Académique Documents

Professionnel Documents

Culture Documents

RR Anova 27

Transféré par

angel_garcia6877Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RR Anova 27

Transféré par

angel_garcia6877Droits d'auteur :

Formats disponibles

August 2012 This month's newsletter is the first in a multi-part series on using the ANOVA method for an ANOVA

5 2.2 2.08 2.16 Gage R&R study. This method simply uses analysis of variance to analyze the results of a gage R&R study instead of the classical average and range 1 2 3 4 5 1 2 3 4 5 3.08 2.53 4.19 3.01 2.44 3.04 1.62 3.88 3.14 1.54 3.25 1.78 3.94 4.03 1.8 2.89 1.87 4.09 3.2 1.93 3.07 2.9800 0.0013 2.32 4.34 3.2 1.72 2.85 2.6947 0.0621 2.04 3.67 3.11 1.55 Sum of 0.1087 Deviations 15(Sum of 1.6304 Deviations)

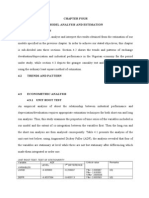

Thus, SSO = 1.6304 So, you can see that the sum of squares due to the operators is based on how the operator averages deviate from the overall average. There are three operator averages. Since we calculated the overall average, we lost one degree of freedom. The degrees of freedom associated with the operators are 3 - 1 = 2, or k -1 = 2. The variability chart below shows the results by operator by part. The horizontal blue line is the average for the operator. The horizontal green line is the overall average. The difference between those two lines is the deivation. other sources of variation present in all put one of these variances. We must use the Expected Mean Square to find out what other sources of variation are present. We will use 2 to denote a variance due to a single source.

Expected Mean Squares

As stated above, the mean square column contains a variance that is related to the source of variation in the first column. To find the variance of each source of variation, we have to use the expected mean square (EMS). The expected mean square represents the variance that the mean square column is estimating. There are algorithms that allow you to generate the expected mean squares. This is beyond the scope of this newsletter. So, we will just present the expected mean squares. Lets start at the bottom with the equipment variation. This is really the within variation (also called error). It is the repeatability portion of the Gage R&R study. The expected mean square for equipment is the repeatability variance. The repeatability variance is the mean square of the equipment from the ANOVA table.

Now consider the interaction expected mean square which is given by:

Note that the EMS for the interaction tern contains the repeatability variance as well as the variance of the interaction between the operators and parts. This is what is estimated by the mean square of the interaction. The parts expected mean square is shown below. The Measurement Systems Analysis manual published by AIAG (www.aiag.org) provides the following definition: The measurement system variation for repeatability and reproducibility (or GRR) is defined as the following: GRR2=EV2 + AV2 where EV is the equipment variance and AV is the appraiser (or operator) variance. Thus:

The total variance is the sum of the components:

We can use the total variance to determine the % contribution of each source to the total variance. This is done by dividing the variance for each source by the total variance. For example, the % variation due to GRR is given by:

The results for all the sources of variation are shown in the table below. Source GRR % of Variance Total Variance 0.1109 12.14%

Equipment (Repeatability) Operators (Reproducibility) Interaction Parts Total

0.0571 0.0538 0.0000 0.8021 0.9130

6.25% 5.89% 0.00% 87.86% 100.00%

Based on this analysis, the measurement system is responsibility for 12.14% of the total variance. This may or may not be acceptable depending on the process and what your customer needs and wants. Note that this result is based on the total variance. It is very important that the parts you use in the Gage R&R study represent the range of values you will get from production. One of the major problems people have with Gage R&R studies is selecting samples that do not truly reflect the range of production. If you have to do that, you can begin to look at how the results compare to specifications. We will take a look at that next month as we compare the ANOVA method to the Average and Range method for analyzing a Gage R&R experiment. You could also use a variance calculated directly from a month's worth of production in place of the total variance in the analysis.

Summary

In this newsletter, we continued our exploration of the using ANOVA to analyze a Gage R&R experiment. We completed the ANOVA table, presented the expected mean squares and how to use those to estimate the variances of the components, and showed how to determine the %GRR as a percent of the total variance. In the next newsletter, we will compare the ANOVA method to the Average and Range method for Gage R&R.

