Académique Documents

Professionnel Documents

Culture Documents

Higher - Compression - Two - Stroke PDF

Transféré par

Imung Pernah SehatTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Higher - Compression - Two - Stroke PDF

Transféré par

Imung Pernah SehatDroits d'auteur :

Formats disponibles

The Effect of Higher Compression Ratio in Two-Stroke Engines

Yuh Motoyama and Tohru Gotoh Yamaha Motor Co, Ltd.

The effect of higher compression ratio on fuel consumption and power output was investigated for an air-cooled two-stroke motorcycle engine. The results show that actual fuel consumption can improve by 1-3% for each unit increase of compression ratio over the compression ratio range of 6.6 to 13.6. The rate of improvement is smaller however as compared to theoretical values. The discrepancies are mainly due to increased mechanical and cooling losses, shortcircuiting at low loads, and increased time losses at heavy loads. Power output also improves, but the maximum compression ratio is limited due to knock and the increase in thermal load. In addition, the investigation covered the implementation of higher compression ratio in practical engines by retarding the full-load ignition timing.

INTRODUCTION Adopting a higher compression ratio is one of 'the most important considerations regarding improved fuel consumption and power output in gasoline engines. Much research has been devoted to the effect of higher compression ratio in four-stroke engines, but little attention has been given to two-stroke engines. A two-stroke engine is different from a four-stroke engine in the gas exchange process and in the composition, pressure, and temperature characteristics of the working gases. Accordingly, the compression ratio has a different effect on the thermal efficiency for the respective engine types. To address the shortfall of study on two-stroke motorcycle engines, the effect of higher compression ratio on fuel consumption and power output was investigated. This paper specifically

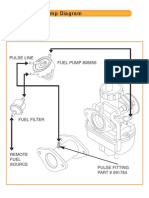

discusses thermal loads as well as knock problems at high speeds and heavy loads for higher compression ratios. FUEL CONSUMPTION IMPROVEMENT WITH HIGHER COMPRESSION RATIO The experiment was conducted on an air-cooled, Schnurle crankcase scavenged, single-cylinder, two-stroke engine. The engine specifications are detailed in Table 1. Compression ratios ranging from 6.6 to 13.6 in seven steps were attained by varying the combustion chamber dome depth. The compression ratio referred to in this paper represents the effective compression ratio calculated by assuming the exhaust portclose timing volume is the volume before compression. T o ascertain the scavenging characteristics, delivery ratio and air fuel

Table 1 Test Engine Specifications

Engine Type 2-Stroke, Air-Cooled,

, Sinale-Cvlinder

Scavenging System Crankcase Scavenging 154 x 50 mm Bore and Stroke 1114.5 cm' Displacement Compression Ratio 16.6 (STD), 7.8, 8.4, 8.7, 9.5, 11.2, 13.6 Exhaust Timing 91' A & B T D C Scavenaina Timina 122- A & B TDC * Combustion Two-Staged SemiChamber S~hericalT v ~ e

ratio are calculated from the intake air capacity. Trapping efficiency is calculated from the exhaust 0, concentration(1)'. Unleaded regular gasoline (RON 91) is used as the fuel. In the LA-4 mode, a motorcycle equipped with an experimental engine is operated mostly at idle and the load range is less than 3kW (350kPa BMEP) within 40005000 rpm.(2) Consequently, the test engine speed was set to 4500rpm to investigate engine characteristics. Figure 1 shows the specific fuel consumption results at various compression ratios. Figure 2 is the improvement rate for fuel consumption at a standard.compression ratio of 6.6. The effect of increasing compression ratio can be seen in the results whereby the fuel consumption improves by 1-3% for each unit increase in compression ratio. At any particular compression ratio and load, however, the measured values for the improvement rate are half as much as the theoretical values (air cycle y = 1.40). This is considered to be as a result of the following: (i) Increased short-circuiting (ii) Reduced specific heat ratio of the working gases (iii) Increased mechanical loss (iv) Increased cooling loss (v) Increased time loss The above factors are discussed in more detail below.

