Académique Documents

Professionnel Documents

Culture Documents

UltraSonics (Degree First Year)

Transféré par

surya_kotniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UltraSonics (Degree First Year)

Transféré par

surya_kotniDroits d'auteur :

Formats disponibles

16 Ultrasonics

16.1 Ultrasonic Waves:

We all know that sound is due to vibrations f one or the other kind of particles. The

human ear can hear the sound waves between 20 Hz to 20 kHz. This range is known as audible

range. The sound waves having frequencies above the audible range are known as ultrasonic

waves or supersonic waves. The wavelengths of ultrasonic waves are very small as compared to

audible sound. Most of the applications of the ultrasonic waves have been possible on account of

their small wavelengths. The wavelength of ultrasonic waves I air will be 1.8cms at 2.khz and

becomes much less at higher frequencies (0.035 m at 1M Hz). The ultrasonic waves are acoustic

waves of short wavelength and very high frequency. The sound waves which have frequencies

less than the audible range are called infrasonic waves.

16.2 Production of Ultrasonic waves.

This ultrasonic waves cannot be produced by our usual method of a diaphragm

loudspeaker fed with alternating current. This is due the fact that a very high frequencies, the

inductive effect of the loudspeaker coil is so large that practically no current passes through it.

Moreover, the diaphragm of a loudspeaker cannot vibrate at such high frequencies. Hence other

methods are used for the production of ultrasonic waves. There are two important methods

namely magnetostriction and piezo electric method which are mostly used now-a-days.

Magnetostriction method is used when frequencies up to 100 kHz are needed while piezo electric

generators are used mostly for frequencies above that. Here we shall discuss these two methods:

(1) Magnetostriction method. This method is based on the phenomenon of

Magnetostriction. According to this phenomenon when a rod of ferromagnetic material, such

as iron or nickel, is placed in a magnetic field parallel to its length, a small expansion or

contraction occurs. This change of length is independent of the sign of the field and depends

only upon the magnitude of the field and nature of the material. If the rod is placed inside a

coil carrying an alternating current, then it suffers the same change in length for each half

cycle of alternating current. This result in setting up vibrations in the rod whose frequency is

twice that of alternating current. Ordinarily the amplitude of the vibrations of rod is small. If,

however, the frequency of the alternating current is the same as the natural frequency of the

rod, then resonance occurs and the amplitude of vibrations is considerable increased. Sound

waves are now emitted from the ends of the rod. Moreover, if the applied frequency is of the

order of ultrasonic frequency, the rod sends out ultrasonic waves.

An experimental arrangement due to Pierce for producing ultrasonic waves is shown in

Fig. (1). There is a short nickel rod AB which is clamped at the centre. The rod is permanently

magnetized in the beginning by passing a direct current in the coil which is wrapped round the

rod. There are two other coils L

1

and L

2

which are wrapped round the rod as shown in the figure.

The coil L

2

is connected in the plate circuit of a valve V while L

1

is connected in the grid circuit.

The frequency of the oscillating plate circuit is adjusted with the help of a variable condenser C

connected across the coil L

2

. The direct current milli ammeter (mA) reads the plate current.

When the frequency of plate circuit is the same as the natural frequency of the rod, resonant

vibrations are produced in the surrounding medium. The vibrations are maintained due to the

coupling provided b coil L

1

. When the resonant oscillations start, the milli ammeter records the

maximum current. The maintenance of the oscillations of the rod is as follows :

When the plate current passing through the coil L

2

is changed, it causes a

corresponding change in the magnetization of the rod (the rod is already magnetized by the

steady polarizing magnetic field). Thus there is a change in the length of the rod. This vibration

in the length causes a vibration in the magnetic flux through the grid coil L

1

which in turn

changes the e.m.f developed across L

1

. This e.m.f acts on the grid and produces an amplified

current change in the plate circuit i.e., in the coil L

2

. In this way the plate current builds upto a

large amplitude with a frequency determined by the frequency of the longitudinal vibration of the

rod. Thus, the vibrations of the rod are maintained. When the frequency of the circuit becomes

equal to the frequency of the rod, resonance occurs and the sound waves of maximum amplitude

are generated. By adjusting the length of the rod and the capacity of the condenser, high

frequency oscillations of different frequencies are obtained.

