Académique Documents

Professionnel Documents

Culture Documents

Desk Top Publishing DTP Center

Transféré par

suryanathDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Desk Top Publishing DTP Center

Transféré par

suryanathDroits d'auteur :

Formats disponibles

PROJECT PROFILE ON DESK TOP PUBLISHING (DTP) CENTRE

PRODUCT CODE (ASICC) QUALITY & STANDARDS PRODUCTION CAPACITY

: : :

97926 As per Customers Specification Qty : 50,000 Pages per annum Value : Rs. 10,00,000 2006-07 MSME - Development Institute Electronics Complex Chambaghat Solan (HP) - 173213 & Office of DC (MSME) New Delhi 01792-230766 (Tele.) 230265 (Fax) e-mail:dcdi-solan@dcmsme.gov.in

YEAR OF PREPARATION PREPARED / UPDATED BY

: :

11

1. INTRODUCTION Desk Top Publishing (DTP) primarily pertain to designing of documents using personal computer loaded with DTP software packages like page maker, coral draw, MS word, Venus, Parkashak etc. and laser printing. Laser printer has the capability of printing the pages that has text and graphics. The DTP has many advantages in comparison with the manual process. It is a factual and can quickly edit with minimum mistakes. Text and graphics can be merged into single file. Achieve higher productivity, efficiency and quality in printing and publishing with economy. DTP is used for type setting, layout, printing, graphics and photographs etc. With the latest DTP software packages it is possible to undertake a variety of work in the field of printing and publishing. 2. MARKET POTENTIAL DTP has modernised the traditional printing industry by improving the quality, efficiency, productivity etc. DTP has replaced the old concept of letter setting and printing. DTP facility has ample opportunities for undertaking job work on sub-contract basis for printing and publishing houses, Govt. departments, educational institutions, business houses, industries, advertisement agencies, bank etc. There is good scope for using DTP facility for designing and producing newsletter, certificates, data sheets, brochures, invitation cards, catalogues etc. With Proper marketing, high quality and competitive price this type of Industries have sufficient scope. 3. Basis and Presumption i) The basis for calculation of Production capacity has been taken on Single Shift basis on 75% efficiency. The maximum capacity utilization on Single Shift basis for 300 days a year. During first year and Second Year of operations the capacity utilization is 60% and 80% respectively. The unit is expected to achieve full capacity utilization from the 3rd year onwards.

ii)

iii) The salaries & Wages Cost of Raw Materials, Utilities, Cost of Land and Rents etc. are based on prevailing rates in 2006-07 in and around Himachal Pradesh. These cost factors are likely to vary with time and with location. iv) Interest on term loan and working capital loan has been taken at the rate of 16% on an average. This rate may vary depending upon the policy of the financial Institutions/agencies from time to time. The cost of Machinery and Equipments refer to a particular make/model and the prices are approximate prevailing in 2006-07.

v)

12

vi)

The breakeven point percentage indicated is of full capacity utilization.

vii) The project preparation cost etc., whenever required could be considered under preoperative expenses. viii) The essential production machinery and test equipment required for the project have been indicated. The unit may also utilize common test facilities available at Electronics Test and Development Centres (ETDCs), Electronic Regional Test Laboratories (ERTLs) and Regional Test Centres (RTCs) Implementation Schedule The major activities in the implementation of the project have been listed and the average time for implementation of the project is estimated at 12 months 1. 2. 3. 4. Preparation of Project Report Registration & Other Formalities Sanction of Loan by Financial Institutions Plant & Machinery a) Placement of Orders b) Procurement c) Power Connection / Electrification d) Installation / Erection of Machinery/Test Equipment Procurement of Raw Materials Recruitment of Technical Personnel etc. Trial Production Commercial Production Period (in month) (Suggestive) 1 1 3 1 2 2 2 2 2 11 12

5. 6. 7. 8.

NOTE: 1) 2) 3) Many of the above activities shall be initiated concurrently. Procurement of raw materials commences from the 8th month onwards. When imported plant and machinery are required the implementation period of project may vary from 12 months to 15 months.