Fig. 1 Fuel Consumption Characteristics at Practical Engine Speeds

AIR CYCLE k , = 1.41

6 5 0 0 rpm MBT A,F 1 5

/ / /

'

BMEP IkPal

10

it

IA

COMPRESSION RATIO

Fig. 2 Improvement Rate in Fuel Consumption at Various Loads INCREASED SHORT-CIRCUITING If the scavenging characteristics vary with compression ratio, fuel consumption will be affected with the variation of closed-cycle thermal efficiency as well as the variation of scavenging characteristics. Figure 3 shows the relationship between the delivery ratio and the trapping efficiency. The trapping efficiency is reduced as the compression ratio rises within the tested delivery ratio range. More specifically, for the same fuel supply, increased short-circuiting is induced. 'Numbers in parentheses designate references at the end of paper

45W rom

..- -

Fig. 3 Relationship between the Delivery Ratio and the Trapping Efficiency

0.85 4 5 0 0 rom MET AlF13

C

>

0.80 0 75

Fig. 4 Relationship between the Trapping Efficiency and BMEP Figure 4 shows the relationship between the trapping efficiency and BMEP. The trapping efficiency improves as the compression ratio increases beyond a BMEP of 360kPa. Figure 5 shows the improvement in fuel consumption for a trapping efficiency equivalent to the standard compression ratio ( and assumes the trapping efficiency is independent of the compression ratio). At 400kPa BMEP, the results show a increase in the improvement rate with reduced shortcircuiting due to the higher compression ratios. At 200 and 300kPa BMEP, under actual operating conditions, however, the improvement rate in fuel consumption decreases with the increase in shortcircuiting. At a compression ratio of 12, 200kPa BMEP, for example, the improvement rate would be 1.4% higher (an increase from 9.8% to 11.2%) without an increase in short-circuiting.

p,.a+. - .,

4500rgm*ff15

AIR CYCLE 7'1.4

------

-A C W A L

EOUNALENT TRAPPlNG EFF. TO STANDARD COMP. RATIO

./

BMEP kP.1

DELIVERY RAT10

0 L b ' 6

10

12

14

COMPRESSION R A T I O

----. -...--..--.-0

n --.-a

6.6 7.8 9.5 11.2 13.6

Fig. 5 lmprovement Rate in Fuel Consumption. with Trapping Efficiency Equivalent to Standard Compression Ratio REDUCED SPECIFIC HEAT RATIO OF THE WORKING GASES - As observed in many reports, working gas temperature is affected by an increase in compression ratio. The resultant specific heat ratio variation affects the overall thermal efficiency (3)(4). Two-stroke engines differ considerably from four-stroke engines in temperature and pressure behavior. ~ e ~ a r d i e s of s load conditions, the pressure at the beginning of compression approaches atmospheric pressure; and the residual percentage of the working gases is high especially at low loads. The thermal efficiency of the fuel-air

' I

BMEP IkPa)

COMPRESSION RATIO

Fig. 6 lmprovement Rate of The Fuel-Air Cycle Thermal Efficiency

cycle was then calculated to investigate the effect of the specific heat ratio of the working gases. The pressure, the temperature, and the composition at' the beginning of compression were set to the same values as in actual engines. Thermal dissociation was disregarded. Figure 6 shows the improvement rate of the fuel-air cycle thermal efficiency with increasing compressiorl ratio. A compression ratio of 6.6 was used as the standard for the calculations. The fuel-air cycle exhibits a higher improvement rate than the air cycle value. Variation of the working gas specific heat ratio does not prevent the effect of higher compression ratios. To the contrary, the improvement of fuel consumption is enhanced.

4 5 0 0 ,Dm

( W I D C R A N K CASE PUMPING I

lool

COMPRESSION RATIO

Fig. 7

Relationship between the Compression Ratio and the Mechanical Loss

r_

20

.

'

4 5 W rum BMEP 2 0 0 kPm

,CYCLE

EOUNALENT MECU.'LOSS 1 0 ORIGINAL COMP RATIO

FlJEL.AIR

: P

I

Y

l5

OU g4

ACTUAL

5 ,

INCREASED MECHANICAL LOSS Figure 7 shows the variation of mechanical loss as measured by the motoring method. Mechanical loss increases by 27% as the compression ratio is raised from 6.6 to 13.6. The pumping work in the crankcase is excluded from the results. Figure 8 shows the improvement rate in the fuel consumption assuming that the mechanical loss is independent of the compression ratio. The improvement rate shows a marked decrease especially at low loads. At a compression ratio of 12 and at 200kPa BMEP (the same conditions as the earlier example), a 4.5% decrease in improvement rate is observed, and is higher as compared to the increase caused by shortcircuiting. Crankcase pumping work varies closely in proportion to the scavenging volume in two-stroke engines. Therefore, the ratio of the pumping work to the indicated work is almost, but not completely, constant over all loads. The experimental engine also shows a small decrease (0.009-0.012) in brake thermal efficiency due to the pumping work. The effect of higher compression ratio is very small for the same load because of the

