Académique Documents

Professionnel Documents

Culture Documents

BGL

Transféré par

julioalexcmDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BGL

Transféré par

julioalexcmDroits d'auteur :

Formats disponibles

Case Study

EFC

O FU

RNACES (2002)

LTD

BGL Glass Toughening, Birmingham

Two brothers, with almost no experience of the glass processing industry, have in a short time carved out a significant share of the West Midlands glass toughening market. This has been achieved by hard work, giving the best possible service and an investment in the latest EFCO glass toughening equipment.

The Customer West Midlands Builders and Property Developers, Dave and Jas Rama, noticed that they were required to fit more and more toughened glass panels into the properties they were renting. Spurred on by ongoing problems of variable quality, delays and spiralling prices, and with no experience in glass processing, they decided to enter into the toughened glass supply market. A suitable building was found in Birmingham and modifications made to convert it into an efficient glass processing facility. At its heart was to be a tempering furnace and as this would be crucial to the success of the business, and the biggest single capital investment, Dave and Jas took great care researching the various suppliers.

We received proposals from UK, Scandinavian and Far Eastern manufacturers said Dave. Most just wanted to sell us a machine with little regard to us being new to the business, EFCO were the only ones who were happy to work closely with us to establish our requirements, then supply a tempering system that would meet them. Although they were not the cheapest tender, their willing attitude, track record and the fact they were a UK company with an excellent service back up, swung it for us. An oscillating glasstempering system with a 4000mm x 1750mm load area, capable of producing toughened glass from 4 19mm thick, was therefore ordered.

The EFCO glass-tempering system with a 4000mm x 1750mm load area

The loading area

Initially the business would concentrate on supplying 4 6mm thick glass for the double glazing industry. EFCO was able to assure the customer that the running costs and throughput would be comparable with competitive equipment. As it transpired, throughput was well in excess of that promised thanks to a number of new product developments. Aspirated Convection System In order to enable processing of the latest generation of toughenable hard and soft coated Low E glass, at rates almost comparable to float, and increase the quality and processing speed for other glasses, the EFCO machine included a recently developed air aspirated convection system. Operator Interface Screen and Software The system is supplied with EFCOs newly upgraded graphical Windows based operator control station and system software to optimise throughput and produce high quality glass. A comprehensive recipe system with descriptive file names

and screens provide the operator with information on plant condition with pyrometric graphs assisting quality control. Enhanced and simplified fault alarm and machine condition pages ensure that the operator always has full knowledge and control of plant status. Insulation and Heating Element Design Developments in low thermal mass insulation materials and increased side wall insulation where rollers pass through the furnace side walls, has reduced heat losses. This has resulted in more stable furnace temperatures, lower energy costs and quicker heat up times.

The new tempering system was delivered in May 2005 and as it sits directly on the factory floor without the need for excavations or special foundations, within three weeks of delivery, it was fully commissioned, EFCO was the only supplier producing high quality who was happy to work with us toughened glass. EFCO engineers also trained the to establish our requirements BGL's operatives in the then supply a tempering system efficient use of the that would meet them . equipment.

In conclusion Dave Rama says: We are delighted with our new toughener. With EFCOs help we have created a facility capable of producing toughened glass quickly and cost effectively. The optical quality is excellent Even we find it difficult to tell between our toughened and standard float glass. We have such confidence in our product that we have applied for a licence from British Standards showing that our glass is

manufactured to current British and European standards. Although its early days; we are already enjoying repeat business from our growing customer list and are ahead of sales targets. If this continues we expect a return on our investment in about five years. For EFCO Furnaces Limited; this contract is another project to add to its large portfolio of successful installations. The company is a member of the Solent Steel Engineering Group and supplies its products to glass processors in over thirty countries.