(2) Piezo-electric method : This method is based on Piezo electric effect. According to this

effect when certain crystals like quartz, Rochelle salt, tourmaline etc. are stretched or compressed

along certain axis ( known as mechanical axis), an electric potential difference is produced along a

perpendicular axis (known as electric axis). The converse of this effect is also true i.e., when an

alternating potential difference is applied along the electric axis, the crystal is set into elastic vibration

along the corresponding with the natural frequency of the crystal, the vibrations will be of large

amplitude. This phenomenon is utilized for the production of ultrasonic waves. The alternating

potential difference is obtained by a valve oscillator.

Quartz crystal is six sided prism with pyramid shaped ends as shown in fig (2a). it has

following three major axes :

(i) Optic axis or z-axis. The line joining the apexes of the end pyramids is known

as z-axis.

(ii) The electrical axis or x-axis. The axis passes through any set of opposite corners

is known as x-axis.

(iii) The mechanical axis or y-axis. The axis passing through the opposite faces is

known as y-axis.

The X and Y cuts of the crystal are shown in fig. (2b). as shown in fig., the X-cut slab makes an

angle of 90

0

with the X-axis while Y-cut slab makes an angle of 90

0

with Y-axis.

X-cut slabs are used for the generation of ultrasonic because they produce longitudinal waves. Y-

cut produce shear waves, which can travel only in solids.

The experimental arrangement is shown in fig. (3). The high frequency alternating

voltage which is applied to crystal is obtained by Hartley oscillatory circuit. The Hartley circuit

consists of a tuned oscillatory circuit (inductance L

1

and a variable condenser C

1

in parallel). One

end of the tuned circuit is connected to the plate of a valve while the other is connected to the

grid. The coil L

1

is tapped near the centre and joined to the cathode. The X-cut quartz crystal Q is

connected in parallel of variable condenser C

1

.

The proper grid bias is obtained by means of grid leak resistor R

g

and grid condenser C

g

.

The d.c. voltage is applied to the plate through radio frequency choke. The radio frequency

choke prevents the radio frequency current to pass through high tension battery. C

b

is a blocking

capacitor which prevents the direct current to pass through the tank circuit while bypasses the

radio frequency currents. The capacity of the variable condenser C

1

is adjusted so that the

frequency of the oscillating circuit is tuned to the natural frequency of the crystal. Now the

quartz crystal is set into mechanical vibrations and ultrasonic waves are produced. The ultrasonic

waves upto a frequency of 500 kHz with a moderate size crystal can be produced by this method.

However, frequency upto 15 x 10

7

Hz can be produced by tourmaline crystal.

The velocity of quartz along X-direction is given by

Y

v

=

For quartz, Y=7.9 x 10

10

N/m

2

and =2650kg/m

3

10

7.9 10

5450 /

2650

v m s

| |

= =

|

\ .

If t be the thickness of quartz slab in metres, then

(2 ) V t v v = =

5450 2725

2 2

V

Hz

t t t

v = = =

If t is expressed in mm, then

2725 2725000

/ 1000 t t

v = =

2725

kHz

t

v =

So, for a thickness of 1 mm of quartz crystal

v =2725 KHz = 2.725 M Hz

When, by adjusting the variable capacitor C

1

of tank circuit, the crystal is made to vibrate at its

natural frequency, then the frequency of oscillatory circuit gives the frequency of vibrations of

quartz crystal, thus,

( )

1 1

1

2 LC

v

t

=

16.3 DETECTION OF ULTRASONICS

We cannot directly detect the ultrasonics although some animals specially the bat can do

so. However, the ultrasonics can be detected by the following methods :

(1) Piezo electric detector. The quartz crystal can also be used for the detectin of

ultrasonics. One pair of faces of quartz crystal is subjected to ultrasonics. On the other

faces which are perpendicular to the previous one, varying electric charges are produced.