10

12

74

COMPRESSION RATIO

10

12

la

COMPRESSION RATIO

Fig. 8

Improvement Rate in Fuel Consumption without Increased Mechanical Loss

reduced delivery ratio. INCREASED COOLING LOSS - Figure 9 shows the improvement rate in fuel consumption assuming the cooling loss is independent of the compression ratio. The cooling losses are calculated from cycle simulations. The heat transfer coefficient at compression stroke and at expansion stroke are calculated using the equations proposed by G. Woschini(5). The gas exchange process has only a slight effect on the cooling loss and is . excluded from the ...

1 5 W rpm BMEP 1 0 0 kP. FUELAIR CYCLE

. , '

TO STANOARO C O W RATIO

-40

-20

TOC 2 0

40

60

80

10

12

14

CRANK ANGLE I'ATDCI

COMPRESSION RATIO

lo W E .

FUEL A R CYCLE

A L W W I

-A0

- 20

TOC

20

40

60

80

CRANK ANGLE IoATDCI

COMPRESSION R A T 0

Fig. 10 Rate of Heat Release kPa BMEP and above a compression ratio of 10. Therefore, i t seems reasonable to suppose that the improvement rate in fuel consumption is smaller with high compression ratio at heavy load. The discussion above pertains to improvement in fuel consumption with higher compression ratios. However, because of higher mechanical losses and higher cooling losses, the fuel consumption at very low loads seems to increase with an increase in compression ratio. The results for idling fuel consumption are shown in Figure 11. The fuel consumption becomes disadvantaged as the compression ratio increases. It is clear from

Fig. 9 Improvement Rate in Fuel Consumption wlthout Increased Cooling Loss calculations. The results show that the cooling loss considerably reduces the effect of high compression ratio especially at low loads, though the decreased rate due to cooling loss is not so high as compared to the mechanical loss. At a compression ratio of 12 and at 200kPa BMEP, the improvement rate is 3.8% less d u e . to the increase in cooling loss.

INCREASED TIME LOSS - Time loss variation was investigated using combustion pressure analysis. The results of the rate of the heat release are shown in Figure 10. At low loads, the greater the compression ratio, the shorter the combustion time. Time loss is subsequently reduced. At heavy loads, the combustion time is longer as compression ratio increases. This is considered to be caused by the flattened combustion chamber shape due to the increased compression ratio. In addition, it is necessary to retard the ignition timing to avoid knocking above 300

COMPRESSION RATIO

Fig. 11 Idling Fuel Consumption

3 Z

50

L A . 4 MODE

06.6

40

! 30

$

0

20

10

E 5

0

" I

3

2

F C.

HC

CO

Fig. 12 Fuel Consumption for LA-4 Mode

the results that the increase in the mechanical and the cooling losses are greater than that for thermal efficiency at such loads. The fuel consumpfion was also measured in an actual motorcycle for the LA-4 mode. The compression ratio was set at 9.5 because severe knocking occurred at a compression ratio above 10. The test results are shown in The results show a 5.7% Figure 12. reduction in the fuel consumption and a 4.1% reduction in HC emissions at a standard compression ratio of 6.6. These values are almost equal to the improvement rate in fuel consumption at 4500 rpm and 200kPa BMEP as shown in Figure 2. POWER IMPROVEMENT WITH HIGHER COMPRESSION RATIO - In typical gasoline engines, power output can be improved with a higher compression ratio unless e x c e s s i v e knock problems predominate. Figure 13 shows the results of the full load performance and the scavenging characteristics for compression ratios of 6.6, 7.8, and 9.5. The performance output is improved within the tested speed range, but maximum power occurs at a speed slightly lower than maximum. This is a result of lower synchronizing speeds along with longer relative pressure pulsation due to the lower exhaust temperature. This tendency is evident in the delivery ratio results. The trapping efficiency is slightly decreased. The engine speeds exhibiting the greatest power output can be controlled by altering the exhaust system size.

