Académique Documents

Professionnel Documents

Culture Documents

TC Manual Air Cooled Chillers

Transféré par

vickersCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TC Manual Air Cooled Chillers

Transféré par

vickersDroits d'auteur :

Formats disponibles

Page 1 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Temperature Control Manual

AIR COOLED CHILLERS

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 2 of 26

Temperature Control Manual Air Cooled Chillers

TABLE OF CONTENTS

Section

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Page

IMPORTANT INFORMATION.............................................................................................................3 SERVICE BULLETIN.............................................................................................................................4 1 1.1 1.3 1.3.1 1.3.2 1.3.3 1.3.4 1.3.5 1.3.6 1.4 1.5 1.5.1 1.5.2 2 3 3.1 3.1.1 3.1.2 3.1.3 3.1.4 3.1.5 3.3 3.3.1 3.4 3.4.1 3.4.2 3.4.3 3.4.2 3.5 3.6 3.6.1 3.6.2 3.6.3 3.6.4 3.6.5 3.6.9 1.6 4 INTRODUCTION................................................................................................................5 Description........................................................................................................................5 Equipment .........................................................................................................................5 Compressor ..................................................................................................................5 Oil Separator ................................................................................................................6 Condenser ....................................................................................................................6 Expansion Valve ..........................................................................................................7 Evaporator....................................................................................................................7 Control Devices ...........................................................................................................7 Applications ......................................................................................................................7 Process ..............................................................................................................................8 Refrigerant Cycle.........................................................................................................8 Oil Cycle ......................................................................................................................8 TECHNICAL DATA ...........................................................................................................9 INSTALLATION, OPERATION AND MAINTENANCE (IOM)................................15 Installation.......................................................................................................................15 Handling.....................................................................................................................15 Foundation .................................................................................................................15 Water Drain Hole.......................................................................................................15 Clearances..................................................................................................................15 Water to Evaporator Connection ...............................................................................15 Commissioning ...............................................................................................................16 Starting the Unit.........................................................................................................16 Operation.........................................................................................................................16 Temporary Shut Down and Restart............................................................................16 Emergency Stop.........................................................................................................16 Final Check ................................................................................................................17 Principal of Operation................................................................................................17 Decommissioning ...........................................................................................................17 Maintenance Procedures .................................................................................................18 Condenser ..................................................................................................................18 Refrigerant Charge.....................................................................................................18 Weekly Maintenance and Checks..............................................................................18 Monthly Maintenance and Checks.............................................................................18 Annual Maintenance ..................................................................................................18 Maintenance Schedules..............................................................................................19 Troubleshooting ..............................................................................................................22 ELECTRICAL ...................................................................................................................25

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 3 of 26

Temperature Control Manual Air Cooled Chillers

IMPORTANT INFORMATION

Fluid Flow through the chiller: � � � Fluid pump MUST always feed into the Chiller Proper flow MUST be established for optimum operation The pressure across the chiller barrel is set to 40kPa delta p (delta p = fluid press entering the chiller minus fluid leaving the chiller) � Correct Pump size Installation: � � � � Have technical information with you at all times to refer to

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Position equipment on a level surface and leave room for air intake and room to work Keep hosing lengths as short as possible and tidy Complete a commissioning report Chiller Settings:

� � � � �

Leaving fluid temperature setting (Set Point) Cut in / Cut out temperature settings (Range / Dead Band) Low water temperature cut out setting Low refrigerant cut out setting Fluid Flow (delta p) Chiller Safety:

� � � � � � � �

Contamination of chiller barrels Proper fluid flow Correct Power Supply Correct Phase Rotation PRE HEAT CHILLERS (minimum 24 hrs) Service valves Follow manufacturers recommendations Install strainers

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 4 of 26

Temperature Control Manual Air Cooled Chillers

SERVICE BULLETIN

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

BULLETIN NUMBER REFERENCE SUBJECT

ASB0088A

ISSUE DATE

4th September 2006

YCAS chillers supplied to Aggreko N/A

WITHDRAWAL DATE

Re: YCAS0623 chillers supplied to Aggreko for the chiller rental market A number of YCAS chillers have been supplied to Aggreko for use as rental chillers. These machines have been especially modified so that they will operate on normal air conditioning duty down to 4oC, low temperature glycol duty down to -12oC and ultra low temperature glycol duty down to -19oC. As for a standard machine, for air conditioning duty dip switch number one must be in the open position. For normal glycol mode (down to -12oC) dip switch number one must be in the closed position. If ultra low temperature glycol is required (down to -19oC) a special procedure is required. Procedure for ultra low temperature glycol operation (down to -19oC). 1. Program chiller panel for imperial units mode (ultra low temperature duty will not operate in SI units mode). 2. Enter special password code 7522. The display will indicate standard mode. 3. Using the scroll buttons select low temperature mode. 4. Once low temperature mode is selected the desired leaving liquid control temperature, leaving liquid temperature cut out and suction pressure cut out can be programmed in the usual manner (settings must be in Fahrenheit for temperature and PSIG for pressure). CAUTION Do not operate the chiller in a lower temperature mode than is required for a particular application. Low temperature operation does require close attention to glycol concentration so only ever select glycol mode or ultra low temperature mode when absolutely necessary.

Graham Parry Technical support.

PLEASE FILE THIS BULLETIN IN YOUR APPLIED BULLETIN BINDER AND POST ON THE APPLIED SECTION OF YOUR BULLETIN NOTICE BOARD. TC Manual Air Cooled Chillers.doc Aggreko Australia Pacific

Page 5 of 26

Temperature Control Manual Air Cooled Chillers

1 INTRODUCTION

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

This manual contains directions regarding the descriptions, installation, and operations of the Aggreko Air Cooled Fluid Chillers.

1.1

Description

The units are intended for the cooling of water or non corrosive fluids. They are designed to be located outside (rooftop or ground), not in an enclosed plant room or sealed building. They are used for a wide variety of applications in the mining, process, HVAC, Food, Industrial, and Manufacturing industries. The outlet temperatures for the chillers vary from our standard 6C water mixture to the lower temperatures of -19C (50% water / glycol mixture).

1.3 1.3.1

Equipment Compressor

The air cooled chiller consists of two distinct components; motor and rotor. A two pole, hermetic, squirrel cage induction motor directly drives the compressor rotors. The motor is cooled by suction refrigerant gas from the evaporator, entering the end of the motor housing through the suction line. The compressor is a semi-hermetic direct drive helical rotor compressor. Each compressor has only 3 moving parts, 2 rotors and a slide valve to control the capacity. The male rotor is attached to, and driven by the motor. The refrigerant from the evaporator is drawn into the suction opening at the end of the motor barrel, through a suction strainer screen, across the motor, and into the intake of the compressor rotor section. The gas is then compressed and discharged directly into the discharge line.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 6 of 26

Temperature Control Manual Air Cooled Chillers

1.3.2 Oil Separator

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The oil leaves the compressor entrained within the discharged refrigerant vapour, and it is the oil separator that recovers this oil. The separator consists of a vertical cylinder surrounding an exit passageway. As the refrigerant and oil mixture is discharged into this passageway the oil is forced outward by centrifugal force, collects on the walls of the cylinder and drains to the bottom. This accumulated oil drains out of the cylinder and collects in the oil sump located near the bottom of the chiller. The oil sump is heated to ensure proper lubrication and minimise refrigerant condensation in the sump.