TECHNICAL ASPECTS 1. Process of Manufacture

Personal computer loaded with DTP software like Corel draw, page maker, MS word, venus,

13

Parkashak etc. alongwith peripheral is required for designing and producing the printed matter. The text is typed, composed and arranged as per requirement. The whole text is displayed on colour monitor for correction and edition. The edited page is then printed on plain paper or butter paper or page master using the laser printer. The out put from the laser printer can be Xeroxed for small volume but when the volume is in large range the out put from laser printer is taken to offset printing machine for required no. of copies. 2. QUALITY STANDARDS As per customers specification 3. PRODUCTION CAPACITY PER ANNUM : QUANTITY VALUE : : 50,000 Nos. Rs. 10,00,000/3 KVA (Approx.)

4. MOTIVE POWER:

5. POLLUTION CONTROL: The Desk Top Publishing facility is not characterised as polluting industry so it is free from pollution control. 6. ENERGY CONSERVATION: With the growing energy demand and shortage coupled with rising energy cost, a greater thrust in energy efficiency in industrial sector has been given by the Govt. of India since 1980s. The energy conservation Act, 2001 has been enacted on 18th August, 2001, which provides for efficient use of energy, its conservation and capacity building of bureau energy efficiency created under the Act. The following steps may help for conservation of electrical energy : i) ii) Adoption of energy conserving technologies, production aids and testing facilities. Efficient management of process/manufacturing machinery and systems, QC and testing equipments for yielding maximum energy conservation.

iii) Optimum use of electrical energy for heating during soldering process can be obtained by using efficient temperature controlled soldering and de-soldering stations. iv) Periodical maintenance of motors, compressors etc. use of power factor correction capacitors. Proper selection and layout of lighting system.

v)

14

vi)

Timely switching On-Off of the lights;

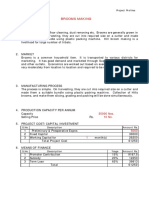

vii) Use of compact fluorescent lamps wherever possible etc. FINANCIAL ASPECTS (i) Land & Building 150 Sq. meter 50 Sq. meter 50 Sq. meter. 60,000

Built-up area Office, Stores DTP area Rent Payable per Annum (Rs.) (ii) Machinery and Equipments Description Computer System (Pentium IV with Network card 2.4 GHz/40 GE/ 128 ME/ 15 colour monitor, key board, optical mouse, speakers etc.) 2. 3. 4. 5. 6. 7. 8. Laser printer Dot matrix printer Colour printer Scanner UPS 500 VA Spike suppressor DTP Software package Other fixed Assets 9. 10. 11. Electrification Charges @ 10% of Cost Machinery & Equipments Office Equipments, Furniture & Working tables etc. Pre-Operative Expenses Total LS Ind. Ind. Ind. Ind. Ind. Ind. Ind. Total

Sl.No 1.

Ind./Imp. Ind.

Qty. 3

Value(Rs.) 1,20,000

3 1 1 1 3 1 LS

27,000 9,000 15,000 20,000 7,500 1,500 20,000 2,20,000

22,000 30,000 20,000 72,000 Rs. 3,92,000 Total fixed Capital

15

Working Capital Per Month : (i) Staff & Labour Sl. No. 1. 2. 3. Designation Manager DTP operator Peon/Helper + Pre requisites @ 15% of Salary Nos. 1 3 2 Salary/month (Rs.) 6,000 4,000 2,000 Total (ii) Raw Material Requirement per Month : Description DTP Stationery CD/Floppy Disketts. Toner for laser jet printer Toner for colour printer Ink and Printer ribbon & other misc. items Ind./Imp. Ind. Ind. Ind. Ind. Ind. Qty. LS LS LS LS LS Total (iii) Utilities Per Month Power Water Total (iv) 1. 2. 3. 4. 5. 6. 7. 8. Other contingent Expenses per month Rent Postage and Stationery Telephone/Telex/Fax charges Repair & Maintenance Transport and conveyance Charges Advertisement / Publicity Insurance and Taxes Miscellaneous expenses Total 5,000 1,000 2,000 1,000 2,000 1,000 1,000 1,000 14,000 2,000 200 2,200 Value(Rs.) 2,500 500 3,500 3,500 2,000 12,000 Total Salary/ month (Rs.) 6,000 12,000 4,000 3,300 25,300

Sl.No 1. 2. 3. 4. 4.

