Académique Documents

Professionnel Documents

Culture Documents

Cleaner, Cheaper Liquid Fuel From Coal - MIT Technology Review

Transféré par

Demo OnlyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cleaner, Cheaper Liquid Fuel From Coal - MIT Technology Review

Transféré par

Demo OnlyDroits d'auteur :

Formats disponibles

Cleaner, Cheaper Liquid Fuel from Coal

A new conversion process promises zero carbon emissions during productionbut some question whether it will scale.

By Peter Fairley on January 6, 2012

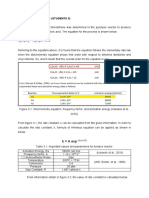

SRI International is developing a process that combines coal and natural gas to produce liquid transportation fuels that are substantially cleaner and cheaper to make than existing synthetic fuels. SRI claims its process addresses three liabilities that have slowed the commercialization of the technology. By blending some natural gas into the conventional coal-to-liquids (CTL) process, the private research lab, based in Menlo Park, California, claims to have eliminated CTLs carbon footprint, slashed water consumption by over 70 percent, and more than halved its capital cost. Chan Park, a gasification and synthetic fuels expert at the University of California, Riversides Center for Environmental Research & Technology, cautions that SRIs work is at an early stage. But Park says the process could be really exciting as a domestic alternative to petroleum fuel in coal and gas-rich countries such as the U.S.if it can be demonstrated at pilot scale. SRIs process is the fruit of a 2008 solicitation by the Pentagons Defense Advanced Research Projects Agency (DARPA) seeking a cheap, carbon-free CTL process for producing jet fuel. DARPA awarded SRI $1,612,905 to pursue a novel concept: using methane from natural gas as a hydrogen source instead of water in a new CTL process. Conventional CTL plants blend pure oxygen, steam, and coal at high temperatures and pressures, generating carbon monoxide and hydrogen gas that can be catalytically combined to synthesize liquid hydrocarbon fuels. The gasification also generates carbon dioxide, partly from the combustion of some coal with the pure oxygen, and partly through undesirable reactions between water and carbon. In SRIs process, methane preheated to 600 C displaces much of the water required, thus reducing the unwanted reaction with the coal. The methane also reduces the amount of heat absorbed by the gasification process, eliminating the need for oxygen and combustion to maintain the 1,400 to 1,500 C temperatures the process requires. As a result SRI says it can eliminate the use of oxygen-fired combustion that the process requires, making do with zero-carbon renewable or nuclear power instead. Skipping oxygen not only eliminates a source of carbon dioxide, but contributes substantial cost savings by eliminating the need for an oxygen plant. Further savings are achieved through more efficient fuel synthesis.

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Biology 12 - Collision Thoery Gizmo QuizDocument5 pagesBiology 12 - Collision Thoery Gizmo QuizMinPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Sop Drilling Peer ReviewedDocument51 pagesSop Drilling Peer ReviewedErland Prasetya67% (3)

- Full ThesisDocument90 pagesFull ThesisKrishna DangiPas encore d'évaluation

- Success in Science P2Document103 pagesSuccess in Science P2Nelson Muchindikeniko Phiri80% (5)

- C7 Matrix AcidizingDocument73 pagesC7 Matrix AcidizingNguyễnTrường100% (1)

- Pyrophoric Ignition Hazards in Typical Refinery OperationsDocument16 pagesPyrophoric Ignition Hazards in Typical Refinery Operationssb309uchPas encore d'évaluation

- GL Principles and Practice of PET-CT Part 2Document166 pagesGL Principles and Practice of PET-CT Part 2Alejandra CorkPas encore d'évaluation

- Fire TriangleDocument14 pagesFire TrianglesikatogusPas encore d'évaluation

- Organic Student SmallDocument64 pagesOrganic Student SmallJeffery GanskiPas encore d'évaluation

- Equilibrium Multiple Choice ReviewDocument33 pagesEquilibrium Multiple Choice ReviewXUPas encore d'évaluation

- 7WSWvw27eqsko1Xlz6AZLqr 02942KyM PDFDocument32 pages7WSWvw27eqsko1Xlz6AZLqr 02942KyM PDFDemo OnlyPas encore d'évaluation

- Datasheet QNAP TS-x31 x21 x12 NAS ENG v1 PDFDocument48 pagesDatasheet QNAP TS-x31 x21 x12 NAS ENG v1 PDFDemo OnlyPas encore d'évaluation