1.3.3

Condenser

The air cooled condenser coils have aluminium fins mechanically bonded to internally finned seamless copper tubing. The condenser coil has an integral sub cooling circuit. Direct drive vertical discharge airfoil condenser fans are dynamically balanced. The water is pumped through the tubes of the shell and tube heat exchanger while refrigerant vapour fills the shell space surrounding the tubes. The condenser has a baffle plate that helps distribute the refrigerant evenly within the shell. As heat is transferred from hot, high pressure refrigerant vapour to the water, refrigerant condenses on the tube surfaces.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 7 of 26

Temperature Control Manual Air Cooled Chillers

1.3.4 Expansion Valve

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The expansion valve is used to maintain the pressure difference between the highpressure (condenser) and the low pressure (evaporator) sides of the system, as established by the compressor. This pressure difference allows the evaporator temperature to be low enough to absorb heat from the water being cooled, whilst allowing the refrigerant to be at high enough temperature in the condenser to reject heat to water at normally available temperatures. High pressure liquid refrigerant flows through the expansion device, causing a large pressure drop that reduces the refrigerant pressure to that of the evaporator. This pressure reduction causes a small portion of the liquid to boil off, or flash, cooling the remaining refrigerant to the desired temperature.

1.3.5

Evaporator

The evaporator is a tube in shell heat exchanger design, with internally finned copper tubes roller expanded into the tube sheet. The evaporator is designed for a waterside working pressure of 14 bar. Water connections are grooved pipe for victaulic couplings. Each shell includes a vent, a drain, and fitting for temperature control sensors, and is insulated. Evaporator heaters with thermostats provide protection to the evaporator from freezing at ambient temperatures of -29C.

1.3.6

Control Devices

The unit controls are housed in a weather tight enclosure with removable plates to allow for connection of power wiring and remote interlocks. Microcomputer controls provide all control functions including startup and shutdown, leaving chilled water temperature control, compressor and electronic expansion valve modulation, fan sequencing, anti-recycle logic, automatic lead/lag compressor starting and load limiting. The controls also automatically take action to avoid unit shutdown due to abnormal operating conditions associated with low refrigerant pressure, high condensing pressure, and motor current overload. Unit protective functions include loss of chilled water flow, evaporator freezing, loss of refrigerant, low/high refrigerant pressure, phase reversal, and loss of oil flow.

1.4

Applications

The air cooled chiller can be used in a wide variety of applications in various industries. The chiller is often used in conjunction with other Aggreko equipment such as cooling towers, fluid pumps, and heat exchangers.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 8 of 26

Temperature Control Manual Air Cooled Chillers

1.5 1.5.1 Process Refrigerant Cycle

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Saturated refrigerant vapour from the evaporator is drawn into the suction opening of the screw compressor. The gas is compressed and discharged through a check valve into the discharge line. An oil separator removes the oil from the refrigerant going to the air cooled condenser, where the heat of compression and cooling load are rejected, (the refrigerant condenses). In the sub-cooler, which is a part of the condenser, the refrigerant is cooled down further. The refrigerant passes through the expansion valve, where the pressure is dropped, which results in vaporisation of some of the refrigerant. The liquid vapour refrigerant mixture enters the liquid vapour separator where liquid and gas are separated, the vapour is directed to the evaporator suction. The liquid is evenly distributed over the length of the evaporator by the distribution liquid system. Heat is transferred from the water inside the tubes to the refrigerant as the film of refrigerant evaporates on the surface of the tube, refrigerant vapour exits the evaporator through the suction baffle where is mixes with the vapour from the liquid vapour separator.

1.5.2

Oil Cycle

The compressor oil supply is obtained from the oil separator. Due to the pressure differential between discharge and suction pressure, oil is injected via the oil cooler into the compression chamber and the bearings of the compressor from where it is returned together with the compressed gas to the oil separator. The oil and gas are separated, oil flows down to the bottom of the separator, from where it again flows to the compressor. Oil that gets past the oil separator flows through the condenser, sub-cooler and expansion valve into the evaporator. This oil is collected in the pool of refrigerant that is maintained in the bottom of the evaporator. A small amount of oil and refrigerant from this pool is returned through a line that is connected to the compressor down stream of the motor. This oil and refrigerant mixes with the refrigerant vapour that was drawn out of the evaporator.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 9 of 26

Temperature Control Manual Air Cooled Chillers

2 TECHNICAL DATA

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

17.12.2002

Revision:

Page 9 of 26

Document number

Fluid Chillers

AIR COOLED SCROLL FC50A

au.1.3

1.

INTRODUCTION

The Aggreko -C- range air cooled fluid chillers are designed for water or water-Glycol cooling. All units are designed to be located outside. The units are completely assembled with all interconnecting refrigerant piping and internal wiring, ready for installation. The unit base and frame is of heavy-gauge steel and is fully tested and certified 2. KEY-DATA 52 kW at 6 degrees leaving water temperature 19 kW +15 C to -12 C 43C 2.36 metres 1.20 metres 2.11 metres 1250 kg

Cooling Capacity Absorbed Power Temperature Range Maximum ambient temp. Dimensions length width height Weight 3. LAYOUT

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 10 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

17.12.2002

Revision:

Page 10 of 26

Document number

Fluid Chillers

AIR COOLED SCROLL FC50A

TECHNICAL SPECIFICATIONS

UNITS kW C / C C / C C / C C C / C

au.1.3

4.