Quick Links

Vous aimerez peut-être aussi

- Number of Parts and Operators For A Gage R&R Study - MinitabDocument12 pagesNumber of Parts and Operators For A Gage R&R Study - Minitabtehky63Pas encore d'évaluation

- MSA Training Material - 18 - 04 - 2018Document10 pagesMSA Training Material - 18 - 04 - 2018Mark AntonyPas encore d'évaluation

- GRR Worksheet (Blank)Document11 pagesGRR Worksheet (Blank)Farhan ShariffPas encore d'évaluation

- An Honest Gauge R&R Study PDFDocument19 pagesAn Honest Gauge R&R Study PDFAbi ZuñigaPas encore d'évaluation

- The Basics of Gage RDocument4 pagesThe Basics of Gage RBharatPas encore d'évaluation

- Msa (NDC)Document7 pagesMsa (NDC)rkshpanchalPas encore d'évaluation

- How To Design, Analyze and Interpret The Results of An Expanded Gage R&R StudyDocument10 pagesHow To Design, Analyze and Interpret The Results of An Expanded Gage R&R Studymassman02143Pas encore d'évaluation

- 6.5 Checkpoint Reliability and MaintenanceDocument5 pages6.5 Checkpoint Reliability and MaintenanceherrajohnPas encore d'évaluation

- Earthquak Analysis in AnsysDocument14 pagesEarthquak Analysis in AnsysIgor GjorgjievPas encore d'évaluation

- Statistical Analysis in ExcelDocument21 pagesStatistical Analysis in Excelwaiting4addPas encore d'évaluation

- Chapter 4 The Normal DistributionDocument12 pagesChapter 4 The Normal Distributionleonessa jorban cortesPas encore d'évaluation

- ANSYS Tutorial Seismic AnalysisDocument11 pagesANSYS Tutorial Seismic AnalysisArut MV100% (1)

- Measure of Position or LocationDocument2 pagesMeasure of Position or LocationMelvin CabonegroPas encore d'évaluation

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- Measurement System AnalysisDocument7 pagesMeasurement System AnalysisselvamPas encore d'évaluation

- Gage R&RDocument16 pagesGage R&RAl-Kawthari As-SunniPas encore d'évaluation

- LeanDocument154 pagesLeanZakria Ezzat Mohamed100% (1)

- Core Tools: Measurement Systems Analysis (MSA)Document6 pagesCore Tools: Measurement Systems Analysis (MSA)Salvador Hernandez ColoradoPas encore d'évaluation

- August 2012: The ANOVA Table For Gage R&RDocument6 pagesAugust 2012: The ANOVA Table For Gage R&Rangel_garcia6877Pas encore d'évaluation

- RR Anova 36Document18 pagesRR Anova 36angel_garcia6877Pas encore d'évaluation

- RR Anova 38Document17 pagesRR Anova 38angel_garcia6877Pas encore d'évaluation

- RR Anova 31Document4 pagesRR Anova 31angel_garcia6877Pas encore d'évaluation

- RR Anova 30Document4 pagesRR Anova 30angel_garcia6877Pas encore d'évaluation

- Gauge Repeatability & Reproducibility - CampbellDocument4 pagesGauge Repeatability & Reproducibility - Campbelltehky63Pas encore d'évaluation

- RR Anova 32Document3 pagesRR Anova 32angel_garcia6877Pas encore d'évaluation

- ANOVA Gauge R&RDocument3 pagesANOVA Gauge R&Rmia farrow100% (1)

- Data Considerations For Crossed Gage RDocument11 pagesData Considerations For Crossed Gage RVivekanandan THANGARAJPas encore d'évaluation

- A Better Way To Do R&R StudiesDocument10 pagesA Better Way To Do R&R StudiesJosé Esqueda LeyvaPas encore d'évaluation

- The ANOVA Table Results: First Part of This SeriesDocument1 pageThe ANOVA Table Results: First Part of This Seriesangel_garcia6877Pas encore d'évaluation

- Acceptance Crieteria For MsaDocument17 pagesAcceptance Crieteria For MsaVaishaliYadavPas encore d'évaluation

- Expected Mean SquaresDocument1 pageExpected Mean Squaresangel_garcia6877Pas encore d'évaluation

- The ANOVA Table Results: Each Source of Variation - This Is The Key To Analyzing The Gage R&R ResultsDocument2 pagesThe ANOVA Table Results: Each Source of Variation - This Is The Key To Analyzing The Gage R&R Resultsangel_garcia6877Pas encore d'évaluation

- Gentlemen, Start Your Gages: R&R and Variability: Gagepack Gordon ConstableDocument4 pagesGentlemen, Start Your Gages: R&R and Variability: Gagepack Gordon Constablevijay2101Pas encore d'évaluation

- Nested Gage RRDocument6 pagesNested Gage RRgobu269104Pas encore d'évaluation

- Gagerandr: How To Data ExampleDocument3 pagesGagerandr: How To Data ExampleJassan ArtetaPas encore d'évaluation

- Part 1 Improved Gage RR Measurement StudiesDocument3 pagesPart 1 Improved Gage RR Measurement Studiesnelson.rodriguezm6142Pas encore d'évaluation

