Académique Documents

Professionnel Documents

Culture Documents

Property of FRP Chart 1 PDF

Transféré par

Kurt FinkTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Property of FRP Chart 1 PDF

Transféré par

Kurt FinkDroits d'auteur :

Formats disponibles

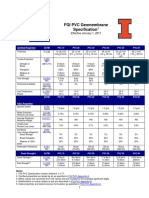

PROPERTY

Units

ATM Test Method

Glas

s Fiber

Speci

fic

Gravity

Densi

ty

lb./in

Tensil

e

Strength

3

Tensil

e

Modulus

6

Elon

gation

10 psi

10 psi

D638

D638

D638

Flexur

al

Strength

3

10 psi

Flexur

al

Modulus

Compre

ss

Strength

Impac

t

Strength

Flam

ma-bility

10 psi

10 psi

ft.lb/in

of notch

D790

D695

D256

UL-94

Speci

fic Heat

Ther

mal

Coeff of

Therm

al

Conduct.

Dielect

ric

Strength

BTU

/lb. oF

106 in./

in. oF

F at

264 psi

BTU/hr./

ft3/oF/in.

V/mil.

D696

D648

C177

Heat

Distortion

o

Water

Absorption

Mold

Shrinkage

in./in.

D149

% in 24

hrs.

D570

D790

D792

D955

24

1.74

0.063

11.5

1.70

2.5

28.5

1.32

20.0

20.8

0.30

14.0

400+

1.3

400

0.80

0.000

25

40

1.55

1.70

0.056

0.061

27.0

38.5

25.0

26.0

1.10

1.50

2.00

1.60

*

*

0.30

0.30

1.5

1.5

0.001

0.0005

16.0

0.30

400+

1.5

400

400

N/A

400

0.25

0.40

24.0

14.0

14.0

*

12.0

350+

400+

0.067

2.5

2.5

1.0

<1

18.0

23.0

1.85

1.80

2.25

2.10

1.70

25.0

32.0

30

13.5

21.5

23.0

12.0

0.20

0.001

22

50

0.064

0.072

1.70

2.27

6.00

1.75

1.53

2.50

0.4

1.7

0.4

0.5

0.5

---

21.2

45.0

71.0

12.8

12.7

30.0

1.40

2.00

4.00

1.58

1.44

1.60

12.0

19.4

1.5

1.5

500

--400+

1.5

1.5

1.5

400

375

N/A

200

250

350

0.20

0.50

0.13

0.50

0.50

0.50

0.001

0.0005

4.3

2.9

25.0

12.0

15.0

*

8.0

4.0

350+

500

20.0

--30.0

*

*

*

*

*

*

0.30

0.30

0.066

0.066

0.061

10.5

23.0

22.0

6.0

4.9

30.0

23.0

32.0

22

22

55

1.78

2.00

1.50

1.82

1.82

1.69

30

1.37

0.049

12.5

1.00

1.3

28.0

0.75

22.0

14.0

---

---

400+

---

300

0.50

0.002

50

1.64

0.059

37.0

2.25

1.6

46.0

2.25

37.0

33.0

V-0

0.23

---

400+

1.92

---

0.50

0.008

80

2.08

0.075

80.0

4.00

1.6

100.0

5.00

45.0

45.0

V-0

---

---

---

---

---

---

13

1.07

0.039

2.8

---

140.0

---

0.05

---

V-0

---

---

---

---

---

23

1.17

0.042

4.4

---

38.9

---

0.15

---

2.1

---

---

20

25

30

30

10

30

30

20

40

20

20

1.22

1.61

1.37

1.48

1.26

1.52

1.56

1.21

1.64

1.04

1.22

0.044

0.058

0.049

0.053

0.045

0.055

0.056

0.044

0.059

0.037

0.044

11.0

18.5

23.0

36.0

12.0

19.0

21.0

14.5

22.0

6.5

14.5

0.90

1.25

1.05

1.20

0.75

1.20

1.30

0.92

2.05

0.54

1.25

2.0

3.0

3.0

1.9

9.0

4.0

6.6

5.0

3.0

3.0

1.8

15.5

28.0

29.0

35.0

16.0

28.0

32.0

18.5

37.0

8.3

19.0

0.87

1.10

1.20

1.30

0.60

1.40

1.42

0.75

1.90

0.52

1.10

14.0

17.0

24.0

26.5

14.0

18.0

25.0

17.6

21.0

25.0

17.5

1.4

1.8

2.3

2.0

3.7

1.8

1.8

1.7

1.5

3.0

1.0

0.14

0.29

1.10

0.90

0.14

0.06

0.05

0.06

0.01

0.03

0.10

0.002

0.004

0.004

0.002

0.001

0.003

0.003

0.003

0.002

0.003

0.002

Fiberglass Reinforced

Thermosets

Polyester preform, low profile

(Compression)

general

purpose

high glass

Carbon/ Epoxy

fabric

Polyester SMC LP low profile

(Compression)

general

purpose

high glass

Carbon/ Vinyl Ester

Polyester BMC

(compression)