ITEM Performance Data Design Capacity Design Operation Fluid Temperature IN / OUT Minimum / Maximum Outlet Fluid Temperature Minimum / Maximum Chilled Liquid Temperature Difference Design Ambient Temperature Minimum / Maximum Ambient Temperature Compressor Compressor Type Number Of Compressors Number Of Capacity Steps Evaporator Data Evaporator Type Evaporator Material Design Flow Minimum / Maximum Flow Evaporator Capacity Evaporator Maximum Working Pressure Design Chiller Barrel Pressure Drop Recommended System Fluid Volume Condenser Data Number Of Condenser Fans kW per Fan Total Air Volume External Static Pressure Refrigerant Data Refrigerant Type Number of Circuits Refrigerant Charge circuit 1 / 2 Type Of Compressor Oil Oil Charge circuit 1 / 2 Electrical Data Design Electrical Supply Voltage Design Electrical Rating Design / Maximum Operating Current Starting Current Pre-Heating Supply Recommended Generator Set Required Cable Size per Phase Electrical Connection Noise Data Sound Pressure Level at 10 metres - Lp(A) Sound Power Level - Lw(A) Physical Data Overall Length Overall Width Overall Height Weight Fluid Coupling Size

VALUE 52 12 / 6 -12 / +15 3.5 / 10.2 35 3 / +43 Semi Hermetic Scroll 2 2/ 50 Plate S.Steel & Copper 2.07 1/4 4 1000 30 315 1 1.2 5.5 0 R22 1 9 025E 7.6

No. / %

l/s l/s / l/s litres kPa kPa litres

kW m/s Pa

kg litres

Volts kVA / kW Ampere Ampere Volts / VA kVA mm

440 3ph / 50/60hz 22 / 19.1 30 / 45 107 N/a 30 10 40A Clipsal Plug 54 82 2.30 1.20 2.11 1250 50 / 2" Camlock

dB(A) dB(A) metres metres metres kg mm / inch

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 11 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 11 of 26

Document number

Fluid Chillers

AIR COOLED SCROLL FC160A

au.1.2

1.

INTRODUCTION

The Aggreko -C- range air cooled fluid chillers are designed for water or water-Glycol cooling. All units are designed to be located outside. The units are completely assembled with all interconnecting refrigerant piping and internal wiring, ready for installation. The unit base and frame is of heavy-gauge steel and is fully tested and certified 2. KEY-DATA 157 kW at 7 degrees leaving water temperature 71 kW +15 C to -12 C 43C 2.80 metres 2.20 metres 2.08 metres 2400 kg

Cooling Capacity Absorbed Power Temperature Range Maximum ambient temp. Dimensions length width height Weight

3.

LAYOUT

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 12 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 12 of 26

Document number

Fluid Chillers

AIR COOLED SCROLL FC160A

TECHNICAL SPECIFICATIONS

UNITS kW C / C C / C C / C C C / C VALUE

au.1.2

4.

ITEM Performance Data Design Capacity Design Operation Fluid Temperature IN / OUT Minimum / Maximum Outlet Fluid Temperature Minimum / Maximum Chilled Liquid Temperature Difference Design Ambient Temperature Minimum / Maximum Ambient Temperature Compressor Compressor Type Number Of Compressors Number Of Capacity Steps Evaporator Data Evaporator Type Evaporator Material Design Flow Minimum / Maximum Flow Evaporator Capacity Evaporator Maximum Working Pressure Design Chiller Barrel Pressure Drop Recommended System Fluid Volume Condenser Data Number Of Condenser Fans kW per Fan Total Air Volume External Static Pressure Refrigerant Data Refrigerant Type Number of Circuits Refrigerant Charge circuit 1 / 2 Type Of Compressor Oil Oil Charge circuit 1 / 2 Electrical Data Design Electrical Supply Voltage Design Electrical Rating Design / Maximum Operating Current Starting Current Pre-Heating Supply Recommended Generator Set Required Cable Size per Phase Electrical Connection Noise Data Sound Pressure Level at 10 metres - Lp(A) Sound Power Level - Lw(A) Physical Data Overall Length Overall Width Overall Height Weight Fluid Coupling Size

157 12 / 6 -12 / +15 3.5 / 10.2 35 3 / +43 Semi Hermetic Scroll 4 4/ 25 Plate Steel & Copper 7.45 1 / 10 1400 40 208 4 1.2 16.2 0 R22 2 14.45/14.45 025E 11 / 11 440 3ph / 50/60hz 88 / 71 116 247 N/a 100 35 M12 63 91 2.80 2.20 2.02 2400 100 / 4"

No. / %

l/s l/s / l/s litres kPa kPa litres

kW m/s Pa

kg / kg litres Volts kVA / kW Ampere Ampere Volts / VA kVA mm

dB(A) dB(A) metres metres metres kg mm / inch

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 13 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 13 of 26

Document number

Fluid Chillers

AIR COOLED SCREW FC600A

au.1.1

1.

INTRODUCTION

The Aggreko -C- range air cooled fluid chillers are designed for water or water-Glycol cooling. All units are designed to be located outside. The units are completely assembled with all interconnecting refrigerant piping and internal wiring, ready for installation. The unit base and frame is of heavy-gauge steel with the dimensions of a standard 20 ft container tested and certified . 2. KEY-DATA 612 kW at 6 degrees leaving water temperature 182 kW +15 C to -12 C 40 C standard ISO 20ft. Container. 6.05 metres 2.43 metres 2.59 metres 6820 kg

Cooling Capacity Absorbed Power Temperature Range Maximum ambient temp. Dimensions length width height Weight

3.

LAYOUT

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 14 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 14 of 26

Document number

Fluid Chillers

AIR COOLED SCREW FC600A

au.1.1

4.

TECHNICAL SPECIFICATIONS

UNITS kW C / C C / C C / C C C / C VALUE 612 12 / 6 -18 / +30 3.5 / 10.2 30 0 / +40 Semi Hermetic Screw 2 12.5 thru 100 Shell & Tube Steel & Copper 24.5 15 / 44 204 1000 34 5.66 2520 10 0.85 139 0 R22 2 62 / 62 ISO 68 17 / 17 400 3ph / 50 Hz 213 / 182 308 / 443 543 220 / 600 350 240 Busbar M12 66 94 6.0 2.4 2.6 6820 100 / 4"

ITEM Performance Data Design Capacity Design Operation Fluid Temperature IN / OUT Minimum / Maximum Outlet Fluid Temperature Minimum / Maximum Chilled Liquid Temperature Difference Design Ambient Temperature Minimum / Maximum Ambient Temperature Compressor Compressor Type Number Of Compressors Number Of Capacity Steps Evaporator Data Evaporator Type Evaporator Material Design Flow Minimum / Maximum Flow Chiller Barrel Capacity Chiller Barrel Maximum Working Pressure Design Chiller Barrel Pressure Drop Chiller Barrel Pressure Drop Factor Recommended System Water Volume Condenser Data Number Of Condenser Fans kW per Fan Total Air Volume External Static Pressure Refrigerant Data Refrigerant Type Number of Circuits Refrigerant Charge circuit 1 / 2 Type Of Compressor Oil Oil Charge circuit 1 / 2 Electrical Data Design Electrical Supply Voltage Design Electrical Rating Design / Maximum Operating Current Starting Current Pre-Heating Supply Recommended Generator Set Required Cable Size per Phase Electrical Connection Noise Data Sound Pressure Level at 10 metres - Lp(A) Sound Power Level - Lw(A) Physical Data Overall Length Overall Width Overall Height Weight Fluid Coupling Size

l/s l/s / l/s litres kPa kPa p.u. litres

kW m/h Pa

kg / kg litres Volts kVA / kW Ampere Ampere Volts / VA kVA mm

dB(A) dB(A) metres metres metres kg mm / inch

NOTE: Contact Technical Department If application conditions differ from design conditions

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 15 of 26

Temperature Control Manual Air Cooled Chillers

3 3.1

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

INSTALLATION, OPERATION AND MAINTENANCE (IOM) Installation

Installation of the Chillers is of utmost importance. The operating life will be improved with the correct installation of the equipment.

