-order specifications

Dual stroke Both sides rod 10Z 3Q2 Dual stroke one side rod 10Z 3Q1

Cylinder bore mm 20, 25, 32, 40, 50, 63

Cylinder bore mm 20, 25, 32, 40, 50, 63

With stroke adjustment push side 10Z 3A1

With stroke adjustment pull side 10Z 3A2

Cylinder bore mm 20, 25, 32, 40, 50, 63

Cylinder bore mm 20, 25, 32, 40, 50, 63

Stroke adjustable range050mm

Stroke adjustable range050mm

Small Air Cylinder

Round Rod Type/Double Acting

Basic weight Double Acting/Single Rod Bore mm Basic type Clevis cut type Standard type Val set Standard type 155 137 20 530 220 203 25 600 320 32 705 297 520 910 482 40 985 920 50 1350 1280 63 Post-port type Standard type 137 203 297 487 935 1300 Double Acting/Double Rod Basic type Standard type 186 274 398 630 1165 1530

10Z3

Unitg Additional weight per stroke 1mm Single Rod 0.85 1.15 1.65 2.15 3.27 4.36 Double Rod 1.25 1.8 2.55 3.4 5.73 6.82

22

Round Rod Type/Single Acting Type

Basic weight Single Acting/Single Rod Bore mm Basic type Clevis cut type Post-port type Standard type Standard type Standard type 20 221 203 203 25 312 295 295 32 457 434 434 40 701 663 663 Stroke additional weight 15 12 16.5 24 31.5 25 20 27.5 40 52.5 30 90 125 185 244 50 106 147 217 286 75 192 266.5 394 519.5

Unitg

100 278 386 571 753

Non-rotating Rod Type/Double Acting

Basic weight Double Acting/Single Rod Bore mm Basic type Clevis cut type Standard type Val set Standard type 25 220 600 203 40 510 900 472 50 985 920 63 1350 1280 Post-port type Standard type 203 472 935 1300 Double Acting/Double Rod Basic type Standard type 274 620 1165 1530

Unitg Additional weight per stroke 1mm Single Rod 1.1 2.1 3.27 4.36 Double Rod 1.8 3.4 5.73 6.82

Mounting AccessoriesRod End Attachment Weight

Bore mmSD/ B 20 115 25 115 32 150 40 185 50 63 Basic type LS LB LC 60 60 FA TA TA/B CA FB TB TB/B 140 150 55 55 140 140 150 55 55 140 220 210 90 90 210 280 280 110 130 275 560 315 30 335 795 705 420 30 335 795 TC 30 30 30 70 Mounting accessories weight Clevis cut type TC/ CU/ CU B B 100 130 240 100 130 280 125 125 275 175 150 335 LK FK TK 60 60 TK/ B 58 55 140 55 55 140 90 90 210 110 130 275 315 335 795 420 335 795 AD BD Post-port type LP FP TP TP/ B 55 55 140 55 55 140 90 90 210 110 130 275 315 335 795 420 335 795 AP BP

Unitg Rod end attachment weight Eye Eye Clevis S T Y F 200 200 55 100 100 175 340 340 60 100 100 100 380 380

11 29 8 76 60 38 55 26 43 60 62 85 45 68 78 116 49 87 180 245105 170 270 335135 200

11 29 8 76 50 38 55 26 43 75 62 85 45 68 75 78 116 49 87 110 180 245105 170210 270 335135 200210

Parenthesized are the mounting accessries weight of double rod type.

Switch additional weight

Unitg

JRJS type SR type AX type ZC type Bore mmCode length 1.5m Code length 5m Connector type Code length 1m Code length 3m Code length 1.5m Code length 5m Code length 5m 20 25 32 130 40 25 55 35 98 271 50 40 50 63 Note Switch additional weight includes the weight of switch bracket. Calculation formula Calculation example Cylinder weight g Basic weight Cylinder stroke mmAdditional weight per stroke 1mm Switch additional weightSwitch quantity Mounting accessories weightRod end attachment weight 10Z3Clevis cut typeBore 20Cylinder stroke 50mmAX215A Code length 5m 2piecesFK type 137 0.8550 1302 60499.5g

23

10Z3

SD

Double Acting Single Rod

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Round rod type Non-rotating rod type

10Z3

SD Bore Cushioning Stroke

20 25 32 40

D ZCStroke XCStroke D

10Z3G SK Bore Cushioning Stroke

2040

Non-rotating rod type 25 40

A h Hexagonal rod width across flat MG KK Lock nut for rod end attachment width across flat B1 MM

A h

WF YP VF RH

PStroke 2Rc1/8 LR CD E MR

KK MB Lock nut for rod end attachment width across flat B1 Lock nut for mounting accessories width across flat B2

HStroke LLStroke

MB

EW EB

All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

127Stroke 73Stroke

For non-rotating rod type, clevis cut type is standard.