- Quality Control 4. What Are Meant by Median and Mode? Give Examples From A Set of Data Characterize The Other Types of QC ChartsDocument2 pagesQuality Control 4. What Are Meant by Median and Mode? Give Examples From A Set of Data Characterize The Other Types of QC ChartsDennis ValdezPas encore d'évaluation

- Assistant Gage R and RDocument19 pagesAssistant Gage R and ROrlando Yaguas100% (1)

- Gage R&R For One PartDocument2 pagesGage R&R For One Partking0% (1)

- An Honest Gage - R&R StudyDocument19 pagesAn Honest Gage - R&R StudyHEmreKPas encore d'évaluation

- Anova - One Way - Part 1 of 2Document4 pagesAnova - One Way - Part 1 of 2anjo0225Pas encore d'évaluation

- Anova: Anuj Rana (Telecom & IT) Aditi Arora (InfrastructureDocument11 pagesAnova: Anuj Rana (Telecom & IT) Aditi Arora (Infrastructureanujrana777Pas encore d'évaluation

- What Is A General Linear ModelDocument70 pagesWhat Is A General Linear ModelAshish PandeyPas encore d'évaluation

- SPSS 16.0 Tutorial To Develop A Regression ModelDocument12 pagesSPSS 16.0 Tutorial To Develop A Regression ModelSatwant SinghPas encore d'évaluation

- Statistical Analysis of Parameter Variations Using The Taguchi MethodDocument18 pagesStatistical Analysis of Parameter Variations Using The Taguchi MethodMohamedKamalPas encore d'évaluation

- An Honest Gauge R&RDocument19 pagesAn Honest Gauge R&Rnelson.rodriguezm6142Pas encore d'évaluation

- Measurement System AnalysisDocument3 pagesMeasurement System Analysisjaikel1994Pas encore d'évaluation

- StatsprojDocument12 pagesStatsprojapi-257819714Pas encore d'évaluation

- Fuel Injector NozzlesDocument19 pagesFuel Injector NozzlesAnnisa RakhmawatiPas encore d'évaluation

- Annotated SPSS Output Factor AnalysisDocument20 pagesAnnotated SPSS Output Factor AnalysisrobbierajanPas encore d'évaluation

- Anova Gauge RDocument2 pagesAnova Gauge RSuhas ChinchanikarPas encore d'évaluation

- ProcessMeasure CapabilityDocument16 pagesProcessMeasure CapabilityeuserodriguezPas encore d'évaluation

- Earthquake Analyses in Ansys WorkbenchDocument14 pagesEarthquake Analyses in Ansys WorkbenchEmmanuel Ikhaiduwor100% (1)

- Construction of Control Charts For RM, DW Sample Types: Initial AnalysesDocument4 pagesConstruction of Control Charts For RM, DW Sample Types: Initial Analyseshoria96Pas encore d'évaluation

- Arellano BondDocument22 pagesArellano BondVu Thi Duong BaPas encore d'évaluation

- Reml GuideDocument93 pagesReml GuideMartin GrondonaPas encore d'évaluation

- Error MeasuresDocument18 pagesError MeasuresbrennoPas encore d'évaluation

- Chapter Four Model Analysis and Estimation 4.1Document8 pagesChapter Four Model Analysis and Estimation 4.1Oladipupo Mayowa PaulPas encore d'évaluation

- Ranova Help Tcm18-242064Document20 pagesRanova Help Tcm18-242064BruzziPas encore d'évaluation

- Datalyzer Msa GR&RDocument17 pagesDatalyzer Msa GR&Rhazwan2283Pas encore d'évaluation

- Statistical Procedures For Measurement Systems Verification and Validation ElsmarDocument15 pagesStatistical Procedures For Measurement Systems Verification and Validation ElsmarEmeka ChieduPas encore d'évaluation

- Quantile Regression: Estimation and SimulationD'EverandQuantile Regression: Estimation and SimulationÉvaluation : 3.5 sur 5 étoiles3.5/5 (1)

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- 020 Oil Change 1Document8 pages020 Oil Change 1angel_garcia6877Pas encore d'évaluation

- RR Anova 41Document11 pagesRR Anova 41angel_garcia6877Pas encore d'évaluation

- Optimize Attribute Responses Using Design of Experiments: Example ExperimentDocument6 pagesOptimize Attribute Responses Using Design of Experiments: Example Experimentangel_garcia6877Pas encore d'évaluation

- 020 Oil Change 1Document8 pages020 Oil Change 1angel_garcia6877Pas encore d'évaluation

