Académique Documents

Professionnel Documents

Culture Documents

Buckling of Thin Metal Shells 84

Transféré par

pawkomDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Buckling of Thin Metal Shells 84

Transféré par

pawkomDroits d'auteur :

Formats disponibles

Cylindrical shells under axial compression

59

imperfection pattern for a given structure and loading; (c) a search for theoretical lower bound strengths that make design independent of the form and amplitude of imperfections; and (d) attempts to base design on imperfection patterns found in real structures. Lower bounds on test results The simplest and oldest procedure in addressing the scatter shown in Fig. 2.3 has been to draw a lower bound on all available test results. This approach can be traced back at least to Robertson (1928) and Wilson and Newmark (1933), but has been continually used right up to the present time, with the studies of Donnell (1934), Timoshenko (1936), Harris et al. (1957), Weingarten et al. (1965a), Hoff and Soong (1967), Almroth et al. (1970), Steinhardt and Schulz (1971) and Bornscheuer (1982) being steps on this path. The process of empirical rule development may be read in Bornscheuer (1982). This method has a number of key disadvantages. First, if all tests are included, some have extremely low strengths, and the lower bound or 90 percentile value is found to be very low indeed. Some of the tests are affected by plasticity, and some have poor loading arrangements or poor boundary support, and many are poorly documented so that these questions cannot be resolved. Thus many tests must be eliminated from the database, often with only weak justication, so that the apparently scientic process of devising a lower bound becomes rather dependent on the subjective view of the assessor. Second, there is generally little evidence of the amplitude and pattern of the geometric imperfections in these test shells, so that the huge literature on imperfection sensitivity is useless, and it is not possible to derive tolerance measures in relation to the dened strengths. Third, the method of fabrication of laboratory shells is generally very different from that used for full-scale structures, so the imperfection forms and residual stresses in them are probably unrepresentative of real construction. In addition, the load application and boundary conditions of real construction are rarely represented in laboratory tests, so they may again be quite unrepresentative. Despite all these disadvantages, all current standards are effectively based on such empirical lower bounds. The most recent change, introduced into the ENV 1993-1-6 standard, attempts to break away from lower bounds by dening different curves with associated amplitudes of imperfections. These curves are still empirically based, but they do attempt to dene strengths that can be checked against tolerance measures. Few attempts have been made to use modern calculation methods to relate imperfection sensitivity and tolerance measurements to empirical curves used in design. The only known attempt is that of Rotter (1997). The worst imperfection pattern The search for the worst imperfection pattern directly addresses the rst question identied above. The mostly widely used interpretation of this concept is that an

Vous aimerez peut-être aussi

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (7)

- Schlaich Truss Models PCI 1987Document39 pagesSchlaich Truss Models PCI 1987mcunh4Pas encore d'évaluation

- Framing With RoofsDocument5 pagesFraming With Roofsgreenelephant150Pas encore d'évaluation

- Wood Joints in Classical Japanese Architecture PDFDocument69 pagesWood Joints in Classical Japanese Architecture PDFDavid Freire CuevaPas encore d'évaluation

- Fixing Bracing Guidelines - Timber Roof TrussesDocument20 pagesFixing Bracing Guidelines - Timber Roof TrussesjaffnaPas encore d'évaluation

- Timber Frame ShedDocument5 pagesTimber Frame Shedpawkom100% (5)

- Principles of Timber Framed ConstructionDocument76 pagesPrinciples of Timber Framed Constructionpawkom67% (6)

- Overhead Water Tank Structural AnalysisDocument28 pagesOverhead Water Tank Structural Analysiscollins unanka100% (3)

- Adverb Affirmation Negation LessonDocument4 pagesAdverb Affirmation Negation LessonMire-chan Bacon100% (1)

- The Role of Biaxial Stresses in Discriminating Between Meaningful and Illusory Composite Failure TheoriesDocument18 pagesThe Role of Biaxial Stresses in Discriminating Between Meaningful and Illusory Composite Failure Theorieskhudhayer1970Pas encore d'évaluation

- 1626-Article Text (.Docx, Max 100 MB) - 6145-1-10-20151224Document9 pages1626-Article Text (.Docx, Max 100 MB) - 6145-1-10-20151224Anonymous ZC1ld1CLmPas encore d'évaluation