5063

Width across flats 19

Non-rotating rod type

20

32 11 26 24 22 17 10 11

2Rc1/4 Cushion valve

45

M161.5 Lock nut for rod end attachment width across flat 24 Width across flats 17 M402 Lock nut for mounting accessories width across flat 50

22

51Stroke 95Stroke

22

22 17

M402

EB

Parenthesized figure is the dimension of screw length. All the dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Dimensional Table

Bore Symbol

50 63

E 56 70

EB 54 68

Relative modelClevis cut type SK Post-port type SP With boots

For non-rotating rod type, clevis cut type is standard.

Double Acting Single Rod 2040

Round rod type

10Z3V2 SD Bore N Stroke Valve operation method Valve voltage

135 121 port 1/8

Non-rotating rod type 10Z3V2G SD Bore N Stroke Valve operation method Valve voltage

Non-rotating rod type 25 40

A h Hexagonal rod width across flat MG KK Lock nut for rod end attachment width across flat B1 About 16 EC J

EC

EC

30

19 1111 28.6 36.7

18 42.1 Wiring port Compatible cable outer diameter

h RH

Energized push type-pull type conversion structure Exhaust throttle valve Manual operation button

All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type. For the energized push type and pull type, all positions of P port, exhaust throttle valve, terminal and manual operation button differ at 180

EH

21

R port 1/8With plug silencer Accessories mounting hole

22 38

51

VF K A WF

Stroke

Lock nut for rod end attachment width across flat B1

Lock nut for mounting accessories width across flat B2

Stroke Stroke

Relative modelsWith boots

The above drawings are the dimensional drawings of energized push type.

Unitmm

Small Air Cylinder

10Z3

h KK J K Round rod Non-rotating type rod type M81.25

24

Dimensional Table

Symbol A B1 CD D E EB EC EH EW

0.1

Bore 20 25 32 40 Symbol

Round Non- Round Non- B2 rod rotating rod rotating type rod type type rod type 20 20 13 13 19

Round Nonrod rotating type rod type 5 6 6 7 5 7

30 8H9 30 8H9

6 8

28 31 38 46

26 29 36 44

36 36 36 44

38 16 0.3 31 38 38 46

0.1 16 0.3

25 25

14

22 2220 17 17 22 19 17

35 40 42

14.5 M101.25 M81.25 M101.25

32 10H9 10 41 12H9 12

16 0.1 0.3 20 0.1 0.3

25.5 15 30 15

21 19 24 2124

M121.25 M121.25

L Bore 20 25 32 40 12 12 14 16

LC 205 209.5 215.5 222

LL 59 64 70 72

LR R11 R11 R13 R15

MB M221.5 M221.5 M242 M302

MG 9 14

MM 8 10 12 14

MR R12 R12 R14 R16

P 45 49 55 57

RH 7 7 8 9

VF

WF

XC 95 104 114 120

YP 7 7.5 7.5 7.5

ZC 105 114 126 132

ZE 229 237.5 245.5 254

16 13 24 18 15 28 20 16 30 22 18 32

Parenthesized figure of AVF is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

25

10Z3

20 40

Small Air Cylinder

Unitmm

Relative model Clevis cut type/SK Basic type

5063

26 24 A h YP ZJStroke PStroke 2Rc1/8 20 M161.5 Lock nut for rod end attachment width across flat 24 M402 YP 10 127Stroke 11 73Stroke 2Rc1/4 Cushion valve 11

45

MM Lock nut for rod end KK attachment width across flat B1 MB K HStroke K EB

22

51Stroke

22

EB

For dimensions not given in the above drawings, ref to SD type basic type

Parenthesized figure is the dimension of screw length.

Relative model Post-port type/SP Basic type

20 40 5063

26 24 A h YP Rc1/8 20 M161.5 Lock nut for rod end attachment width across flat 24 M402 40 E Rc1/4 22 51Stroke 22 4 EB ZJStroke 10 11 Rc1/4 Cushion valve 131Stroke

45

MM Lock nut for rod end KK attachment width across flat B1 MB K HStroke K EB

E Rc1/8

For dimensions not given in the above drawings, ref to SD type basic type

Dimensional table

Bore Symbol

E 56 70

EB 54 68

50 63

Parenthesized figure is the dimension of screw length.

Relative model With cushion/SD Basic type

20 25

Cushion valve MAX WW

3240

Cushion valve 45

AX M W W

For dimensions not given in the above drawings, ref to SD type basic type

Clevis cut type

Post-port type

EP K 4 Rc1/8

For the above sectional drawings. bore is 20, 25.