Of course, the charges are very small. These charges are, therefore, amplified and then

detected by some suitable means.

(2) Kundts tube method: A Kundts tube can be used to detect ultrasonic waves of

relatively large wavelength as done for audible sound waves. When ultrasonic waves are

passed through the tube, the lycopodium powder sprinkled in the tube collects in the form

of heaps at the nodal points and is blown off at the antinodal points.

(3) Sensitive flame method: When a narrow sensitive flame is moved in a medium

where ultrasonic waves are present, the flame remains stationary at antinodes and flickers

at nodes.

(4) Thermal detector method: in this method a fine platinum wire is moved in the medium

of ultrasonic waves, the temperature of the medium changes due to alternate compressions

and rarefractions. There is a change of temperature at nodes while at antinodes, the

temperature remains constant. Hence, there resistance of the platinum wire changes at

nodes and remains constant at antinodes. The change in the resistance of platinum wire

with respect to time can be detected by using sensitive bridge arrangement. The bridge will

be in the balanced position when the platinum wire is at antinodes.

16.4 PROPERTIES OF ULTRASONICS

(i) They are highly energetic

(ii) Their speed of propagation depends upon their frequency, i.e., increase in frequency.

(iii) They show negligible diffraction due to their small wavelength. Hence they can be

transmitted over long distances without any appreciable loss of energy.

(iv) Intense ultrasonic radiation has a disruptive effect on liquids by causing bubbies to be

formed.

(v) When ultrasonic waves are propagated in a liquid bath, stationary wave pattern is

formed due to the reflection of wave from the other end. The density of the liquid thus varies

from layer to layer along the direction of propagation. In this way a plane diffraction grating is

formed which can diffract light.

16.5 WAVELENGTH OF ULTRASONIC WAVES

The phenomenon of diffraction of light by ultrasonic waves passing through a liquid was

first observed by Debye and Sears in America in 1932. When ultrasonic waves are propagated in

a liquid, the density varies from layer to layer due to periodic variations of pressure. If under this

condition, monochromatic light is passed through the liquid at right angles to the waves, the

liquid behaves as a diffraction grating. Such a grating is known as acoustical grating. This

grating behaves in the same way as a ruled grating. Hence the method can be used for finding the

wavelength and velocity of ultrasonic waves in liquid.

The experimental arrangement is shown in fig.(4). The light from a monochromatic

source of light S, is focused on the narrow slit O by lens L

1

. The light from the slit now passes

through lens L

2

which turns it in a parallel beam. This parallel beam then passes through the

ultrasonic cell. This cell consists of a rectangular glass tank containing the liquid. The crystal is

dipped into the liquid and is connected to the oscillating circuit. The crystal produces ultrasonic

waves which travel through the liquid. The waves are reflected from the wall of the cell and form

a stationary wave pattern which acts as acoustical grating. The crystal is placed in the cell in such

a way that the acoustical grating is formed in a perpendicular direction of the propagation of

light. Now light emerging from the cell is focused by lens L

3

and can be seen through a

telescope.

When the crystal is at rest, a single image of the slit is observed. But when ultrasonic

waves are produced in the liquid by excitation of crystal, the intensity of the central image

decreases and a number of diffracted mages appears on either side of centre. The angular

separation between the direct image of the slit and the diffracted image of any order, say n

measured. Applying the theory of diffraction grating the wavelength of ultrasonic waves can be

calculated. Here the grating element is the same as the wavelength of ultrasonic waves. Let it be

L

. if is the wavelength of the monochromic light used, then

In this way, can be calculated.