- Unit Types Sentosa West Residence PDFDocument13 pagesUnit Types Sentosa West Residence PDFDemo OnlyPas encore d'évaluation

- Menteng Village E-Brochure - Compressed PDFDocument15 pagesMenteng Village E-Brochure - Compressed PDFDemo OnlyPas encore d'évaluation

- High Sierra PDFDocument260 pagesHigh Sierra PDFDemo OnlyPas encore d'évaluation

- Brochure PDFDocument29 pagesBrochure PDFDemo OnlyPas encore d'évaluation

- Investment EBrochure Sentosa West Residence PDFDocument11 pagesInvestment EBrochure Sentosa West Residence PDFDemo OnlyPas encore d'évaluation

- E Brochure YarraDocument19 pagesE Brochure YarraDemo OnlyPas encore d'évaluation

- Ip Camera/Nvr Management System: Camera Models: Aircam, Aircam Dome, Aircam Mini NVR Model: Airvision-CDocument9 pagesIp Camera/Nvr Management System: Camera Models: Aircam, Aircam Dome, Aircam Mini NVR Model: Airvision-CDemo OnlyPas encore d'évaluation

- XADO-Catalogue 2013 en WebDocument84 pagesXADO-Catalogue 2013 en WebDemo OnlyPas encore d'évaluation

- Rv180 VPN RouterDocument187 pagesRv180 VPN RouterDemo OnlyPas encore d'évaluation

- Nuc Kit D54250wyk Product BriefDocument4 pagesNuc Kit D54250wyk Product BriefDemo OnlyPas encore d'évaluation

- 26 Elizabeth Street, South Perth, WA 6151: Character & CharmDocument2 pages26 Elizabeth Street, South Perth, WA 6151: Character & CharmDemo OnlyPas encore d'évaluation

- 34 Tully Road, East Perth, WA 6004: This Beautiful Home Presents As New!Document2 pages34 Tully Road, East Perth, WA 6004: This Beautiful Home Presents As New!Demo OnlyPas encore d'évaluation

- Gpsmap 76Csx: Mapping Gps With Sensors Owner'S ManualDocument0 pageGpsmap 76Csx: Mapping Gps With Sensors Owner'S ManualDemo OnlyPas encore d'évaluation

- Excavation Trenching Procedure V1 0Document11 pagesExcavation Trenching Procedure V1 0Demo OnlyPas encore d'évaluation

- Gpsmap: Mapping Gps Quick Reference GuideDocument2 pagesGpsmap: Mapping Gps Quick Reference GuideDemo OnlyPas encore d'évaluation

- 19 Victoria Street, South Perth, WA 6151: Vogue, Contemporary, StyleDocument2 pages19 Victoria Street, South Perth, WA 6151: Vogue, Contemporary, StyleDemo OnlyPas encore d'évaluation

- It Is Time To Clean Up Coal ExtractionDocument2 pagesIt Is Time To Clean Up Coal ExtractionDemo OnlyPas encore d'évaluation

- Gpsmap 76Cx: Mapping Gps Owner's ManualDocument0 pageGpsmap 76Cx: Mapping Gps Owner's ManualDemo OnlyPas encore d'évaluation

- Volvo Construction Equipment Matris ReportDocument16 pagesVolvo Construction Equipment Matris ReportDemo Only100% (1)

- Excavation and Trenching - Policies and Procedures - Environmental Health and Safety - Finance Operations - UND - University of North DakotaDocument20 pagesExcavation and Trenching - Policies and Procedures - Environmental Health and Safety - Finance Operations - UND - University of North DakotaDemo OnlyPas encore d'évaluation

- Harvard Coal Report SummaryDocument8 pagesHarvard Coal Report SummaryDemo OnlyPas encore d'évaluation

- Kaplan Small Scale Geothermal Power Plants With Less Than 5.0 MW CapacityDocument8 pagesKaplan Small Scale Geothermal Power Plants With Less Than 5.0 MW CapacityDemo OnlyPas encore d'évaluation

- Excavation TrenchingDocument11 pagesExcavation Trenchingharry.anjh3613Pas encore d'évaluation

