Académique Documents

Professionnel Documents

Culture Documents

LF 2 Material

Transféré par

mohdnazirCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LF 2 Material

Transféré par

mohdnazirDroits d'auteur :

Formats disponibles

Bramm er Standard Comp any, Inc.

Data Sheet for Setting-up Material

BS SU LF-2

ASTM A350 (LF2) Carbo n Steel

(UNS Number K03011)

Estimated Analysis1

Estimated Analysis1

Analysis listed as percent by weight

C Mn P S Si Cu Ni Cr Mo Al

1

0.17 1.13 0.007 0.008 0.24 0.19 0.115 0.12 0.035 0.040

Co N O

0.014 0.0074 0.002

The above chemistry is supplied as an approximate guide to the composition and must not be regarded as the certified analysis. The analysis is based on the results of a Proficiency Testing Program. According to ASTM Standard Practice E 2027, the data from proficiency testing programs must never be used to assign certification values to the materials used in the program. This material may be used for instrument drift control. It must not be used for instrument calibration.

See the following pages for more information. Data Sheet Number SU-LF-2-091201p1

Brammer Standard Com pany, Inc., 14603 Benfer Road, Houston, TX 77069-2895 Telephone (281) 440-9396 Fax (281) 440-4432 brammerstandard.com

Analytical data : This material was used as an unknown test specimen number 3991 in a nationally recognized Proficiency Testing Program (PTP) for low alloy steel. Most of the participating laboratories used one or more of the ASTM Standard Test Methods E 322, E 415, E 1019, and E 1085. The data shown below are the results from the PTP. Combustion Instrument Analysis using ASTM Standard Test Method E 1019 C Number of Labs Grand Average Standard Deviation 51 0.1756 0.0057 S 46 0.0069 0.0008 N 38 0.0074 0.0004 O 29 0.0018 0.0007

Optical Emission Spectrometric Analysis using ASTM Standard Test Method E 415 C Number of Labs Grand Average Standard Deviation 70 0.1727 0.0076 Cr Number of Labs Grand Average Standard Deviation 72 0.1181 0.0049 Mn 71 1.1322 0.0236 Mo 71 0.0346 0.0031 P 73 0.0067 0.0010 Al 70 0.0399 0.0030 S 67 0.0080 0.0011 Co 33 0.0112 0.0010 Si 74 0.2364 0.0086 Cu 73 0.1884 0.0077 Ni 71 0.1147 0.0056 N 22 0.0073 0.0008

X-ray Emission Spectrometric Analysis using ASTM Standard Test Method E 322 Mn Number of Labs Grand Average Standard Deviation 6 1.1370 0.0145 Cu 6 0.1901 0.0062 Ni 6 0.1151 0.0040 Cr 6 0.1165 0.0039 Mo 6 0.0356 0.0005

X-ray Emission Spectrometric Analysis using ASTM Standard Test Method E 1085 Mn Number of Labs Grand Average Standard Deviation 6 1.1356 0.0068 P 3 0.0066 0.0016 Si 6 0.2382 0.0103 Cu 6 0.1908 0.0028 Ni 6 0.1180 0.0034 Cr 6 0.1144 0.0019 Mo 6 0.0338 0.0017 Co 4 0.0128 0.0015

Other Analytical Methods such as AA, ICP, and GDOES spectrometric analysis and combustion methods C Number of Labs Average Standard Deviation 5 0.1738 0.0069 Al Number of Labs Average Standard Deviation 6 0.0398 0.0029 Mn 8 1.1400 0.0193 Co 4 0.0118 0.0018 P 5 0.0062 0.0010 S 5 0.0077 0.0022 Si 10 0.2383 0.0051 Cu 10 0.1891 0.0076 Mn 4 1.1449 Ni 8 0.1161 0.0061 Cr 7 0.1168 0.0077 Mo 6 0.0343 0.0008

ASTM E 350 >

0.0128

Overall Summary C Robust Mean Robust. Std. Deviation 0.1740 0.0069 Al Robust Mean Robust. Std. Deviation 0.0399 0.0029 Mn 1.1342 0.0209 Co 0.0144 0.0011 P 0.0066 0.0011 N 0.0074 0.0005 S 0.0076 0.0012 O 0.0018 0.0007 Si 0.2369 0.0083 Cu 0.1887 0.0072 Ni 0.1151 0.0054 Cr 0.1176 0.0049 Mo 0.0346 0.0026

Data Sheet Number SU-LF-2-091201p2

Homogeneity : This Setting-up Material was tested for homogeneity using ASTM Standard Method E 826 and found acceptable. It was also examined by optical emission spectrometry using ASTM Standard Test Method E 1086 and found to be compatible with the following Reference Materials: SS 433/1, 454/1; CKD 165D, 181A; BS 13B, 50D, 61D.