We are delighted with our new toughener. With EFCOs help we have created a facility capable of producing toughened glass quickly and cost effectively

Dave and Jas Rama

EFCO Furnaces (2002) Ltd 5 Pipers Wood Industrial Park, Waterlooville, Hampshire, PO7 7XU, United Kingdom Tel: +44 (0)23 9223 2348 Fax: +44 (0)23 9224 1458 Email: sales@efcofurnaces.co.uk

EFC

O FU

RNACES (2002)

LTD

Vous aimerez peut-être aussi

- Tecnoglass Changes All Tempering Furnaces Over To Glaston FC500Document2 pagesTecnoglass Changes All Tempering Furnaces Over To Glaston FC500Christian DaesPas encore d'évaluation

- Emco Case StudyDocument15 pagesEmco Case StudyUsman Hamid100% (1)

- GYPROCK 547 Residential - Installation - Guide 201111 PDFDocument56 pagesGYPROCK 547 Residential - Installation - Guide 201111 PDFduckePas encore d'évaluation

- Autoclaved Aerated Concrete ProductionDocument10 pagesAutoclaved Aerated Concrete ProductionshareefkabakaPas encore d'évaluation

- Review The Essential Building Product - Autumn 08Document35 pagesReview The Essential Building Product - Autumn 08abdelhassanPas encore d'évaluation

- Iceburg BrochureDocument16 pagesIceburg BrochuremohitPas encore d'évaluation

- Koemmerling Brochure 8 PagesDocument8 pagesKoemmerling Brochure 8 Pagesnasareyan1Pas encore d'évaluation

- Vertical Roller Mill Repair: Enduring PerformanceDocument12 pagesVertical Roller Mill Repair: Enduring PerformanceSunny KumarPas encore d'évaluation

- Airlight Energy Vue D'ensemble Projet CSPDocument11 pagesAirlight Energy Vue D'ensemble Projet CSPusinemaroc100% (2)

- Display Technologies: Kevin LongDocument34 pagesDisplay Technologies: Kevin LongJason ChiangPas encore d'évaluation

- H+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductsDocument12 pagesH+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductspseudosilPas encore d'évaluation

- Brochure Dramix For Concrete ReinforcementDocument15 pagesBrochure Dramix For Concrete ReinforcementVincentPas encore d'évaluation

- Acoustic Insulation DG Generator Canopy HSD TankDocument16 pagesAcoustic Insulation DG Generator Canopy HSD TankAnonymous sWqPozhJPas encore d'évaluation

- Atmatec - Fibreglass Products For Drainage Systems PDFDocument44 pagesAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalPas encore d'évaluation

- Catalogo Cefil NuevoDocument52 pagesCatalogo Cefil NuevoRikjard VarolatzPas encore d'évaluation

- Trimapanel® Brochure PDFDocument36 pagesTrimapanel® Brochure PDFyasserPas encore d'évaluation

- Flexitallic Product ServicesDocument20 pagesFlexitallic Product ServicesFrankie TeoPas encore d'évaluation

- Synchronous Generato6rDocument18 pagesSynchronous Generato6rVictor Felipe Domínguez Malo100% (1)

- Refractory Solutions ICR December 2007 PDFDocument2 pagesRefractory Solutions ICR December 2007 PDFFrancisco Uribe ParraPas encore d'évaluation

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamPas encore d'évaluation

- Enexco BrochureDocument35 pagesEnexco BrochureErin CraigPas encore d'évaluation

- Precast Flooring Solutions: Therma-Beam™Document20 pagesPrecast Flooring Solutions: Therma-Beam™VijayPas encore d'évaluation

- Bhoruka Aluminum LTD PDFDocument12 pagesBhoruka Aluminum LTD PDFGediya RockyPas encore d'évaluation

- BDF 4 Forming Is Machine @Document28 pagesBDF 4 Forming Is Machine @John Paul EspanoPas encore d'évaluation

- Ele Matic Company Brochure enDocument16 pagesEle Matic Company Brochure enPurushotam TapariyaPas encore d'évaluation

- Plastbau Case Study Birm AirportDocument2 pagesPlastbau Case Study Birm AirportzakwanramliPas encore d'évaluation

- Nelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedDocument5 pagesNelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedjackPas encore d'évaluation

- K450 Plus Updated PDFDocument138 pagesK450 Plus Updated PDFCongson JeffPas encore d'évaluation

