Académique Documents

Professionnel Documents

Culture Documents

Leca 2

Transféré par

manil_5Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Leca 2

Transféré par

manil_5Droits d'auteur :

Formats disponibles

Amazing Lightness Through the pyro- process, clay is expanded like popcorn and becomes porous, the cellular

structure of Leca aggregate optimizes density and resistance ratio of Leca. Therefore Leca could play an important role as a raw material to produce other

lightweight concrete products and be a fantastic solution to iron out weight issues in projects, in addition to its further benefits and improvements.

Physical and chemical Properties

Leca is formed into round shape of individual pellet and irregular shape with a rough surface. lts color is light to dark brown. Leca is free from organic substances and is non- decomposable material, nor even under high temperature or humidity condition loses its

features. Leca pH is about 7, and also is a high resistant material

against acids and solvents.

Compressive Strength

with a stable structure and is not compactable, due to outer compact and resistant shell structure, comparing to other lightweight aggregate, Leca has remarkable compressive strength. Leca aggregates stick together by adding a low ratio of cement, which is great for supporting the low load, used for non- structural construction components (floors, partition walls, supports ,..)

Leca enjoys

Natural and Environmentaly-Friendly

not release silica, nor fibrous substances radon gas or other harmful materials even in case of fire. Leca is a natural and eco-friendly product.

Leca contains no silica and obviously does

Thermal lnsulation

Leca aggregate with low thermal conductivity (approximate 0.1 w/mk) could be used in many products (such as Block, Grout ...) to increase

thermal resistance.

Sound lnsulation

The cellular and porous of Leca structure contributes to assure noise absorption and also has insulating property, so Leca can be utilized

for sound insulating and noise damping purposes. This application is useful in schools, libraries, hotels etc.

Fire Resistance

When tested according to the procedures of ASTM E 1,1,9, structural LWC of slabs, walls, and beams have demonstrated greater

fire-endurance periods than equivalent- thickness members made with normal density aggregate.

Superior performance is according to ACI 2l-3, due to a combination

of lower thermal conductivity (lower temperature rises on unexposed surfaces), lower coefficient of thermal expansion

(lower forces developed under restraint), and the inherent thermal stability developed by aggregates that have been already exposed to temperatures greater than 1.0930c during preprocessing.

Vous aimerez peut-être aussi

- Audit Report-2 SignedDocument12 pagesAudit Report-2 Signedmanil_5100% (2)

- Building MaterialsDocument16 pagesBuilding MaterialsgloryyotlelyPas encore d'évaluation

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- Design Practice For General Piping DesignDocument28 pagesDesign Practice For General Piping DesignAnanto Yusuf WPas encore d'évaluation

- Epoxy Resin Arts and Crafts for BeginnersD'EverandEpoxy Resin Arts and Crafts for BeginnersÉvaluation : 3 sur 5 étoiles3/5 (5)

- C88 2013Document5 pagesC88 2013manil_5Pas encore d'évaluation

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5Pas encore d'évaluation

- 5R55W (Ranger / Explorer) & 5R55S: 5 SPEED 4WD WITH LOCK UP (Full Electronic Control)Document4 pages5R55W (Ranger / Explorer) & 5R55S: 5 SPEED 4WD WITH LOCK UP (Full Electronic Control)Krzysztof Kjb100% (1)

- Light Weight ConcreteDocument15 pagesLight Weight ConcreteKarthik UPas encore d'évaluation

- 10 1199367786-K Deutz FahrDocument27 pages10 1199367786-K Deutz FahrJoe2030us82100% (2)

- Audit Report 2 - ClientDocument10 pagesAudit Report 2 - Clientmanil_5Pas encore d'évaluation

- Fisa Tehnica CelenitDocument44 pagesFisa Tehnica CelenitStuparu VictorPas encore d'évaluation

- Using Pulsation Damper With A Reciprocating PumpDocument4 pagesUsing Pulsation Damper With A Reciprocating PumpIkechukwu EjimPas encore d'évaluation

- Autoclaved Aerated Concret11Document5 pagesAutoclaved Aerated Concret11Ahmed SaberPas encore d'évaluation

- Arcelor - Catalog Cu Palplanse Metalice - 1 PDFDocument80 pagesArcelor - Catalog Cu Palplanse Metalice - 1 PDFVG_victo100% (1)

- Transparent WoodDocument10 pagesTransparent WoodankithaPas encore d'évaluation

- High Performance Plastics Materials Guide: Craftech Industries'Document20 pagesHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarPas encore d'évaluation