Source: This material was melted by Operadora de Industrias C H, S.A. de C.V., Tlalnepantla, Edo. de Mexico, Mexico. It was melted by an electric arc furnace, vacuum degassed, bottom poured into ingots, aluminum killed, hot rolled, and annealed.

Form : This Setting-up Material is in the form of a disc, app roximately 38 mm (1.50 inches) diame ter and 40 mm (1.57 inch es) thick.

Use : This material is intended for use in optical emissio n and x-ray spectrometric methods of ana lysis.

Analytical area: The entire depth of the disc may be used . Caution: As with any bar material, avoid optical emission spectrometric burns in the center of the disc (5 mm radius), as some segregation may be present.

Sample Preparation: For best analytical results, use the same method for preparing the analytical surface on all setting-up samples as you use for production specimens. Avoid overheating the bar during surface preparation.

Data Sheet Number : The unique identification nu mber for this data sheet is SU-LF-2-09 1201-px, where x in dicates the page number. Refer to future Brammer Standard C ompany catalogs for inform ation on any revisions to th is or other Brammer Standard m aterials. You may also obtain information on revisions from the internet at brammerstandard.com.

Safety Notice: A Material Safety Data Sheet (MSD S) is not required for this material. This material will not release or otherw ise result in exposure to a hazardous chemical under normal conditions of use. Inquiries concerning this Setting-up Material should be directed to: Brammer Standard Co., Inc. 14603 Benfer Road Houston, Texas 77069-2895 USA Phone: Fax: (281) 440-9396 (281) 440-4432 web e-mail brammerstandard.com bramstan@netropolis.net

Prepared by: ____________________________ on September 12, 2001. G. R. Brammer

Data Sheet Number SU-LF-2-091201p3

Brammer Standard Company, Inc., is accredited to ISO Guide 34 as a Reference Material Producer for the production of Certified Reference Materials and Reference Materials by A2LA (Certificate Number 656.02) The scope of accreditation is listed on the website: www.brammerstandard.com By Certificate Number 10539, the Quality System of Brammer Standard Company, Inc., is registered to ISO 9002:1994 by National Quality Assurance, U.S.A. Bramm er Standa rd Compa ny's Chemi cal Labora tory is accred ited to ISO Gu ide 25 by A2LA. (Certificate Number 656.01)

References:

ASTM docum ents available from A STM, 100 Barr Harbo r Drive, West Cons hohocken, PA 19428-2959, Telephone: 610-83 2-9500 Fax: 610-832-955 5 e-mail: service@a stm.org Website: ww w.astm.org

E 322 - 96 Standard Test Method for X-Ray Emission Spectrometric Analysis of Low-Alloy Steels and Cast Irons E 35 0 - 90 Stan dard Tes t Met hod s for Che mic al An alysis of Ca rbon Stee l, Low -Alloy S teel, S ilicon E lectric al Ste el, Ingot Iron, and Wrought Iron E 415 - 85 (Reapproved 1999) Standard Test Method for Optical Emission Vacuum Spectrometric Analysis of Carbon and Low-Alloy Steel E 826 - 85 (Reapproved 1996) Standard Practice for Testing Homogeneity of Materials for the Development of Ref eren ce M ateria ls E 1019 - 2000 Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel and in Iron, Nick el, an d Co balt A lloys E 10 85 - 9 5 Sta nda rd T est M etho d for X-R ay Em issio n Sp ectro me tric An alysis of Lo w-A lloy Ste els E 2027 - 99 Standard Practice for Conducting Proficiency Tests in the Chemical Analysis of Metals, Ores, and Related Materials

Data Sheet Number SU-LF-2-091201p4

Vous aimerez peut-être aussi

- Denver's Sewer Design Technical Criteria ManualDocument75 pagesDenver's Sewer Design Technical Criteria ManualmohdnazirPas encore d'évaluation

- Boost pump calc project name locationDocument6 pagesBoost pump calc project name locationmohdnazirPas encore d'évaluation