- Gpsmap 76Csx: Mapping Gps With Sensors Owner'S ManualDocument0 pageGpsmap 76Csx: Mapping Gps With Sensors Owner'S ManualDemo OnlyPas encore d'évaluation

- Gpsmap 76Cx: Mapping Gps Owner's ManualDocument0 pageGpsmap 76Cx: Mapping Gps Owner's ManualDemo OnlyPas encore d'évaluation

- Excavation Trenching Procedure V1 0Document11 pagesExcavation Trenching Procedure V1 0Demo OnlyPas encore d'évaluation

- Excavation and Trenching - Policies and Procedures - Environmental Health and Safety - Finance Operations - UND - University of North DakotaDocument20 pagesExcavation and Trenching - Policies and Procedures - Environmental Health and Safety - Finance Operations - UND - University of North DakotaDemo OnlyPas encore d'évaluation

- Lab Hesss Law MgoDocument4 pagesLab Hesss Law MgoWillow QuinnPas encore d'évaluation

- Ipa Acetone KineticsDocument6 pagesIpa Acetone Kineticsbobcruise2k2Pas encore d'évaluation

- 2012 H2 Chemistry Mock P3Document6 pages2012 H2 Chemistry Mock P3Michael LinPas encore d'évaluation

- Chemistry Full Set-September-FullsetDocument40 pagesChemistry Full Set-September-FullsetAbhiPas encore d'évaluation

- Acids and Bases YMS X ALJDocument9 pagesAcids and Bases YMS X ALJFaqihah Syahindah Mohammed FiroozPas encore d'évaluation

- General ChemistryDocument34 pagesGeneral ChemistryTrixie HicaldePas encore d'évaluation

- Graffius 2014Document11 pagesGraffius 2014yurdanurturkerPas encore d'évaluation

- Student 3 Stage 2 UpdateDocument10 pagesStudent 3 Stage 2 UpdateMeck LotfiPas encore d'évaluation

- Parjanya Kumar Shukla Dr. Amita VermaDocument23 pagesParjanya Kumar Shukla Dr. Amita VermaPrathiPas encore d'évaluation

- Class 11 Chemistry Notes 2023-24 8. Redox ReactionsDocument40 pagesClass 11 Chemistry Notes 2023-24 8. Redox ReactionsAyushi Shah100% (1)

- Local Charge Distributions, Electric Dipole Moments, and Local Electric Fields Influence Reactivity Patterns and Guide Regioselectivities in α‑Ketoglutarate-Dependent Non-heme Iron DioxygenasesDocument10 pagesLocal Charge Distributions, Electric Dipole Moments, and Local Electric Fields Influence Reactivity Patterns and Guide Regioselectivities in α‑Ketoglutarate-Dependent Non-heme Iron DioxygenasesJohnPas encore d'évaluation

- Karnataka 1st Puc Chemistry Annual Exam QP 2018 MandyaDocument2 pagesKarnataka 1st Puc Chemistry Annual Exam QP 2018 Mandyaswarnikakashyap26Pas encore d'évaluation

- Method of Preparing S Nitrofurfural DiacetateDocument8 pagesMethod of Preparing S Nitrofurfural DiacetateKarla VTPas encore d'évaluation

- 2022 SAC 2 Marking SchemeDocument12 pages2022 SAC 2 Marking SchemeNishita AroraPas encore d'évaluation

- Test 4 - Chemistry of ArenesDocument3 pagesTest 4 - Chemistry of ArenesElizabeth ProtoctisPas encore d'évaluation

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary EducationZo775 YoutubePas encore d'évaluation

- Decomposition of Hydrogen Peroxide Using Chemical and Catalytic Methods: A Reactor-Based ApproachDocument7 pagesDecomposition of Hydrogen Peroxide Using Chemical and Catalytic Methods: A Reactor-Based Approachchee huiyinPas encore d'évaluation

- ACS Catal., 2016, 6 (2), PP 873-877Document5 pagesACS Catal., 2016, 6 (2), PP 873-877ludoPas encore d'évaluation

- Backmixing in The Design of Chemical ReactorsDocument4 pagesBackmixing in The Design of Chemical ReactorsChristian CândidoPas encore d'évaluation

- RSM Two Year PDFDocument6 pagesRSM Two Year PDFmiliPas encore d'évaluation

- BiotransformationDocument3 pagesBiotransformationTarequl Islam NishadPas encore d'évaluation