Académique Documents

Professionnel Documents

Culture Documents

62super Ti Se en 0

Transféré par

Jhony MedranoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

62super Ti Se en 0

Transféré par

Jhony MedranoDroits d'auteur :

Formats disponibles

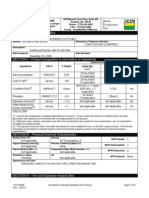

BOHLER THYSSEN WELDING USA, INC.

MATERIAL SAFETY DATA SHEET May be used to comply with OSHA's Hazard Communication Standard, 29 CFR 1910.1200. Standard must be consulted for specific requirements, see Referenced Standards in Detailed Explanation. SECTION I IDENTITY Product: UTP 62 SUPER Ti AWS or other spec: A5.5 E110-18M Manufacturer/Distributor Name: BOHLER THYSSEN WELDING USA, INC. Telephone Number: (281) 499-1212 1-800-527-0791 SECTION II HAZARDOUS INGREDIENTS/COMPONENTS OSHA PEL(mg/m ) ACGIH TLV(mg/m ) PERCENT TWA-10 TWA-5 60-100% TWA-15 TWA-10 1-5% 5 CEILING TWA-0.2 0.5-1.5% TWA-[5/%Si0(2) +2]/2 TWA-0.05 Respirable 0.1-1% Respirable Dust TWA-[15/%Si0(2) +2]/2 Total Dust CALCIUM CARBONATE 471-34-1 TWA-5-Respirable TWA-10-Inhalable 7-13% 15-Total 3-Respirable POTASSIUM SILICATE 1312-76-1 TWA-5-Respirable TWA-10-Inhalable 1-5% 15-Total 3-Respirable SODIUM SILICATE 6834-92-0 TWA-80/%(SiO2) TWA-10 1-5% CALCIUM FLUORIDE 7789-75-5 TWA-2.5 TWA-2.5 7-13% LITHIUM Al SILICATE 12068-40-5 TWA-5-Respirable TWA-2 1-5% 15-Total NICKEL 7440-02-0 TWA-1 TWA-0.5 Inhalable 0.5-1.5% MOLYBDENUM 7439-98-7 TWA-15 TWA-10 0.1-1% CHROMIUM 7440-47-3 TWA-1 TWA-0.05 0.1-1% IMPORTANT! This section covers the material from which this product is manufactured. The fumes and gases produced during welding with this product are covered by SECTION VI. The term "hazardous" in "Hazardous Materials" should be interpreted as a term required and defined in OSHA 2265 (29 CFR 1910.1200) and does not necessarily imply the existence of any hazard. SECTION III PHYSICAL/CHEMICAL CHARACTERISTICS Boiling Point: N/A Specific Gravity(H2O=1): N/A Chemical Identity IRON TITANIUM DIOXIDE MANGANESE SILICON DIOXIDE CAS 7439-89-6 13463-67-7 7439-96-5 14464-46-1

3 3

Product Type: Shielded Metal Arc Welding Electrode Address: 10401 GREENBOUGH STAFFORD, TEXAS 77477 Date Prepared: REVISED 10/97

Vapor Pressure(mmHg.): N/A Melting Point: N/A

Vapor Density (AIR-1): N/A Evaporation Rate: N/A Solubility in Water: N/A Appearance and Odor: N/A SECTION IV FIRE AND EXPLOSION HAZARD DATA Flash Point(Method Used): N/A Flammable Limits N/A LEL-N/A UEL-N/A Extinguishing Media: N/A Special Fire Fighting Procedures: N/A Unusual Fire and Explosion Hazards: N/A See Section IV in Detailed Explanation SECTION V REACTIVITY DATA Stability: Unstable N/A Stable N/A Conditions to avoid N/A Hazardous Decomposition or Byproducts: See Section V in Detailed