If N be the frequency of ultrasonic oscillations, then the velocity ultrasonic waves in liquid can

be calculated by the formula.

16.6 APPLICATIONS OF ULTRASONICS WAVES

(1) Detection of flaws in metals. Ultrasonic waves can be used to detect flaws in

metal. We know that flaw in the metal produces a change in the medium due to which reflection

of ultrasonic waves takes place. Hence when ultrasonic waves pass through a metal having some

hole or crack inside it, an appreciable reflection occurs. The reflection also takes place at the

back surface of the metal. The reflected pulses are picked up by receiver an are suitable

amplified. These pulses are now applied to one set of plate of cathode ray oscillograph. The

transmitted signal and reflected

signal from the flaw and back surface of metal produce a peak each. The position of the second

peak on the time base of oscillograph will give distance of flaw.

(2) Detection of submarines, Iceberg and other objects in ocean. A sharp ultrasonic

beam is directed in various directions into the sea. The reflection of waves from any direction

shows into the sea. The reflection of waves from any direction shows the presence of some

reflecting body in the sea.

(3) Depth of sea. We know that ultrasonic waves are highly energetic and show a little

diffraction effect. Thus they can be used for finding the depth of the sea. The time interval

between sending the wave and the reflected wave from the sea is recorded. As the velocity of the

wave is known, hence the depth of the sea can be estimated.

(4) Cleaning and Clearing. The waves can be used for cleaning utensils, washing clothes,

removing dust and soot from the chimney.

(5) Direction signaling. The ultrasonic waves can be concentrated into a sharp beam due to

smaller wavelength and hence can be used for signallling in a particular direction.

(6) Soldering and metal cutting. Ultrasonic waves can be used for drilling and cutting

processes in metals. These waves can also be used for soldering, for example, aluminium cannot

be soldered by normal methods. To solder aluminium ultrasonic wave along with electrical

soldering iron are used. Ultrasonic welding can be done at room temperatures.

(7) formation of alloys. The constituents of alloys, having widely different densities, can

be kept mixed uniformly by a beam of ultrasonic. Thus it is easy to get alloy of uniform

composition.

(8) Ultrasonic mixing. A colloid solution or emulsion of two non-miscible liquids like oil

and water can be formed by simultaneously subjecting to ultrasonic radiations. Now-a-days most

of the emulsion like polishes, paints, food products and pharmaceutical preparations are prepared

by using ultrasonic mixing.

(9) Coagulation and crystallization. The particle of a suspended liquid, by ultrasonics,

can be brought quite close to each other so that coagulation may be take place. The

crystallization rate is also affected by ultrasonics. The size of crystals, when molten metal is put

to crystallization, can be made smaller and more uniform by the use of ultrasonics.

(10) Ultrasonics in metallurgy. To irradiate molten metals which are in the process of

cooling so as to refine the gain size and to prevent the formation of cores and to release trapped

gases, the ultrasonic waves are use.

(11) Destruction of lower life. The animals like rats, frogs, fishes, etc. can be killed or

injured by high intensity ultrasonics.

(12) Treatment of neuralgic pain. The body parts effected due to neuralgic or rheumatic pains

on being exposed to ultrasonics get great relied from pain.

(13) Detection of abnormal growth. Abnormal growth in the brain, certain tumours

which cannot be detected by X-rays can be detected by ultrasonic waves.