Unitmm

Small Air Cylinder

10Z3

h H 31 35 40 42 Round rod type 5 6 6 7 Non-rotating rod type 5 7 K 14 14.5 15 15

26

Dimensional Table

Symbol Bore 20 25 32 40 Symbol Bore 20 25 32 40 Round rod type M81.25 M101.25 M101.25 M121.25 Round rod type 20 20 22 22 22 19 24 21 A Non-rotating rod type 20 17 24 21 KK Non-rotating rod type M81.25 M121.25 Round rod type 13 17 17 19 B1 Non-rotating rod type 13 19 E 28 31 38 46 EB 26 29 36 44

MB M221.5 M221.5 M242 M302

MM 8 10 12 14

P 45 49 55 57

WW 21 22.5 29 33

YP 7 7.5 7.5 7.5

ZJ 83 92 100 104

Parenthesized figure of AVF is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

27

10Z3

SD

Double Acting Double Rod

Small Air Cylinder

Unitmm

Round rod type

10Z3D

SD Bore Cushioning Stroke

Non-rotating rod type 10Z3GD SD Bore Cushioning Stroke 2040

20 25

D

32 40

D

Non-rotating rod type 25 40

A h

A h

WF

YP

PStroke 2Rc1/8

YP

WF Stroke

Hexagonal rod width across flat MG KK

MM Lock nut for rod end attachment width across flat B1 KK Lock nut for mounting accessories width across flat B2 MB K HStroke LLStroke K

EB

Lock nut for rod end attachment width across flat B1 10Z-3GD's standard has one non-rotating rod and another round rod.

50 63

26 32 24 10

45

11

73Stroke 2Rc1/4 Cushion valve

11 32Stroke

26 24

Non-rotating rod type

Width across flats 19 10Z-3GD's standard has one non-rotating rod and another round rod. 20 M161.5 M402 22 51Stroke 95Stroke 22

EB

Lock nut for rod end attachment width across flat 24

Lock nut for mounting accessories width across flat 50

Parenthesized figure is the dimension of screw length.

Dimensional Table

Bore Symbol

Relative modelWith boots

50 63

E 56 70

EB 54 68

Unitmm

Small Air Cylinder

10Z3

h H Round Non-rotating rod type rod type 5 6 6 7 5 7 K

28

Dimensional Table

Symbol Bore 20 25 32 40 Symbol Bore 20 25 32 40 Round rod type M81.25 M101.25 M101.25 M121.25 A B1 B2 D E EB Round Non-rotating Round Non-rotating rod type rod type rod type rod type 20 20 13 17 17 19 13 19

30 30 32 41

6 8 10 12

28 31 38 46

26 29 36 44

31 35 40 42

14 14.5 15 15

22 22 20 17 22 19

24 21 24 21 KK

Non-rotating rod type M81.25 M121.25

LL 59 64 70 72

MB M221.5 M221.5 M242 M302

MG 9 14

MM 8 10 12 14

P 45 49 55 57

WF 24 28 30 32

YP 7 7.5 7.5 7.5

Parenthesized figure of A is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

29

10Z3

SD

Single Acting Type Spring Return Type Spring Push Type

Small Air Cylinder

Unitmm

Round rod type Round rod type

10Z3SR 10Z3SH

SD Bore Cushioning Stroke SD Bore Cushioning Stroke

Non-rotating rod type 10Z3GSR SK Bore Cushioning Stroke Non-rotating rod type 10Z3GSH SK Bore Cushioning Stroke

20 25

D

32 40

D

Spring Return TypeSR type

ZC

Spring Push Type SH type

ZC XC YP A h WFStroke YP Rc1/8 Filter

Non-rotating rod type 25 40

A h Hexagonal rod width across flat MG KK Lock nut for rod end attachment width across flat B1

XC A h WF Filter Rc1/8

MM Lock nut for rod KK end attachment width across flat B1 MB K H LL K

MM Lock nut for rod KK end attachment width across flat B1 MB Lock nut for mounting accessories width across flat B2

H LL

Lock nut for mounting accessories width across flat B2

All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Relative modelClevis cut type SK Post-port type SP With boots

For non-rotating rod type, clevis cut type is standard.

Relative model Clevis cut type/SK Basic type

Spring Return TypeSR type

ZJ Filter Rc1/8

Spring Push Type SH type

ZJ Rc1/8 Filter

For the dimensions of clevis cut type, post-port type except the above-mensioned, refer to SD type basic type .