Incompatibility (Materials to avoid): N/A

Hazardous Polymerization May occur N/A Will not occur N/A Conditions to avoid N/A SECTION VI HEALTH HAZARD DATA Route(s) of entry: Inhalation? ** Skin? Unlikely Ingestion? Unlikely ** Gases and fumes generated while welding may be dangerous to your health. See Section VI in Detailed Explanation Carcinogenicity: Nickel X (See Section VI in Detailed Explanation) Chromium: X (See Section VI in Detailed Explanation) Signs and Symptoms of Over Exposure: Short-term (acute): See Section VI in Detailed Explanation Long-term (chronic): See Section VI in Detailed Explanation Emergency and First Aid Procedures: In Case of Fume Inhalation Remove to Fresh Air. Employ First Aid Techniques Recommended by the American Red Cross. In an Emergency Call Physician. WARNING: This product contains or produces a chemical known to the State of California to cause cancer and birth defects (or other reproductive harm). (California Health & Safety Code Sec. 25249.5 et. seq.) SECTION VII PRECAUTIONS FOR SAFE HANDLING AND USE Steps to be taken in case material is released or spilled: N/A Waste Disposal Method: Prevent Waste from Contaminating Surrounding Environment. Discard Any Product, Residue, Disposable Container or Liner in an Environmentally Acceptable Manner, in Full Compliance with Federal, State, and Local Regulations. Precautions to be taken in handling and storing: Cool and Dry Storage Other Precautions: When Welding, Brazing, or Soldering: Welding Arc or Torch Flame May Be a Source of Ignition of Combustible Product. SECTION VIII CONTROL MEASURES Respiratory Protection (specify type): See Section VIII in Detailed Explanation Ventilation: Local Exhaust required in semi-open or poorly ventilated space. See Section VIII in Detailed Explanation Protective Gloves: See Section VIII in Detailed Explanation Other Protective Clothing or Equipment: See Section VIII in Detailed Explanation Work/Hygienic Practices: See Section VIII in Detailed Explanation The information in this MSDS was obtained from sources we believe are reliable. However, this information is provided without any representation of warranty, expressed or implied, regarding accuracy or correctness.

BOHLER THYSSEN WELDING USA, INC. MSDS DETAILED EXPLANATION

REFERENCED STANDARDS In this publication, reference is made to the standards listed below. Copies are available from the indicated sources. American Welding Society, Inc. 550 N.W. LeJeune Road Miami, FL 33126 AWS F1.1-1992 AWS F1.2-1992 Methods for Sampling Airborne Particulates Generated by Welding and Allied Processes Laboratory Method for Measuring Fume Generation Rates and Total Fume Emission for Welding and Allied Processes

American National Standards Institute 11 West 42nd Street New York, NY 10036 ANSI Z49.1-1994 Safety in Welding, Cutting and Allied Processes

Superintendent of Documents Administration U.S. Government Printing Office Washington, DC 20402 OSHA Standard 29 CFR 1910 Toxic and Hazardous Substances Subpart Z 1910.1000 Air Contaminants Table Z-2 U.S. Department of Labor Occupational Safety and Health Administration 200 Constitution Avenue Room N-3101 Washington, DC 20210 OSHA Standard 29 CFR 1910.1200 Environmental Protection Agency 401 M Street, S.W. Washington, DC 20460 Sections 311, 312, 313 Emergency Planning and Community Right-To-Know Act of 1986 (EPCRA) Material Safety Data Sheet (Non-Mandatory Form)

American Conferencel of Governmental Industrial Hygienists Technical Affairs Office Kemper Woods Center 1330 Kemper Meadow Drive Cincinnati, OH 45240 Threshold Limit Values (TLVs) for Chemical Substances and Physical Agents and Biological Exposure Indices (BEIs)

SECTION IV FIRE AND EXPLOSION HAZARD DATA IMPORTANT! (Non Flammable) Welding arc and sparks can ignite combustibles and flammables. Refer to American National Standard Z49.1 for fire prevention and protection information during the use of welding and allied procedures. SECTION V REACTIVITY DATA

