Académique Documents

Professionnel Documents

Culture Documents

Installation PDF

Transféré par

nikola5nikolicTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Installation PDF

Transféré par

nikola5nikolicDroits d'auteur :

Formats disponibles

GLASEI-00

FEATURES: ! Software driven, 8/12 bit microprocessorcontrolled digital signal processing (8 MHz) ! High energy, low frequency sound pressure pulse detection ! Full audio spectrum 7 frequency signal and impact analysis including infra-sound pressure analysis

INITIATING TEST MODE: (Refer to Fig. 2) Remove jumper J1. The red LED flashes. Replace jumper J1. The green LED illuminates for 4 seconds, followed by an intermittent flashing of the red LED. The detector now operates in "test" mode for about 4 minutes. It will automatically return to normal mode after this period. To cancel test mode, pull out and replace J1 again. CONDUCTING TESTS: Once in "test" mode, with the red LED flashing intermittently, move to the part of the protected surface furthest from the Glasstrek detector to conduct the test. Press and hold the "push" switch on the Testtrek until a full test tone is produced. The Glasstrek's green LED should respond to this tone. If the green LED does not respond to the test tone, the detector should be relocated. Testtrek checks the high audio frequency detection. Operation of the Glasstrek's infra-sound analysis capability is tested when it is in "test" mode. While green LED is "ON", carefully strike the protected surface with a cushioned tool. This will generate an alarm. Please note that the unit must be in "test" mode to conduct coverage tests. Glasstrek will not respond effectively to test signals if it is not set in "test" mode. For UL installations, unit must be connected to a listed control unit or power supply with a minimum 4hrs standby power. ****Following installation, Glasstrek should be retested at least once a year.

! 2-colour display of impact and spectrum analysis, alarm and test mode ! Digital RFI/EMI filtering, extremely high immunity ! Field test mode

! Unique acoustic microphone chamber and casing design ! High/low sensitivity settings ! Alarm latch mode

! Optional audio monitor output with alarm indication for event verification INSTALLATION LOCATION AND SENSITIVITY SETTINGS: A good location must be selected for optimal Glasstrek detection performance. Set the sensitivity setting (J2) to suit the acoustic environment where Glasstrek will be located. Remove the cover by pressing the opening pin (1) on the side of the detector. See Fig. 2 for the sensitivity jumper location. ! If the environment produces echoes, as when the walls and ceilings are concrete or metal, set the sensitivity jumper to LOW (jumper in) and only consider installation locations from 4 to 15ft from the protected glass. ! If the environment has damping materials such as drapes, carpets, furniture, set the sensitivity jumper to HIGH (jumper out) and consider installation locations from 4 to 30ft from the protected glass. Look for installation locations on the ceiling or walls adjacent or opposite to the protected glass. Do not use the wall housing the protected glass. Avoid proximity to noisy objects such as bells, fans, compressors and loud machinery. Determine the exact location and orientation of Glasstrek by making sure that the microphone side of the detector has a direct and unobstructed view of the protected glass and that the detector is positioned so that the protected glass lies within the optimal detection angle. If Glasstrek is on a wall opposite to the protected glass, this may affect the efficiency of detection if the glass to be protected is outside the optimal detection angle. See Fig. 1. INSTALLING GLASSTREK: (Refer to Fig. 2) 1) Remove the cover by pressing the opening pin (1) on the side of the detector. 2) Run the wires through one of the holes at the back or side openings of the case. 3) Connect the terminals. 4) Mount the detector in its location with a screw inserted into screw holes (2) and (3). 5) Replace the cover. 6) Test the Glasstrek. TESTING THE GLASSTREK 456: Verify detector operations in "test" mode with the Testtrek 1. Use of other testers is not recommended because only Testtrek is properly calibrated for use with the Glasstrek detector.

WARRANTY The Seller warrants its products to be free from defects in materials and workmanship under normal use for a period of one year. Except as specifically stated herein, all express or implied warranties whatsoever, statutory or otherwise, including without limitation, any implied warranty of merchantability and fitness for a particular purpose, are expressly excluded. Because Seller does not install or connect the products and because the products may be used in conjunction with products not manufactured by Seller. Seller cannot guarantee the performance of the security system. Seller obligation and liability under this warranty is expressly limited to repairing or replacing, at Seller's option, any product not meeting the specifications. In no event shall the Seller be liable to the buyer or any other person for any loss or damages whether direct or indirect or consequential or incidental, including without limitation, any damages for lost profits stolen goods, or claims by any other party, caused by defective goods or otherwise arising from the improper, incorrect or otherwise faulty installation or use of the merchandise sold.