3.1.1

Handling

The fluid chiller can be handled by a forklift or slings. Ensure that the weight of the fluid chiller does not exceed the maximum allowable lifting capacity of the crane, slings or forklift. Ensure all doors are closed and locked before moving.

3.1.2

Foundation

A solid foundation is required for the positioning of the unit, and must be flat, level and able to withstand the weight of the unit.

3.1.3

Water Drain Hole

Ensure that there is a drain hole wide enough to drain any water from the unit in the event of shutdown or repair. Note: Chemicals added to the chilled water system can affect the environment if drained. Ensure water is free of these before draining.

3.1.4

Clearances

Ensure there are sufficient clearances around the unit to allow maintenance operations to take place without obstruction. The following minimum distances are required to prevent condenser air recirculation and faulty operation: a. b. c. d. Front clearance of 1.5m Side and rear clearance of 1.5m Clearance above unit of 10m Distance between adjacent units of 3m.

3.1.5

Water to Evaporator Connection

Install the water circulation pump upstream of the evaporator, making sure that the evaporator is under positive pressure. The water must enter the evaporator by the inlet connection. Pipe work and fittings must be separately supported to prevent any loading on the evaporator. Flexible connections or hoses are recommended.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 16 of 26

Temperature Control Manual Air Cooled Chillers

3.3 Commissioning

Before starting up the system, the following should be checked; a. b. c. d. e. f. e. Connect 32A auxiliary supply, min preheating time is 4hrs

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Chilled water circuits ready to operate, filled with water, pressure and leak tests have been carried out and purging has taken place Ensure that all water and refrigerant valves are in the service position Where mechanical guards are provided these must be in position when the unit is running Check that all electrical connections are clean Close all panel doors Switch on supply circuit breaker

3.3.1

Starting the Unit

a. b. c. d. Switch on the main circuit breaker Start water pump, adjust flow rate with flow valve if necessary Reset alarm (if any) by pressing Reset all active Diagnostics in alarm tab To start the unit, press the Auto tab on the unit control module

NOTE: The unit will automatically start and try to maintain the set temperatures if the following conditions are met: a. b. c. d. e. f. Supply voltages are within operating parameters Preheating time elapsed and oil temperature within parameters All anti-recycle timers are timed out All safety systems are within operating parameters Sufficient fluid flow Cooling demand exists

3.4 3.4.1

Operation Temporary Shut Down and Restart

a. b. Press the stop tab on the control panel, compressors will stop To restart the unit, press the Auto Tab

3.4.2

Emergency Stop

A push button located on the unit causes the unit to stop immediately. To restart the unit after an emergency stop, pull out the stop button and reset the alarm on the touch screen.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 17 of 26

Temperature Control Manual Air Cooled Chillers

3.4.3 Final Check

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

After start up, leave the unit in operation for at least 15 minutes, to ensure that the refrigerant pressures are stabilised. The following must then be checked: a. Both suction and pressure / temperature gauges must show approx 2 - 5C below leaving liquid temperature. (When running at low temp applications, this value can be higher) b. Both discharge pressure / temperature gauges must be approx 15C above ambient air temperature c. The sight glass in expansion valve must be clear d. Check for any noise and vibrations

3.4.2

Principal of Operation

3.5

Decommissioning

The decommissioning procedure is as follows: a. b. c. d. e. f. Press the stop tab on the control panel, compressors will stop Stop all fluid pumps Switch off unit power supplies Disconnect supply cable, lock access panel Drain the chilled water system Disconnect fluid hoses (water circuit to evaporator might be under pressure. Reduce before opening up the system

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 18 of 26

Temperature Control Manual Air Cooled Chillers

3.6 3.6.1 Maintenance Procedures Condenser

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

In some environments the condenser coils may get dirty and shutdown due to high condensing pressure. If this happens, clean condenser coils with a brush or jet of water. Note: Fins of condenser coils may be sharp, use appropriate PPE.

3.6.2

Refrigerant Charge

The amount and type of refrigerant charge is listed on the unit name plate. Check monthly for unit leaks. Oil marks can be symptoms of refrigerant leaks.

3.6.3

Weekly Maintenance and Checks

After the unit has operated for approx 30 minutes and the system has stabilised, check the operating conditions and complete the following: a. b. Log the chiller Check evaporator and condenser pressures with gauges and compare to the reading on the display. Pressure readings should fall within the operating ranges.

3.6.4

Monthly Maintenance and Checks

On a monthly basis, the following should be done: a. b. c. d. e. f. Review the operating log Clean all water strainers in both chilled and condensing water piping system Measure the oil filter pressure drop. Replace oil filter if required Measure and log the sub-cooling and superheat If operating conditions indicate a refrigerant shortage, leak check the unit using soap bubbles and repair all leaks Trim refrigerant charge until the unit operates in accordance with settings.

3.6.5

Annual Maintenance

Shut down the chiller once per year to check the following: a. b. c. d. e. f. g. h. Perform all weekly and monthly maintenance procedures; Check refrigerant charge and oil level; Perform oil analysis; Check pressure drop across the oil filter; Inspect all piping for leakage and damage. Clean strainers; Clean and repaint; Test vent piping of all relief valves for presence of refrigerant to detect improperly sealed relief valves. Replace any leaking relief valves; and Inspect condenser tubes for fouling; clean if necessary.

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 19 of 26

Temperature Control Manual Air Cooled Chillers

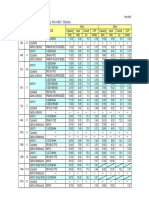

3.6.9 Maintenance Schedules

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The following are the Maintenance Schedules for the Aggreko Fluid Pumps:

Maintenance Schedule for Aggreko's Water-Cooled Liquid Chiller Fleet Series No: FC1200 (RTHA), FC1300 (RTHB), and FC1500 (RTHC) with Helical Rotary (Screw) Compressors:

On Hire and Installation Monthly or at 750 Hours 6-Monthly or at 4300 Hours Completion of Hiring and Decomm. At 36 Cumulative Months of Operation

Item No.