Relative model Post-port type/SP Basic type

Spring Return TypeSR type

ZJ Filter Rc1/8

Unitmm

Small Air Cylinder

10Z3

MB MG MM WF YP

30

Dimensional Table

Symbol A B1 B2 D h Round Nonrod rotating type rod type 5 6 6 7 5 7 K KK Round rod Non-rotating type rod type M81.25 Stroke Round Non- Round Nonrod rotating rod rotating type rod type type rod type Bore 20 25 32 40 Symbol Stroke Bore 20 25 32 40 Symbol Stroke Bore 20 25 32 40 Symbol 15 25 30 50 75 71 75 80 82 81 85 90 92 111 115 120 122 131 135 140 142 181 185 190 192 231 235 240 242 281 285 290 292 331 335 340 342 381 385 390 392 431 465 440 442 99 104 110 112 109 114 120 122 139 144 150 152 159 164 170 172 209 214 220 222 259 264 270 272 309 314 320 322 359 364 370 372 409 414 420 422 459 464 470 472 15 25 30 50 75 20 20 13 13 19

30 30 32 41 H

6 8 10 12

14

M221.5 M221.5 M242 M302 LL

9 14

8 10 12 14

24 28 30 32

7 7.5 7.5 7.5

22 2220 17 17 22 19 17

14.5 M101.25 M81.25 15 15 M101.25

21 19 24 2124

M121.25 M121.25

100

125

150

175

200

15

25

30

50

75

100

125

150

175

200

XC 100 125 150 175 200

SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type 135 144 154 160 150 159 169 175 145 154 164 170 170 179 189 195 175 184 194 200 205 214 224 230 195 204 214 220 245 254 264 270 245 254 264 270 320 329 339 345 295 304 314 320 395 404 414 420 345 354 364 370 470 479 489 495 395 404 414 420 545 554 564 570 445 454 464 470 620 629 639 645 495 504 514 520 695 704 714 720

ZC 15 25 30 50 75 100 125 150 175 200

Stroke

Bore 20 25 32 40 Symbol

SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type 145 154 166 172 160 169 181 187 155 164 176 182 180 189 201 207 185 194 206 212 215 224 236 242 205 214 226 232 255 264 276 282 255 264 276 282 330 339 351 357 305 314 326 332 ZJ 15 25 30 50 75 100 125 150 175 200 405 414 426 432 355 364 376 382 480 489 501 507 405 414 426 432 555 564 676 582 455 464 476 482 630 639 651 657 505 514 526 532 705 714 726 732

Stroke

Bore 20 25 32 40

SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type SR type SH type 123 132 140 144 138 147 155 159 133 142 150 154 158 167 175 179 163 172 180 184 193 202 210 214 183 192 200 204 233 242 250 254 233 242 250 254 308 317 325 329 283 292 300 304 383 392 400 404 333 342 350 354 458 467 475 479 383 392 400 404 533 542 550 554 433 442 450 454 608 617 625 629 483 492 500 504 683 692 700 704

Parenthesized figure of A is the dimension of screw length.

31

10Z3

SD with B

Small Air Cylinder

Unitmm

Double Acting Single Rod Round rod type 10Z3 SD Bore Cushioning Stroke B 2040

20 25

D XCStroke A WF YP VF h RH 2Rc1/8 PStroke EB PA

32 40

D

MM KK Lock nut for rod end attachment width across flat B1

K

CD

HStroke

K

BT BF/2 BF/2 8 BU BF

BH

MB KAStroke 8 XM WM 22 6.6 8 BY 17 25 8

Lock nut for mounting accessories width across flat B2

Non-rotating rod is not available. For dimensions not given in the above drawings,ref to SD type basic type .

Relative modelWith cushionWith boots

Unitmm

Small Air Cylinder

10Z3

E 28 31 38 46 EB 26 29 36 44 H 31 35 40 42 h 5 6 6 7 K 14 14.5 15 15

32

Dimensional Table

Symbol A Bore 20 25 32 40 Symbol KA Bore 20 25 32 40 119 128 140 148 M81.25 M101.25 M101.25 M121.25 M221.5 M221.5 M242 M302 8 10 12 14 45 49 55 57 31 31 32 36 7 7 8 9 16 13 24 18 15 28 20 16 30 22 18 32 67 67 67 71 95 104 114 120 51 51 51 55 7 7.5 7.5 7.5 KK MB MM P PA RH VF WF WM XC XM YP 20 20 13 22 22 17 22 19 17 24 21 19 30 30 32 41 32 32 36 40 32 32 36 40 3.2 3.2 4 4 48 48 52 56 21.8 21.8 21 21 8 8 10 12 6 8 10 12 B1 B2 BF BH BT BU BY CD D

Parenthesized figure of AVF is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

33

10Z3

LB

Double Acting Single Rod 20 40

Lock nut for rod end attachment width across flat B1

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Round rod type 10Z3 LB Bore Cushioning Stroke Non-rotating rod type 10Z3G LB Bore Cushioning Stroke