- 8 - SOG Company Profile - 2018Document3 pages8 - SOG Company Profile - 2018Masood KhanPas encore d'évaluation

- Engineered MaterialsDocument23 pagesEngineered MaterialsMukesh A. JanePas encore d'évaluation

- Ameron CatalogDocument719 pagesAmeron CatalogLeianne050610100% (5)

- Rapid Protyping FTJ May 2010Document9 pagesRapid Protyping FTJ May 2010chown2k9Pas encore d'évaluation

- 16341535Document6 pages16341535Kevin VaderPas encore d'évaluation

- H4 301e Saf 2009Document32 pagesH4 301e Saf 2009Taeu YuPas encore d'évaluation

- Life Saving Composite Lamp PostsDocument2 pagesLife Saving Composite Lamp PostsMatthew TurnerPas encore d'évaluation

- Steel Frame Wall Systems Installation GuideDocument48 pagesSteel Frame Wall Systems Installation Guide陳宗煌Pas encore d'évaluation

- Catalogo Horno Tamglastamglass ProEDocument8 pagesCatalogo Horno Tamglastamglass ProEДушан СлијепчевићPas encore d'évaluation

- 2018 Catalogue enDocument157 pages2018 Catalogue enDan RomanPas encore d'évaluation

- GYP547 ResGuide 2011 - 557fDocument56 pagesGYP547 ResGuide 2011 - 557fduckman2009Pas encore d'évaluation

- Insulated FormworkDocument2 pagesInsulated FormworkhimanshuPas encore d'évaluation

- BENA BrochureDocument8 pagesBENA BrochureNashit ZabihPas encore d'évaluation

- Bestline Mining Supplies LTD - 2010 EditionDocument50 pagesBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaPas encore d'évaluation

- Thermatile Technical BrochureDocument40 pagesThermatile Technical BrochureVictoria FalzonPas encore d'évaluation

- Catalogue Ramblock English 2012 PDFDocument411 pagesCatalogue Ramblock English 2012 PDFAbdelRhman ElfkyPas encore d'évaluation

- Magne Win PDFDocument8 pagesMagne Win PDFsantosh_babar_26Pas encore d'évaluation

- SKF Economos SteelDocument22 pagesSKF Economos SteelJurun_BidanshiPas encore d'évaluation

- Technical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemDocument17 pagesTechnical Achievements in Wire-Rod Production: Technologies and Processes of The H SystemsaikatPas encore d'évaluation

- CPB Brochure Diaphragms en 2Document12 pagesCPB Brochure Diaphragms en 2ebrahimPas encore d'évaluation

- Coatings For Wind Power UkDocument7 pagesCoatings For Wind Power Ukcharles083100% (1)

- V-MAKE Broucher October 2021Document32 pagesV-MAKE Broucher October 2021Roy Estate (Sajila Roy)Pas encore d'évaluation

- Hex 922e - 925e t4f 44 PG Broch A4Document44 pagesHex 922e - 925e t4f 44 PG Broch A4davi henrique boazPas encore d'évaluation

- Everest Industrial Brochure Ver 2 2Document16 pagesEverest Industrial Brochure Ver 2 2ravi PatelPas encore d'évaluation

- Adding Value To ConcreteDocument16 pagesAdding Value To ConcreteFrancois KokPas encore d'évaluation

- Sika's Support For The Design, Construction and Maintenance of HotelsDocument4 pagesSika's Support For The Design, Construction and Maintenance of HotelsCarlos ChoquePas encore d'évaluation

- Enviro Kerb SystemDocument26 pagesEnviro Kerb SystemΜανος ΦιοράκηςPas encore d'évaluation

- Welcome To Gubbi !!: Plant in IndiaDocument15 pagesWelcome To Gubbi !!: Plant in IndiaGubbi EnterprisesPas encore d'évaluation

- Refractory and Castables CatalogueDocument29 pagesRefractory and Castables CatalogueAzhar MandhraPas encore d'évaluation

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016D'Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramPas encore d'évaluation

