Académique Documents

Professionnel Documents

Culture Documents

An Inexpensive and Quick Fluid Mechanics Experiment

Transféré par

barbara_ropeDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

An Inexpensive and Quick Fluid Mechanics Experiment

Transféré par

barbara_ropeDroits d'auteur :

Formats disponibles

..

laboratory )

AN INEXPENSIVE AND QUICK

FLUID MECHANICS EXPERIMENT

J.T. R YAN, R.K. W OOD, P.J. CRICKMORE

University ofAlberta

Edmonton, Alberta, Canada T6G 2G6

T

he fir st laboratory course in che mical engi-

neering at the University of Alberta is taught

to about seventy students in the first term of

t heir j unior year, and its primary objective is to

improve and develop the st udent s' writing skills.

They are re quired to write three reports. The first

two repor ts are each about ten pages in length and

deal with technical material which is fami liar to t he

student. Each of the first two experiments is per-

formed and t he reports written within a period of

two wee ks, and the corrected re ports are returned

to the st udents within another t wo weeks. The En-

gli sh construction and t he presentation of t he re-

port s are brut ally cri t icized by the academi c staff

responsible for t he course. The students then do a

st anda r d engi neering experiment and write t heir

third (hopefully r eadable) report.

The key to this approach is to present simple and

short experiments. Typicall y, the first two experi-

ments should each t ake less than t en minutes t o

complete. Quick exper ime nts have t he advantage of

conveying t o t he students that even though t he tech-

nical aspects are easy, descri bing them in clear, un-

derstandable English is often very difficul t .

For t he last six years t he first experi ment we have

used has been a computer simulat ion of a simple

concept that t he students should be able to under-

st and. Us ually, t he si mulated experiment is based

on a fundamental principle t hat was taught to t he

st udents in t he previous semest er, i.e., the vapor

pressure of water as a function of temperature . The

st udents run the program, specifying t he t empera-

ture, with the simulat or re t urning a slight ly inaccu-

rat e value of t he vapor pressure. Th e students are

asked to compare the si mulated vapor pressures

with t hose in t he st eam tables and those calculated

Copyr ight ChE Di vision ofASEE 1993

140

from a published correlation of vapor pressure and

te mperature. They then write a re port about the

simulated experiment.

Experience has taught us that both of the short

experiments should not be simulations si nce, if t hey

are, the st udents will write a simulated second r e-

por t. Their attitude seems to be, "If you don't t ake

t he exper iment seriously, why should we take t he

report ser ious ly?" Clearly, t his is not the objective of

t he course. So, we make t he second exper iment a

real experiment-but st ill quick.

One experiment that is simple and fas t is t he

filling and blowdown of a tank of air. In spite of

its simplicity, t his experiment is surprisingly rich in

its technical cont ent, involving ideal gas ther-

modynamics, unsteady state mat erial bala nces, and

simple fluid mechanics. All of t hese subj ects have

been covere d in t he preceding t erm or are being

taken concurrently with this course. A further

advant age is that t he complexity of the data analy-

sis can be adjusted t o accommodate t he t echnical

skills of the students.

EXPERIMENTAL EQUIPMENT AND PROCEDURE

Th e experiment consist s of two stages: 1) filling

the tank with air at about 90 psig and 70F, and 2)

emptyi ng the tank by venting t he compressed air to

the atmosphere. The equipment (shown in Figure 1)

J. T. Ryan is a professor and registered engineer. He has taught thermo-

dynamics, fluid mechanics, and process design for more than twenty-five

years.

R. K. Wood is professor of chemical engineering at the University of

Alberta. His recent teaching responsibilities, in addi tion to the introduc-

tory laboratory course, have involved process analysis, optimization,

dynamic modeling, and simulation. His research is concerned with digital

simulation of the dynamic and control behavior of process systems and

the computer control of distillat ion columns.

P. J. Crickmore is an associate professor of chemical engineering at the

University of Alberta. He received his BSc (Chemical Engineering), MSc

(Mathematics), and PhD (Chemical Engineering) degrees from Queen's

University, Kingston. Research areas include oil sands, coal and envi-

ronmental sampling, and remediation.