20 25

D EB Lock nut for mounting accessories width across flat B2

32 40

D

Non-rotating rod type 25 40

A h

A h

WF YP VF RH

ZAStroke XAStroke PStroke 2Rc1/8

E AH R UA

AE

Hexagonal rod width across flats MG

MM KK KK MB AV AL 8 SKStroke LLStroke SAStroke AV AL 8

AT 6.8 22

Lock nut for rod end attachment width across flat B1

For dimensions not given in the above drawings, ref to SD type basic type . All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Relative modelWith cushionWith boots

50 63

Lock nut for rod end attachment width across flat 24 EB

45

26 32 11 24 22 10 11

167Stroke 152Stroke 73Stroke 2Rc1/4 Cushion valve

E AH Lock nut for mounting accessories width across flat 50 6 R UA

AE

Width across flats 19

Non-rotating rod type

20 M161.5 Width across flat 17 M402 15

19 25

22 9

57Stroke 95Stroke 145Stroke

19 25 15

Parenthesized figure is the dimension of screw length. All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Dimensional Table

Bore Symbol

50 63

AE 70 80

AH 40 45

E 56 70

EB 54 68

R 60 74

UA 80 95

Relative modelWith boots

Val Set Double Acting Single Rod 20 40

LC

Round rod type 10Z3V2 LC Bore N Stroke Valve operation method Valve voltage Non-rotating rod type 10Z3V2G LC Bore N Stroke Valve operation method Valve voltage

20 25 40

EC EC 18 J J 19 1111 28.6 36.7 Wiring port Compatible cable outer diameter 4.57 42.1 30 135 121 port 1/8

32

For dimensions not given in the EC above drawings,ref to SD type basic type . J All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type. For the energizd push type and pull type of val set and SV set cylinder, all positions of P port, exhaust throttle valve, terminal and 51 manual operation button differ at 180 .

21 About PE AH

Non-rotating rod type 25 40

A h Hexagonal rod width across flat MG

A h

WF VF RH

Stroke Stroke

Energized push type-pull type conversion structure Exhaust throttle valve

Manual operation button port Rc1/8With plug silencer 2 6.8 8 20 12

XB WB UA R

AT 2 6.8 8 AL AF

Lock nut for rod end attachment width across flat B1

Lock nut for rod end attachment width across flat B1

AV AL 8 Stroke Stroke AD 8 35

Lock nut for mounting accessories width across flat B2

Relative modelWith boots

The above drawings are the dimensional drawings of energized push type.

Unitmm

Small Air Cylinder

10Z3

h KK J Round rod type M81.25 Nonrotating rod type EC Round Nonrod rotating type rod type 36 36 36 44 5 6 6 7

34

Dimensional Table

Symbol A Round Non- AD rod rotating type rod type 20 20 19 AE AF AH AL AT B1 AV Round Non- B2 rod rotating type rod type 13 19 30 30 32 41 D E EB

Bore 20 25 32 40 Symbol

42 42 51 59

24 24 33 33

25 25 32 36

16 16 25 25

3.2 12.8 13 3.2 12.8 17 4 4 21 21 17 19

6 28 26 8 31 29 10 38 36 12 46 44

25 5 25

22 2220 17 19 22 19 17

M101.25 M81.25

25.5 M101.25 7 30

21 15 24 2124

M121.25 M121.25

LC Bore 20 25 32 40 205

LD

LL

MB M221.5 M221.5 M242 M302

MG MM 8

P 45

PE

PV

R 40

RH 7 7 8 9

SA 91

SH

SK

UA

VF WB WF XA 24 28 30 32 99 108 125 129

XB 71 71 71 79

YP 7

ZA 107

62.5 59 64 70 72

59 100

97.5 33.4 55 16 13 87 38.4 55 18 15 87 28 30 60 20 16 87 65 22 18 95

209.5 67 215.5 73 222 77

9 10 49 12 55 14 14 57

59 104.5 40 66 110.5 45 74 117 50

96 102 120 115 122 117

7.5 116 7.5 133 7.5 137

Parenthesized figure of AVF is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

35

10Z3

LS

Double Acting Single Rod

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Round rod type 10Z3 LS Bore Cushioning Stroke Non-rotating rod type 10Z3G LK Bore Cushioning Stroke

D ZCStroke

20 25

Non-rotating rod type 25

EB A h

WF YP VF

PStroke

2Rc1/8

E 3.2 25

Hexagonal rod 42 Width across flat MG KK Lock nut for rod end attachment Width across flat B1

MM KK Lock nut for rod end attachment Width across flat B1 M22 1.5 16 WL 8

16 24 8 40 55 2 6.8

Lock nut for mounting accessories Width across flat 30

For dimensions not given in the above drawings, ref to SD type basic type . All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Relative modelClevis cut type LK type Post-port type LP type With cushion With boots

For non-rotating rod type, clevis cut type is standard.