Polyester BMC

(injection)

Polyester

(pultruded)

Polyester

(spray-up, layup)

Polyester woven roving

(Layup)

Epoxy

(filament

wound)

Polyurethane, milled fibers

(RRIM)

glass flake

(RRIM)

Fiberglass Reinforced

Thermoplastics

ABS

Acetal

Nylon 6

Nylon 6/6

Polycarbonate

Polyester (PBT)

Polyester (PET)

Polyphenylene ether (PPO)

Polyphenylene sulfide

Polypropylene

SAN

* Polester thermosets can be formulated to meet a wide range of flame, smoke and toxicity specifications.

HB

HB

HB

HB

V-1

HB

HB

HB

V-0/5V

HB

HB

0.30

0.28

0.31

------0.30

0.29

0.11

--0.30

0.25

-----

21.0

47.0

17.0

13.0

18.0

12.0

17.0

20.0

11.0

24.0

21.0

220

325

420

480

300

430

420

310

510

295

215

1.4

--5.8-11.4

1.5

4.6

7.0

6.5

3.8

2.0

8.4

2.8

465

580

500

400

500

375

520

500

380

440

490

0.001

--0.003

Vous aimerez peut-être aussi

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanPas encore d'évaluation

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesD'EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerPas encore d'évaluation

- 17 - Glazing Tape PVC&EVADocument5 pages17 - Glazing Tape PVC&EVANibras RawnakPas encore d'évaluation

- A.L BH#1 D3Document22 pagesA.L BH#1 D3ISHTIAQ NOORPas encore d'évaluation

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsD'EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Plastic Specification Sheets Hayford PDFDocument78 pagesPlastic Specification Sheets Hayford PDFjesrcontreras1976Pas encore d'évaluation

- Drilling FormulasDocument87 pagesDrilling FormulasVeCoMo100% (1)

- LT DiffusersDocument8 pagesLT DiffusersJam OdonelPas encore d'évaluation

- Polypipe Gdy20 Pe2406/Pe2708 Gas Pipe: Other Dimensional Standards or Custom Requirements AvailableDocument2 pagesPolypipe Gdy20 Pe2406/Pe2708 Gas Pipe: Other Dimensional Standards or Custom Requirements AvailableAdam KnottPas encore d'évaluation

- FGI PVC Geomembrane Specification: Effective January 1, 2017Document3 pagesFGI PVC Geomembrane Specification: Effective January 1, 2017Paul Alex Quiroz BarrionuevoPas encore d'évaluation

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertPas encore d'évaluation

- Section 18 Design of Plastic Gears PDFDocument15 pagesSection 18 Design of Plastic Gears PDFSergio CandiottiPas encore d'évaluation

- Nylon 6 - 6 - Plastic ProductsDocument3 pagesNylon 6 - 6 - Plastic ProductsS.Mohana sundaramPas encore d'évaluation

- G19 - S8 - Plate and Frame Filter & Froth FloatationDocument7 pagesG19 - S8 - Plate and Frame Filter & Froth FloatationArya AgarwalPas encore d'évaluation

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkPas encore d'évaluation

- VDM Data Sheet Nicrofer 6025 HT - e PDFDocument0 pageVDM Data Sheet Nicrofer 6025 HT - e PDFeugenio.gutenbertPas encore d'évaluation

- Sag Moly CopDocument29 pagesSag Moly CopVolney Quispe Ayala100% (2)

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1Pas encore d'évaluation

- Heatron Compare Thick FilmDocument1 pageHeatron Compare Thick FilmAnonymous USblmd3Pas encore d'évaluation

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcPas encore d'évaluation

- HDPE 4710 FM Pipe SpecificationDocument2 pagesHDPE 4710 FM Pipe SpecificationJulio CongonaPas encore d'évaluation

- ESP Lesson 7 (Industrial Applications For Fabric Filters)Document24 pagesESP Lesson 7 (Industrial Applications For Fabric Filters)jkaunoPas encore d'évaluation

- GehepaDocument3 pagesGehepaAbdullah.N FAAliPas encore d'évaluation

- Technical Data Sheet: EPIKURE™ Curing Agent 3046Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3046Maha MuflehPas encore d'évaluation

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234Pas encore d'évaluation

- OL2 DatasheetDocument3 pagesOL2 DatasheetHimanshu UniyalPas encore d'évaluation