Thank you for selecting the Glasstrek "glass break" detector, designed for professional security applications. Please follow the instructions in this manual carefully to optimize use of your Glasstrek detector, which has been 100% quality control tested to ensure proper operation and unit durability. Glasstrek's innovative Model 456 incorporates stateof-the-art audio frequency glass break detection and infra-sound impact analysis in its full spectrum. Model 456 can simultaneously recognize the low frequency signal generated when pressure is applied to glass surfaces in protected areas, as well as the characteristic sound created when glass is broken. The result of this dual analysis is virtually "false alarm free" glass break detection. Combine bilevel analysis with sensitivity adjustment and you've got Glasstrek 456, the most advanced glass break detector available on today's security market. APPLICATIONS: Glasstrek delivers effective coverage in the presence of plate, tempered, and laminated glass, without the need for special sensitivity adjustments. However, since optimal performance is dependent on secure, vibration-free mounting, there must be no play between the panes under surveillance and their framework. Glasstrek can be used in most protected areas, including rooms with blinds, curtains, or multiple windows, as long as careful coverage tests are conducted using Testtrek 1. Breakage in panes of glass 16" X 24" or larger will be detected, for every standard thickness of plate (1/8"-1/4") and tempered glass (1/8"-1/4"). Breakage in panes of glass 28" X 28" or larger will be detected for every standard thickness of laminated glass (1/8"-1/4"). Glasstrek detector should not be connected to 24 hour protection zones. Installation is not recommended in protected areas that contain any of the following: 1) windows with closed wooden interior shutters; 2) windows with insulated, lined, or sound-muffling drapes; 3) rooms with ceilings higher than 15' (if ceilingmounted); 4) rooms smaller than 10' X 10' where loud noise is common (due to use of kitchen appliances or stereo systems); 5) rooms where machinery noise is present (air compressors, etc.)

WARNING: Testtrek produces high sound pressure levels, and should never be pointed directly at the human ear. Keep at least 12" from the ear.

DISPLAY MODE: Normal mode: Red LED: 1) Intermittent flashing takes place upon recognition of high level attack signals. (Can be visually tested by clapping or knocking close to the detector.) 2) 4 second illumination if a glass break is detected when memory latch is "off" (Jumper J1 "in") 3) Continuous illumination upon detection of a glass break when memory latch is "on" (Jumper J1 "out") 4) 4 minute continuous flashing indicates unit is in "test" mode. Normal mode: Green LED: Will flash intermittently when spectrum analysis is in progress. This indicates that attack analysis has been successfully confirmed, and part of the frequency spectrum is valid. Test mode: See "Testing the Glasstrek" ALARM MEMORY: The Glasstrek is equipped with a latching circuit. When jumper J1 is removed, an alarm condition latches the red LED on. Only the LED is affected by the latching circuit. Alarm relay operation is not interrupted. The alarm relay remains open for three seconds when an alarm condition is reached. The LED can be reset in "latch" mode by replacing jumper J1 and removing it again, or by disconnecting and restoring power to the detector. USING AUDIO OUTPUT: (not UL tested) This output can be connected to any amplifier "aux" input, if you wish to monitor the sound in the protected area. A tone will be generated when the Glasstrek detects glass break conditions, indicating alarm status. (Use of coax cable will permit noise reduction).

Look for and marks on products. Only products bearing those marks are UL and ULC listed. ULC-listed in compliance with Standard S306: intrusion detection unit UL-listed in compliance with Standard 639: intrusion detection unit (ANSR)

Paradox Security Systems Graphic Dept - PRINTED IN CANADA - 11/98

Vous aimerez peut-être aussi

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationD'EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationPas encore d'évaluation

- Honeywell Fg1625 Install GuideDocument2 pagesHoneywell Fg1625 Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Honeywell Fg1625rfm Install GuideDocument2 pagesHoneywell Fg1625rfm Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Detector Geam Spart DSCDocument0 pageDetector Geam Spart DSCTibiPas encore d'évaluation

- GBD PlusDocument2 pagesGBD PlusseinnationalPas encore d'évaluation

- Glasstrek - UputstvoDocument2 pagesGlasstrek - UputstvoKimberly KennedyPas encore d'évaluation