HAZARDOUS DECOMPOSITION PRODUCTS

Welding fumes and gases cannot be classified simply. The composition and quantity of both are dependent upon the metal being welded, the process, procedure and electrodes used. Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be exposed include: coatings on the metal being welded (such as paint, plating, or galvanizing), the number of welders and the volume of the work area, the quality and amount of ventilation, the position of the welder's head with respect to the fume plume, as well as the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon vapors from cleaning and degreasing activities). When the electrode is consumed, the fume and gas decomposition products generated are different in percent and form from the ingredients listed in SECTION II. Fume and gas decomposition products, and not the ingredients in the electrode are important. The concentration of a given fume or gas component may decrease or increase by many times the original concentration in the electrode. Also, new compounds not in the electrodes may form. Decomposition products of normal operation include those originating from the volatilization, reaction, or oxidation of the materials shown in SECTION II, plus those from the base metal and coating, etc..., as noted above. Reasonably expected fume constituents of this product would include: Example for Carbon dioxide shielded flux-cored electrode (AWS 5.20 E70-T-1): Reasonably expected fume constituents of this product would include: 3 primarily oxides of Iron; secondarily complex oxides of Manganese, Silicon, Titanium and Sodium. The present ACGIH TLV for Manganese, 0.2 mg/m 3 will result in a significant reduction from the 5 mg/m general welding fume (NOC) level. Example for Stainless Steel covered electrodes (AWS 5.4): Reasonably expected fume constituents of this product would include: primarily fluorides and complex oxides of Iron and Silicon, secondarily complex oxides of Manganese, titanium, chromium, nickel, sodium and potassium. The present 1995 OSHA PEL (Permissible Exposure Limit) for hexavalent

Chromium (Cr ) is 0.05 mg/m which will result in a significant reduction from the 5 mg/m general welding fume (NOC) level. The limit of 0.05 3 mg/m for hexavalent chromium from the decomposition products in these electrodes comes from the limit shown at the bottom of OSHA Table Z-2, 3+6 3 which is for 0.1 mg of CrO which calculates to 0.05 mg of Cr /m . It applies to soluble chromates of the types found in covered stainless electrode fumes. Reasonably expected gaseous constituents would include Carbon monoxide and Carbon dioxide. Ozone and nitrogen oxides may be formed by the radiation from the arc. One recommended way to determine the composition and quantity of fumes and gases to which workers are exposed is to take an air sample from inside the welder's helmet if worn or in the worker's breathing zone. See ANSI/AWS F1.1 and ANSI/AWS F1.2-1992

+6

SECTION VI HEALTH HAZARD DATA

THRESHOLD LIMIT VALUE:

The ACGIH recommended general limit for welding fume NOC- (not otherwise classified) is 5 mg/m . ACGIH-1995 (or latest date) preface states, "These values are not fine lines between safe and dangerous concentrations and should not be used by anyone untrained in the discipline of industrial hygiene." See SECTION V for specific fume constituents which may modify the TLV.

EFFECTS OF OVER EXPOSURE: WARNING: PROTECT yourself and others. Read and understand FUMES AND GASES can be dangerous to your health.

this information.

Short-term (acute) overexposure to welding fumes may result in discomfort such as metal fume fever, dizziness, nausea, or dryness or irritation of nose, throat or eyes and may aggravate pre-existing respiratory problems (e.g. asthma, emphysema). See SECTIONS IV and VII. Exposure to extremely high levels of fluorides can cause abdominal pain, diarrhea, muscular weakness, and convulsions. In extreme cases it can cause loss of consciousness and death. Long-term (chronic) overexposure to welding fumes can lead to siderosis (iron deposits in lung) and may affect pulmonary function. Manganese overexposure can affect the central nervous system, resulting in impaired speech and movement. The primary entry route for welding fumes and gases is by inhalation Bronchitis and some lung fibrosis have been reported. Repeated exposure to fluorides may cause excessive calcification of the bone and calcification of ligaments of the ribs, pelvis and spinal column. May cause skin rash. Arc Rays can injure eyes and burn skin. Electric Shock can kill. Before use, read and understand the manufacturer's instructions., MSDSs, and your employer's safety practices. Keep your head out of the fumes. Use enough ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing zone and the general area. Wear correct eye, ear, and body protection.. Do not touch live electrical parts. See American National Standard Z49.1, and OSHA Safety and Health Standards.