- RR Anova 33Document10 pagesRR Anova 33angel_garcia6877Pas encore d'évaluation

- RR Anova 35Document7 pagesRR Anova 35angel_garcia6877Pas encore d'évaluation

- RR Anova 32Document3 pagesRR Anova 32angel_garcia6877Pas encore d'évaluation

- RR Anova 34Document8 pagesRR Anova 34angel_garcia6877Pas encore d'évaluation

- RR Anova 26Document4 pagesRR Anova 26angel_garcia6877Pas encore d'évaluation

- RR Anova 25Document5 pagesRR Anova 25angel_garcia6877Pas encore d'évaluation

- RR Anova 25Document5 pagesRR Anova 25angel_garcia6877Pas encore d'évaluation

- RR Anova 29Document15 pagesRR Anova 29angel_garcia6877Pas encore d'évaluation

- RR Anova 24Document8 pagesRR Anova 24angel_garcia6877Pas encore d'évaluation

- 5 1 1-Ridf-CurvesDocument18 pages5 1 1-Ridf-Curvesjohn rey toledoPas encore d'évaluation

- Widi Taufik Aliftiyo 22010111130058 Lap - KTI Bab8Document26 pagesWidi Taufik Aliftiyo 22010111130058 Lap - KTI Bab8Audry YuniarPas encore d'évaluation

- Prob Stat (Course Outline) at UolDocument8 pagesProb Stat (Course Outline) at Uolmuhammadali12345667890Pas encore d'évaluation

- Naidu (2015)Document25 pagesNaidu (2015)Jamae ClementePas encore d'évaluation

- Chapter 4: Probability DistributionsDocument8 pagesChapter 4: Probability DistributionsŞterbeţ RuxandraPas encore d'évaluation

- Jumping Performance and Hand Grip Strength Between Smasher and Setter U-17 Volleyball PlayersDocument4 pagesJumping Performance and Hand Grip Strength Between Smasher and Setter U-17 Volleyball PlayersvladillionairePas encore d'évaluation

- 6.4 Process CapabilityDocument13 pages6.4 Process CapabilitychuszPas encore d'évaluation

- The New HDI Index Lecture 2Document4 pagesThe New HDI Index Lecture 2Hussein Ahmed BelalPas encore d'évaluation

- 8 ChapterDocument8 pages8 ChapterSaahil LedwaniPas encore d'évaluation

- Chapter 5 Image Restoration - 01Document37 pagesChapter 5 Image Restoration - 01Aman Ahmad SiddiqueePas encore d'évaluation

- Unit-3 DS StudentsDocument35 pagesUnit-3 DS StudentsHarpreet Singh BaggaPas encore d'évaluation

- Chapter 3Document5 pagesChapter 3Lj Kma SañolPas encore d'évaluation

- Introductory Business Statistics 2e - WEBDocument627 pagesIntroductory Business Statistics 2e - WEBloannttPas encore d'évaluation

- STAT Summative Test - Q3 (Week 3-4)Document2 pagesSTAT Summative Test - Q3 (Week 3-4)Jennifer MagangoPas encore d'évaluation

- All Bangladesh IBA BBA Live Exam Sample PaperDocument21 pagesAll Bangladesh IBA BBA Live Exam Sample PaperPallab KumarPas encore d'évaluation

- Probabilitydistribution - Unit-4Document17 pagesProbabilitydistribution - Unit-4rajeshPas encore d'évaluation

- Chapter 1 StatisticsDocument74 pagesChapter 1 StatisticsAmizan AbdullahPas encore d'évaluation

- BUS 310 - Problem Set 3Document9 pagesBUS 310 - Problem Set 3GregPas encore d'évaluation

- 75120bos60683 Init p3Document15 pages75120bos60683 Init p3Shivam SinghPas encore d'évaluation

- Nonlinear FilteringDocument16 pagesNonlinear Filteringscribd_1962Pas encore d'évaluation

- STIMULI To The REVISION PROCESS An Evaluation of The Indifference Zone of The USP 905 Content Uniformity Test1Document21 pagesSTIMULI To The REVISION PROCESS An Evaluation of The Indifference Zone of The USP 905 Content Uniformity Test1jljimenez1969Pas encore d'évaluation

- SB 2023 Lecture5Document62 pagesSB 2023 Lecture5Quyen Pham Tran ThucPas encore d'évaluation

- Statistics Notes For IIT JEE - pdf-83Document5 pagesStatistics Notes For IIT JEE - pdf-83ManitPas encore d'évaluation

- Final Report SpssDocument14 pagesFinal Report SpssZinda Rood NetworkPas encore d'évaluation

- KEnyatta University Notes EPS 400 Education Statistics PDFDocument122 pagesKEnyatta University Notes EPS 400 Education Statistics PDFDAVID KOIYA100% (1)

- Confidence IntervalDocument44 pagesConfidence IntervalShaivy TyagiPas encore d'évaluation