Vous aimerez peut-être aussi

- Theory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationD'EverandTheory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationPas encore d'évaluation

- Ultrasonics For First Year .B.Tech. StudentsDocument9 pagesUltrasonics For First Year .B.Tech. StudentsSuryasrikar Peruri100% (1)

- Daylight Illumination–Color–Contrast Tables for Full-form ObjectsD'EverandDaylight Illumination–Color–Contrast Tables for Full-form ObjectsPas encore d'évaluation

- Ultrasonic Waves: 1. Production of UltrasonicsDocument7 pagesUltrasonic Waves: 1. Production of UltrasonicsAmit KumarPas encore d'évaluation

- 8 Ultrasonics: Mechanical MethodDocument6 pages8 Ultrasonics: Mechanical MethodShank ManPas encore d'évaluation

- Pepe's Tesla PagesDocument19 pagesPepe's Tesla PagesMerényi OszkárPas encore d'évaluation

- LABORATORY 12 Observing Sound WavesDocument2 pagesLABORATORY 12 Observing Sound WavesKelseyPas encore d'évaluation

- Atomic Structure - Discovery of Subatomic ParticlesDocument6 pagesAtomic Structure - Discovery of Subatomic ParticlesDivyansh DangiPas encore d'évaluation

- Ultrasonic Acoustic LevitationDocument38 pagesUltrasonic Acoustic LevitationPS LinnPas encore d'évaluation

- (Done 5) Mechanical and Chemical Effects On The Frequency of UltrasonicDocument5 pages(Done 5) Mechanical and Chemical Effects On The Frequency of Ultrasonicاشکان صفربالیPas encore d'évaluation

- Electrostatics Is The Branch of Physics That Deals With The Phenomena and Properties of Stationary or SlowDocument6 pagesElectrostatics Is The Branch of Physics That Deals With The Phenomena and Properties of Stationary or SlowfunandruinsPas encore d'évaluation

- Applications of Electromagnetic InductionDocument6 pagesApplications of Electromagnetic InductionAdeniji OlusegunPas encore d'évaluation

- Ultrasonic InterferometerDocument5 pagesUltrasonic InterferometerRadot ChandraPas encore d'évaluation

- Application of Ultrasonic Technology For Water andDocument17 pagesApplication of Ultrasonic Technology For Water andMartin DarmasetiawanPas encore d'évaluation

- Introduction To Electrochemistry: The Scope of ElectrochemistryDocument10 pagesIntroduction To Electrochemistry: The Scope of ElectrochemistrymariaPas encore d'évaluation

- Chemistry: Acoustic CavitationDocument2 pagesChemistry: Acoustic CavitationRohit ChauhanPas encore d'évaluation

- Magnetizing GuideDocument50 pagesMagnetizing GuideChava MichiganPas encore d'évaluation

- PDF Air1Document13 pagesPDF Air1olipoppoPas encore d'évaluation

- Investigations On A Standing Wave Thermoacoustic RefrigeratorDocument8 pagesInvestigations On A Standing Wave Thermoacoustic RefrigeratorAli AHPas encore d'évaluation

- The History of Power Transmission by Radio WavesDocument13 pagesThe History of Power Transmission by Radio WavesJorge SantamariaPas encore d'évaluation

- Electron ModelsDocument13 pagesElectron ModelsNooruddin SheikPas encore d'évaluation

- Richard L. Davis - Non-Inductive ResistanceDocument10 pagesRichard L. Davis - Non-Inductive Resistancealexanderf_20Pas encore d'évaluation

- Atomic StructureDocument6 pagesAtomic StructureDileep KumarPas encore d'évaluation

- Electromagnetic Induction: (A) Electricity From MagnetismDocument6 pagesElectromagnetic Induction: (A) Electricity From MagnetismGaurav ChopraPas encore d'évaluation

- Sfra For Condition Monitoring of Power TransformerDocument3 pagesSfra For Condition Monitoring of Power TransformerSarojakanti SahooPas encore d'évaluation

- Resonance UnlockedDocument5 pagesResonance UnlockedgjjgPas encore d'évaluation

- The Discovery of Schumann Resonance: CapacitorsDocument5 pagesThe Discovery of Schumann Resonance: Capacitorssagor sagorPas encore d'évaluation