CARCINOGENICITY: NICKEL: The

International Agency for Research on Cancer indicates nickel refining and "certain nickel compounds" were cancer-causing, but could not state with certainty which forms of nickel may be carcinogenic. The National Toxicology Program lists nickel powder, nickel subsulfide, nickel oxide, nickel carbonate, nickel carbonyl and nickelocene as substances "that may reasonably anticipated to be carcinogens." Because of this, the OSHA Hazard Communication Standard requires that everyone who manufactures or imports these substances or mixtures or alloys containing these substances must warn of a cancer hazard on their MSDS's and labels. This warning is mandated by OSHA even though studies have not demonstrated cancer risks associated with the use of nickel. Intramuscular injection and implantation of nickel powder produced localized tumors in rats and mice. Inhalation studies using animals showed no evidence of carcinogenicity. The International Agency for Research on Cancer and The National Toxicology Program indicates there is sufficient evidence for carcinogenicity of chromium compounds both in humans and experimental animals. IARC notes that "the compounds responsible for the carcinogenic effect in humans cannot be specified." Studies with chromium metal and trivalent forms of chromium compounds have shown inadequate evidence for carcinogenicity in both animals and humans.

CHROMIUM :

SECTION VIII CONTROL MEASURES

SPECIAL PROTECTION INFORMATION AND PRECAUTIONS

Read and understand the manufacturer's instruction and the precautionary label on the product. See American National Standard Z49.1 and OSHA Publication (29 CFR 1910 Hazard Communication Standard for more detail on many of the following.

VENTILATION

Use enough ventilation, local exhaust at the arc, or both, to keep the fumes and gases from the worker's breathing zone and the general area. Train the welder to keep his head out of the fumes. Keep exposures as low as possible

RESPIRATORY PROTECTION

Use respirable fumes respirator or air supplied respirator when welding in confined space or where local exhaust or ventilation does not keep exposure below the recommended exposure limit.

EYE PROTECTION

Wear helmet or use face shield with filter lens. Provide protective screens and flash goggles, if necessary, to shield others. As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go the next lighter shade which gives sufficient view of the weld zone.

PROTECTIVE CLOTHING

Wear hand, head, and body protection which help to prevent injury from radiation, sparks, and electrical shock. See ANSI Z49.1. At a minimum this includes welder's gloves and a protective face shield, and may include arm protectors, aprons, hats, shoulder protection, and well as dark substantial clothing. Train the welder not to touch live electrical parts and to insulate himself from work and ground.

SECTION IX: DOCUMENTARY INFORMATION DISCLAIMER OF EXPRESSED AND IMPLIED WARRANTIES The information in this document is believed to be correct as of the date of issuance. However, NO WARRANTY OF MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY OTHER WARRANTY IS EXPRESSED, OR IS TO BE IMPLIED REGARDING THE ACCURACY OR COMPLETENESS OF THIS INFORMATION, THE RESULTS TO BE OBTAINED FROM THE USE OF THIS INFORMATION, OR THE PRODUCT, THE SAFETY OF THIS PRODUCT, OR THE HAZARDS RELATED TO ITS USE. This information and product are furnished on the condition that the person receiving them shall make his own determination as to the suitability of each product, process and application for his particular purpose, and on the condition that he assumes the risk of his use thereof.

Vous aimerez peut-être aussi

- A967A967M-13 Standard Specification For Chemical Passivation Treatments For Stainless Steel PartsDocument7 pagesA967A967M-13 Standard Specification For Chemical Passivation Treatments For Stainless Steel Partstjt4779100% (1)

- AWS D1.1 Short Code Tests #3Document4 pagesAWS D1.1 Short Code Tests #3Malcolm DiamondPas encore d'évaluation

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshPas encore d'évaluation

- Applied HydrogeologyDocument10 pagesApplied HydrogeologyJuliana Quinderé Carneiro0% (1)

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoPas encore d'évaluation

- Geotextile BookDocument63 pagesGeotextile BookIsparmoPas encore d'évaluation

- Hot Dip GalvanizingDocument24 pagesHot Dip GalvanizingKarthikeyan MuniaswamyPas encore d'évaluation

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesD'EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesPas encore d'évaluation

- M - ENG - MSDS v1.2Document157 pagesM - ENG - MSDS v1.2sunthron somchaiPas encore d'évaluation

- Chem Note SS1 1st TermDocument32 pagesChem Note SS1 1st TermVictor Okosun94% (16)

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesD'EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesPas encore d'évaluation

- Trashracks and Raking Equipment, Water Power PDFDocument16 pagesTrashracks and Raking Equipment, Water Power PDFJhony MedranoPas encore d'évaluation