16

Total Recurring Expenditure Per month ( i + ii + iii + iv ) Total Capital Investment (Rs.) Fixed Capital Working Capital on 3 months basis Total Financial Analysis: Cost of Production (Per annum) Total Recurring Expenditure Depreciation on Plant & Machinery @ 10%

Say

= Rs. 53,500/= Rs. 54,000/-

2,92,000 1,62,000 4,54,000

6,48,000 22,000 6,000 72,640 Total or Say 7,48,640 7,48,600

Depreciation on office equipment, furniture etc. @ 20% Interest on total capital investment @ 16%

Turnover Per Annum : Item DTP Service (Pages) Qty. (Nos.) 50,000 Rate/Unit (Rs.) 20 Total Sales (Rs.) 10,00,000

Profit Per Annum (Before Tax)

= Sales turnover-cost of production per annum (per Annum) = Rs. 2,51,400/= (Profit x 100) / Sales turnover = 25% = (Profit x 100) / Total capital Investment = 55.3%

Profit Ratio

Rate of Return

17

BREAK EVEN POINT Fixed Cost per annum Rent Depreciation on machinery & equipment @ 10% Depreciation on office equipment, furniture etc. @ 20 % Interest on total capital investment @ 16% Insurance 40% of Salary and Wages 40% of Other Contingencies & utilities (Excluding rent & insurance) Total Say Break even point (BEP) = = Additional Information a) The Project Profile may be modified/tailored to suit the individual entrepreneurship qualities/capacity, production Programme and also to suit the locational characteristics, wherever applicable. The Electronics Technology is undergoing rapid strides of change and there is need for regular monitoring of the national and international technology scenario. The unit may, therefore, keep abreast with the new technologies in order to keep them in pace with the developments for global competition. Quality today is not only confined to the product or service alone. It also extends to the process and environment in which they are generated. The ISO 9000 defines standards for quality management systems and ISO 14001 defines standards for Environmental Management System for acceptability at international level. The unit may adopt ISO 9000 standards for global competition. The margin money recommended is 25% of the working capital requirement at an average. However, the percentage of margin money may vary as per banks discretion. [FC/ (FC + Profit)] x 100 56.9% 60,000 22,000 6,000 72,640 12,000 1,21,440 38,400 3,32,480 3,32,400

b)

c)

d)

18

NAME AND ADDRESSES OF MACHINERY, EQUIPMENTS SUPPLIERS 1. M/s. Bergen Associates Pvt. Ltd. 1082, Sector-27 B, Chandigarh-19. 2. M/s. Microtek International Ltd. Microtek House, Udyog Nagar, Rohtak Road, Delhi-110041. 3. M/s. Vintron Informatics Ltd. F -90/1 A, Okhla Industrial Area, Phase-I, New Delhi-110020. 4. M/s. Sumitron Marketing, A-46, Naraina Industrial Area Phase-I, New Delhi- 110028. 5. M/s. Advance Tech Services 56, 2nd floor, Rani Jhansi Road, New Delhi-110055. 6. M/s. Computer People The Mall, Solan, Himachal Pradesh 7. M/s. Crown Electronics System J G-l /7 A, Vikas Puri, New Delhi - 110018.

Name and Address of Raw Material Supplier: All the leading branded computer manufacturer have their broad network and hence nearest dealer at Solan, Shimla, Kalka, Chandigarh may be contacted for computer hardware/software & Computer stationary related items.

19

Vous aimerez peut-être aussi

- DTP Msme ProjectDocument22 pagesDTP Msme ProjectGolden Shower தமிழ்Pas encore d'évaluation

- Offset Printing Press (Job Work) : NtroductionDocument4 pagesOffset Printing Press (Job Work) : NtroductionMMjagpreetPas encore d'évaluation

- Offset Printing PressDocument11 pagesOffset Printing PressMujahid MalikPas encore d'évaluation

- Project Report On DTP CentreDocument6 pagesProject Report On DTP CentrekamalayelloduPas encore d'évaluation

- DPR For Walnut ProcessingDocument74 pagesDPR For Walnut ProcessingMohd touseefPas encore d'évaluation

- Pulses MillDocument2 pagesPulses Millram100% (1)

- Computerised Wheel Balancing & Wheel Alighnment Wiorkshop PDFDocument6 pagesComputerised Wheel Balancing & Wheel Alighnment Wiorkshop PDFYADAV ANIL KUMARPas encore d'évaluation

- Auto RickshawDocument4 pagesAuto Rickshawpradip_kumarPas encore d'évaluation

- Bicycle Parts Manufacturing Unit CarrierDocument17 pagesBicycle Parts Manufacturing Unit CarrierAftabunarPas encore d'évaluation