Unitmm

Small Air Cylinder

10Z3

EB 26 29 h Round rod type Non-rotating rod type 5 6 5

36

Dimensional Table

Symbol Bore 20 25 Symbol Bore 20 25 Round rod type M81.25 M101.25 A B1 Round rod type Non-rotating rod type Round rod type Non-rotating rod type 20 20 22 22 20 17 KK Non-rotating rod type M81.25 13 17 13 D 6 8 E 28 31

MM 8 10

MG 9

P 45 49

VF 16 18

WF 24 28

WL 36.8 40.8

YP 7 7.5

ZC 105 114

Parenthesized figure of A is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

37

10Z3

FA

Double Acting Single Rod 20 40

EF

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Round rod type 10Z3 FA Bore Cushioning Stroke Non-rotating rod type 10Z3G FK Bore Cushioning Stroke

20 25

2 6.6 D

20 25

32 40

D

Non-rotating rod type 25 40

TF 4 6.6 Hexagonal rod width across flat MG KK Lock nut for rod end attachment width across flat B1 A h MM KK Lock nut for rod end attachment width across flat B1 UF

A h

WF YP RH

PStroke 2Rc1/8

32 40

EF

R TF UF

MB 4 VF K HStroke ZXStroke K

Lock nut for mounting accessories width across flat B2

For dimensions not given in the above drawings, refer to SD type basic type . All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Relative modelClevis cut type FK type Post-port type FP type With cushion With boots

For non-rotating rod type, clevis cut type is standard.

73Stroke

50 63

45

32 26 24 22 4 9 10 11

11

2Rc1/4 Cushion valve

Non-rotating rod type

EF ER E width across flats 19 20 M161.5 Width across Lock nut for rod end attachment flats 17 width across flat 24 M402 Lock nut for mounting accessories width across flat 50

TF UF

10 22 22 17

51Stroke 117Stroke

22

Parenthesized figure is the dimension of screw length. All the dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

Dimensional Table

Bore Symbol

50 63

E 56 70

EF 60 70

ER 40 50

TF 74 80

UF 94 100

Relative modelClevis cut type FK Post-port type FP With boots

For non-rotating rod type, clevis cut type is standard.

Val Set Double Acting Single Rod 20 40

Round rod type 10Z3V2 FA Bore N Stroke Valve operation method Valve voltage Non-rotating rod type 10Z3V2G FA Bore N Stroke Valve operation method Valve voltage

135 121

20 25 20 25

2 6.6 About 51 EC J EF TF UF 51 EC

40

EC

32

30

port 1/8

18 42.1 J J 19 1111 28.6 36.7 A h WF RH 4 Stroke Stroke Energized push type-pull type conversion structure Wiring port Compatible cable outer diameter 4.57

For dimensions not given in the above drawings, refer to SD type basic type . All dimensions of non-rotating rod type except the rod end 32 40 are the same as those of round rod type. About For the energizd push type and pull type of Val set and SV set cylinder, all positions 46.6 of P port, exhaust throttle valve, terminal and manual operation button differ at 180

Non-rotating rod type 25 40

A h Hexagonal rod width across 21 R EF flat MG

TF UF

Lock nut for rod end attachment VF K Lock nut for rod width across end attachment flat B1 width across Lock nut for mounting flat B1 accessories width across flat B2

Stroke

Manual operation button port Rc1/8With plug silencer

Exhaust throttle valve

Relative modelsWith boots

The above drawings are those of energized push type.

Unitmm

Small Air Cylinder

10Z3

h H Round Nonrod rotating type rod type 5 6 6 7 5 7 J K

38

Dimensional Table

Symbol A B1 B2 D E EC EF EQ Round Non- Round Nonrod rotating rod rotating type rod type type rod type 20 20 13 13 19

Bore 20 25 32 40 Symbol Bore 20 25 32 40

30 30 32 41

6 8 10 12

28 31 38 46

36 36 36 44

38 38 47 51

34 34 34 38

31 35 40 42

25 25 25.5 30

14 14.5 15 15

22 2220 17 17 22 19 17

24 2124 21 19 KK Round rod type M81.25 M101.25 M101.25 M121.25 Non-rotating rod type M81.25

LC 205

MB M221.5

MG 9 14

MM 8 10 12 14

P 45 49 55 57

PV 100 104.5 110.5 117

R 33 36

RH 7 7 8 9

TF 50 50 58 70

UF 65 65 72 84

VF 16 18 20 22

WF 24 28 30 32

YP 7 7.5 7.5 7.5

ZX 81 86 96 100

209.5 M221.5 215.5 M242 M302

M121.25 222

Parenthesized figure of A is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

39

10Z3

FB

20 40

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Double Acting Single Rod Round rod type 10Z3 FB Bore Cushioning Stroke

20 25

D

32 40

D EF

20 25

2 6.6

ZCStroke ZFStroke A h WF YP VF PStroke 2Rc1/8 MB RH TF UF

32 40

4 6.6

MM KK Lock nut for rod end attachment width across flat B1 MB K HStroke K 4 ML

EF

Lock nut for mounting accessories width across flat B2

TF UF

Non-rotating rod type is not available. For dimensions not given in the above drawings, ref to SD type basic type .