- Lightweight ConcreteDocument20 pagesLightweight ConcreteRanjeev RamachandranPas encore d'évaluation

- Itt Grinnell Pipe Hanger Design & Engineering 2008Document80 pagesItt Grinnell Pipe Hanger Design & Engineering 2008ITT GRINNELLPas encore d'évaluation

- LECADocument4 pagesLECAjurko5Pas encore d'évaluation

- LIGHT STRAW CLAY - Brief DescriptionDocument3 pagesLIGHT STRAW CLAY - Brief DescriptionCharmaine R. Taylor100% (1)

- AP Physics C Mechanics Course at A GlanceDocument3 pagesAP Physics C Mechanics Course at A GlanceTarun AgarwalPas encore d'évaluation

- Vibration of The Millenium Bridge LondonDocument16 pagesVibration of The Millenium Bridge LondonSilver Olguín CamachoPas encore d'évaluation

- LECA Building Material Trading LLC LECA Building Material Trading LLCDocument12 pagesLECA Building Material Trading LLC LECA Building Material Trading LLCagung prasetyoPas encore d'évaluation

- LecaDocument20 pagesLecav_sujeevan1546Pas encore d'évaluation

- A Study On Light Expanded Clay Aggregate LECA in ADocument6 pagesA Study On Light Expanded Clay Aggregate LECA in AGuy DrorPas encore d'évaluation

- Aac Blocks TheoryDocument1 pageAac Blocks TheorySapan SrivastavPas encore d'évaluation

- ReactionDocument14 pagesReactionHeather KangPas encore d'évaluation

- Lexan SheetDocument28 pagesLexan SheetRishiPas encore d'évaluation

- CLC BricksDocument19 pagesCLC BricksAJ Darphynit100% (1)

- Advance Building MaterialsDocument29 pagesAdvance Building MaterialsShivam RavalPas encore d'évaluation

- CLC Advantage A4 14BDocument9 pagesCLC Advantage A4 14BVladoiu SorinPas encore d'évaluation

- CMT Report FinalDocument6 pagesCMT Report FinalMrunaliPas encore d'évaluation

- Development of Light Weight ConcreteDocument14 pagesDevelopment of Light Weight ConcreteAmit ChougulePas encore d'évaluation

- 1 - Angel Abisaid Aldana Camacho - YesoDocument5 pages1 - Angel Abisaid Aldana Camacho - YesoAngeldash 27Pas encore d'évaluation

- Lectures On PlasticDocument15 pagesLectures On PlasticKaushik RPas encore d'évaluation

- ASSIGNMENT 1 Types of Insulation MaterialsDocument3 pagesASSIGNMENT 1 Types of Insulation MaterialsMistyPas encore d'évaluation

- Timber CreteDocument4 pagesTimber Creteblah blehPas encore d'évaluation

- Untitled DocumentDocument3 pagesUntitled DocumentSilendrina MishaPas encore d'évaluation

- Francesco Patti Professor Cuevas CHM-1020 04 November 2020: History of Epoxy ResinsDocument2 pagesFrancesco Patti Professor Cuevas CHM-1020 04 November 2020: History of Epoxy Resinsfrancesco pattiPas encore d'évaluation

- Betopan Betopanplus Eng KKDocument48 pagesBetopan Betopanplus Eng KKkashmir_sefPas encore d'évaluation

- Teal and Navy Modern Professional Business Leadership PresentationDocument12 pagesTeal and Navy Modern Professional Business Leadership PresentationSilendrina MishaPas encore d'évaluation

- Aac BlocksDocument5 pagesAac Blocksgouri hooliPas encore d'évaluation

- Climacoustic® Duct Roll - HVAC & OEM InsulationDocument2 pagesClimacoustic® Duct Roll - HVAC & OEM InsulationJhay SalvatierraPas encore d'évaluation

- Basic Building Materials: Autoclaved Aerated (AAC) Blocks and PanelsDocument5 pagesBasic Building Materials: Autoclaved Aerated (AAC) Blocks and PanelsjashndeepPas encore d'évaluation

- Presentation On Lexan (Co-Polymer)Document26 pagesPresentation On Lexan (Co-Polymer)Saleha SohailPas encore d'évaluation

- Plastic in Architecture: Team: 1) Eric Alan 2) Christy AlexDocument15 pagesPlastic in Architecture: Team: 1) Eric Alan 2) Christy AlexChristy AlexPas encore d'évaluation