- Detailed Business Plan On Stationary Market in IndiaDocument13 pagesDetailed Business Plan On Stationary Market in IndiaVikky SinghPas encore d'évaluation

- Plastic Bag Project ReportDocument21 pagesPlastic Bag Project ReportRajesh Kumar50% (2)

- Model Business Activity: Agricultural Machinery Custom Hiring Centre (CHC) at Farmers Producer Organizations (Fpos)Document9 pagesModel Business Activity: Agricultural Machinery Custom Hiring Centre (CHC) at Farmers Producer Organizations (Fpos)akhalikPas encore d'évaluation

- Photo Developing and Printing (Digital)Document28 pagesPhoto Developing and Printing (Digital)Asad Ullah BaigPas encore d'évaluation

- Jute BagDocument9 pagesJute Bagafham84Pas encore d'évaluation

- Bread Manufacturing Plant Rs. 28.57 Million Jun-2017Document33 pagesBread Manufacturing Plant Rs. 28.57 Million Jun-2017ТаймурАбдуллах75% (4)

- Business Plan For Smart BoutiqueDocument25 pagesBusiness Plan For Smart BoutiqueAnonymous NM7hmMfPas encore d'évaluation

- Aluminum Household Utensil Making PlantDocument26 pagesAluminum Household Utensil Making PlantYohannes Woldekidan100% (1)

- Sandpaper Project ProfileDocument15 pagesSandpaper Project ProfileTekeba Birhane100% (3)

- Marketing Plan For TillersDocument15 pagesMarketing Plan For TillersBharat Veer Singh RathorePas encore d'évaluation

- Yeshi 2022 ProposalDocument16 pagesYeshi 2022 Proposalsham wonPas encore d'évaluation

- 20-Project Profile-Meat Processing UnitDocument6 pages20-Project Profile-Meat Processing UnitSyed Ali Zain0% (1)

- Brooms MakingDocument3 pagesBrooms MakingGohilaRajPas encore d'évaluation

- Project Report Tissue PaperDocument5 pagesProject Report Tissue PaperShadow PrincePas encore d'évaluation

- Bankable Project Report & Quotation For GreenhouseDocument40 pagesBankable Project Report & Quotation For Greenhousetiyasee25Pas encore d'évaluation

- Mango Jelly NSIC ProjectDocument3 pagesMango Jelly NSIC ProjectAnonymous EAineTizPas encore d'évaluation

- New Vikas Stove Bba.2 30Document60 pagesNew Vikas Stove Bba.2 30Prince Nathvani100% (1)

- Project Report PAPADDocument3 pagesProject Report PAPADsagayapriya0% (1)

- A Project ReportDocument24 pagesA Project ReportshariquesayeedPas encore d'évaluation

- Briquetted Fuel: Profile No.: 08 NIC Code:19204Document7 pagesBriquetted Fuel: Profile No.: 08 NIC Code:19204Sabhaya ChiragPas encore d'évaluation

- Wooden Furniture Manufacturing Unit: (1) IntroductionDocument8 pagesWooden Furniture Manufacturing Unit: (1) Introductionpatel princePas encore d'évaluation

- Mini Flour Mill KarnalDocument9 pagesMini Flour Mill KarnalAnand Kishore100% (2)

- Plastic Carry BagsDocument8 pagesPlastic Carry BagsRavi PrakashPas encore d'évaluation

- Project Report Tent PDFDocument10 pagesProject Report Tent PDFBasant KumarPas encore d'évaluation

- Pmegp Project Report Cement ProductDocument8 pagesPmegp Project Report Cement ProductMangesh Alhat100% (1)

- Project Profile For A Boutique - Based On Assumption - Nagaveni - MA FMDocument10 pagesProject Profile For A Boutique - Based On Assumption - Nagaveni - MA FMvstyleinPas encore d'évaluation

- Project Proposal On The Production of Filter Elements For Vehicles Feasibility Study in Ethiopia. - Haqiqa Investment Consultant in EthiopiaDocument1 pageProject Proposal On The Production of Filter Elements For Vehicles Feasibility Study in Ethiopia. - Haqiqa Investment Consultant in EthiopiaSuleman100% (1)

- Summer Training At: Swot Analysis OnDocument99 pagesSummer Training At: Swot Analysis OnVivek KumarPas encore d'évaluation