- Honeywell Fg1625rfm Data SheetDocument2 pagesHoneywell Fg1625rfm Data SheetAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityDocument2 pagesLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaPas encore d'évaluation

- Bravo 5 Pir - Manual Instalare PDFDocument2 pagesBravo 5 Pir - Manual Instalare PDFDarie SilviuPas encore d'évaluation

- Ja 80pDocument1 pageJa 80pmjpjardimPas encore d'évaluation

- Bravo 2&3 Pir - Manual Instalare PDFDocument1 pageBravo 2&3 Pir - Manual Instalare PDFDarie SilviuPas encore d'évaluation

- Detector Quiebre Paradox DG-50Document2 pagesDetector Quiebre Paradox DG-50Pablo Garay NarváezPas encore d'évaluation

- XX930A1A1M12Document2 pagesXX930A1A1M12Yohn MartPas encore d'évaluation

- Honeywell Fg730 Install GuideDocument2 pagesHoneywell Fg730 Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- JS-25 COMBO" P.I.R. & Glass Break DetectorDocument2 pagesJS-25 COMBO" P.I.R. & Glass Break DetectorBatkhishig Tumen-OidovPas encore d'évaluation

- Honeywell IS2535 Install GuideDocument2 pagesHoneywell IS2535 Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Thermo Milton Roy Spectronic 501 601 ManualDocument24 pagesThermo Milton Roy Spectronic 501 601 ManualAlessandro MoreniPas encore d'évaluation

- DSC Lc105dgbDocument2 pagesDSC Lc105dgbImi Michał SmulskiPas encore d'évaluation

- Genius Plus: Electronic Engineering LTDDocument2 pagesGenius Plus: Electronic Engineering LTDpil;zoPas encore d'évaluation

- Designing The X-Ray Room and Dark RoomDocument11 pagesDesigning The X-Ray Room and Dark Roomimmortalneo100% (3)

- TEK-Mate: Operating ManualDocument14 pagesTEK-Mate: Operating ManualJoe ShoemanPas encore d'évaluation

- 100-110 WINdose System PI 031405Document2 pages100-110 WINdose System PI 031405bagasPas encore d'évaluation

- Instruction Manual: EnglishDocument22 pagesInstruction Manual: EnglishMilcaAlejandraCardosoPas encore d'évaluation

- Everspring Sm103 ManualDocument4 pagesEverspring Sm103 ManualLokanatha ReddyPas encore d'évaluation

- Single EOL Double EOL Tamper Proof Security System WiringDocument6 pagesSingle EOL Double EOL Tamper Proof Security System WiringpitigoiPas encore d'évaluation

- Newton: User ManualDocument10 pagesNewton: User ManualjuliocastPas encore d'évaluation

- Operating Manual Minidop ES-100VX Pocket DopplerDocument28 pagesOperating Manual Minidop ES-100VX Pocket DopplerJose Luis Merino FigueirasPas encore d'évaluation

- ULTRA SLIM Instruction ManualDocument7 pagesULTRA SLIM Instruction ManualWardaPas encore d'évaluation

- InstructionsDocument6 pagesInstructionsHamidPas encore d'évaluation

- FD705RVDS FD710RVDS Instrukcja Instalacji enDocument14 pagesFD705RVDS FD710RVDS Instrukcja Instalacji enb7246757nwldxcomPas encore d'évaluation

- IFU K0000663 ES Rev1.0Document16 pagesIFU K0000663 ES Rev1.0Nabaes BarraganPas encore d'évaluation

- Maestronano Pro Spectrophotometer: Instruction ManualDocument40 pagesMaestronano Pro Spectrophotometer: Instruction ManualYuriAlexanderEspinozaPugaPas encore d'évaluation

- TX5633 IOD-Vibration SensorDocument6 pagesTX5633 IOD-Vibration Sensorkiki270977Pas encore d'évaluation

- Manual Instalacion LC151 PDFDocument80 pagesManual Instalacion LC151 PDFGino GueAsPas encore d'évaluation

- IloudDocument24 pagesIloudd79d56h8g6Pas encore d'évaluation

- Ja-60B Wireless Glass Break Detector: SpecificationDocument2 pagesJa-60B Wireless Glass Break Detector: SpecificationDragus IonelPas encore d'évaluation