10

ENGINE SPEED Irpml 1 1 0 '

Fig. 13 Full-Load Performance and Scavenging Characteristics FACTORS RATIO LIMITING COMPRESSION

Higher compression ratio makes it possible to improve power output., but causes serious problems such as knock and piston thermal load increase. To solve the problems, several reports have proposed low compression ratio at high-speeds and heavy loads with variable combustion chamber volumes.(6)(7). In this paper, retarded ignition timing is discussed as a remedy for the problems. Figure 14 shows the full-load knocking range for the compression ratio of 9.5. The knock intensity is estimated from the sum of the absolute values of the pressure differences(8). Under MBT operation, a very strong knock occurs above 8000 rprn which is apt to cause piston top erosion.

COMPRESSION RATIO 9 . 5 WOT A I F - 1 3 INTENSE KNOCK AREA SERIOUS KNOCK AREA LIGHT KNOCK AREA

e

I?

l o / / ~ N I T l 0 TIMING N WITH EOLIWALENT POWER TO STANOARO COMPRESSION RATIO

ENGINE SPEED Irpml x 1 0 '

Fig. 14 Full-Load Knocking Range

The dashed line in the figure shows the ignition timing with equivalent power at the standard compression ratio. Knocking is absent even at overspeed. Therefore, above 7000 rpm, using an ignition timing later than MBT, power output can remain advantaged and knock problems can be solved. A compression ratio of 9.5 is the maximum limit at which knock can be avoided and power output ensured.

Concerning the thermal load, Figure 15 shows the cylinder pressure and the instantaneous heat flux calculated from simulations. The results show that re.tarded ignition timing is more advantageous for equivalent power output levels since heat flux is reduced as well. The engine tests also indicate that the plug seat temperature is also lower by this method as compared to the results for the standard compression ratio. The countermeasures taken for problems associated with high speeds and heavy loads were discussed above. However, at a compression ratio of 9.5, combustion accompanied by a strong impact was observed in road tests at very low loads, and at medium and high speeds. This combustion under irregular conditions is called "low-load knock" or "high-speed and low-delivery ratio knock". These types of knocking are said to arise from the same principles as heavy-load knocking(9). Figure 16 is an indicator diagram for low-load knock. Figure 17 shows the

I-

IMEP 5 5 0 kPa

-80-60-40-20

20

4 0

60

8 0

CRANK ANGLE I o A T D C I

Fig. 16 Low-Load Knock

0LESS FREOUENTLY

OCCURRENCE MORE FREOUENTLY FREOUENTLV

COMPRESSION RATIO 9 5

4500 , r n '

DELNERY RATIO

30,

r 0

-80-60-60-20

20 4 0 6 0 8 0

P ,-

20 .

' ,

CRANK ANGLE l D A T D C l

L .

Fig. 15 Calculated Cylinder Pressure and Instantaneous Heat Flux with Retarded Ignition Timing

II

13 AIF

15

17

Fig. 17 Low-Load Knocking Rage

knocking range for air-fuel ratio and ignition timing. The low-load knock can barely be controlled through ignition timing; so there are still problems with the avowed similarity between low-load and heavy-load knocks. However, removing the deposit shows no effect implying that this combustion is clearly not a kind of surface ignition. We consider that the results indicate a form of compressed self-ignition. T o remedy lowload knock, the use of premium gasoline and improving cooling are effective measures. If premium gasoline is not used, the permissible limit of the compression ratio is approximately 8.4 without liquid-cooling and 8.7 with liquid-cooling. CONCLUSIONS Investigations were conducted on the effect of higher compression ratio in aircooled two-stroke motorcycle engines. The results can be summarized as follows: (1) It is possible to improve fuel consumption with higher compression ratio, though, due to various losses, the improvement rate fails to achieve theoretically expected values. At very low loads, such as idling, increases in the losses surpass the increase in the thermal efficiency and this can cause unfavorable fuel consumption in some cases. (2) The increases in losses can be classified into increased short-circuiting and increased mechanical and cooling losses at low loads. At heavy loads, the time loss increases, but the influence of shortcircuiting as well as mechanical and cooling losses are reduced. Varying the specific heat ratio of the working gases can be an effective countermeasure to contain losses. (3) Higher compression ratios make it possible to improve power output, though there is a limit imposed by knocking and increased thermal load to the maximum compression ratio.

