Académique Documents

Professionnel Documents

Culture Documents

Herzog HTP 40 60

Transféré par

As WandyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Herzog HTP 40 60

Transféré par

As WandyDroits d'auteur :

Formats disponibles

SAMPLE PREPARATION FOR X-RAY FLUORESCENCE

HTP 40 Pellet Press (left) Beside HSM 100 Grinding Mill (right)

HERZOG pellet presses offer the full benefits of program controlled pressing processes for the preparation of samples for x ray fluorescence analyses. Control by programmable controller results in a substantial improvement in the reproducibility of sample preparation, and consequently optimum analysis results. HERZOG hydraulic HTP 40 and HTP 60 pellet presses for preparation of samples for x ray fluorescence analysis are an essential part of the manufacturing process for stable pressed pellets. They possess all the characteristics required to guarantee the homogeneity and stability of each individual pellet. With the high press forces of 400 kN in the case of the HTP 40 and up to 600 kN with the HTP 60, a high compression is achieved, even with large sample diameters. The pressing processes performed by HERZOG pellet presses are controlled reliably by a PLC program. The result is a substantial improvement in the reproducibility of sample preparation , and consequently improved analysis results. Parameters of relevance to the pressing process, such as press pressure, rate of compression and pressure holding time, can be varied. They are controlled reliably through a program. The build-up and release of pressure during pressing are controlled such that inner stress within the sample are reduced. This ensures perfect pressing even of materials which in the past have proved difficult to press. The programmable controller eliminates improper handling or incorrect settings as a source of errors. The parameters can be accessed only through a password.

A swing-out cross head makes filling and cleaning of the die quick, simple and safe.

Precision press tools with a range of diameters And materials permit free pressing, pressing in Aluminum shells, and pressing in steel rings.

HERZOG pellet presses are fully encapsulated, insulated against noise, and have safety cut outs for operator protection. The dust and noise burden at the workplace is therefore reduced considerably, and the safety enhanced. HERZOG pellet presses are high-quality, precision engineering products with compact dimensions, and are therefore ideally suited to laboratory requirements.

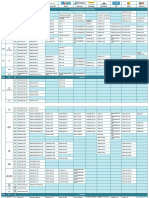

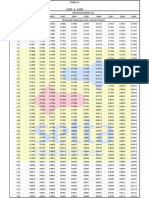

TECHNICAL DATA:

Available models: HTP 40: Maximum press pressure of 400 KN HTP 60: Maximum press pressure of 600 KN Dimensions: 550 x 620 x 1250 mm Weight : approx. 340 kg Electrical power supply and consumption: 400 V , 50 Hz, 3 phase, or other as required Neutral conductor not required Power consumption of approx. 1,9 kVA Electrical switchgear cabinet: Programmable controller SIMATIC Degree of protection : IP 54 Insulation class: B Control parameters: Pressure build up / pressure decrease Pressure holding time Press force Pneumatic supply: Not required Pressing process and pressing tools: Pressing in steel rings Pressing in aluminum shells Free pressing

A wide range of steel rings, aluminum shells and pressing tools are available

The design of the machines correspond to the current German accident prevention and VDE regulations. We reserve the right to make technical changes.

Vous aimerez peut-être aussi

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationD'EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationPas encore d'évaluation

- HALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionD'EverandHALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionPas encore d'évaluation

- BD 108 - Engine - 3110 - Ob2226659 - BDocument1 pageBD 108 - Engine - 3110 - Ob2226659 - Bopen hartigPas encore d'évaluation

- Computerised Wear Particle Atlas For Ferrogram and Filtergram AnalysesDocument7 pagesComputerised Wear Particle Atlas For Ferrogram and Filtergram AnalysesHARVY19Pas encore d'évaluation

- RD 215 - Engine - 3110 - Ob2226661 - NDocument1 pageRD 215 - Engine - 3110 - Ob2226661 - Nopen hartigPas encore d'évaluation

- CM 43-95Document4 pagesCM 43-95Batara L ToruanPas encore d'évaluation

- LK Series Metering Pump Instruction Manual: Five Boynton Road Hopping Brook Park Holliston, MA 01746 USADocument34 pagesLK Series Metering Pump Instruction Manual: Five Boynton Road Hopping Brook Park Holliston, MA 01746 USAEdgar NercarPas encore d'évaluation