Installation, Operation, and Maintenance Instructions

General: Check and record the following operational data, as much as possible, on Commissioning and Start-up Report Sheet and check monthly and at decommissioning time: 1. ambient air dry bulb and wet bulb temperatures ( C) 2. compressor suction and discharge pressures (kPa) o 3. compressor suction and discharge temperatures ( C) o 4. compressor suction superheat temperature ( C) o 5. low refrigerant temp safety cut out set point ( C) o 6. chilled water leaving temperature set point value ( C) o 7. chilled water return temperature ( C) o 8. low chilled water temp. safety cut out set point ( C) o 9. condenser water leaving temperature ( C) o 10. condenser water return temperature ( C) 11. condenser water return limit set point value (%) 12. power supply Voltage (V) and frequency (Hz) 13. FLC: full load current (Amps) 14. phase currents (Amps) 15. current limit set point value (%) Check and record pressure drops through chilled water recirculation system and condenser water recirculation, and compare with design specifications and the job site-specific chiller selection/ rating data. Check and record sump heater operation when unit is off. Check and expedite any undue vibrations on the chiller unit. Seek for solution(s) to rectify. Check and record oil pressure. Compare with the operating range in chiller manufacturer's IOM manual. Check liquid refrigerant flow in sight glass for presence of moisture or any shortage of refrigerant. Check the settings of the HP and LP safety switches and oil control functions and compare with the allowable limit values in the manufacturer's IOM Manual. Reset if necessary. Check motor and drive and record the rated running load current in Amps. Check the existence of any refrigerant leaks. Report the leaks for rectification. Prove solenoid operation, as applicable. Check the functionality of the flow switches on chilled water system and condenser water system, as applicable.

o

3 4 5 6

X X X X X X X

X X

8 9 10

X X X

X X X X X

11

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 20 of 26

Temperature Control Manual Air Cooled Chillers

Item No. On Hire and Installation Monthly or at 750 Hours 6-Monthly or at 4300 Hours

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Maintenance and Servicing Instructions

Completion of Hiring and Decomm.

At 36 Cumulative Months of Operation

12 13 14

Check the TX valve or electronic expansion valve and superheat, as applicable. Check operation and calibration of chilled water temperature controller to maintain the intended design temperature. Check setting and operation of chilled water, low temperature safety thermostat, and record trip temperature. Check the thermal insulation over the chiller components. Replace or repair if necessary. Re-establish vapour seal around the chiller unit. Inspect corrosion protection device, as applicable. Remove insulation and water boxes. Clean and fit new gaskets. Clean chilled water tubes, plates, bolts, grease threads, and reassemble. Slug dose chilled water upon refilling or replenishing CHW in the recirculation system. Check and clean in-line strainers and scale traps on both the chilled water and condenser water recirculation systems, as necessary, depending on the type of cooling application and quality of the chilled water. Check oil level and top up if necessary. Test oil for acidity. Flush oil sump and change oil, if necessary. Check driers and change if necessary. Check oil filters and change if necessary. Check and align coupling and report on rubber wear. Set unit to work, prove operation. Lubricate and grease all points and linkages. Repair and paint any corrosion, clean generally. Electrical: Check for signs of burnt, hot connections and burnt contacts on starters and relays. Clean, rectify, and tighten. Replace any faulty indicator lights. Examine general condition of conduits, connectors, switches, and wiring, especially when chiller installed in damp and outdoor areas. Check operation of each item of equipment. Check for proper operation of Voltmeter and Ammeter as applicable. Replace faulty meters. Inspect, clean, and replace contacts, as necessary. Inspect relays. Replace faulty relays, as necessary. Check overload ratings against motor nameplate. Check connections to compressor motors, control panel/ MCCB (Motor Control Centre Board), and at points where the equipment is subjected to vibrations. Examine external switches for possible damages to seals. Check all time delays. Check all fuses for correct rating. Replace any safety warning, instructional, and operational labels that have fallen off, damaged, or removed. Check and rectify condition of exposed cable insulation. Strictly follow safe power isolation procedures prior to cable repair works. X X X X X X X X X X

15 16 17 18 19

X X

X X X X

20

21 22 23 24 25 26 27 28 29

X X X X

X X X X X X X X X

X X X

1 2 3 4 5 6 7 8 9 10 11 12 13

X X X X X X

X X

X X X X X X

X X X X X X X X

14

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 21 of 26

Temperature Control Manual Air Cooled Chillers

Item No. On Hire and Installation Monthly or at 750 Hours 6-Monthly or at 4300 Hours

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Maintenance and Servicing Instructions

Completion of Hiring and Decomm.

At 36 Cumulative Months of Operation

15 16 17 18

Vacuum clean interior of the control panel/ MCCB. Check and ensure that conduits are securely fixed. Examine and rectify the seals on the control panel/ MCCB. Check for the existence of electrical wiring diagram inside the control panel/ MCCB. Check the consistency of the electrical wiring diagram with the actual wiring and the components of the chiller. Ensure that it is 'as-installed'. Report any inconsistencies. Report any required revisions on the electrical diagram as per electrical modifications done or planned. Lubricate all pivot points. Use pure petroleum jelly. Piping and Fittings Associated with Chiller Installation: X X

X X X X

X X X X

19

20 21

X X

X X

1 2 3 4 5 6 7 8

Check rigid and flexible CHW and CDW pipework and valve glands for leaks, and repair leaks. Clean rigid and flexible pipework, wipe flexible pipe connections with grease, as applicable. Check and ensure that all valves are in correct position and orientation. Check proper functioning/ operation of all valves. Check strainers and clean, as necessary, as applicable. Vent all high points in the system, as applicable. Check all vents or scale pockets, vent or drain as necessary. Check condition of pipe insulation, test pipe insulation, as applicable.

X X X X X X X X

X X

X X

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 22 of 26

Temperature Control Manual Air Cooled Chillers

1.6 Troubleshooting

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Problem

No lights on panel Display A53 not on

Possible Cause

Mains supply to control system not on 1Q5-2 tripped (380V) 1Q5-2 tripped (24V) Power Supply Module A10 Incorrect Phase Rotation

Action

Switch on main supply if safe to do so Reset if safe to do so Reset if safe to do so Check fuse Check Phase Rotation, correct if req Check voltage according to name plate data Check / Replace 1U1 Reset Reset if safe to do so Reset if safe to do so Check / Replace Check / Replace Check / Replace Reset if safe to do so Reset if safe to do so Reset if safe to do so Check / Replace Check / Replace Check / Replace Reset if safe to do so Reset if safe to do so Reset if safe to do so Reset if safe to do so Check / Replace Check / Replace Check display on B31 module to confirm oil temp is slowly rising, check time remaining Check setting on dyna view module Wait until timers are timed out Check setting temp controller Check calibration temp sensors Check set point Check for airflow restrictions caused by blockage Check for fouling of condenser coils Check for damaged fins/return bends Check for correct fan operation Check for recirculation of ejected air Check ambient temp is above design conditions Check leaving water temp is below max operating limits Open service valves Check for signs of air in refrig. system Check sub-cooling is correct Check filter Check / Replace Check / Replace Check / Replace