- Acer X193W Service Guide 20080320Document43 pagesAcer X193W Service Guide 20080320Victor FriasPas encore d'évaluation

- Honeywell Is2500lt Install GuideDocument2 pagesHoneywell Is2500lt Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- 269-3595 Smart Integrating SphereDocument20 pages269-3595 Smart Integrating SpherezhengzzPas encore d'évaluation

- 525d Manual Instalare Detector Paradox Cu MicroundeDocument2 pages525d Manual Instalare Detector Paradox Cu MicroundeGheorghiescu AndreiPas encore d'évaluation

- TOAD AI606 Install and ProgrammingDocument16 pagesTOAD AI606 Install and ProgrammingT HPas encore d'évaluation

- Daewoo DWC-054R Air ConditionerDocument20 pagesDaewoo DWC-054R Air ConditionerericPas encore d'évaluation

- Honeywell FG1625 Data SheetDocument2 pagesHoneywell FG1625 Data SheetAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Motion Sensor Light Control: OperationDocument12 pagesMotion Sensor Light Control: OperationHomer Sadych Henao MarinPas encore d'évaluation

- 01 - PTB - Data - Sheet (5 Files Merged) (13 Files Merged)Document27 pages01 - PTB - Data - Sheet (5 Files Merged) (13 Files Merged)bzivkovicPas encore d'évaluation

- Operators & Service ManualDocument18 pagesOperators & Service ManualdocumentshitPas encore d'évaluation

- Manuel PDFDocument57 pagesManuel PDFFrankSimonCristobalPas encore d'évaluation

- Gs Gene Linker Uv ChamberDocument19 pagesGs Gene Linker Uv ChamberEdgar Mendoza GarcíaPas encore d'évaluation

- 476 Plus Detector Miscare ParadoxDocument2 pages476 Plus Detector Miscare ParadoxsbloinazPas encore d'évaluation

- Ceiling Speaker System F-1522SC: Instruction ManualDocument8 pagesCeiling Speaker System F-1522SC: Instruction ManualYuwono WaluyoPas encore d'évaluation

- Ihome328 User Manual-USDocument21 pagesIhome328 User Manual-USAlex AlexiadisPas encore d'évaluation

- Honeywell IS216T CUR Install GuideDocument2 pagesHoneywell IS216T CUR Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Maintenance of Goniophotometer and Integrating SphereDocument3 pagesMaintenance of Goniophotometer and Integrating SphereLisun GroupPas encore d'évaluation

- NVX80 Ei00 PDFDocument20 pagesNVX80 Ei00 PDFZoltan MarosanPas encore d'évaluation

- 6.3.9 Test 16 Darkroom FogDocument2 pages6.3.9 Test 16 Darkroom FogKristine JavinesPas encore d'évaluation

- Takex DA-4800H Data SheetDocument2 pagesTakex DA-4800H Data SheetJMAC SupplyPas encore d'évaluation

- Honeywell 997 Install GuideDocument4 pagesHoneywell 997 Install GuideAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- XGT7000V ManualDocument69 pagesXGT7000V ManualthuronPas encore d'évaluation

- A e Specification Enus 2636468491ds1103idetectorderoturasmontajempotradoDocument2 pagesA e Specification Enus 2636468491ds1103idetectorderoturasmontajempotradoWalter TarcoPas encore d'évaluation

- Tannoy Reveal 402/502/802 Studio Monitor ManualDocument12 pagesTannoy Reveal 402/502/802 Studio Monitor ManualRob ZanderPas encore d'évaluation

- SDVR 4300 User Guide - 070710Document51 pagesSDVR 4300 User Guide - 070710nikola5nikolicPas encore d'évaluation

- Proximity Reader User Manual - V2.3 - 10wiresDocument8 pagesProximity Reader User Manual - V2.3 - 10wiresnikola5nikolicPas encore d'évaluation

- Elv 6 LCD ManualDocument24 pagesElv 6 LCD Manualnikola5nikolicPas encore d'évaluation

- SVD-4300 Series Quick Install Guide: 1. InstallationDocument2 pagesSVD-4300 Series Quick Install Guide: 1. Installationnikola5nikolicPas encore d'évaluation

- Samsung SIR 4150Document6 pagesSamsung SIR 4150nikola5nikolicPas encore d'évaluation

- The Product ID Is 5CA2 35C5 0AA6 E60A Pw64Document1 pageThe Product ID Is 5CA2 35C5 0AA6 E60A Pw64nikola5nikolicPas encore d'évaluation