- BHS LFK Pugmill Thompson Rock MixersDocument12 pagesBHS LFK Pugmill Thompson Rock MixersNarvaxisPas encore d'évaluation

- Kluberplex AG 11 462 eDocument2 pagesKluberplex AG 11 462 eseegna100% (2)

- Tabela de Similaridade de Lubrificantes Industriais DocxDocument4 pagesTabela de Similaridade de Lubrificantes Industriais Docxjulioebc2014100% (1)

- Manual InfraCal TOG TPH PDFDocument30 pagesManual InfraCal TOG TPH PDFEko Yudie Setyawan100% (1)

- Industrial Instrumentation ppt1Document22 pagesIndustrial Instrumentation ppt1Prashant ShahPas encore d'évaluation

- Four Ball Graxa - D2266-1Document3 pagesFour Ball Graxa - D2266-1Joel CunhaPas encore d'évaluation

- 628series NDocument510 pages628series NLaura MarcelaPas encore d'évaluation

- Tillage Planting SeedingDocument28 pagesTillage Planting SeedingdedidarmaandriansPas encore d'évaluation

- Komatsu PC 400Document1 pageKomatsu PC 400kingpin182Pas encore d'évaluation

- E925 09 2014Document7 pagesE925 09 2014Indra Aditama100% (1)

- Astm D1519-95Document4 pagesAstm D1519-95Júlio César PestanaPas encore d'évaluation

- Instruction Manual Multi-Parameter Testr 35 Series Parameter SetupDocument2 pagesInstruction Manual Multi-Parameter Testr 35 Series Parameter Setupcesar zolaPas encore d'évaluation

- Engine Oil Volatility Noack Evaporation MethodDocument5 pagesEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Tabela Oleo DieselDocument20 pagesTabela Oleo DieselIgor RossiniPas encore d'évaluation

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthPas encore d'évaluation

- 16899Document33 pages16899Edson BastoPas encore d'évaluation

- Flyer Sewage Sludge DryingDocument6 pagesFlyer Sewage Sludge Dryingkosmc123Pas encore d'évaluation

- Svan 953 Manual July 2007Document258 pagesSvan 953 Manual July 2007muhammad ramdhaniPas encore d'évaluation

- Catalog 2019 V 1Document190 pagesCatalog 2019 V 1somkiat kongprasiatPas encore d'évaluation

- Application Note Hardness Testing EnglishDocument12 pagesApplication Note Hardness Testing EnglishAnubhav LakhmaniPas encore d'évaluation

- OE AN41244 Steel Spark DAT Fe Advanced 0713Document4 pagesOE AN41244 Steel Spark DAT Fe Advanced 0713megacobPas encore d'évaluation

- BrochureSugarpress, EngDocument15 pagesBrochureSugarpress, EngAnibal RiosPas encore d'évaluation

- Model FXDocument2 pagesModel FXManuel100% (1)

- Iso 2271 1989Document8 pagesIso 2271 1989JOSEPH OMONDIPas encore d'évaluation

- Van Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001Document2 pagesVan Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001TienQuan DoPas encore d'évaluation

- Tool Operating Manual: Caterpillar 375T Track Press MaintenanceDocument36 pagesTool Operating Manual: Caterpillar 375T Track Press MaintenanceJhoncyto Borys100% (1)

- Ethanol 96Document1 pageEthanol 96Brilian WidiantoPas encore d'évaluation

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- Aviation Fuel Color and Particle Assessment PDFDocument1 pageAviation Fuel Color and Particle Assessment PDFgulfpipinggmailcomPas encore d'évaluation

- Sonic Scan DatasheetDocument4 pagesSonic Scan DatasheetChandravadanPas encore d'évaluation

- M21a PDFDocument188 pagesM21a PDFMandy NormanPas encore d'évaluation

- Astm D 445 - 03Document10 pagesAstm D 445 - 03Jako MishyPas encore d'évaluation

- Improving Calibration and Measurement Capability (CMC) of Psychrometer CalibrationDocument7 pagesImproving Calibration and Measurement Capability (CMC) of Psychrometer CalibrationMiguel Angel Pacahuala CristobalPas encore d'évaluation