Chemical Engineering Education

cons ists of a modified 30-pound propane bottle and

a manifold mount ed at the top of t he bottl e. The

manifold has four nozzles, each of which is isolated

wit h a quick-acting ball valve. St andard 1/2-inch

copper tube and fittings are used for t he manifold.

The nozzles are brass plugs which have hol es dri lled

to diameters ranging fr om 1/ 16 to 7/64 inch. These

plugs are soldere d into the outlet of 1/2-inch unions

which are located above each of the ball valves.

While it is not required because of the limited air

supply pressur e, a relief valve is installed on the

tank for educational purposes. A cheaper alterna-

tive would be t o incorporat e t he r elief valve in t he

manifold. High-pressure air is supplied from t he

building service air through a flexibl e hose. Another

quick-acting ball valve is installed on t he tank at

t he hose connect ion.

The instrumentation consists of a fast response

t hermocouple , a pressure transducer, and associ-

ated signal conditioni ng equipment. The thermo-

couple is installed t hrough t he t ank wall. Since one

of t he objectives of t he experiment is to finish the

experi ment quickly, t he dat a-l ogging was done with

a microcomputer using an OPTO 22 int erface.

The experi mental procedure is straightforwar d:

With the pressure in the tank at atmospheric, close

valves (Vi - V4). Start logging the pressure and tem-

perature using a one-second sampling time. Open V5.

(2)

When it is combine d with the definit ions of hand u

for an ideal gas , t his equat ion can be us ed to solve

all the cases appr opri ate to this experiment . The

simplest case occurs if t he incoming kinetic energy

and the init ial mass of the syst em is neglected. Then

hi == u

2

(3)

If we assume constant heat capaciti es, then

T

2

==kT

j

(4)

141

Qcv+Lmj {hj+(t ~ +gZj}

= Lme{he +(t )v; +gZe }+W

cv

+ID2 {h2+(t ~ +gZ2 }

-ml{hI+(t )vi +gZI} ( 1)

When we apply t his equation to the filli ng of a tank,

neglecting the heat t ransfer, work, pot ential energy

changes, an d all kinet ic energy t erms except for t he

input, we get

FILLING THE TANK

This part of t he experime nt focuses pr imarily on

t he r modynamics. As it is usuall y present ed in ther-

modynamics texts, t he t heory for filli ng a tank with

an ideal gas is correct-but t he maj or assumption is

wrong. The st andar d assumption is that t he proces s

is adiabatic. When t he experiment is actually per-

formed, however, t he domin ant influe nce is the heat

t r ans fer, not t he thermodynamics. But , t he st udents

believe the textbooks and t heir professors-who also

believe t he textbooks!

Van Wylen and Sonntag' !' give the following equa-

t ion as the appropriate for m of the first law of ther-

modyn amics over a control volume for a uniform

state, uniform flow process:

The tank wi ll reach the supply pressure in about ten

seconds . Close V5 and open one or more valves in the

manifold. Th e pressure in the tank will reduce to

near atmospheric in about one minute, depending on

whi ch oalueis) is opened. At this time the data-log-

ging can be stopped or the experiment repeated.

The cost of t he equi pment is small (less than $100,

not counting t he instrumentation and microcom-

put er ), and the total shop time r equired for machin-

ing and wel ding is less than two hours. Our advice

is to purchase a new propa ne bottle an d have t he

propane relief valve removed upon purchase since

t his valve is extremely difficul t to remove . An enti re

class can perform t he experi ment in about two days

by using sche duled 15-minute t ime slots, so the in-

str umentation and dat a-logging computer can usu-

ally be borrowed.

High pressure

air supply

#30 propane

bottle

Figure 1.

V

1

<,

V V

4

Unions

3

E8

8l\ .

1/2" Quick acting

Cu pipe ball valves

Spring 1993

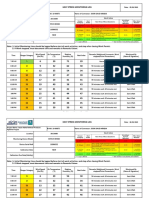

TABLE 1

Comparison of Exper imental and Calculated

Adiabatic, Final Air Temperatures

dm .