- Handbook of Air Pollution Prevention and ControlD'EverandHandbook of Air Pollution Prevention and ControlÉvaluation : 5 sur 5 étoiles5/5 (2)

- Manufacturing of Light Weight Composite Parts For Automotive ApplicationsDocument84 pagesManufacturing of Light Weight Composite Parts For Automotive ApplicationsvkrishnarajPas encore d'évaluation

- Chem 210 Lab Report 1Document6 pagesChem 210 Lab Report 1Mxokzah Cmoh100% (1)

- Material Safety Data SheetsDocument5 pagesMaterial Safety Data SheetsSuryanarayanan VenkataramananPas encore d'évaluation

- Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Document2 pagesMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Rama Krishna Reddy DonthireddyPas encore d'évaluation

- MSDS Tungsten Electrode Safety DataDocument2 pagesMSDS Tungsten Electrode Safety DataSerkan ApayPas encore d'évaluation

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoPas encore d'évaluation

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoPas encore d'évaluation

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803Pas encore d'évaluation

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgePas encore d'évaluation

- Aluminum Wires and Rods 1Document2 pagesAluminum Wires and Rods 1OteranmoralesPas encore d'évaluation

- Aluminum Msds 8-05Document3 pagesAluminum Msds 8-05mohamed AdelPas encore d'évaluation

- ZULFI E6013 Welding ElectrodesDocument1 pageZULFI E6013 Welding ElectrodesJunard M. Lu HapPas encore d'évaluation

- Material Safety Data Sheet (MSDS)Document2 pagesMaterial Safety Data Sheet (MSDS)Heri SusantoPas encore d'évaluation

- MSDS NiCrDocument2 pagesMSDS NiCrBety FajriaPas encore d'évaluation

- S 800wtxm 12k Msds EngDocument2 pagesS 800wtxm 12k Msds Eng이상훈Pas encore d'évaluation

- Member of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETDocument6 pagesMember of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETantoncanuckPas encore d'évaluation

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoPas encore d'évaluation

- Heat Fence Inorganic MineralsDocument3 pagesHeat Fence Inorganic MineralsmePas encore d'évaluation

- Rci RodDocument2 pagesRci Rodabdul rochimPas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoPas encore d'évaluation

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelPas encore d'évaluation

- MsdsDocument3 pagesMsdsTobi MazzoccaPas encore d'évaluation

- 103 Solution EC Msds 5-08Document3 pages103 Solution EC Msds 5-08Brian HernandezPas encore d'évaluation

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanPas encore d'évaluation

- Material Safety Data Sheet: Section 1 - IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - IdentificationAmjad MehmoodPas encore d'évaluation

- Lincoln 5P+ MsdsDocument2 pagesLincoln 5P+ MsdssalcabesPas encore d'évaluation

- MSDS for US Forge E 6010 Covered ElectrodeDocument3 pagesMSDS for US Forge E 6010 Covered Electrodemohamed AdelPas encore d'évaluation

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelPas encore d'évaluation

- 360, 370, 380 Brazing Rod MG MSDS 6-09Document3 pages360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27Pas encore d'évaluation

- Nic-L-Weld 99 59Document9 pagesNic-L-Weld 99 59CezaryCezasPas encore d'évaluation

- MSDS METAL CORED WIREDocument2 pagesMSDS METAL CORED WIREElMacheteDelHuesoPas encore d'évaluation

- Safely weld alloys with MSDSDocument2 pagesSafely weld alloys with MSDSElMacheteDelHuesoPas encore d'évaluation

- K 87 009 - PrintDocument3 pagesK 87 009 - PrintVictor MoraesPas encore d'évaluation

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelPas encore d'évaluation

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayePas encore d'évaluation

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiPas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoPas encore d'évaluation

- ARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02Document3 pagesARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02PubcrawlPas encore d'évaluation

- Hot-Dip Galvanizing Material Safety Data SheetDocument5 pagesHot-Dip Galvanizing Material Safety Data SheetyeezeePas encore d'évaluation

- Acero HSDocument2 pagesAcero HSEdgar MOrenoPas encore d'évaluation

- Material Safety Data Sheet: Welding Alloys USA IncDocument4 pagesMaterial Safety Data Sheet: Welding Alloys USA IncShenny AldanaPas encore d'évaluation