- Additive Manufacturing and Strategic Technologies in Advanced CeramicsD'EverandAdditive Manufacturing and Strategic Technologies in Advanced CeramicsKiyoshi ShimamuraPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Werling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FrameDocument8 pagesWerling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FramehugoPas encore d'évaluation

- APAVE Tiger CP - UK - FINAL2Document1 pageAPAVE Tiger CP - UK - FINAL2AdrewhassTechnicaPas encore d'évaluation

- 16 Advantages & 10 Disadvantages of Solar Panels in 2022Document29 pages16 Advantages & 10 Disadvantages of Solar Panels in 2022xaxinev359100% (1)

- 1 Conformity Asch StudyDocument31 pages1 Conformity Asch StudyjasbruPas encore d'évaluation

- Oracle CRM On DemandDocument2 pagesOracle CRM On Demandajazahmednet3946Pas encore d'évaluation

- Reemergent Scientism, Postmodernism, and Dialogue Across DifferencesDocument7 pagesReemergent Scientism, Postmodernism, and Dialogue Across DifferencesJose Luis Ramos CañonPas encore d'évaluation

- Upload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiDocument3 pagesUpload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiArun Varshney (MULAYAM)Pas encore d'évaluation

- Akruti Marathi MultiFont Engine ReadmeDocument22 pagesAkruti Marathi MultiFont Engine Readmenmshingote2779% (38)

- STEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Document30 pagesSTEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Harsh chhedaPas encore d'évaluation

- UntitledDocument44 pagesUntitledFrancesco TauroPas encore d'évaluation

- Education During The Ancient Period Primitive EducationDocument5 pagesEducation During The Ancient Period Primitive EducationEn CyPas encore d'évaluation

- GNDU Contract Jobs 2013 Advertisement PDFDocument8 pagesGNDU Contract Jobs 2013 Advertisement PDFAnonymous zwCV8ZPas encore d'évaluation

- Refraction Through A Lens PDFDocument3 pagesRefraction Through A Lens PDFPrudhvi JoshiPas encore d'évaluation

- HTTPHeader LiveDocument199 pagesHTTPHeader LiveDenys BautistaPas encore d'évaluation

- Ballsim DirectDocument58 pagesBallsim DirectDiego GaliciaPas encore d'évaluation

- Fema 310Document12 pagesFema 310Anil BasnetPas encore d'évaluation

- 136 OsgoodeDocument8 pages136 Osgoodejawaid6970Pas encore d'évaluation

- Cultural Diversity in Vikram Seth's A Suitable Boy'Document3 pagesCultural Diversity in Vikram Seth's A Suitable Boy'Sneha PradhanPas encore d'évaluation

- JRX118SP SpecsheetDocument2 pagesJRX118SP SpecsheetLuisPas encore d'évaluation

- 01-Toy Product DesignDocument54 pages01-Toy Product DesignJuanPas encore d'évaluation

- Sample Question Paper Computer GraphicsDocument4 pagesSample Question Paper Computer Graphicsrohit sanjay shindePas encore d'évaluation

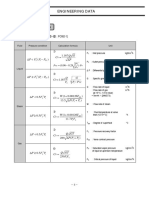

- Engineering Data: 2. CV CalculationDocument1 pageEngineering Data: 2. CV Calculationdj22500Pas encore d'évaluation

- QuestionnaireDocument5 pagesQuestionnairePrisca FolorunsoPas encore d'évaluation

- Overseas Assignment 18thseptDocument6 pagesOverseas Assignment 18thseptSuresh VanierPas encore d'évaluation

- A-W and A-F Oil SeparatorsDocument1 pageA-W and A-F Oil SeparatorstribleprincePas encore d'évaluation

- The Complete MARILLION Discography V2 PDFDocument13 pagesThe Complete MARILLION Discography V2 PDFtotalmenteprovisorioPas encore d'évaluation

- 63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebDocument2 pages63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebAradhana AradhanaPas encore d'évaluation

- Viaje Del SolDocument3 pagesViaje Del SolJanella UmiehPas encore d'évaluation

- Computer Typing History of TypingDocument9 pagesComputer Typing History of TypingRamPas encore d'évaluation