CIt = - m

N

(6)

Since t he volume of the system is constant and the

temperature is nearly constant, t he material equa-

tion for the air in the tank is

dm _ VCY dP (7)

CIt = RT <It

The mass flow rate of air through the nozzlets) is

m N =PNAN v N (8)

Provided that the air pressure in the t ank is above

the critical pressure required for sonic velocit y, the

velocity of the air t hrough the nozzle is equal to

v

N

= (kRT

N

) I/ 2 (9)

Th e different ial equation for the unsteady st at e ma-

terial balance reduce s to

v; dP _ ( )112

RT <It = - PNA N kRT

N

(10)

The trick is to convert, in a simple way, the ther-

modynamic variables evaluated at nozzl e conditions

Chemical Engi neeri ng Education

(5)

100F

315F

305F

355F

Approximate Final

Air Temperature

Met hod of

Det ermination

Experiment

Equation 4

Equation 2 (corrected for initial mass)

Equation 2

T _ p ( n- l j / n

To = Po

If the decompr ession is isothermal, n is equal t o

one. The pr ocess is isentropic when n =k. Th e value

of n is found from the slope of the line t hr ough the

measured pressure and temperature data when plot-

ted on log-log paper. Many st udent s use a regr es-

sion program t o est imate n from their data; how-

ever, we require the T versus P plot for educat ional

reasons. Using the equipment and procedure de-

scribed earlier, the typical exper imental value of n

was 1.04 0.005. Even though the temperature of

the air in the tank drops by approximately 85F, the

students conclude that the decompression process is

better approximated by an isothermal process than

by an ise ntropic one. This conclusion simplifies the

mathematics of the material balance. A more accu-

rate analysis is possible but is not worthwhile given

the intent of the course.

After the st udents have established t hat t he de-

compression process is approximately isothermal,

t he unsteady state material balance equation fol-

lows easily

where k == C

p

/ c. .

A better approximation of the final t emperature

can be made, a priori , by correcting for t he initial

mass of air in the tank. A further refinement can be

mad e, after t he experi ment, by incl uding an esti-

mat e of the incomi ng kinetic energy. Supposedly,

t he theory can be expanded or refined-however,

our objective is to introduce the st udent s to a simple

laboratory experiment and t o the difficulty of writ-

ing a technical r eport on such a simple experiment.

Table 1 shows a comparison of the measured final

temperature and those calculated from Eq . (2),

cor rected for both the initial mass and kinetic en-

ergy of the incoming air but still assuming no heat

transfer. The point to be mad e from t his table is

that all of the calculations are si mply wrong and

differ from the measurement by a minimum of ap-

pr oximat ely 200F.

As soon as the st udent s see the difference between

the theory taught in thermodynamics lectures and

t he results of t he experiment, they question the ex-

peri ment . There is sufficient time to do multiple

runs, but t hey find that the repeated experiments

produce virtually t he same results. The students

are faced wit h an experiment which has precision

but , in t heir minds, is of dubious accuracy. To ex-

plain the difference between the experiment and

t he temperature calculated from Eq. (4), many stu-

dent s do all the corrections indicated in Table 1.

They work hard to prove that the theory is right and

the experiment is wrong. Ultimately, they realize

Eqs. (2) and (4) are simply not t rue and are based on

a bad assumption, and finally they concl ude that

the process is not adiabatic and t hat the heat trans-

fer is t he domin ant effect. A typical value of the

heat trans fer is 14 - 18 Btu/cycle.

VENTING THE TANK

At this point the students are convi nced t hat ex-

peri ment s are worthwhile, but they are somewhat

ske ptical of t heory. Venting of t he tank is designed

to resolve this conflict for them. The venting of air

illust r at es t he polytropic decompression of an ideal

gas and an unsteady state material balance.

The relations hi p bet ween the te mperature and the

pressure of air in the tank, as it empties, must be

established before t he material balance is attempted.

Analysis of t he dat a is relatively simple and is cov-

ered in most introductory courses in engi neering

t he rmo dynamics. The decompression of t he ai r in

t he tank is taken to be a polytropic pr ocess. The

appropriate equation in terms of t he measured vari-

ables is

142

Time (sec)

Figure 2.