- Friction factor calculation sheetDocument2 pagesFriction factor calculation sheetmohdnazirPas encore d'évaluation

- Eaching High-Rise Plumbing DesignDocument19 pagesEaching High-Rise Plumbing Designm_salah20202000Pas encore d'évaluation

- Funke Phe eDocument0 pageFunke Phe emohdnazirPas encore d'évaluation

- Simplified Sizing Procedure For Solar Domestic Hot Water SystemsDocument0 pageSimplified Sizing Procedure For Solar Domestic Hot Water SystemsmohdnazirPas encore d'évaluation

- ASPE Sump Pump SizingDocument60 pagesASPE Sump Pump Sizingzaqhusanz100% (5)

- ColebrookDocument12 pagesColebrookmohdnazirPas encore d'évaluation

- Colebrook White EquationDocument1 pageColebrook White EquationRendi KurniawanPas encore d'évaluation

- Sewage Lift StationDocument110 pagesSewage Lift Stationmohdnazir100% (1)

- Back To Basics WebDocument3 pagesBack To Basics WebmohdnazirPas encore d'évaluation

- Quick Calculation of Cooling Tower Blowdown and MakeupDocument3 pagesQuick Calculation of Cooling Tower Blowdown and Makeupmohdnazir100% (1)

- Preferred Option:: Install A Permanent Plumbing Fixture On Vehicle To Allow For Air GapDocument1 pagePreferred Option:: Install A Permanent Plumbing Fixture On Vehicle To Allow For Air GapmohdnazirPas encore d'évaluation

- Module3 Part1Document11 pagesModule3 Part1mohdnazirPas encore d'évaluation

- DUCT Large Comm BuildingsDocument11 pagesDUCT Large Comm BuildingsmohdnazirPas encore d'évaluation

- Fire Sprinkler DesignDocument1 pageFire Sprinkler DesignmohdnazirPas encore d'évaluation

- Minor Pipe Losses (Equivalent Lengths)Document4 pagesMinor Pipe Losses (Equivalent Lengths)Hassan AbdulAzim FadilPas encore d'évaluation

- ASPE Sump Pump SizingDocument60 pagesASPE Sump Pump Sizingzaqhusanz100% (5)

- Pump Room Piping Schematic DiagramDocument1 pagePump Room Piping Schematic DiagrammohdnazirPas encore d'évaluation

- Simplified Sizing Procedure For Solar Domestic Hot Water SystemsDocument0 pageSimplified Sizing Procedure For Solar Domestic Hot Water SystemsmohdnazirPas encore d'évaluation

- 500 GPM Inline W EnclDocument1 page500 GPM Inline W EnclmohdnazirPas encore d'évaluation

- 500 GPM Electric W EnclDocument1 page500 GPM Electric W EnclmohdnazirPas encore d'évaluation

- Focus On Fire ProtectionDocument3 pagesFocus On Fire ProtectionmohdnazirPas encore d'évaluation

- 500 GPM Diesel W EnclDocument1 page500 GPM Diesel W EnclmohdnazirPas encore d'évaluation

- Mega EnglishDocument4 pagesMega EnglishmohdnazirPas encore d'évaluation

- Tall Building Drainage Design GuidanceDocument24 pagesTall Building Drainage Design GuidancemohdnazirPas encore d'évaluation

- V 13 I 5Document11 pagesV 13 I 5mohdnazirPas encore d'évaluation

- One-And Two-Family Residential Building Fires (2008-2010) : T F R SDocument14 pagesOne-And Two-Family Residential Building Fires (2008-2010) : T F R SmohdnazirPas encore d'évaluation

- Heavy DensityDocument4 pagesHeavy DensitymohdnazirPas encore d'évaluation

- 500 GPM Electric W EnclDocument1 page500 GPM Electric W EnclmohdnazirPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Updated materials properties list with aluminum alloysDocument36 pagesUpdated materials properties list with aluminum alloysChenthil Kumar KPas encore d'évaluation

- Mixtures & Separation Chapter GuideDocument24 pagesMixtures & Separation Chapter Guideameerul_hazeeqPas encore d'évaluation

- Mendeleev's Major Contributions to the Periodic TableDocument8 pagesMendeleev's Major Contributions to the Periodic TableHot LadyPas encore d'évaluation