- On Basic Features of Constitutive Models For Geoma PDFDocument20 pagesOn Basic Features of Constitutive Models For Geoma PDFعبد القادر جمالPas encore d'évaluation

- Biaxial test methods reviewDocument6 pagesBiaxial test methods reviewGuilherme de FaveriPas encore d'évaluation

- Free Stress Strain Withers2007Document14 pagesFree Stress Strain Withers2007Phạm Đình NguyệnPas encore d'évaluation

- Buckling of Thin Metal Shells 85Document1 pageBuckling of Thin Metal Shells 85pawkomPas encore d'évaluation

- 1974 - Load Distribution and Deformational Response in DiscontinuaDocument14 pages1974 - Load Distribution and Deformational Response in DiscontinuaafuhcivPas encore d'évaluation

- Buckling and Post Buckling of Imperfect Cylindrical Shells, G.simitsesDocument8 pagesBuckling and Post Buckling of Imperfect Cylindrical Shells, G.simitsesНаталья КультинаPas encore d'évaluation

- Buckling of Thin Metal Shells 44Document1 pageBuckling of Thin Metal Shells 44pawkomPas encore d'évaluation

- Anisotropic Modelling and Numerical Simulation of Brittle Damage in ConcreteDocument23 pagesAnisotropic Modelling and Numerical Simulation of Brittle Damage in ConcreteamarPas encore d'évaluation

- Fracture mechanics of concrete applicationsDocument16 pagesFracture mechanics of concrete applicationsrafaelnmbarrosPas encore d'évaluation

- Fatigue of CompositesDocument32 pagesFatigue of CompositesshreedharkolekarPas encore d'évaluation

- Wooldridge 2010Document42 pagesWooldridge 2010iamsbikasPas encore d'évaluation

- Crack Modeling For Structural Health MonitoringDocument11 pagesCrack Modeling For Structural Health MonitoringWayne PhillipsPas encore d'évaluation

- Biaxial Tensile Strength Characterization of Textile Composite MaterialsDocument24 pagesBiaxial Tensile Strength Characterization of Textile Composite MaterialsmrezaianPas encore d'évaluation

- Structural Analysis Modeling of Unbonded Prestressing in Prestressed Concrete ContainmentsDocument8 pagesStructural Analysis Modeling of Unbonded Prestressing in Prestressed Concrete ContainmentshemalcmistryPas encore d'évaluation

- Nonlinear Finite Element Analysis of Shells: Part I. Threedimensional ShellsDocument32 pagesNonlinear Finite Element Analysis of Shells: Part I. Threedimensional ShellsJorge PalominoPas encore d'évaluation

- Prediction of Damage in Cold Bulk Forming ProcessesDocument4 pagesPrediction of Damage in Cold Bulk Forming ProcessesKemo TufoPas encore d'évaluation

- EN1993 Practice Paper-Buckling Analysis of Steel BridgesDocument16 pagesEN1993 Practice Paper-Buckling Analysis of Steel BridgesaktcPas encore d'évaluation

- 2.1 Parameters Not Taken Into AccountDocument8 pages2.1 Parameters Not Taken Into AccountEder Ch GPas encore d'évaluation

- fd09 Résumé GallandDocument2 pagesfd09 Résumé GallandflolagalePas encore d'évaluation

- James Allen - As A Man Thinketh (2007)Document21 pagesJames Allen - As A Man Thinketh (2007)AbrehaAbayPas encore d'évaluation

- Meshless Methods: An Overview and Recent Developments: T. Belytschko Y. Krongauz D. Organ M. Fleming P. Krysl May 2, 1996Document79 pagesMeshless Methods: An Overview and Recent Developments: T. Belytschko Y. Krongauz D. Organ M. Fleming P. Krysl May 2, 1996Teodor PetrutPas encore d'évaluation

- OMAE2022 FinalDocument12 pagesOMAE2022 FinalEven EnglundPas encore d'évaluation

- Using Plate #Nite Elements For Modeling #Llets in Global Response AnalysisDocument13 pagesUsing Plate #Nite Elements For Modeling #Llets in Global Response AnalysisJohn RongPas encore d'évaluation