- Bursting Strength Tester Type Mullen MTA-2000eDocument1 pageBursting Strength Tester Type Mullen MTA-2000eAndi FebriantoPas encore d'évaluation

- HydroPure Vesta Hydraulic Oils H (AW) SeriesDocument2 pagesHydroPure Vesta Hydraulic Oils H (AW) SeriesdnoaisapsPas encore d'évaluation

- Sat420 Felling Grapple: Satco SatcoDocument2 pagesSat420 Felling Grapple: Satco SatcoKornelius Gian FebritamaPas encore d'évaluation

- Astm C670 - 15.Document9 pagesAstm C670 - 15.wilson VANEGASPas encore d'évaluation

- Astm D1208 - 1 (En)Document3 pagesAstm D1208 - 1 (En)rezokaPas encore d'évaluation

- BS en 12823-1-2014Document20 pagesBS en 12823-1-2014Abdullah FouadPas encore d'évaluation

- Iodine Value of BeerDocument1 pageIodine Value of BeerLaura MarcelaPas encore d'évaluation

- D 3474 - 90 R97 Rdm0nzqtotbsotcDocument3 pagesD 3474 - 90 R97 Rdm0nzqtotbsotcHernan MartPas encore d'évaluation

- Komtrax: Instruction ManualDocument30 pagesKomtrax: Instruction ManualPMV DeptPas encore d'évaluation

- Smart Sensor 4 Gases AS8900 - Manual de OperaçãoDocument12 pagesSmart Sensor 4 Gases AS8900 - Manual de OperaçãoRogerioPascualPas encore d'évaluation

- New Coldbox BinderDocument8 pagesNew Coldbox BinderAnudatt A. Gowda100% (1)

- Astm A380 06Document1 pageAstm A380 06Nguyễn Duy Biên0% (1)

- ZA3000 07 SpecificationsDocument2 pagesZA3000 07 SpecificationsAnh Vương0% (1)

- As - 2853Document13 pagesAs - 2853jepri purwantoPas encore d'évaluation

- 2-SHG, HGC, HGC-VD - Manuel de Maintenance V1.0 ENDocument48 pages2-SHG, HGC, HGC-VD - Manuel de Maintenance V1.0 ENdungdhtsPas encore d'évaluation

- Herzog HP m100pDocument4 pagesHerzog HP m100pAs Wandy0% (1)

- HZ PB HSM HTP en PDFDocument4 pagesHZ PB HSM HTP en PDFomar rahmounPas encore d'évaluation

- Membrane Pilot Unit Labbrain V3: Technical Data Cfu-Labbrain-Ver3Document2 pagesMembrane Pilot Unit Labbrain V3: Technical Data Cfu-Labbrain-Ver3Gabriel Montoya CorreaPas encore d'évaluation

- Sejong HRC Tablet PressDocument12 pagesSejong HRC Tablet Pressrahman50% (2)

- Hyperformance Plasma Hpr130Document4 pagesHyperformance Plasma Hpr130jnmendes1Pas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Oregon200 DeclarationofConformityDocument1 pageOregon200 DeclarationofConformityAs WandyPas encore d'évaluation

- Herzog HP m100pDocument4 pagesHerzog HP m100pAs Wandy0% (1)

- Electrode Ovens PDFDocument1 pageElectrode Ovens PDFAs WandyPas encore d'évaluation

- SuperSting R8 IPDocument1 pageSuperSting R8 IPAs Wandy100% (1)

- JWMarin-Shipping & Dredging Division Rev0 Ver01Document4 pagesJWMarin-Shipping & Dredging Division Rev0 Ver01As WandyPas encore d'évaluation

- Katalog KingsDocument5 pagesKatalog KingsAs WandyPas encore d'évaluation

- 1960 Mower LearningtheoryDocument585 pages1960 Mower Learningtheoryfatty_mvPas encore d'évaluation

- Catalogo GreenfieldDocument24 pagesCatalogo GreenfieldTeodoroPas encore d'évaluation

- Hydraulics and Geotechnical TermsDocument4 pagesHydraulics and Geotechnical TermsAndrea RamirezPas encore d'évaluation