(4) As the compression ratio is increased, it is effective to use an ignition timing later than MBT in regards to knocking and thermal load avoidance. The maximum compression ratio needs to be reduced,' however, because of the occurrence unmanageable abnormal combustion at very low loads. REFERENCES

I. K. Tsuchiya and S. Hirano, "Characteristics of 2-stroke Motorcycle Exhaust HC Emission and Effects of AirFuel Ratio and Ignition Timing," SAE. 750908. 2. K. Nomura, S. Hirano, T. Gotoh, and Y. Motoyama, "Improvement of Fuel Consumption with Variable Exhaust Port Timing in a Two-Stroke Gasoline Engine," SpLE. 850183. 3. S. Matsuoka and H. Tasaka, "The Thermal Efficiency and a Future Concept of Gasoline Engine and Diesel Engine from the View Point of CqvcleTheory." INTERNAL COMBUSTION ENGINE,Vol. 21, No. 258 (1982), pp. 85-96. (in Japanese) 4. S. Muranaka, Y. Takagi, T. Ishida, "Factors Limiting the Improvement in Thermal Efficiency of S. I. Engine at Higher Compression Ratio," SAE, 870548. 5. G. Woschni, "A Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine", SAE. 670931. 6. W. H. Adams, H. G, Hinrichs et al, "Analysis of the combustion Process of a Spark Ignition Engine with a Variable Compression Ratio," SAE, 870610. 7. V. Harne and S. R. Marathe, "Variabie Compression Ratio Two-Stroke Engine," SAE. 891750. 8. T. Fujikawa and S. Abe, "Abnormal Combustion of Two Stroke Cycle Gasoline Snowmobile Engine at High Speed and full Load," SAE, 790841. 9. H. Nakahara et al, TRANSACTIONS

Vous aimerez peut-être aussi

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualD'EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- 2012 Comet Catalog Web PDFDocument244 pages2012 Comet Catalog Web PDFTEXASBAGMANPas encore d'évaluation

- Mikuni Motorcycle Carburetor Theory 101: Understanding Atmospheric Pressure and JettingDocument8 pagesMikuni Motorcycle Carburetor Theory 101: Understanding Atmospheric Pressure and JettingRiski HartonoPas encore d'évaluation

- Port Timing Diagram of Two Stroke Cycle Pertrol EngineDocument4 pagesPort Timing Diagram of Two Stroke Cycle Pertrol Enginemechanical-engg50% (4)

- Dyno BlairDocument10 pagesDyno BlairAntonino ScordatoPas encore d'évaluation

- 2003 ExhaustDocument47 pages2003 ExhaustThip ZazaPas encore d'évaluation

- 2 Stroke Guide r2Document177 pages2 Stroke Guide r2Larry Terrell100% (1)

- Bimotion 2-Stroke Case StudyDocument11 pagesBimotion 2-Stroke Case Studytfour200080% (5)

- Carburetor Tuning: Understanding CarburetionDocument11 pagesCarburetor Tuning: Understanding CarburetionMuhammad Rashid Jaidon ⎝⏠⏝⏠⎠80% (5)

- TuningDocument16 pagesTuningKidKawie100% (1)

- Basic Two Stroke Tuning by Eric Gorr (I Think)Document7 pagesBasic Two Stroke Tuning by Eric Gorr (I Think)Dr DPas encore d'évaluation

- 2 Stroke Top End and PerformanceDocument41 pages2 Stroke Top End and PerformanceAndre Ruesl0% (1)

- How a 2-Stroke Engine WorksDocument6 pagesHow a 2-Stroke Engine WorksifzaePas encore d'évaluation

- Mikuni AgulhasDocument4 pagesMikuni AgulhasJaKa1Pas encore d'évaluation

- Crankcase Volume 2 StrokesDocument19 pagesCrankcase Volume 2 Strokespistonbreaker100% (4)

- 2-Stroke-Porting TerminologyDocument5 pages2-Stroke-Porting TerminologyMithun Miranda100% (2)

- 2 Stroke Top End and PerformanceDocument41 pages2 Stroke Top End and PerformancePaul Martin0% (1)

- How to re-jet your bike's carburetor for optimal performanceDocument4 pagesHow to re-jet your bike's carburetor for optimal performanceviks505100% (1)

- 2 Stroke ExhaustDocument4 pages2 Stroke ExhaustAniket Das100% (1)

- Animal Carb TuningDocument5 pagesAnimal Carb TuningRusty100% (1)

- Tuning Suzuki GT250A MDocument2 pagesTuning Suzuki GT250A Mgorlan50% (2)

- Kx500af 07 BuildDocument22 pagesKx500af 07 BuildMarcelo Tapia Maureira0% (1)