CONCLUSION

The experiment described in this paper is ideal

when the experiment requirements are a quick t urn-

around time, inexpensive equi pment, and flexible

technical content.

tion, shown below, is simple; however, it is valid

only until t he critical pr essure ratio is reached.

fn ( == - KI t (15)

Another tack would be to regard this equation

merely as t he basi s of a correlating equation. The

equation would be the same as Eq. (15) but have a

leading coefficient of K

2

, as

( 16)

The students are required to plot the ratio of the

measured pressure to the maximum pressure ver-

sus time on semi-logarithmic paper. They then com-

pare the slope of the line determined by t he data

and Eq. (14) and that predicted by Eq. (13).

A typical set of data taken by the staff, a regres-

sion line based on Eq. (16), and the theoretical pre-

diction from the solut ion of Eq. (15) are shown in

Figure 2. A nozzle with an internal diameter of 3/

32-inch was used. The empirical value of was

foun d to be 0.028 based on ten runs with a total of

462 data points. The value of'K, predicted by theory,

at the average temperature, was 0.027.

About 90% of the st udent s find that the difference

in the slope of the lines between theory and dat a is

5% or less. This difference is not st at ist ically signifi-

cant given the inaccuracies in measurement of the

nozzle diameters and the volume of the tank and

manifold. Surprisingly, the ot her 10% of students,

who predict differences of up to 200%, make the

mistake of using the wrong nozzlets ) or recording

the nozzle diameter(s) incorrectly. None of the stu-

dent s have difficulty with the mathematics, t hough

some think that Eqs. (14) and (16) apply even whe n

the velocity in the nozzle is subsonic.

NOMENCLATURE

A Area ; fe

h ent halpy; Btu/lb

K, cons t ant ; defined by Eq. ( 14)

cons tant; defined by Eq. ( 16)

ke kinetic energy; Btu/lb

m mass flow rate; lb/s

m mass of syste m; lb

n polytropic exponent

P pressure; psi a

Q rate of heat transfer; BTU/cycle

Cont inued on page 149.

70

60

50 40 30

- - Empirical K2 = 0.028

20 10

Limit for

sonic velocity

0.2

0.3

0.1

o

0.25

0.4

P

Po

0.5

0.6

to t hose measured in t he tank. The theory required

for t his transformation is full y develope d in most

mechanical engineering thermodynamics texts,

though not in many chemical engineeri ng texts. Our

students do not deal with compressible flow in lec-

ture courses unt il after the experiment. This prob-

lem is solved by simply stating that the thermody-

namic variables at t he nozzle can be evaluated at

tank conditions by applying a correction factor. Stu-

dent s seem to like correction factors. The two rela-

tionshi ps, shown below, are derived by Holman.!"

TN= T k 1 ( 11)

P = (12)

N k + 1

When the change in mass inventory is equated to

t he mass flow rate out of the nozz lers), the differen-

tial equation for t he pressure in the tank is

dP = _ AN(kRT)1/2(_ 2_ )( 2r

k

+-\>J p (13)

dt - V

cv

k + 1

Since t he students previously established that the

absolute temperature in t he tank is approximately

a constant, they can now write t his differential equa-

tion in a short form as

dP = - KIP (14)

dt -

where K

1

is the constant term in Eq. (13). The solu-

1.01 _-------- ----- - ------,

0.9

0.8 - - Theory K1=0.027

0.7

Spring 1993 143

Fluid Mechanics Experiment

Continued from page 143.

R gas constant; Bt ull b(R)

t time; s

u internal energy; Bt ull b

v velocity; ftis

V volume; ft3

W power input; BTU/cycle

p density; lb/ft"

Subscripts

cv control volume

e exiting air

incomi ng ai r

N nozzle

o t ime zero - valve opening

1 initial state

2 final st ate

REFERENCES

1. Van Wylen an d Sonntag, Fundamentals of Classical Ther-

modynamics, 3rd ed., SI Ver sion, J ohn Wiley, New York

(1985)

2. Holman, J.P., Thermodynamics, 4th ed., McGraw-Hili , New

York (1988) 0

REVIEW: Mass Transfer

Continued from page 126

st rongly recommended.

Chapter 17, on sorption processes, discusses fixed

bed adsorption and ion exchange. The presentat ion

on why loading and elution in ion exchange are not

symmetrical is particularly clear and easy to under-

stand. In general, t he authors assume that the reader

is familiar with these separation processes. Readers

who are not (par t icularl y elect rodialysis ) will find

these chapters difficult , but readers familiar with

the processes will gain deeper insight.