- LAB Find Out The Bottle ContentsDocument4 pagesLAB Find Out The Bottle ContentschanPas encore d'évaluation

- Proof Hi PDFDocument29 pagesProof Hi PDF孙中体Pas encore d'évaluation

- Kseeb I Puc Chemistry Model Paper 2022Document3 pagesKseeb I Puc Chemistry Model Paper 2022Chimmi ChimmiPas encore d'évaluation

- Geology: - What Is A Mineral? - What Is A Gem? - What Is A Rock? - How Are These Formed?Document26 pagesGeology: - What Is A Mineral? - What Is A Gem? - What Is A Rock? - How Are These Formed?OcZzPas encore d'évaluation

- Atomic Structure QuestionsDocument37 pagesAtomic Structure QuestionsRochelle NuguidPas encore d'évaluation

- Electrolysis Principles ExplainedDocument12 pagesElectrolysis Principles ExplainedsaeikipPas encore d'évaluation

- Worksheet LR - ERDocument3 pagesWorksheet LR - ERTanvi GandhiPas encore d'évaluation

- SRL Catalogue 20 21 Excel Version 27-05-2020Document315 pagesSRL Catalogue 20 21 Excel Version 27-05-2020Vanshika JainPas encore d'évaluation

- QuantitativeDocument87 pagesQuantitativeMohamed DahmanePas encore d'évaluation

- Redox Test 2Document8 pagesRedox Test 2Arhum AliPas encore d'évaluation

- Compliant Tattoo Ink Formulation and TestingDocument1 pageCompliant Tattoo Ink Formulation and TestingJuan DominguezPas encore d'évaluation

- Some Basic Concept of Chemistry - Mind MapDocument2 pagesSome Basic Concept of Chemistry - Mind MapAbbas AliPas encore d'évaluation

- NCERT Class 11 Chemistry Textbook Solved QuestionsDocument3 pagesNCERT Class 11 Chemistry Textbook Solved QuestionsSri DharshanPas encore d'évaluation

- Lect 1crystalline Structure of MetalsDocument44 pagesLect 1crystalline Structure of MetalsAli RazaPas encore d'évaluation

- S Block Elemetns QBDocument8 pagesS Block Elemetns QBRajeev KaushikPas encore d'évaluation

- Chem Module 1 OnScreenDocument73 pagesChem Module 1 OnScreenLarah XeniaPas encore d'évaluation

- Oms A Bupivacaina FARMACOPEA INTERNACIONALDocument3 pagesOms A Bupivacaina FARMACOPEA INTERNACIONALsociedad de servicios farmaceuticos a la comunidadPas encore d'évaluation

- Mingos 1-4 PartDocument414 pagesMingos 1-4 PartSofter AlvesPas encore d'évaluation

- Color Coding The Periodic Table - InstructionsDocument2 pagesColor Coding The Periodic Table - InstructionsVictoria LowmanPas encore d'évaluation

- Module 7-12 NotesDocument27 pagesModule 7-12 Notesjared.greenwood93Pas encore d'évaluation

- EdExcel A Level Chemistry Unit 3 Paper 1 Jan 2009Document16 pagesEdExcel A Level Chemistry Unit 3 Paper 1 Jan 2009chuasioklengPas encore d'évaluation

- Lab Report Kimia 1Document11 pagesLab Report Kimia 1nur anith aqilahPas encore d'évaluation

- Chemical Reactions For KS3 - WorksheetDocument3 pagesChemical Reactions For KS3 - Worksheetmadam100% (1)

- Learning Activity 2 Engineering Sciences and Allied Subjects Chemistry SourceDocument3 pagesLearning Activity 2 Engineering Sciences and Allied Subjects Chemistry SourceAraiza FloresPas encore d'évaluation

- Preconcentration of Trace Metals Using Morpholine DithiocarbamateDocument7 pagesPreconcentration of Trace Metals Using Morpholine DithiocarbamateAnonymous FW5PVUpPas encore d'évaluation

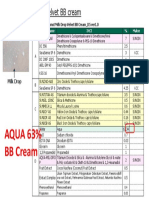

- Coconut Milk BB Cream for Velvety SkinDocument1 pageCoconut Milk BB Cream for Velvety SkinSandiePas encore d'évaluation

- Covalent CompoundsDocument15 pagesCovalent CompoundsTingal, Jaynore C.Pas encore d'évaluation