- De-211 Quick Install v2Document2 pagesDe-211 Quick Install v2nikola5nikolicPas encore d'évaluation

- Access Code Master Code: One-Touch Button, If EnabledDocument2 pagesAccess Code Master Code: One-Touch Button, If Enablednikola5nikolicPas encore d'évaluation

- Apr3pgm4s Ei03 PDFDocument2 pagesApr3pgm4s Ei03 PDFnikola5nikolicPas encore d'évaluation

- MGRTX3 Ei02 PDFDocument2 pagesMGRTX3 Ei02 PDFnikola5nikolicPas encore d'évaluation

- Beam Paradox Brand PDFDocument4 pagesBeam Paradox Brand PDFnikola5nikolic100% (1)

- 1686 Eq02 PDFDocument2 pages1686 Eq02 PDFnikola5nikolicPas encore d'évaluation

- Aeroskills DiplomaDocument6 pagesAeroskills DiplomaDadir AliPas encore d'évaluation

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocument2 pagesMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorPas encore d'évaluation

- Menu Siklus RSDocument3 pagesMenu Siklus RSChika VionitaPas encore d'évaluation

- Measurement of Bioreactor K ADocument18 pagesMeasurement of Bioreactor K AAtif MehfoozPas encore d'évaluation

- Fundamental Molecular Biology: GenomesDocument45 pagesFundamental Molecular Biology: GenomesMoonHoLeePas encore d'évaluation

- Earth Loop ImpedanceDocument5 pagesEarth Loop ImpedanceKaranjaPas encore d'évaluation

- Lesson 49Document2 pagesLesson 49Андрій ХомишакPas encore d'évaluation

- E10b MERCHANT NAVY CODE OF CONDUCTDocument1 pageE10b MERCHANT NAVY CODE OF CONDUCTssabih75Pas encore d'évaluation

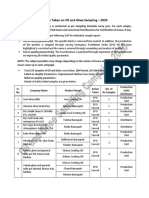

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiPas encore d'évaluation

- Cemco T80Document140 pagesCemco T80Eduardo Ariel Bernal100% (3)

- Key ScientificDocument4 pagesKey ScientificGarrettPas encore d'évaluation

- Thai Guava Production PDF by VNRDocument29 pagesThai Guava Production PDF by VNRDatta100% (2)

- Library PDFDocument74 pagesLibrary PDFfumiPas encore d'évaluation

- SA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh CommentedDocument31 pagesSA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh Commentedamini_mohiPas encore d'évaluation

- Biology Q PDFDocument9 pagesBiology Q PDFsumon chowdhuryPas encore d'évaluation

- Thorley Amended Complaint (Signed)Document13 pagesThorley Amended Complaint (Signed)Heather ClemenceauPas encore d'évaluation

- OKRA Standards For UKDocument8 pagesOKRA Standards For UKabc111007100% (2)

- 2021 Life Skills ATP Grade 5Document10 pages2021 Life Skills ATP Grade 5Koketso SekwenyanePas encore d'évaluation

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaPas encore d'évaluation

- Microsoft Security Intelligence Report Volume 21 EnglishDocument180 pagesMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoPas encore d'évaluation

- Family Stress TheoryDocument10 pagesFamily Stress TheoryKarina Megasari WinahyuPas encore d'évaluation

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDocument34 pages220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMPas encore d'évaluation

- Facts About Concussion and Brain Injury: Where To Get HelpDocument20 pagesFacts About Concussion and Brain Injury: Where To Get HelpJess GracaPas encore d'évaluation

- SA 8000 Audit Check List VeeraDocument6 pagesSA 8000 Audit Check List Veeranallasivam v92% (12)

- Carolyn Green Release FinalDocument3 pagesCarolyn Green Release FinalAlex MilesPas encore d'évaluation

- Variance AnalysisDocument22 pagesVariance AnalysisFrederick GbliPas encore d'évaluation

- 13105389Document22 pages13105389Larry RicoPas encore d'évaluation

- Aakanksha ProjectDocument32 pagesAakanksha ProjectAakash murarkaPas encore d'évaluation

- Hemostatic AgentsDocument18 pagesHemostatic AgentshariPas encore d'évaluation

- Probni Test 1. Godina - Ina KlipaDocument4 pagesProbni Test 1. Godina - Ina KlipaMickoPas encore d'évaluation