Relative modelWith cushionWith boots

50 63

26 32 11 24 22 10 17

149Stroke 137Stroke 73Stroke 2Rc1/4 Cushion valve

11

45

M402 EB 4 9

20 M161.5 Lock nut for rod end attachment width across flat 24 Width across flats 17

EF ER

22

51Stroke

22 10 12

Non-rotating rod type is not available. Parenthesized figure is the dimension of screw length.

Lock nut for mounting accessories width across flat 50

TF UF

Dimensional Table

Bore Symbol

Relative modelWith boots

50 63

E 56 70

EB 54 68

Unitmm

Small Air Cylinder

10Z3

K 14 14.5 15 15 KK M81.25 M101.25 M101.25 M121.25 MB M221.5 M221.5 M242 M302

40

Dimensional Table

Symbol A Bore 20 25 32 40 Symbol ML Bore 20 25 32 40 18 18 22 24 8 10 12 14 45 49 55 57 33 36 7 7 8 9 50 50 58 70 65 65 72 84 16 13 18 15 20 16 22 18 24 28 30 32 7 7.5 7.5 7.5 105 114 126 132 87 96 104 108 MM P R RH TF UF VF WF YP ZC ZF 20 20 22 22 22 19 24 21 13 17 17 19 30 30 32 41 6 8 10 12 28 31 38 46 38 38 47 51 31 35 40 42 5 6 6 7 B1 B2 D E EF H h

Parenthesized figure of AVF is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 Fractions less than decimal point shall be raised.

Dimensional Table

Symbol

A

Stroke Bore

Round Nonrod rotating type rod type

Chart of the XX dimensions WW 25 50 75 100 125 150 175 200 250 300 350 400 450 500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 49 59 69 74 84 94 104 114 134 154 174 194 214 234 22 2220 17 36 53 46 63 56 73 66 78 71 88 81 98 91 108 101 118 111 138 131 158 151 178 171 198 191 218 211 238 231 22 19 40 45 55 65 70 80 85 21 24 2124 45 42 35 52 45 57 50 62 55 72 65 82 75 95 100 120 130 150 170 190 210 87 80 92 85 102 95 117 110 127 120 142 135 162 155 182 175

Parenthesized figure of A is the dimension of screw length.

41

10Z3

TA

Double Acting Single Rod 20 40

Small Air Cylinder

Unitmm CAD/DATA is 10Z-3/TAZ3 Bore A available.

Round rod type 10Z3 TA Bore Cushioning Stroke Non-rotating rod type 10Z3G TK Bore Cushioning Stroke

20 25

D

32 40

D

Non-rotating rod type 25 40

A h

A h

WF YP

PStroke 2Rc1/8

TU TD TA attachment outer dia

TL

TM UM

TL

Hexagonal rod MM width across flat MG KK KK Lock nut for Lock nut for rod end attachment rod end attachment width across flat B1 width across flat B1 Lock nut for mounting accessories width across flat B2

RH BD K XG

HStroke XJStroke

For dimensions not given in the above drawings, ref to SD type basic type . All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

For non-rotating rod type, clevis cut type is standard.

Relative modelClevis cut type TK Post-port type TP With cushion With boots

50 63

45

26 32 24 10 width across flats 19

11

73Stroke 2Rc1/4 Cushion valve

Non-rotating rod type

20 M161.5 Width across flats 17 Lock nut for mounting accessories width across flat 54

58 56 Lock nut for mounting accessories dia 16 72 104 16

16e9

Lock nut for rod end attachment width across flat 24

4 23

18 22

51Stroke 126Stroke

22

Parenthesized figure is the dimension of screw length. All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

For non-rotating rod type, clevis cut type is standard.

Relative modelClevis cut type TK Post-port type TP

Val Set Double Acting Single Rod 20 40

Round rod type 10Z3V2 TA Bore N Stroke Valve operation method Valve voltage Non-rotating rod type 10Z3V2G TA Bore N Stroke Valve operation method Valve voltage

135 121 port 1/8

20 25

For dimensions not given in the above drawings,ref to SD type basic type . All dimensions of non-rotating rod type except the rod end are the same as those of round rod type. For the energized push type and pull type, all positions of P port, exhaust throttle valve, terminal and manual operation TD button differ at 180.