A third part of the book st arts with Chapter 18,

whi ch compares the M-S, Ficki an, and irreversibl e

thermodynamics approaches to mass trans fer. This

is a very enlight ening chapter, and sophisticate d

readers should re ad it following Chapter 2 or 3.

Chapt er 19 cites references. A rather complete list

of symbols starts on page 160. I found myself refer-

ring t o t hi s li st often and wish it were in a more

prominent location.

Th e fourth part of t he book consists of t hirty-six

wor ked exercises (pages 163 to 238) which consider

some very interesting and chall enging problems. Al-

though the solut ions are not polished, t hey are cer-

tainly sufficient to show how to attack the problems.

A major problem with this book is highlighted in

the Guidelines to the Reader on page 11: "This t ext

was written to accompany overhead transparencies

Spring 1993

The 1993 (maroon) revised printing of the

CHEMICAL RE A CTOR OMNIBOOK

is now out,

and it still costs $24.

Order at your bookstore,

or FAX your order and card number to

OSU Bookstores, Corvallis, OR at 503-737-3398

in a course on mult icomponent mass trans fer. So

the Figures are quite important. " Unfort unately,

many readers will not pay enough attention to this

section and will find reading t he book difficult until

they have learned t he proper way t o read it . Also,

since t he figures are hand drawn, t he reader needs

to learn how t o decipher t he authors ' script. The

inclusion of equat ion numbers would be useful. Some

of t he examples are confusing si nce t he problem

statements are not clear (e.g., Figure 6.2) and dat a

or formulas are sli pped into the solutions wit h little

explanation te.g., Figures 3.7 and 5.5). Stat ements

such as "Qualitat ively the reasoning shoul d be clear,"

(page 91) will unintenti onally demoti vat e readers

who are struggling, and they shoul d be removed.

The basic ideas of t he M-S approach are not sum-

mari zed until pages 64 and 65. A much earlier expo-

sition of t his would he lp many readers. Also, since

t he authors assume considerable fami liarity with

mass transfer, Chapter 18 coul d appear earlier in

the text. If a second edition is planned, the authors

could ai d readers by correcting t hese probl ems. One

hopes that t he authors will make t his effort si nce

t he book presents a very important t opic in a way

which will be accessibl e to most readers.

Where can t his book be used in t he curriculum?

The book is a curious mix of sophist icat ion (M-S

t heory and challengi ng problems) and of approxi ma-

ti ons (difference solutions and overly si mplified t her-

modynamics). Because of t he subject mat ter and t he

assumed high degree of knowledge in mass t rans fer

and separations, t his text is appropriate at the gr adu-

ate level. However, t he approximations and some

lack of rigor may cause difficult ies. It book would be

a very useful supplement in a graduate-level course,

part icul arly if journal articles are used in most of

the course. It is also a very good source of problems

and exa mples for a graduate-level course.

Finally, for pract icing professionals who mi ssed

the M-S t heory in their formal education, t his book

would be very useful for self study. Wesselingh and

Kri shna will st imulate and frust rate, but the reader

will never be bored. 0

149

Vous aimerez peut-être aussi

- UNIT - II Partial Differentiation 12 Hrs PDFDocument350 pagesUNIT - II Partial Differentiation 12 Hrs PDFbarbara_ropePas encore d'évaluation

- Degrees of Freedom in Dynamic and Static SystemsDocument8 pagesDegrees of Freedom in Dynamic and Static Systemsbarbara_ropePas encore d'évaluation

- Ways To Optimize The Energy Balance of Municipal Wastewater (Energía)Document7 pagesWays To Optimize The Energy Balance of Municipal Wastewater (Energía)barbara_ropePas encore d'évaluation

- Amundson's Matrix Method For Binary Distillation RevisitedDocument3 pagesAmundson's Matrix Method For Binary Distillation Revisitedbarbara_ropePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Multiphase Systems PDFDocument11 pagesMultiphase Systems PDFDicky HartantoPas encore d'évaluation

- Environmental PhysicsDocument63 pagesEnvironmental PhysicsNGOGA NISINGIZWE NESTOR100% (1)