- Spiral Hose Guard: REF Length Wall ID OD Range Box WeightDocument2 pagesSpiral Hose Guard: REF Length Wall ID OD Range Box Weightviktor_gligorovPas encore d'évaluation

- Viscowrap-Ht: Product Data SheetDocument2 pagesViscowrap-Ht: Product Data SheetFarid HarisPas encore d'évaluation

- KIARATEX Technical Data Sheet Non Woven Prod SpecDocument1 pageKIARATEX Technical Data Sheet Non Woven Prod Specnw__ayPas encore d'évaluation

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosPas encore d'évaluation

- Co-Efficient of Friction Test Report: Test SR - No. Test Date Test Time Customer Name Customer Code Operator NameDocument11 pagesCo-Efficient of Friction Test Report: Test SR - No. Test Date Test Time Customer Name Customer Code Operator NameAshish PatelPas encore d'évaluation

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- GUARD-TYPE-II-Data-SheetDocument1 pageGUARD-TYPE-II-Data-SheetAlvi SarowarPas encore d'évaluation

- Perhitungan CT, Hydrant, Dan BlowerDocument13 pagesPerhitungan CT, Hydrant, Dan BlowerNicholas GeorgePas encore d'évaluation

- FRP Rebar Data SheetDocument2 pagesFRP Rebar Data Sheetkevin smith100% (1)

- Air Compressor Details Rev.01Document2 pagesAir Compressor Details Rev.01ramsey222Pas encore d'évaluation

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanPas encore d'évaluation

- Desidn AopDocument73 pagesDesidn AopDavid LambertPas encore d'évaluation

- PLUMBING PPR-Pipe DesoDocument11 pagesPLUMBING PPR-Pipe DesoOwen Francis Arles MaongatPas encore d'évaluation

- 10.1515 htmp.1996.15.3.217Document6 pages10.1515 htmp.1996.15.3.217Thinishaa NishaaPas encore d'évaluation

- HDPE Double Side TextureDocument1 pageHDPE Double Side TextureArun Chandra BabuPas encore d'évaluation

- NTC Probe Ass K45Document14 pagesNTC Probe Ass K45brecoborPas encore d'évaluation

- HDPE Brochure (Lamson)Document6 pagesHDPE Brochure (Lamson)arkadjyothiprakashPas encore d'évaluation

- PWC - Water Cooled Packaged UnitsDocument12 pagesPWC - Water Cooled Packaged UnitsSameera LakmalPas encore d'évaluation

- ทล.-ก. 407 Specification for Polymer Modified Asphalt Cement for Porous Asphalt ConcreteDocument1 pageทล.-ก. 407 Specification for Polymer Modified Asphalt Cement for Porous Asphalt ConcreteKongsak AkkharawongwhatthanaPas encore d'évaluation

- Salamat-1 Mud Report 53-27092012Document4 pagesSalamat-1 Mud Report 53-27092012mega87_2000100% (1)

- CSP SMC 40774 Data Sheet 2012 PDFDocument1 pageCSP SMC 40774 Data Sheet 2012 PDFMarioni Antonio HerreraPas encore d'évaluation

- Tunnel DryerDocument15 pagesTunnel Dryerمحمد العراقيPas encore d'évaluation

- Geotextile FIBERTEXDocument2 pagesGeotextile FIBERTEXdanfaurPas encore d'évaluation

- Plain Elastodec BrochureDocument6 pagesPlain Elastodec BrochureaomareltayebPas encore d'évaluation

- Price ListDocument8 pagesPrice ListKausik GhoshPas encore d'évaluation

- Salamat-1 Mud Report 54-28092012Document4 pagesSalamat-1 Mud Report 54-28092012mega87_2000Pas encore d'évaluation

- Doneldson Air Breather FilterDocument14 pagesDoneldson Air Breather FilterParinpa KetarPas encore d'évaluation

- TDS Flexalen600 Heating v1 EUDocument4 pagesTDS Flexalen600 Heating v1 EUmichel.cermenoPas encore d'évaluation

- How To Get Started Danfoss Compressors - BD SolarDocument12 pagesHow To Get Started Danfoss Compressors - BD SolarFEF777Pas encore d'évaluation

- Garware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, DensityDocument2 pagesGarware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, Densitybenghoe77100% (2)

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerPas encore d'évaluation

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnPas encore d'évaluation

- Phased Ps Wwith P Pap Tracking FormDocument3 pagesPhased Ps Wwith P Pap Tracking FormKurt FinkPas encore d'évaluation

- Combating Trafficking in Persons: Supplier Training GuideDocument16 pagesCombating Trafficking in Persons: Supplier Training GuideKurt FinkPas encore d'évaluation

- Ssfiles Tools FMEAScalesGuideDocument1 pageSsfiles Tools FMEAScalesGuideKurt FinkPas encore d'évaluation