- 1 s2.0 S0142112321000372 MainDocument21 pages1 s2.0 S0142112321000372 MainJacopo PelizzariPas encore d'évaluation

- Literature (Desgin and Anaysis of Composite Tube)Document8 pagesLiterature (Desgin and Anaysis of Composite Tube)Bashar AlfadliPas encore d'évaluation

- PAPER LahtiharjuDocument15 pagesPAPER LahtiharjuTanner Espinoza0% (1)

- Consti Tuti VeDocument4 pagesConsti Tuti VeDeepak ChachraPas encore d'évaluation

- Capacity Models For Shear Strength of Exterior Joints in RC Frames: Experimental Assessment and RecalibrationDocument23 pagesCapacity Models For Shear Strength of Exterior Joints in RC Frames: Experimental Assessment and RecalibrationMarimuthu KaliyamoorthyPas encore d'évaluation

- Predicting The Behaviour of Laterally Loaded Masonry Panels: AN Fried, JJ Roberts, MC Limbachiya and O KanyetoDocument10 pagesPredicting The Behaviour of Laterally Loaded Masonry Panels: AN Fried, JJ Roberts, MC Limbachiya and O KanyetoRadekPas encore d'évaluation

- Paszkiewicz, Kubiak (2015) - Selected Problems Concerning Determination of The Buckling Load of Channel Section Beams and ColumnsDocument10 pagesPaszkiewicz, Kubiak (2015) - Selected Problems Concerning Determination of The Buckling Load of Channel Section Beams and ColumnsGogyPas encore d'évaluation

- 173-Research Results-693-1-10-20200421Document11 pages173-Research Results-693-1-10-20200421Nathanael Basana HisarPas encore d'évaluation

- New Theory 10nov 2022Document36 pagesNew Theory 10nov 2022Pet85Pas encore d'évaluation

- Czm-On The Practical Application of The Cohesive ModelDocument25 pagesCzm-On The Practical Application of The Cohesive ModelAldyansyah PutraPas encore d'évaluation

- Time-to-Failure Tests of Adhesive Anchor SystemsDocument26 pagesTime-to-Failure Tests of Adhesive Anchor SystemsAlphabrPas encore d'évaluation

- Finite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreDocument8 pagesFinite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreseventhhemanthPas encore d'évaluation

- A Critical Insight On The Use of External Load Cells For FatigueDocument6 pagesA Critical Insight On The Use of External Load Cells For FatigueSergio HenriquePas encore d'évaluation

- Studies On Fatigue Crack Growth in GraphiteDocument3 pagesStudies On Fatigue Crack Growth in GraphiteShwetha JPas encore d'évaluation

- 7 - Biela - Tirante (INGLÊS)Document13 pages7 - Biela - Tirante (INGLÊS)az1993Pas encore d'évaluation

- Brazed JointDocument9 pagesBrazed JointtazzorroPas encore d'évaluation

- Comprehensive Database For Concrete CreeDocument34 pagesComprehensive Database For Concrete CreePablo Peña TorresPas encore d'évaluation

- AIAA2005SDM Failure Analysis of Adhesively Bonded Composite JointsDocument23 pagesAIAA2005SDM Failure Analysis of Adhesively Bonded Composite JointsalfonxxlPas encore d'évaluation

- Figure 7. Primary Modes of VibrationDocument2 pagesFigure 7. Primary Modes of VibrationChristopher LimPas encore d'évaluation

- Preventing out-of-plane buckling of gusset plates in braced framesDocument9 pagesPreventing out-of-plane buckling of gusset plates in braced framestimur sibaevPas encore d'évaluation

- 06_chapter 2Document16 pages06_chapter 2Sid ZainPas encore d'évaluation

- Consolidation Characteristics of Clay Using Constant Rate of Deformation TestDocument10 pagesConsolidation Characteristics of Clay Using Constant Rate of Deformation TestJose Miguel Romero SevillaPas encore d'évaluation

- Testing Concrete E-Modulus at Very Early Ages Through Several Techniques An Inter-Laboratory ComparisonDocument19 pagesTesting Concrete E-Modulus at Very Early Ages Through Several Techniques An Inter-Laboratory ComparisonJose Juan Reyes ZamudioPas encore d'évaluation