- Capillary Tube For Refrigeration and Air Conditioning SystemsDocument3 pagesCapillary Tube For Refrigeration and Air Conditioning SystemsIjazzzAliPas encore d'évaluation

- Section 1.1.2 Thermal Conductivity of A GasDocument2 pagesSection 1.1.2 Thermal Conductivity of A GasGho VinsenPas encore d'évaluation

- PH, Ka, Pka and KW Exam Questions MarkschemeDocument3 pagesPH, Ka, Pka and KW Exam Questions Markscheme장채윤Pas encore d'évaluation

- Equipment, Design, and Installation OF Ammonia Mechanical Refrigeration SystemsDocument23 pagesEquipment, Design, and Installation OF Ammonia Mechanical Refrigeration Systemsdiro_shox0% (1)

- Air Separation PlantsDocument28 pagesAir Separation PlantsYan Laksana100% (2)

- Water Cooled ChillerDocument7 pagesWater Cooled ChillerKrishna MurariPas encore d'évaluation

- The Theory Behind Heat TransferDocument7 pagesThe Theory Behind Heat TransferselisenPas encore d'évaluation

- JAPL-F-En-018 Heat Stress Monitoring LogDocument6 pagesJAPL-F-En-018 Heat Stress Monitoring LogFarrukh IjazPas encore d'évaluation

- Chapter 7 ExergyDocument15 pagesChapter 7 ExergyBTS BURN THEIR TRASH TOO HARDPas encore d'évaluation

- 4th ChapterDocument25 pages4th ChapterMOHAMMAD SHOHEL RANAPas encore d'évaluation

- 1970 US Army Vietnam War Artillery Meteorology 321pDocument320 pages1970 US Army Vietnam War Artillery Meteorology 321pwwwsurvivalebookscom100% (1)

- Stack EffectDocument19 pagesStack EffectSourav Kanti Nath100% (1)

- Design & Construction of LiBr - H2O MachineDocument26 pagesDesign & Construction of LiBr - H2O MachineRana Abdul RehmanPas encore d'évaluation

- ME-204 - Slides Set# 05 (1st Law of Thermo)Document21 pagesME-204 - Slides Set# 05 (1st Law of Thermo)mamoona noreenPas encore d'évaluation

- EES Intro PDFDocument7 pagesEES Intro PDFAnonymous 4Gk3p5Pas encore d'évaluation

- Cooling Tower 6MWDocument6 pagesCooling Tower 6MWtedfdfePas encore d'évaluation

- Order Out of ChaosDocument191 pagesOrder Out of Chaosmaurcioen100% (2)

- CH en 3453 - HW 02 - 2014Document2 pagesCH en 3453 - HW 02 - 2014Dennis LingPas encore d'évaluation

- Heat and Mass Transfer Module 1 Lesson 2Document13 pagesHeat and Mass Transfer Module 1 Lesson 2cool kidPas encore d'évaluation

- Centrifugal CompressorsDocument47 pagesCentrifugal CompressorsKarim BenPas encore d'évaluation

- 2016-09-25 Refrigeration Engineering Syllabus PDFDocument5 pages2016-09-25 Refrigeration Engineering Syllabus PDFTy PhanPas encore d'évaluation

- 48 50P 7T Servicio Arranque Operacion y MantenimientoDocument252 pages48 50P 7T Servicio Arranque Operacion y MantenimientoRaymundo Rangel RdzPas encore d'évaluation

- User Com: Selection of The Heating RateDocument8 pagesUser Com: Selection of The Heating RateJosé FigueroaPas encore d'évaluation

- Hydraulic Engineering Assignment HelpDocument17 pagesHydraulic Engineering Assignment HelpEdu Assignment Help100% (1)

- Artech Cooling Towers Top Quality Cooling Tower 161202110226Document19 pagesArtech Cooling Towers Top Quality Cooling Tower 161202110226Raouia MaalemPas encore d'évaluation

- Iht PracticeDocument3 pagesIht PracticeJoselyn González PeñafielPas encore d'évaluation

- Me Ther - Act 5 Group2Document14 pagesMe Ther - Act 5 Group2ILAGAN ANNE FRANCINEPas encore d'évaluation

- HVACDocument11 pagesHVACDimeji OluwasegunPas encore d'évaluation