TL EC J EC

40

EC

32

30

18 42.1 J J 19 1111 28.6 36.7 Wiring port Compatible cable outer diameter 4.57

Non-rotating rod type 25 40

51 About EQ 21 TM UM TL Hexagonal rod width across flat MG Lock nut for rod end attachment width across flat B1 A h Lock nut for rod end attachment width across flat B1

A h

WF

Stroke Energized push type-pull type conversion structure Exhaust throttle valve

Manual operation button RH BD K Stroke XG port Rc1/8With plug silencer Stroke J

Lock nut for mounting accessories width across flat B2

Relative modelWith boots

The above drawings are the dimensional drawings of energized push type.

Unitmm

Small Air Cylinder

10Z3

h H Round Nonrod rotating type rod type 5 6 6 7 5 7 J K

42

Dimensional Table

Symbol A B1 B2 BD D E EC EQ Round Non- Round Nonrod rotating rod rotating type rod type type rod type 20 20 13 13 19

Bore 20 25 32 40 Symbol Bore 20 25 32 40

30 30 32 41

10 10 12 14

6 8 10 12

28 31 38 46

36 36 36 44

34 34 34 38

31 35 40 42

25 25 25.5 30

14 14.5 15 15

22 2220 17 17 22 19 17

24 2124 21 19 KK Round rod type M81.25 M101.25 M101.25 M121.25 Non-rotating rod type M81.25

LC 205 209.5 215.5

MG 9 14

MM 8 10 12 14

P 45 49 55 57

RH 7 7 8 9

TD 8e9 8e9 10e9 12e9

TL 8 8 10 12

TM 36 36 44 50

TU 32 32 36 44

UM 52 52 64 74

WF 24 28 30 32

XG 19 23 24 25

XH 210 214.5

XJ 86 91

YP 7 7.5 7.5 7.5

221.5 102 229 107

M121.25 222

Parenthesized figure of A is the dimension of screw length.

CAD/DATA is 10Z-3/TAZ3 Bore K available.

With Boots

20 40

Non-rotating rod type 25 40

A

WW

XX

50 63

60

26 24

XX

Dimensional Table

Symbol

Parenthesized figure is the dimension of screw length. XX1/4X Stroke 65 At less than 50mm stroke, equation above can't be applied. Please calculate by thisXX1/4 Stroke 80 Fractions less than decimal point shall be raised. Chart of the XX dimensions

A

Stroke Bore

Round Nonrod rotating type rod type

WW 25

50

75

100

125

150

175

200

250

300

350

400

450

500

Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Non- Round Nonrod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating rod rotating type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type type rod type

20 25 32 40

20 20 36 59 69 79 84 94 104 114 124 144 164 184 204 224 244 22 2220 17 36 63 56 73 66 83 76 88 81 98 91 108 101 118 111 128 121 148 141 168 161 188 181 208 201 228 221 248 241 22 19 40 55 65 75 80 90 21 24 2124 45 52 45 62 55 67 60 72 65 82 75 95 105 110 130 140 160 180 200 220 92 85 97 90 102 95 112 105 127 120 137 130 152 145 172 165 192 185

Parenthesized figure of A is the dimension of screw length.

43

10Z3

TA with B

20 40 Double Acting Single Rod

Small Air Cylinder

Unitmm

Round rod type 10Z3 TA Bore Cushioning Stroke B Non-rotating rod type 10Z3G TK Bore Cushioning Stroke B

20 25

D

32 40

D ZCStroke WF YP A h XG RH BD 2Rc1/8 PStroke

UM TL TM TL

Non-rotating rod type 25 40

A h Hexagonal rod width across MM flat MG KK KK Lock nut for Lock nut for rod end attachment rod end attachment width across flat B1 width across flat B1 Lock nut for mounting accessories width across flat B2

TU TD TA attachment outer dia BH 17 8 XM WM 17 8

E BT 8 BF/2 BF/2 BF 6.6 22

For dimensions not given in the above drawings, ref to SD type basic type . All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.

For non-rotating rod type, clevis cut type is standard.

Relative modelClevis cut type TK with B Post-port type TP with B With cushion With boots

50 63

16

104 72

45

16 Width across flats 17

26 32 24 23 10 418

11

149Stroke 73Stroke 2Rc1/4 Cushion valve

Non-rotating rod type

58 16 Lock nut for mounting accessories dia Width across flats 19 56 20 M161.5

Lock nut for rod end attachment width across flat 24 Lock nut for mounting accessories width across flat 54 Width across flats 17 25 12 50 74 25 12 6 22 9

21 11 120 142

21 11

Parenthesized figure is the dimension of screw length. All dimensions of non-rotating rod type except the above rod end are the same as those of round rod type.