- Mikuni Sudco Tuning Manual Ed4 OcrDocument97 pagesMikuni Sudco Tuning Manual Ed4 OcrAlexander Chekalin50% (2)

- CV Carb TuningDocument7 pagesCV Carb Tuningmark_dayPas encore d'évaluation

- Keihin Jet ListDocument2 pagesKeihin Jet ListPetarPas encore d'évaluation

- Basic Two-Stroke TuningDocument9 pagesBasic Two-Stroke TuningAdyPas encore d'évaluation

- Mikuni Carburetor TuningDocument3 pagesMikuni Carburetor TuningGeorgePas encore d'évaluation

- 2 Stroke GuideDocument161 pages2 Stroke Guide2hard100% (1)

- Two-stroke Basics: How They Work and Their AdvantagesDocument11 pagesTwo-stroke Basics: How They Work and Their AdvantagesAfzal Shams100% (1)

- Champion Spark Plugs for Proven PerformanceDocument7 pagesChampion Spark Plugs for Proven PerformanceMGD040452100% (1)

- Race Tuning 05-07 KX250Document6 pagesRace Tuning 05-07 KX250KidKawiePas encore d'évaluation

- Piston-To-Wall Clearance Myths, Mysteries, and Misconceptions ExplainedDocument20 pagesPiston-To-Wall Clearance Myths, Mysteries, and Misconceptions ExplainedAnonymous SYwPALTPas encore d'évaluation

- Isky - Valve Timing For Maximum Output - ExcerptsDocument11 pagesIsky - Valve Timing For Maximum Output - ExcerptsgaragepunkfanPas encore d'évaluation

- Ch7-2stroke 1Document24 pagesCh7-2stroke 1suresh_gs9999Pas encore d'évaluation

- Mikuni TuningDocument22 pagesMikuni TuningStathis Ventouris89% (9)

- 2 Stroke Tuners HandbookDocument78 pages2 Stroke Tuners HandbookAnthony Van Hamond100% (2)

- 2 Stroke Guide r2Document178 pages2 Stroke Guide r2Jan Crombez100% (1)

- Basic Porting - What To CutDocument5 pagesBasic Porting - What To CutPratik Bajracharya Nepali100% (4)

- Mikuni VM Roundslide Parts DiagramDocument19 pagesMikuni VM Roundslide Parts DiagramTamil Selvan100% (2)

- 2 Stroke TuningDocument6 pages2 Stroke TuningRahul NakhePas encore d'évaluation

- ClutchDocument59 pagesClutchdforeman4509Pas encore d'évaluation

- Advances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesDocument34 pagesAdvances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesenjpetPas encore d'évaluation

- A New Generation of Two Stroke EngineDocument11 pagesA New Generation of Two Stroke Engineshax001100% (2)

- Mikuni Tuning Manual For HSR42 - 45 CarbsDocument12 pagesMikuni Tuning Manual For HSR42 - 45 Carbscarlos_hitech100% (1)

- Engine - Blower Hardware - All 110101Document58 pagesEngine - Blower Hardware - All 110101Didier Van Der LeePas encore d'évaluation

- Connecting Rod Vs Stroke RatioDocument11 pagesConnecting Rod Vs Stroke RatioJameel Khan0% (1)

- 2003 KX250 Race TuningDocument4 pages2003 KX250 Race TuningKidKawie100% (1)

- CamshaftsDocument5 pagesCamshaftsbluebelle2Pas encore d'évaluation

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- Aprilia SR, Dragster, Runner, Typhoon, Skipper tuning guideDocument6 pagesAprilia SR, Dragster, Runner, Typhoon, Skipper tuning guideCarlos Barba PPas encore d'évaluation

- Two-Stroke Engine Top-End Inspection: Study UnitDocument53 pagesTwo-Stroke Engine Top-End Inspection: Study UnitDiego CRPas encore d'évaluation

- 50cc GY6 Engine 01Document12 pages50cc GY6 Engine 01Milena Bustamante0% (1)

- Wankle Exhausts and The Relevance of Two-Stroke Design: An Engine's Exhaust Port Can Be Thought of As A Sound GeneratorDocument11 pagesWankle Exhausts and The Relevance of Two-Stroke Design: An Engine's Exhaust Port Can Be Thought of As A Sound GeneratorAndré Matsumoto100% (2)

- Two Cycle Carburetor and the Back Alley MechanicD'EverandTwo Cycle Carburetor and the Back Alley MechanicÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarD'EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarPas encore d'évaluation