- 7 ODE 2nd Order v2Document3 pages7 ODE 2nd Order v2Agung GuskaPas encore d'évaluation

- HDPOps-ManageAmbari Docker GA Rev3Document485 pagesHDPOps-ManageAmbari Docker GA Rev3narsingthakurPas encore d'évaluation

- Accuracy Standards: and ISOIDocument4 pagesAccuracy Standards: and ISOIali_yy2003100% (1)

- 22 Oktober 2019 - EP UNPARDocument73 pages22 Oktober 2019 - EP UNPARGina AnindithaPas encore d'évaluation

- Stochastic ProgrammingDocument315 pagesStochastic Programmingfeiying1980100% (1)

- The Highlands Critical Resources and Teasured LandscapesDocument381 pagesThe Highlands Critical Resources and Teasured LandscapesYaqun CaiPas encore d'évaluation

- Erickson - 1981 - Secret Societies and Social StructureDocument24 pagesErickson - 1981 - Secret Societies and Social StructureRene PlascenciaPas encore d'évaluation

- Computer Graphics Lab Introduction To Opengl and Glut PrerequisitesDocument6 pagesComputer Graphics Lab Introduction To Opengl and Glut PrerequisitesNourhan M. NahnoushPas encore d'évaluation

- Davos ProgramDocument80 pagesDavos ProgramhamiltajPas encore d'évaluation

- Maths Assessment Year 3 Term 3: Addition and Subtraction: NameDocument4 pagesMaths Assessment Year 3 Term 3: Addition and Subtraction: NamebayaPas encore d'évaluation

- SCITECH - OBE SyllabusDocument12 pagesSCITECH - OBE SyllabusMary Athena100% (1)

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document92 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Shannon OpallaPas encore d'évaluation

- FusingDocument2 pagesFusingsusanta2uPas encore d'évaluation

- Loquendo TTS User GuideDocument73 pagesLoquendo TTS User GuideNakedCityPas encore d'évaluation

- 2016/2017 Master Timetable (Tentative) : Published: May 2016Document19 pages2016/2017 Master Timetable (Tentative) : Published: May 2016Ken StaynerPas encore d'évaluation

- ST - Lucia Seventh-Day Adventist Academy Physics Notes Form 5 October 18, 2016Document3 pagesST - Lucia Seventh-Day Adventist Academy Physics Notes Form 5 October 18, 2016Anna Lyse MosesPas encore d'évaluation

- Oracle Retail Invoice Matching 12.0 Defect Report: Bug Number: Severity: Functional Areas: Cross-Product ImpactDocument4 pagesOracle Retail Invoice Matching 12.0 Defect Report: Bug Number: Severity: Functional Areas: Cross-Product ImpactBali BalisPas encore d'évaluation

- 2nd Grading Examniation in MathDocument3 pages2nd Grading Examniation in MathearnestPas encore d'évaluation

- Image ClassificationDocument18 pagesImage ClassificationDarshna GuptaPas encore d'évaluation

- Significance Testing (T-Tests)Document3 pagesSignificance Testing (T-Tests)Madison HartfieldPas encore d'évaluation

- Naac Uma Maha PandharpurDocument204 pagesNaac Uma Maha Pandharpurapi-191430885Pas encore d'évaluation

- AA Metatron The Rays of Atlantian Knowledge and Rays of Healing Through Jim SelfDocument14 pagesAA Metatron The Rays of Atlantian Knowledge and Rays of Healing Through Jim SelfMeaghan Mathews100% (1)

- Zhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)Document465 pagesZhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)IrinaPas encore d'évaluation

- ELTJ (1990) Pyramid Discussions - JordanDocument9 pagesELTJ (1990) Pyramid Discussions - Jordanmariangoud100% (2)

- Ei GSM IcbDocument11 pagesEi GSM IcbwimaxaaabglPas encore d'évaluation

- Full HRM Notes by Ram Chad Ran SirDocument122 pagesFull HRM Notes by Ram Chad Ran SirKrupa PatilPas encore d'évaluation

- MQL For Traders PDFDocument129 pagesMQL For Traders PDFgorkemkebirPas encore d'évaluation