- Material Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationAdel AbduoPas encore d'évaluation

- In-W610 (Merit LMC 6 - Er70s-6) - 1Document2 pagesIn-W610 (Merit LMC 6 - Er70s-6) - 1Pratik LadPas encore d'évaluation

- Brassmsds 2007Document4 pagesBrassmsds 2007api-256162920Pas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelPas encore d'évaluation

- Mild Steel Solid Mig Wire MSDSDocument2 pagesMild Steel Solid Mig Wire MSDSsalcabesPas encore d'évaluation

- Niti Wire SdsDocument4 pagesNiti Wire Sdsfernieves1409Pas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoPas encore d'évaluation

- Tungsten Electrodes MSDSDocument4 pagesTungsten Electrodes MSDSsalcabesPas encore d'évaluation

- Product Name: Galvalume Sheet Severstal Sparrows Point LLCDocument4 pagesProduct Name: Galvalume Sheet Severstal Sparrows Point LLCT Bagus Tri LusmonoPas encore d'évaluation

- Bezpečnostní List S-717 - EngDocument8 pagesBezpečnostní List S-717 - Engz9zsbwnnfvPas encore d'évaluation

- TruExterior MSDSDocument3 pagesTruExterior MSDS100livPas encore d'évaluation

- MSDS Er70s 6Document1 pageMSDS Er70s 6RosyidiMuhammadMahfudzPas encore d'évaluation

- MSDS Katalco - 61 1TDocument6 pagesMSDS Katalco - 61 1Tricko4001100% (2)

- Msds 51910419745 Titan SilverDocument6 pagesMsds 51910419745 Titan SilverAnonymous fXWzyInPas encore d'évaluation

- 4 EC SMAW Msds 5-08Document4 pages4 EC SMAW Msds 5-08Mohamed AdelPas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationadityadhPas encore d'évaluation

- Caucho RecubrimientoDocument4 pagesCaucho RecubrimientoJhony MedranoPas encore d'évaluation

- Soporte de Pedestal PDFDocument1 pageSoporte de Pedestal PDFJhony MedranoPas encore d'évaluation

- Caucho RecubrimientoDocument4 pagesCaucho RecubrimientoJhony MedranoPas encore d'évaluation

- PT14 HOBAS 20140520 HOBAS Mine 2014 Presentation ALI SharedDocument38 pagesPT14 HOBAS 20140520 HOBAS Mine 2014 Presentation ALI SharedJhony MedranoPas encore d'évaluation

- Cyclone Dust CollectorsDocument16 pagesCyclone Dust CollectorsJhony Medrano100% (1)

- Product Design Benefits: 1. Corrosion ProtectionDocument2 pagesProduct Design Benefits: 1. Corrosion ProtectionJhony MedranoPas encore d'évaluation

- Ford Tapping AbrazaderasDocument36 pagesFord Tapping AbrazaderasJhony MedranoPas encore d'évaluation

- Pages From ASME B16!5!1996 3Document1 pagePages From ASME B16!5!1996 3Jhony MedranoPas encore d'évaluation

- Us 2261390 ADocument8 pagesUs 2261390 AJhony MedranoPas encore d'évaluation

- Pages From ASME B16!5!1996 2Document1 pagePages From ASME B16!5!1996 2Jhony MedranoPas encore d'évaluation

- PT14 HOBAS 20140520 HOBAS Mine 2014 Presentation ALI SharedDocument38 pagesPT14 HOBAS 20140520 HOBAS Mine 2014 Presentation ALI SharedJhony MedranoPas encore d'évaluation

- Cyclone Dust CollectorsDocument16 pagesCyclone Dust CollectorsJhony Medrano100% (1)

- Standard Weld JointDocument3 pagesStandard Weld Jointtalparadipak100% (1)

- g0443 MDocument52 pagesg0443 MJhony MedranoPas encore d'évaluation

- g0440 MDocument56 pagesg0440 MJhony MedranoPas encore d'évaluation

- MCI Ball Check Valve Data SheetDocument3 pagesMCI Ball Check Valve Data SheetJhony MedranoPas encore d'évaluation