Unit will not operate

Supply Fault Lit

Voltage outside operating parameters 1U1 faulty

Emergency Stop Main supply

Emergency Stop input is open 1Q531 tripped 1Q532 tripped K8 faulty D20-3 faulty K9 faulty 1Q4 tripped 1Q3 tripped 1Q5-33 tripped D20-4 faulty K10 faulty 1T71 fuse blown 1Q5-31 tripped (main supply) 1Q5-32 tripped (main supply) 1Q3 tripped (auxiliary supply) 1Q5-33 tripped (aux supply) B31 faulty Faulty sensor Oil temp has not reached working temp following power up / or still in 4 hr time delay cycle Set up not correct Unit held off by timers No heat load Incorrect temp reading Incorrect temp setting Discharge high pressure trip due to poor air flow through the condenser coil

Auxiliary Supply Preheating not operational No display

Temperature reading Oil heat delay light on/ compressor lockout Compressor will not start

Compressor locked out Run inhibit Temp Control Mod. Auto display

High Pressure Alarm

Unit operating above load limit

Service valve closed Excessive refrigerant charge Filter Iced up Temperature sensor fault Pressure transducer fault Communication loss Refrigerant filter blocked Bad sensor or LLID Bad sensor or LLID Faulty LLid

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 23 of 26

Temperature Control Manual Air Cooled Chillers

Problem

Starter did not transition (Compressor) 180FO 182 Phase reversal (compressor)

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Possible Cause

Starter module didnt receive a transition complete signal in designated time. A phase reversal was detected on the incoming current, on a compressor startup No current sensed on one or two of the current-transformer inputs while running or starting. If phase reversal protection is enabled and current is not sensed on one or both current transformer inputs, logic will detect and trip in a max of 0.3 sec after compressor start Compressor previously established currents while running, and then all three phases of current were lost A 40% phase current balance is detected on one phase, relative to all 3 phases (for 90 sec) Currents detected when only 1MI is closed, one of the other contactors is shorted Currents detected with only 1K3 closed. 1M contactor is shorted No currents detected within 1.6 sec during startup sequence The transition complete input found to be shorted before compressor started Compressor current exceeded overload time Line voltage above 10% of nominal Line voltage below 10% of nominal Intermediate oil pressure transducer out of acceptable range for 15 sec, while delta pressure greater then 2.45bar. System differential pressure for respective circuit below 2.45 bar for more than 140 bar-sec System differential pressure for respective circuit was above 19.25 bar for two consecutive Oil temp of respective circuit, as supplied to compressors exceeded 93C for 2 consecutive samples or for more then 10 seconds MP received fault signal from condenser fan Variable speed inverter drive and cant clear the fault The liquid level sensor is near low end of range for 80 continuous minutes while compressor is running

Action

Check power supply

19C 19E

Phase loss (compressor)

Check power supply

1A0 1A2 1B2 1B4 1E9 1EB 1ED 1EF 1F1 1F3 5AC 5AE B EC BC D7 D8 198 19B 1AE 1AF 1C6 1C7 1DD 1DF

Power loss (compressor)

Check power supply

Severe Phase Unbalance (compressor) Starter fault type 1 (compressor) Starter fault type 2 (compressor) Starter fault type 3 (compressor) Transition complete input shorted (compressor) Overload trip (compressor) Over voltage Under voltage Low oil flow (compressor)

Check power supply

Check contactors Check contactors Check contactors

Check compressor Check power supply Check power supply Check pressure transducers

Low differential refrigerant pressure High differential refrigerant pressure

High oil temperature

2A1 5B5 583 5B6

Condenser fan VSD fault

Check speed inverter Check fans Check refrigerant Check expansion valve operation Check liquid level sensor

Low evaporator liquid level

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 24 of 26

Temperature Control Manual Air Cooled Chillers

Problem

584 5B7 High evaporator liquid level

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Possible Cause

The liquid level sensor is near high end of range for 80 continuous minutes while compressor is running Input signal out of range (low / high or bad LLID)

Action

Check expansion valve operation Check liquid level sensor This info diagnostic will auto reset if input returns to normal range Check signal Change setting to front panel setpoint This info diagnostic will auto reset if input returns to normal range Check signal Change setting to front panel setpoint Run water pump until the diagnostic Auto resets Auto reset occurs when temp rises 1.1C above cutout for 2 mins. Check flow Check flow safety Check flow Check flow safety Reset the clock Check battery

87

External chilled water set point

89

External current limit set point

Input signal out of range (low / high or bad LLID) Leaving chilled water temp fell below leaving water temp cutout set point (chiller stopped) Chilled water temp fell below cutout set point while compressor running Evaporator water flow was not detected within 4.25 mins of unit being started Chilled water flow switch input open for more than 6-10 continuous seconds The real time clock had an error

C5 C6 384 ED 2E6

Low chilled water temp: unit off Low chilled water temp: unit on Evaporator water flow overdue Evaporator water flow lost Check Clock

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 25 of 26

Temperature Control Manual Air Cooled Chillers

4 ELECTRICAL

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The following schematics are based on the latest supply of the fluid pumps (3l/s, 10l/s, 30l/s, 50l/s, 75l/s and 100l/s)

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Page 26 of 26

Temperature Control Manual Air Cooled Chillers

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Chiller capacity

50 kw 157 kw 200 kw 500 kw 600 kw 1300 kw 1500 kw

Fluid pump 3 l/s 10 l/s 10 l/s 30 l/s 30 l/s 75 l/s 75 l/s

TC Manual Air Cooled Chillers.doc

Aggreko Australia Pacific

Vous aimerez peut-être aussi

- TC Manual Water Cooled ChillersDocument24 pagesTC Manual Water Cooled Chillersvickers100% (1)

- Fdocuments - in J An e Hall Screw Compressor Model 4200 o and M ManualDocument86 pagesFdocuments - in J An e Hall Screw Compressor Model 4200 o and M Manualshazil shaikPas encore d'évaluation

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideD'EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuidePas encore d'évaluation

- Manual de Servicio Compresores Danfoss TurbocorDocument252 pagesManual de Servicio Compresores Danfoss TurbocorRobinson Jimenez100% (2)

- Torres Enfr EvapcoDocument98 pagesTorres Enfr Evapcolaherrans100% (1)

- SMARDT Catalogue TW ClassWaterCooled-En WebDocument7 pagesSMARDT Catalogue TW ClassWaterCooled-En WebBrunoWelterPas encore d'évaluation

- STULZ C7000R 57 1212 enDocument116 pagesSTULZ C7000R 57 1212 enJim JonesjrPas encore d'évaluation

- Brochure For York ChillerDocument8 pagesBrochure For York ChillervenkatearPas encore d'évaluation

- BE YMC2 Operationsandmaintenance BDocument136 pagesBE YMC2 Operationsandmaintenance BJosePas encore d'évaluation

- CIF-15 Data Converter Service ManualDocument30 pagesCIF-15 Data Converter Service ManualBernardo GermanPas encore d'évaluation