- Project Profile of Edible OilDocument47 pagesProject Profile of Edible OilManish Bhoyar100% (2)

- Wet Coffe Procgera Qacho Coffee Trading PLCDocument29 pagesWet Coffe Procgera Qacho Coffee Trading PLCRamon ColonPas encore d'évaluation

- Paper Carry Bags PDFDocument2 pagesPaper Carry Bags PDFSuresh KaushikPas encore d'évaluation

- Dairy Project For Zaru Last EditedDocument15 pagesDairy Project For Zaru Last Editedgaromsa degaga100% (1)

- NasruDocument24 pagesNasrugemechuPas encore d'évaluation

- Automatic Pen Manufacturing ProjectDocument6 pagesAutomatic Pen Manufacturing ProjectKamalPas encore d'évaluation

- Project Report On Exercise Notebook Industry Like ClassmateDocument7 pagesProject Report On Exercise Notebook Industry Like ClassmateEIRI Board of Consultants and Publishers100% (1)

- Ground and Processed Spices and Cereals Project ReportDocument5 pagesGround and Processed Spices and Cereals Project ReportGirish DaryananiPas encore d'évaluation

- Mandap Decoration Project ReportDocument50 pagesMandap Decoration Project ReportNeha Marathe100% (1)

- Hawassa Tegbared Industrial and Construction College: Business Plan of Vertical Band Saw MachineDocument21 pagesHawassa Tegbared Industrial and Construction College: Business Plan of Vertical Band Saw Machinesisay SolomonPas encore d'évaluation

- Project On Shopping MallsDocument38 pagesProject On Shopping Mallsdeep1aroraPas encore d'évaluation

- Packaging FactoryDocument39 pagesPackaging FactoryYonasBirhanuPas encore d'évaluation

- Abera BayisaDocument44 pagesAbera BayisaRamon ColonPas encore d'évaluation

- Cold StoreDocument22 pagesCold StoresajidaliyiPas encore d'évaluation

- Business Plan: FOR Stone and Stone Product Production CorporatesDocument11 pagesBusiness Plan: FOR Stone and Stone Product Production CorporatesshmyePas encore d'évaluation

- Loundary Soap Processing PlantDocument28 pagesLoundary Soap Processing PlantLakew50% (2)

- P P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumDocument10 pagesP P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumNiju K APas encore d'évaluation

- Engineering ScalesDocument7 pagesEngineering ScalesAmshgautamPas encore d'évaluation

- Mobile Phone Repairing and ServicingDocument9 pagesMobile Phone Repairing and Servicingsvkatkar0% (1)

- CH 14Document6 pagesCH 14Vishu5227Pas encore d'évaluation

- Project Profile On Desk Top Publishing Centre: 1. ProductDocument9 pagesProject Profile On Desk Top Publishing Centre: 1. ProductvishuPas encore d'évaluation

- Ridj Offset PrintingDocument9 pagesRidj Offset Printingsanjit laishramPas encore d'évaluation

- Project Report On Printing BusinessDocument11 pagesProject Report On Printing BusinessCA Devangaraj Gogoi100% (1)

- POP PrakasamDocument1 114 pagesPOP PrakasamsuryanathPas encore d'évaluation

- Rtss Man Power Solutions: Pay SlipDocument1 pageRtss Man Power Solutions: Pay SlipsuryanathPas encore d'évaluation

- For That Glossy Hair: Don't Buy What The Devil SellsDocument1 pageFor That Glossy Hair: Don't Buy What The Devil SellssuryanathPas encore d'évaluation

- February Monthly Capsule PDFDocument41 pagesFebruary Monthly Capsule PDFsuryanathPas encore d'évaluation

- Andhra Pradesh Industrial Infrastructure Corporation LimitedDocument1 pageAndhra Pradesh Industrial Infrastructure Corporation LimitedsuryanathPas encore d'évaluation

- Pop SattenaDocument1 pagePop SattenasuryanathPas encore d'évaluation

- Andhra Pradesh Building Rules 2012 GO - Ms.No.168 MA, Dated 07.04.2012Document373 pagesAndhra Pradesh Building Rules 2012 GO - Ms.No.168 MA, Dated 07.04.2012info297287% (54)

- DLTFC DicDocument77 pagesDLTFC DicsuryanathPas encore d'évaluation

- Comments of DepartmentsDocument14 pagesComments of DepartmentssuryanathPas encore d'évaluation