- 12 A 16CM32Document2 pages12 A 16CM32Angel NajarroPas encore d'évaluation

- Cam Timing DDEC S50Document4 pagesCam Timing DDEC S50Hamilton mirandaPas encore d'évaluation

- Weir Novatech Part Number Cross ReferenceDocument1 pageWeir Novatech Part Number Cross ReferencevankarpPas encore d'évaluation

- Isx Motor Tiempo en Arbol de Levas Por CPLDocument7 pagesIsx Motor Tiempo en Arbol de Levas Por CPLandresPas encore d'évaluation

- And Development of The 567 Series General Motors Locomotive EngineDocument8 pagesAnd Development of The 567 Series General Motors Locomotive EngineOscar CherroPas encore d'évaluation

- Torque Motor Kubota D1703Document17 pagesTorque Motor Kubota D1703Marcelo Gustavo Fuentes ValdiviaPas encore d'évaluation

- Daihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Engine MechanicalDocument71 pagesDaihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Engine MechanicalMike Nolan100% (2)

- S & SL Series Hydraulic Cylinders: Special FeaturesDocument2 pagesS & SL Series Hydraulic Cylinders: Special FeaturesmachineCanPas encore d'évaluation

- Additional ProblemsDocument5 pagesAdditional ProblemsPJ PerezPas encore d'évaluation

- MD ProjectDocument35 pagesMD ProjectDar AkhtPas encore d'évaluation

- 06 I C EnginesDocument23 pages06 I C EnginesomkardashetwarPas encore d'évaluation

- Parts Number Cylinder GP Ripper D7G2Document3 pagesParts Number Cylinder GP Ripper D7G2Andri HermantoPas encore d'évaluation

- Kobelco Mini Excavator Parts CatalogDocument26 pagesKobelco Mini Excavator Parts CatalogMega peçasPas encore d'évaluation

- Overhaul Manual - Motor Yanmar - TK482 y TK486 Rev02-06Document156 pagesOverhaul Manual - Motor Yanmar - TK482 y TK486 Rev02-06Carlos CorreaPas encore d'évaluation

- Ottomotores 80KWDocument1 pageOttomotores 80KWFernando VazquezPas encore d'évaluation

- Physical Principles Related To Operation Basic Parts of The Engine Assembly Four Stroke Operating TheoryDocument37 pagesPhysical Principles Related To Operation Basic Parts of The Engine Assembly Four Stroke Operating TheoryVikram PuriPas encore d'évaluation

- Mercedes Intake Manifold Parts for OM 926 LA EngineDocument6 pagesMercedes Intake Manifold Parts for OM 926 LA EngineKarthii AjuPas encore d'évaluation

- Chevrolet Racing Engine Bill JenkinsDocument10 pagesChevrolet Racing Engine Bill Jenkinsnaomi100% (49)

- Intake ProcessDocument9 pagesIntake ProcessHizanorhuda ZurghibaPas encore d'évaluation

- Lokal Accessories Bor MesinDocument4 pagesLokal Accessories Bor MesinpembangunanPas encore d'évaluation

- Engine System FundamentalsDocument17 pagesEngine System FundamentalsJha PuiPas encore d'évaluation

- Parts list for 42bhp TIAS325/NH-F2.1 engineDocument52 pagesParts list for 42bhp TIAS325/NH-F2.1 engineJitendra ChaudhariPas encore d'évaluation

- Export Invoice PartsDocument2 pagesExport Invoice PartsAbhishek MongaPas encore d'évaluation

- Introduction Reciprocating CompressorDocument6 pagesIntroduction Reciprocating CompressorHirak BhattacharyaPas encore d'évaluation

- Step by Step: Installation of RingsDocument1 pageStep by Step: Installation of RingsMoaed KanbarPas encore d'évaluation

- 2010 02 Eui Heui InjectorDocument3 pages2010 02 Eui Heui InjectorMatias Frigerio50% (2)

- Catalago Yc61o8 Model Diesel Engine PartsDocument100 pagesCatalago Yc61o8 Model Diesel Engine PartsAbel GhellerPas encore d'évaluation

- 4 GrfseenDocument4 pages4 GrfseenDustPas encore d'évaluation

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualDocument10 pagesQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477Pas encore d'évaluation

- Despiece Motor Yanmar 4ntDocument24 pagesDespiece Motor Yanmar 4ntjalcazar1810100% (1)