- For Muslim: Always Follow The Way of Islam Completely For Non Muslim: Always Set Goal Before Working Towards ItDocument36 pagesFor Muslim: Always Follow The Way of Islam Completely For Non Muslim: Always Set Goal Before Working Towards ItAman KashyapPas encore d'évaluation

- Building MaterialsDocument17 pagesBuilding MaterialsJukirman SPas encore d'évaluation

- Materials in MechatronicsDocument4 pagesMaterials in MechatronicsvirenPas encore d'évaluation

- Question 1 Diff LWC and LWACDocument1 pageQuestion 1 Diff LWC and LWACelleyashahariPas encore d'évaluation

- English Practical Work PDFDocument4 pagesEnglish Practical Work PDFLaetitia KahesikoPas encore d'évaluation

- Future Material ConstructionDocument31 pagesFuture Material ConstructiongirishPas encore d'évaluation

- Lightweight Aggregate ConcreteDocument36 pagesLightweight Aggregate Concretegopierode4Pas encore d'évaluation

- Experimental Study On Light Weight Concrete by Using Light Expanded Clay Aggregate (LECA)Document6 pagesExperimental Study On Light Weight Concrete by Using Light Expanded Clay Aggregate (LECA)IJRASETPublicationsPas encore d'évaluation

- Modern Technology Assignment FinalDocument15 pagesModern Technology Assignment FinalchuchuPas encore d'évaluation

- Cob Project ReportDocument8 pagesCob Project ReportrituPas encore d'évaluation

- A Study On Foamed Concrete With Silica Fume and Polypropylene FibersDocument3 pagesA Study On Foamed Concrete With Silica Fume and Polypropylene FibersDeepthyPas encore d'évaluation

- Light Weight Blocks: The Right Choice !!Document1 pageLight Weight Blocks: The Right Choice !!smartman35Pas encore d'évaluation

- BMC V - Unit-2 - PlasticsDocument12 pagesBMC V - Unit-2 - PlasticsniviPas encore d'évaluation

- Caracterización de Topas 5013Document17 pagesCaracterización de Topas 5013Juan Manuel Garcia RiveraPas encore d'évaluation

- Polymers For Flex Lam K HariharanDocument58 pagesPolymers For Flex Lam K HariharanEtHical EmoTionPas encore d'évaluation

- Material PropertyDocument19 pagesMaterial PropertyAHMED YOUSEFPas encore d'évaluation

- EZ Inşaat Katalog enDocument13 pagesEZ Inşaat Katalog enHacer YıldırımPas encore d'évaluation

- CPD ClearcoatingsincludingantigraffitiDocument22 pagesCPD Clearcoatingsincludingantigraffitib3ry 17Pas encore d'évaluation

- Experimental Study On Lightweight Concrete Using Leca, Silica Fume, and Limestone As AggregatesDocument14 pagesExperimental Study On Lightweight Concrete Using Leca, Silica Fume, and Limestone As AggregatesAhmadPas encore d'évaluation

- Natural Building & Green BuildingsDocument29 pagesNatural Building & Green BuildingsjessilcaPas encore d'évaluation

- What Is Leca?: Leca Is Initial Letters For: Light Expanded Clay AggregateDocument1 pageWhat Is Leca?: Leca Is Initial Letters For: Light Expanded Clay Aggregatekarthi_ashokkumarPas encore d'évaluation

- Products and Services BRiCks 1Document10 pagesProducts and Services BRiCks 1Hanz DaclanPas encore d'évaluation

- 1 s2.0 S2214785322044777 MainDocument5 pages1 s2.0 S2214785322044777 MainMuhammad Irfan BasriPas encore d'évaluation

- Protective Coating For Steel StructuresDocument21 pagesProtective Coating For Steel StructurescrazyrimzyPas encore d'évaluation

- Building Systems: Report 1 Pirouette HouseDocument9 pagesBuilding Systems: Report 1 Pirouette HouseIpek Bengisu KumasPas encore d'évaluation

- Building Materials English For Civil EngDocument17 pagesBuilding Materials English For Civil EngDipendra AwasthiPas encore d'évaluation

- Norma ASTM C117.1589619-1Document3 pagesNorma ASTM C117.1589619-1Mónica ZúñigaPas encore d'évaluation

- Waste AuditDocument47 pagesWaste Auditmanil_5Pas encore d'évaluation

- Waste AuditDocument47 pagesWaste Auditmanil_5Pas encore d'évaluation

- Load Cell 46-23Document2 pagesLoad Cell 46-23manil_5Pas encore d'évaluation

- Basic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)Document9 pagesBasic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)manil_5Pas encore d'évaluation