- 11m Brazing Lot en 0Document6 pages11m Brazing Lot en 0Jhony MedranoPas encore d'évaluation

- M S D S: Aterial Afety ATA HeetDocument7 pagesM S D S: Aterial Afety ATA HeetJhony MedranoPas encore d'évaluation

- 8-1 Se en 0Document4 pages8-1 Se en 0Jhony MedranoPas encore d'évaluation

- 11 Bare Brazing Lot en 0Document2 pages11 Bare Brazing Lot en 0Jhony MedranoPas encore d'évaluation

- 9-3000 MP en 0Document5 pages9-3000 MP en 0Jhony MedranoPas encore d'évaluation

- Pipe 36pulg Stress Analysis ReportDocument3 pagesPipe 36pulg Stress Analysis ReportJhony MedranoPas encore d'évaluation

- Activity 1 Pxy, Txy DiagramsDocument3 pagesActivity 1 Pxy, Txy DiagramsPatricia ManaogPas encore d'évaluation

- Iso 02834-1-2006Document12 pagesIso 02834-1-2006frodo frodoPas encore d'évaluation

- ApplicationNote PH Measurement JamJellies EN 30538204Document4 pagesApplicationNote PH Measurement JamJellies EN 30538204MarcinPas encore d'évaluation

- Research Programmes: EligibilityDocument14 pagesResearch Programmes: Eligibilitysatyakrishna1234Pas encore d'évaluation

- Macromolecules: Question Paper 1Document8 pagesMacromolecules: Question Paper 1Bridgette LombardPas encore d'évaluation

- Raman Effect: Fingerprinting The UniverseDocument2 pagesRaman Effect: Fingerprinting The UniverserachelPas encore d'évaluation

- Finite Element Analysis: Understanding 1D Rods and 2D TrussesDocument34 pagesFinite Element Analysis: Understanding 1D Rods and 2D TrussesAnonymous hWj4HKIDOFPas encore d'évaluation

- Thin Layer ChromatographyDocument497 pagesThin Layer ChromatographyFrancimauroPas encore d'évaluation

- Outline For PhotosynthesisDocument6 pagesOutline For Photosynthesiswitzy11Pas encore d'évaluation

- Molecules of LifeDocument38 pagesMolecules of LifeYana PanlilioPas encore d'évaluation

- Photosynthesis Lab: Leaf Disk Floating RatesDocument9 pagesPhotosynthesis Lab: Leaf Disk Floating RatesNakuru SandwichPas encore d'évaluation

- Syed Sabir - The Recovery of Gold From Secondary Sources-Imperial College Press (2016)Document233 pagesSyed Sabir - The Recovery of Gold From Secondary Sources-Imperial College Press (2016)RODRIGO ARTURO BORJA CALDERÓNPas encore d'évaluation

- Energy Engineering SyllabusDocument49 pagesEnergy Engineering SyllabusKarthiik88Pas encore d'évaluation

- Coursera BioinfoMethods-II Lab03Document10 pagesCoursera BioinfoMethods-II Lab03Harly CNPas encore d'évaluation

- Incompatibilities in Prescription 4e (1917)Document334 pagesIncompatibilities in Prescription 4e (1917)Benjel AndayaPas encore d'évaluation

- Glassy Carbon - Wikipedia, The Free Encyclopedia PDFDocument5 pagesGlassy Carbon - Wikipedia, The Free Encyclopedia PDFNaveen PalaPas encore d'évaluation

- Carbon Compounds Chemistry GuideDocument20 pagesCarbon Compounds Chemistry Guideirisyyy27Pas encore d'évaluation

- Optional Strain Rate Forms For The Johnson CookDocument17 pagesOptional Strain Rate Forms For The Johnson CookTien KimPas encore d'évaluation

- Ultrasonic Testing Equipment Manufacturers - Canopus InstrumentsDocument1 pageUltrasonic Testing Equipment Manufacturers - Canopus InstrumentscanopusinstrumentsPas encore d'évaluation

- User Manual of Laser Engraving Machine PDFDocument36 pagesUser Manual of Laser Engraving Machine PDFRobby SubhansyahPas encore d'évaluation

- MIT8 02SC Notes16to18Document30 pagesMIT8 02SC Notes16to18GeorgeChangPas encore d'évaluation