- Absorption Chiller Operation ManualDocument58 pagesAbsorption Chiller Operation ManualmohamadPas encore d'évaluation

- Dectron DSV Series CatalogDocument4 pagesDectron DSV Series Catalogbluemojo0% (2)

- GEA Grasso V Series: Reciprocating Compressors For Industrial RefrigerationDocument12 pagesGEA Grasso V Series: Reciprocating Compressors For Industrial RefrigerationHarsha Vardhan BPas encore d'évaluation

- E-Link Gateway: Installation InstructionsDocument26 pagesE-Link Gateway: Installation InstructionsAnonymous mPbkM4vrFlPas encore d'évaluation

- Rooftop TraneDocument108 pagesRooftop TraneJuan Andres ArenasPas encore d'évaluation

- Ucm-Cld Operating and Control Principles: L IM EDocument28 pagesUcm-Cld Operating and Control Principles: L IM EhanamanPas encore d'évaluation

- Technical Information: C S ™ D S R CDocument17 pagesTechnical Information: C S ™ D S R Cfrigoremont100% (1)

- York 2018 Line CardDocument2 pagesYork 2018 Line CardNPUIUPas encore d'évaluation

- Daikin McQuay. Centrifugal Chiller Dual Compressor WDC, TDC, HDC 087. Replacement Parts List No Revision K 11 - 2016Document126 pagesDaikin McQuay. Centrifugal Chiller Dual Compressor WDC, TDC, HDC 087. Replacement Parts List No Revision K 11 - 2016SBD AtkinsPas encore d'évaluation

- RTACDocument60 pagesRTACThukhoadaihocla Ta100% (1)

- SMC 104 106 108 InstructionManual - 2004 05 - EngDocument194 pagesSMC 104 106 108 InstructionManual - 2004 05 - Engrodrigomalvon50% (2)

- Chiller 19XR PDFDocument72 pagesChiller 19XR PDFDaniPas encore d'évaluation

- CG SVU02D E4 - 0107 (Owner Manual)Document44 pagesCG SVU02D E4 - 0107 (Owner Manual)Vinod NairPas encore d'évaluation

- Refrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1Document44 pagesRefrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1James MurrayPas encore d'évaluation

- Chillers ModelosDocument52 pagesChillers ModelosVICTOR100% (1)

- 19XRV Catálogo ProdutoDocument92 pages19XRV Catálogo ProdutoMatheus Ribeiro Lemes100% (1)

- Heat MachineDocument216 pagesHeat MachinecachasbcnPas encore d'évaluation

- MaterialDocument37 pagesMaterialSrelonyPas encore d'évaluation

- Refrigeration Tech Student VersionDocument94 pagesRefrigeration Tech Student VersionAbdalhady JoharjiPas encore d'évaluation

- Chiller Carrier 30XA-400Document26 pagesChiller Carrier 30XA-400edwin ramirezPas encore d'évaluation

- Carel 1tool Guidelines EngDocument13 pagesCarel 1tool Guidelines Englakshman_ksrl100% (1)

- Model YK (Style H) Centrifugal Liquid ChillersDocument56 pagesModel YK (Style H) Centrifugal Liquid ChillersAbdulSattarPas encore d'évaluation

- Condensador Evaporativo KrackDocument20 pagesCondensador Evaporativo KrackFederico RamellaPas encore d'évaluation

- Parts Coalescer 01Document2 pagesParts Coalescer 01Ranjit PaulPas encore d'évaluation

- C0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFDocument20 pagesC0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFNhật Phong NguyễnPas encore d'évaluation

- 201.28-EG1Document56 pages201.28-EG1Time To Use BrainPas encore d'évaluation

- Acson Catalogue Air Handling Unit (1201)Document12 pagesAcson Catalogue Air Handling Unit (1201)William Ball50% (4)

- Trane RTAB Chiller O&MDocument32 pagesTrane RTAB Chiller O&Mlolo100% (2)

- Cgah Chiller IomDocument28 pagesCgah Chiller IomLuong Dao100% (2)

- TraneDocument68 pagesTranededdyPas encore d'évaluation

- BACnet Communication Interface (BCI-I)Document48 pagesBACnet Communication Interface (BCI-I)Rodrigo Lobos AguilarPas encore d'évaluation

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Trane Rtaa 322 - 3151Document32 pagesTrane Rtaa 322 - 3151trutleptPas encore d'évaluation

- Hdpsychart Generic ManualDocument87 pagesHdpsychart Generic Manualwalnasp1Pas encore d'évaluation

- 03-CCM09 - Instal-Operation Manual (A-07-19)Document20 pages03-CCM09 - Instal-Operation Manual (A-07-19)Vitor BuenoPas encore d'évaluation

- System Components: Global Chiller TrainingDocument22 pagesSystem Components: Global Chiller TrainingSyed Ali KhanPas encore d'évaluation

- UCM-CLD Set Up L80 - SB - 050 - EDocument9 pagesUCM-CLD Set Up L80 - SB - 050 - EEvgeniy MaslovPas encore d'évaluation

- McQuay (Plata)Document70 pagesMcQuay (Plata)Ana Gil Pinto Brás100% (2)

- Liebert Challenger 3000 With Liebert ICOM - Operation & Maintenance ManualDocument48 pagesLiebert Challenger 3000 With Liebert ICOM - Operation & Maintenance Manualluis100% (1)

- Carrier chiller-30XADocument12 pagesCarrier chiller-30XAamitbslpawar100% (1)

- 30HXY/HXC: Water-Cooled Screw ChillerDocument15 pages30HXY/HXC: Water-Cooled Screw ChillerJohn Soto100% (1)

- Day 1 E-Link Overview - Version 1Document271 pagesDay 1 E-Link Overview - Version 1Arshad MahmoodPas encore d'évaluation

- Yaep GZDocument36 pagesYaep GZMahmod King75% (4)

- Chiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingDocument7 pagesChiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingBogdan-iulian BalintPas encore d'évaluation

- TC Manual Air ConditionersDocument27 pagesTC Manual Air ConditionersvickersPas encore d'évaluation

- SCWM Midrange Self-ContainedDocument64 pagesSCWM Midrange Self-ContainedVirgilio Jr ArtajoPas encore d'évaluation

- PCU0610A - Chiller (Small)Document16 pagesPCU0610A - Chiller (Small)jeromeduytschePas encore d'évaluation

- PQT LG Lk-0525ccDocument229 pagesPQT LG Lk-0525ccGerardo Zamorano100% (2)

- 1905 - Carrier 30 GZ 190 PDFDocument6 pages1905 - Carrier 30 GZ 190 PDFbilal almelegyPas encore d'évaluation

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootPas encore d'évaluation

- Danfoss Facts Worth Knowing About ACDrivesDocument208 pagesDanfoss Facts Worth Knowing About ACDrivesvickersPas encore d'évaluation