- 277 SpecDocument86 pages277 Specmanil_5Pas encore d'évaluation

- Dakks Bs en 45011Document8 pagesDakks Bs en 45011manil_5Pas encore d'évaluation

- Cebex 100Document2 pagesCebex 100manil_5Pas encore d'évaluation

- Report On Yield Test: 4 8.5 m3 Betomix 7-Jul-15 40058 Plant No./ Name Date Delivery Ticket No. Total Batched QuantityDocument1 pageReport On Yield Test: 4 8.5 m3 Betomix 7-Jul-15 40058 Plant No./ Name Date Delivery Ticket No. Total Batched Quantitymanil_5Pas encore d'évaluation

- Epsilone Vea ControlDocument3 pagesEpsilone Vea Controlmanil_5Pas encore d'évaluation

- 1Document39 pages1aimanzoeyPas encore d'évaluation

- NJIT Module-Liquid Mixing Fundamentals-ArmenanteDocument233 pagesNJIT Module-Liquid Mixing Fundamentals-Armenanteacas35Pas encore d'évaluation

- SidewallPropeller Catalog PDFDocument44 pagesSidewallPropeller Catalog PDFVontrex EngrPas encore d'évaluation

- 1.daily Report Manufacture Steel Structure. TGL 09.07 2Document133 pages1.daily Report Manufacture Steel Structure. TGL 09.07 2Rusman LumbantoruanPas encore d'évaluation

- Air Starting System Slide Set 1Document10 pagesAir Starting System Slide Set 1Jigar PatelPas encore d'évaluation

- 11.4 Formulas For Flat Plates With Straight Boundaries and Constant Thickness (Continued)Document1 page11.4 Formulas For Flat Plates With Straight Boundaries and Constant Thickness (Continued)Anant KumbhejkarPas encore d'évaluation

- Working As A Mechanical EngineerDocument13 pagesWorking As A Mechanical EngineerNikita PawarPas encore d'évaluation

- Design of Vertical Pressure VesselsDocument15 pagesDesign of Vertical Pressure VesselsMohit SinghPas encore d'évaluation

- Hidraulic Hammers Yekn0343Document12 pagesHidraulic Hammers Yekn0343Andy DellepianePas encore d'évaluation

- Grundfos Comfort Pump Installation PDFDocument16 pagesGrundfos Comfort Pump Installation PDFdimensionone1Pas encore d'évaluation

- 1973 - Das - Reed - Eubank - PVT Surface and Thermodynamic Properties of Isobutane PDFDocument10 pages1973 - Das - Reed - Eubank - PVT Surface and Thermodynamic Properties of Isobutane PDFAlexanderPas encore d'évaluation

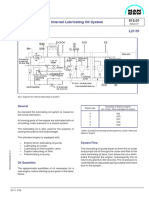

- Internal Lubricating Oil System: GeneralDocument3 pagesInternal Lubricating Oil System: GeneralAtanasio PerezPas encore d'évaluation

- Quality Control of Rebar Couplers in Splicing of Reinforcement BarsDocument12 pagesQuality Control of Rebar Couplers in Splicing of Reinforcement BarsDong-Yong KimPas encore d'évaluation

- SG6250HV-MV Container InstallationDocument3 pagesSG6250HV-MV Container InstallationJesica SantibañezPas encore d'évaluation

- Estimation of Flow Patterns: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical EngineeringDocument4 pagesEstimation of Flow Patterns: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical EngineeringahmedPas encore d'évaluation

- RFQ For Pumps-UpdatedDocument3 pagesRFQ For Pumps-UpdatedpragatheeskPas encore d'évaluation

- Physics 111 Homework SOLUTION, Week 4, Chapter 5, Sec 1-7Document15 pagesPhysics 111 Homework SOLUTION, Week 4, Chapter 5, Sec 1-7Abdullah Ahsan AhmedPas encore d'évaluation

- Ewaq FDocument69 pagesEwaq FCarlos Aguirre100% (1)

- 1st Quarter - SCIENCE 8-WEEK 1-2Document6 pages1st Quarter - SCIENCE 8-WEEK 1-2MICAH NORADAPas encore d'évaluation

- BPW 3Document58 pagesBPW 3ВЛАДИМИРPas encore d'évaluation

- Process Equipment in Petroleum RefiningDocument2 pagesProcess Equipment in Petroleum RefiningKaify ScorpionPas encore d'évaluation