- Navistar Integrated Supplier Quality RequirementsDocument29 pagesNavistar Integrated Supplier Quality RequirementsK FinkPas encore d'évaluation

- CSP Vendor Maintenance FormDocument4 pagesCSP Vendor Maintenance FormKurt FinkPas encore d'évaluation

- Property Compsrisons of Fiberglass Alt MaterialsDocument4 pagesProperty Compsrisons of Fiberglass Alt MaterialsKurt FinkPas encore d'évaluation

- Flat Sheet 1998 Document PDFDocument1 pageFlat Sheet 1998 Document PDFKurt FinkPas encore d'évaluation

- Accounting Test For April 2013 E-Team MeetingDocument4 pagesAccounting Test For April 2013 E-Team MeetingKurt FinkPas encore d'évaluation

- The SparkDocument1 pageThe SparkKurt FinkPas encore d'évaluation

- Egg Hatching Poster en 2015Document1 pageEgg Hatching Poster en 2015mahmudPas encore d'évaluation

- Manual Catia V5 R12Document262 pagesManual Catia V5 R12Leandro SebastiánPas encore d'évaluation

- A Presentation On PumpsDocument34 pagesA Presentation On PumpsSajjad Rasool ChaudhryPas encore d'évaluation

- Boge Up To 300kw - PDFDocument12 pagesBoge Up To 300kw - PDFparsmessengerPas encore d'évaluation

- WeldingDocument27 pagesWeldingankit4565Pas encore d'évaluation

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- 000 SP Pi02 0221Document10 pages000 SP Pi02 0221Samuel ValbuenaPas encore d'évaluation

- Ansi C84.1Document24 pagesAnsi C84.1jojagucaPas encore d'évaluation

- Experiment 1Document4 pagesExperiment 1Kathrine E. BautistaPas encore d'évaluation

- ScrewsDocument21 pagesScrewsRoh GadPas encore d'évaluation

- 2.9.4. Dissolution Test For Transdermal PatchesDocument3 pages2.9.4. Dissolution Test For Transdermal PatchesSandeep KumarPas encore d'évaluation

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaPas encore d'évaluation

- Biomedical Waste Rule 2016 ReviewDocument5 pagesBiomedical Waste Rule 2016 ReviewRakesh VermaPas encore d'évaluation

- 6 - Baker Hughes - Glen BengeDocument21 pages6 - Baker Hughes - Glen BengegeosedPas encore d'évaluation

- Electrodes, Rods and FluxesDocument37 pagesElectrodes, Rods and FluxesSchuldich Schwarz100% (1)

- Front Air Conditioner (2TR-FE, 2KD-FTV) : 268 HIACE (EWD622E)Document10 pagesFront Air Conditioner (2TR-FE, 2KD-FTV) : 268 HIACE (EWD622E)DanielPas encore d'évaluation

- Installation Manual - GRE PIPE - For Marine - Rev.2Document37 pagesInstallation Manual - GRE PIPE - For Marine - Rev.2HuongtrinhAkay100% (1)

- Research (Edible Cutlery)Document9 pagesResearch (Edible Cutlery)Reylsea MayPas encore d'évaluation

- Pyrolysis Presentation - PPTM (Autosaved) .PPTMDocument13 pagesPyrolysis Presentation - PPTM (Autosaved) .PPTMSoul LyricsPas encore d'évaluation

- Fired Heaters - Improving Energy Efficiency in FurnacesDocument2 pagesFired Heaters - Improving Energy Efficiency in FurnacesReyes SanchezPas encore d'évaluation

- Sheetmetal Design GuidelinesDocument5 pagesSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- III-1 & III-2 Specifications Volume 2Document588 pagesIII-1 & III-2 Specifications Volume 2saleem buksh100% (1)

- DNV OS D101 Machi Sys PDFDocument61 pagesDNV OS D101 Machi Sys PDFSaid Elhamydy100% (1)

- Dokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bDocument5 pagesDokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bjuane27Pas encore d'évaluation

- Bolts (Al Rashed Fastners) PDFDocument71 pagesBolts (Al Rashed Fastners) PDFAbu100% (1)

- Shalitape Flex: DescriptionDocument2 pagesShalitape Flex: DescriptionbarunPas encore d'évaluation

- Um DEDocument56 pagesUm DEalvaroPas encore d'évaluation

- ZCS300 ManualDocument24 pagesZCS300 ManualFabricio BorgattaPas encore d'évaluation

- Loose Gear InspectionDocument4 pagesLoose Gear InspectiondomsonengPas encore d'évaluation

- Voltaic Cell - Yale UniversityDocument4 pagesVoltaic Cell - Yale UniversityBelenPas encore d'évaluation