- W A No 425 of 2016 PDFDocument313 pagesW A No 425 of 2016 PDFsuryanathPas encore d'évaluation

- GopiDocument1 pageGopisuryanathPas encore d'évaluation

- E Kiran EDPDocument1 pageE Kiran EDPsuryanathPas encore d'évaluation

- 50 Interview Question Code Galatta - HandbookDocument16 pages50 Interview Question Code Galatta - HandbookSai DhanushPas encore d'évaluation

- D4462045416 PDFDocument3 pagesD4462045416 PDFSamir MazafranPas encore d'évaluation

- Week 1 Macro (DDR)Document49 pagesWeek 1 Macro (DDR)Stevie Sean100% (1)

- To Tell The TruthDocument5 pagesTo Tell The TruthNabeel Ahmed KhanPas encore d'évaluation

- Math Cad 15Document3 pagesMath Cad 15Kim ChanthanPas encore d'évaluation

- Using The Words in The Box, Fill in All The GapsDocument23 pagesUsing The Words in The Box, Fill in All The GapsMo NoPas encore d'évaluation

- Spring Newsletter 2014-LockedDocument4 pagesSpring Newsletter 2014-Lockedapi-244488788Pas encore d'évaluation

- Bach Polonaise G Min BWV 119 A4Document1 pageBach Polonaise G Min BWV 119 A4vincenzovaiaPas encore d'évaluation

- A B&C - List of Residents - VKRWA 12Document10 pagesA B&C - List of Residents - VKRWA 12blr.visheshPas encore d'évaluation

- Cover PageDocument10 pagesCover PageAvijit GhoshPas encore d'évaluation

- Module 11 Activity Based CostingDocument13 pagesModule 11 Activity Based CostingMarjorie NepomucenoPas encore d'évaluation

- Transformational Leadership in The UmcDocument17 pagesTransformational Leadership in The Umcapi-202352366Pas encore d'évaluation

- 02-Fundamentals of Engineering EconomyDocument14 pages02-Fundamentals of Engineering EconomyLin Xian XingPas encore d'évaluation

- Math Habits of MindDocument12 pagesMath Habits of MindAzmi SallehPas encore d'évaluation

- Orange County Sheriff's Office SeaWorld Death Investigative ReportDocument43 pagesOrange County Sheriff's Office SeaWorld Death Investigative ReportWESH2News100% (1)

- 2 TolentinoDocument12 pages2 TolentinoMA. ANGELINE GRANADAPas encore d'évaluation

- Zara Case StudyDocument26 pagesZara Case StudySeminarskiRadovi100% (2)

- HH220i - JAN 11Document1 pageHH220i - JAN 11Achmad GazaliPas encore d'évaluation

- Important Points in SurveyingDocument4 pagesImportant Points in SurveyingAnand BossPas encore d'évaluation

- Electrostatics Practice ProblemsDocument4 pagesElectrostatics Practice ProblemsMohammed Aftab AhmedPas encore d'évaluation

- Tom Rockmore - Hegel's Circular EpistemologyDocument213 pagesTom Rockmore - Hegel's Circular Epistemologyluiz100% (1)

- CN Blue Love Rigt Lyrics (Romanized)Document3 pagesCN Blue Love Rigt Lyrics (Romanized)Dhika Halet NinridarPas encore d'évaluation

- ISA Guidelines PPF 1Document19 pagesISA Guidelines PPF 1Vasu DevanPas encore d'évaluation

- WTSDA2021 TSDBlack Belt ManualDocument160 pagesWTSDA2021 TSDBlack Belt ManualJesus HernandezPas encore d'évaluation

- Lesson Plan - Sight Word ObservationDocument2 pagesLesson Plan - Sight Word Observationapi-253277023Pas encore d'évaluation

- Omega 900 InstructionsDocument27 pagesOmega 900 InstructionsRA Dental LaboratoryPas encore d'évaluation

- FORM Module IpsDocument10 pagesFORM Module IpsRizalPas encore d'évaluation

- TheBigBookOfTeamCulture PDFDocument231 pagesTheBigBookOfTeamCulture PDFavarus100% (1)

- Refrigerant Unit Lab ReportDocument19 pagesRefrigerant Unit Lab Reportakmal100% (2)

- Periodicity Review SL KeyDocument4 pagesPeriodicity Review SL KeyYeyoung ParkPas encore d'évaluation