- Thermal Applications CategoryDocument19 pagesThermal Applications CategoryvickersPas encore d'évaluation

- Chillers and Heat Pumps Control-EngDocument4 pagesChillers and Heat Pumps Control-EngvickersPas encore d'évaluation

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 pagesASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Danfoss Banana Ripening Application BrochureDocument6 pagesDanfoss Banana Ripening Application BrochurevickersPas encore d'évaluation

- Chilled Beam Design GuideDocument46 pagesChilled Beam Design GuiderjchpPas encore d'évaluation

- Sanyo ScrollDocument24 pagesSanyo Scrollworker359567Pas encore d'évaluation

- Frequency of Maintenance TestingDocument5 pagesFrequency of Maintenance TestingIsmael AhmedPas encore d'évaluation

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 pagesReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersPas encore d'évaluation

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersPas encore d'évaluation

- Refrigerant Charge CalculatorDocument1 pageRefrigerant Charge CalculatorBala Krishna GallaPas encore d'évaluation

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 pagesDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersPas encore d'évaluation

- Copeland Scroll Designation 2005Document1 pageCopeland Scroll Designation 2005vickersPas encore d'évaluation

- Cypetherm SuiteDocument72 pagesCypetherm SuitevickersPas encore d'évaluation

- Temperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsDocument1 pageTemperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsvickersPas encore d'évaluation

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- CC - Quick Load CalculationsDocument2 pagesCC - Quick Load CalculationsvickersPas encore d'évaluation

- CC - Rapid Load Calculator PDFDocument1 pageCC - Rapid Load Calculator PDFvickersPas encore d'évaluation

- Comparative Table of ScrollsDocument11 pagesComparative Table of ScrollsvickersPas encore d'évaluation

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 pagesChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersPas encore d'évaluation

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersPas encore d'évaluation

- ZB Scroll Compressors ManualDocument70 pagesZB Scroll Compressors ManualJavier AffifPas encore d'évaluation

- Basics of HVACDocument119 pagesBasics of HVACUmar FarooqPas encore d'évaluation

- Supco TimersDocument7 pagesSupco Timersvickers100% (1)

- ThermostatCatalog 570-280Document12 pagesThermostatCatalog 570-280vickers0% (1)

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 pagesMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionPas encore d'évaluation

- Force & Pressure PPT-3Document11 pagesForce & Pressure PPT-3ARNAB GHOSH CLASS V100% (1)

- Inductor Loss Calcs VishayDocument12 pagesInductor Loss Calcs VishayealbinPas encore d'évaluation

- Calculation Algorithm PDFDocument11 pagesCalculation Algorithm PDFAnonymous zuM28o8IyNPas encore d'évaluation

- DCM 900 ManualDocument12 pagesDCM 900 ManualBhaveshPas encore d'évaluation

- FLD Rico Prasetiyo Retarder System AbnormalDocument1 pageFLD Rico Prasetiyo Retarder System AbnormalImam MaulanaPas encore d'évaluation

- Gas LawsDocument4 pagesGas LawsPrincess Joy Dilim KimayongPas encore d'évaluation

- HRSG - NDE Procedure For Pressure Part (China & Korea)Document502 pagesHRSG - NDE Procedure For Pressure Part (China & Korea)Sreekumar SPas encore d'évaluation

- Answer of Numerical AssignmentsDocument5 pagesAnswer of Numerical AssignmentsKiran GayakwadPas encore d'évaluation

- Overcurrent ProtectionDocument23 pagesOvercurrent ProtectiondaodoquangPas encore d'évaluation

- Transistor Blocking Oscillator Analysis : Summary-Two ADocument7 pagesTransistor Blocking Oscillator Analysis : Summary-Two AmcamhkPas encore d'évaluation

- Ace2 Inverter: User ManualDocument85 pagesAce2 Inverter: User ManualAdam Schwemlein100% (1)

- 219000179-Seperating and throttling-Final-Lab-ReportDocument12 pages219000179-Seperating and throttling-Final-Lab-ReportHerschelle ShongwePas encore d'évaluation

- Ebook LCD Best OneDocument125 pagesEbook LCD Best Oneananad addictPas encore d'évaluation

- 15 (Updated) Electric Fields 2022 - Tutor - Joy - Updated 23 JanDocument74 pages15 (Updated) Electric Fields 2022 - Tutor - Joy - Updated 23 JanJay Teng (Sajc)Pas encore d'évaluation

- Albert Einstein His Annus Mirabilis 1905Document19 pagesAlbert Einstein His Annus Mirabilis 1905lp456Pas encore d'évaluation

- Paper 15 PDFDocument23 pagesPaper 15 PDFRadhesh SharmaPas encore d'évaluation

- D 2283 - 86 R97 - RdiyodmDocument2 pagesD 2283 - 86 R97 - RdiyodmPrakash MakadiaPas encore d'évaluation

- Modelling of Pressure Losses in The Evaporative Emission SystemDocument58 pagesModelling of Pressure Losses in The Evaporative Emission SystemrajuhaveriPas encore d'évaluation

- Semiconductors Properties PDFDocument87 pagesSemiconductors Properties PDFKarthika SathishPas encore d'évaluation

- CLS Aipmt 18 19 XI Phy Study Package 4 SET 2 Chapter 15Document52 pagesCLS Aipmt 18 19 XI Phy Study Package 4 SET 2 Chapter 15Mridul Dhingra100% (2)

- Rotator Baltrotors GR30Document3 pagesRotator Baltrotors GR30Anonymous 80HAPYsoPas encore d'évaluation

- Physics Lab Manual Ohm'S Law: Exp. No: 1 Date: AimDocument54 pagesPhysics Lab Manual Ohm'S Law: Exp. No: 1 Date: Aimvenkatesh jothiPas encore d'évaluation

- Control Relay: NKG3 Time SwitchDocument2 pagesControl Relay: NKG3 Time SwitchRafatPas encore d'évaluation

- EMMI QuestionsDocument31 pagesEMMI QuestionsRAHULPas encore d'évaluation

- Lesson 3 (Componente Resistors)Document45 pagesLesson 3 (Componente Resistors)Jhella Ochoa JuacallaPas encore d'évaluation

- Read and Measure Temperature COTDocument57 pagesRead and Measure Temperature COTCyril Lyn Natividad Credo91% (11)

- Lennox Chiller Climatic KP02, KP07Document103 pagesLennox Chiller Climatic KP02, KP07Alex Cernea100% (1)

- Si Brochure Draft ch123 PDFDocument29 pagesSi Brochure Draft ch123 PDFJosuè Omar GuevaraPas encore d'évaluation

- LUCB1XBLDocument2 pagesLUCB1XBLAlex Ruben Alvarez GallardoPas encore d'évaluation

- Datasheet PWM PDFDocument38 pagesDatasheet PWM PDFEdnaelson SilvaPas encore d'évaluation