- Composites Part B: V. Keryvin, A. Marchandise, P.-Y. Mechin, J.-C. GrandidierDocument7 pagesComposites Part B: V. Keryvin, A. Marchandise, P.-Y. Mechin, J.-C. GrandidierPierre-Yves Harlé-MechinPas encore d'évaluation

- Geotechnical Stability Analysis: Géotechnique June 2013Document43 pagesGeotechnical Stability Analysis: Géotechnique June 2013s w leePas encore d'évaluation

- Martina (2002) - Punching Behavior of Biaxial Hollow SlabsDocument6 pagesMartina (2002) - Punching Behavior of Biaxial Hollow SlabsWanderley NicacioPas encore d'évaluation

- Application of Fracture Mechanics To Engineering DDocument7 pagesApplication of Fracture Mechanics To Engineering DromPas encore d'évaluation

- Building Better Products With FEA Analysis Pg.17Document9 pagesBuilding Better Products With FEA Analysis Pg.17eduardolarangeiraPas encore d'évaluation

- Pavement Response Ullidtz& ZhangDocument22 pagesPavement Response Ullidtz& ZhangsmouroPas encore d'évaluation

- A Cohesive Model For Fatigue Failure of PolymersDocument18 pagesA Cohesive Model For Fatigue Failure of Polymerswoongs73Pas encore d'évaluation

- Verification of Proposed Design Methodologies For Effective Width of Slabs in SlabColumn Frames by J. GrossmanDocument22 pagesVerification of Proposed Design Methodologies For Effective Width of Slabs in SlabColumn Frames by J. Grossmangulilero_yoPas encore d'évaluation

- Modeling Gravity Hazards from Rockfalls to LandslidesD'EverandModeling Gravity Hazards from Rockfalls to LandslidesPas encore d'évaluation

- TIMBER CONNECTION DESIGNDocument17 pagesTIMBER CONNECTION DESIGNAlexandru OlaruPas encore d'évaluation

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Simpson Strong Tie Catalog 09Document196 pagesSimpson Strong Tie Catalog 09Jeff Strickland100% (1)

- Turning Trees To Timber ManualDocument47 pagesTurning Trees To Timber Manualpawkom100% (1)

- Truss Erecting and BracingDocument5 pagesTruss Erecting and BracingpawkomPas encore d'évaluation

- Bracing ManualDocument101 pagesBracing ManualErrol HobdenPas encore d'évaluation

- Structural Bracing ManualDocument20 pagesStructural Bracing ManualKen WolfPas encore d'évaluation

- Falk. .Laminating - Effects.in - Glued Laminated - Timber.beamsDocument7 pagesFalk. .Laminating - Effects.in - Glued Laminated - Timber.beamspawkomPas encore d'évaluation

- Structural Glued-Laminated Timber (40pag)Document40 pagesStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- Composite Repair of Timber Structures (49pag)Document49 pagesComposite Repair of Timber Structures (49pag)cristian_iv8787Pas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 16 - Dependence of Amplitudes On PositionDocument16 pagesFeynmans Lectures - Vol 3 CH 16 - Dependence of Amplitudes On PositionsumalasPas encore d'évaluation

- Practical Approach of Modeling Wood Truss Roof AssembliesDocument6 pagesPractical Approach of Modeling Wood Truss Roof AssembliespawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 09 - The Amonia MASERDocument15 pagesFeynmans Lectures - Vol 3 CH 09 - The Amonia MASERsumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 10 - Other Two State SystemsDocument17 pagesFeynmans Lectures - Vol 3 CH 10 - Other Two State SystemssumalasPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 20Document17 pagesFeynman Lectures On Physics Volume 3 Chapter 20pawkomPas encore d'évaluation

- Bolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)Document11 pagesBolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)pawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 17 - Symmetry and Conservation LawsDocument16 pagesFeynmans Lectures - Vol 3 CH 17 - Symmetry and Conservation LawssumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 07 - The Dependence of Amplitude On TimeDocument13 pagesFeynmans Lectures - Vol 3 CH 07 - The Dependence of Amplitude On TimesumalasPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 05 - Spin OneDocument17 pagesFeynmans Lectures - Vol 3 CH 05 - Spin OnesumalasPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 06 PDFDocument11 pagesFeynman Lectures On Physics Volume 3 Chapter 06 PDFpawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 03 - Probability AmplitudesDocument13 pagesFeynmans Lectures - Vol 3 CH 03 - Probability AmplitudessumalasPas encore d'évaluation

- Feynman Lectures On Physics Volume 3 Chapter 01 PDFDocument16 pagesFeynman Lectures On Physics Volume 3 Chapter 01 PDFpawkomPas encore d'évaluation

- Feynmans Lectures - Vol 3 CH 02 - Relation of Wave & Particle ViewpointsDocument8 pagesFeynmans Lectures - Vol 3 CH 02 - Relation of Wave & Particle ViewpointssumalasPas encore d'évaluation

- Buckling of Thin Metal Shells 300Document1 pageBuckling of Thin Metal Shells 300pawkomPas encore d'évaluation

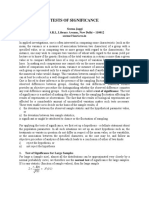

- 5 Tests of Significance SeemaDocument8 pages5 Tests of Significance SeemaFinance dmsrdePas encore d'évaluation

- Be3000 Manual 2016Document77 pagesBe3000 Manual 2016Itzel JuárezPas encore d'évaluation

- Scan & Pay Jio BillDocument22 pagesScan & Pay Jio BillsumeetPas encore d'évaluation

- Final Term Quiz 2 On Cost of Production Report - Average CostingDocument4 pagesFinal Term Quiz 2 On Cost of Production Report - Average CostingYhenuel Josh LucasPas encore d'évaluation

- Xiaomi Mi Drone 4K User Manual GuideDocument47 pagesXiaomi Mi Drone 4K User Manual GuideΜιχάλης ΛαχανάςPas encore d'évaluation

- ERC12864-12 DemoCode 4wire SPI 2Document18 pagesERC12864-12 DemoCode 4wire SPI 2DVTPas encore d'évaluation

- Operation 490BDocument60 pagesOperation 490BYe Min Htike100% (1)

- Science-6 - Q4 - W8-DLL - Mar 10Document2 pagesScience-6 - Q4 - W8-DLL - Mar 10cristina quiambaoPas encore d'évaluation

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorPas encore d'évaluation

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaPas encore d'évaluation

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepairXavier AlvarezPas encore d'évaluation

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnerePas encore d'évaluation

- Lecture 6Document16 pagesLecture 6Dina Saad EskanderePas encore d'évaluation

- Usage Instructions - Hengro PoolProtect 1 - 5Document3 pagesUsage Instructions - Hengro PoolProtect 1 - 5Brian VisserPas encore d'évaluation

- U-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishDocument76 pagesU-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishszerenguettiPas encore d'évaluation

- Inventory ManagementDocument60 pagesInventory Managementdrashti0% (1)

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingPas encore d'évaluation

- SOP Questionnaire GREDocument4 pagesSOP Questionnaire GREYuvraj GuptaPas encore d'évaluation

- SO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BDocument15 pagesSO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BATMMOBILISPas encore d'évaluation

- UN Habitat UPCL Myanmar TranslationDocument254 pagesUN Habitat UPCL Myanmar TranslationzayyarPas encore d'évaluation

- MA4850 Supply Chain & Logistics ManagementDocument21 pagesMA4850 Supply Chain & Logistics ManagementQy LeePas encore d'évaluation

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- 199-Article Text-434-1-10-20200626Document11 pages199-Article Text-434-1-10-20200626ryan renaldiPas encore d'évaluation

- Okto Engineering Experience ShareDocument66 pagesOkto Engineering Experience Sharecengiz kutukcuPas encore d'évaluation

- The Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12Document313 pagesThe Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12justice hayfordPas encore d'évaluation

- Saes H 201Document9 pagesSaes H 201heartbreakkid132Pas encore d'évaluation

- Design and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABDocument5 pagesDesign and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABJeannot MpianaPas encore d'évaluation

- Lux MeterDocument4 pagesLux MeterNmg KumarPas encore d'évaluation