- Chapter 3: Electrolytic Conductance 3.1. Specific Conductance Specific Conductance Is A Measure of The Electric Current in The Water SampledDocument11 pagesChapter 3: Electrolytic Conductance 3.1. Specific Conductance Specific Conductance Is A Measure of The Electric Current in The Water SampledBùi Hữu ĐứcPas encore d'évaluation

- Applications of Electromagnetic InductionDocument6 pagesApplications of Electromagnetic InductionLivombo AveloPas encore d'évaluation

- An Update On Ultrasonic Irrigant ActivationDocument15 pagesAn Update On Ultrasonic Irrigant ActivationkarishmaPas encore d'évaluation

- Theories of LightDocument3 pagesTheories of LightClaiomh Solais100% (1)

- Theory of SuperconductivityDocument135 pagesTheory of SuperconductivityRenjith Raveendran PillaiPas encore d'évaluation

- Electric Charge and Electric FieldDocument3 pagesElectric Charge and Electric FieldAhmet UlusoyPas encore d'évaluation

- Fricke The Use of Polarized Stones As A Method of Clearing Houses and Communities of Detrimental RadiationsDocument8 pagesFricke The Use of Polarized Stones As A Method of Clearing Houses and Communities of Detrimental RadiationsCastenetsPas encore d'évaluation

- CHP 4Document25 pagesCHP 4aza bellaPas encore d'évaluation

- Torsion Field Physics and CommunicationsDocument74 pagesTorsion Field Physics and CommunicationsMickPas encore d'évaluation

- Characterization of Atmospheric Pressure Discharges: R.Barni, S.Zanini, R.Siliprandi, P.Esena, C.RiccardiDocument8 pagesCharacterization of Atmospheric Pressure Discharges: R.Barni, S.Zanini, R.Siliprandi, P.Esena, C.RiccardiRodrigo RamosPas encore d'évaluation

- Introduction To Magnetic CircuitsDocument23 pagesIntroduction To Magnetic Circuitssharad kumarPas encore d'évaluation

- The Generation of ElectricityDocument42 pagesThe Generation of ElectricityNorazlin UjangPas encore d'évaluation

- Introduction To Micro-World: Quantum TheoryDocument13 pagesIntroduction To Micro-World: Quantum TheoryTohin MiahPas encore d'évaluation

- Models - Aco.piezoacoustic TransducerDocument16 pagesModels - Aco.piezoacoustic TransducerLeuca Bogdan-CostinPas encore d'évaluation

- Biological Effects of Magnetic Fields PDFDocument14 pagesBiological Effects of Magnetic Fields PDFPedro PereiraPas encore d'évaluation

- Plasma Orbital Expansion Electrons WaterDocument158 pagesPlasma Orbital Expansion Electrons WaterVincent J. CataldiPas encore d'évaluation

- BIORESONANCE EnglishDocument12 pagesBIORESONANCE EnglishJose La100% (1)

- Intro SpecialDocument130 pagesIntro SpecialKit ChotPas encore d'évaluation

- Wave Motion 1Document53 pagesWave Motion 1AAKASH ChopraPas encore d'évaluation

- The Characterization of Acoustic Cavitation Bubbles - An OverviewDocument9 pagesThe Characterization of Acoustic Cavitation Bubbles - An Overview劉平本Pas encore d'évaluation

- AIRES NeutralizerDocument26 pagesAIRES NeutralizerpeterPas encore d'évaluation

- 03 Marincic Civric MilovanovicDocument18 pages03 Marincic Civric MilovanovicThami KPas encore d'évaluation

- Catalogue - Probe Sonicator - Ultra Autosonic IndiaDocument4 pagesCatalogue - Probe Sonicator - Ultra Autosonic IndiaGirish GuptaPas encore d'évaluation

- WTS 12 ElectrodynamicsDocument28 pagesWTS 12 ElectrodynamicsTondani100% (1)

- Applications of Ultrasound in Organic SynthesisDocument2 pagesApplications of Ultrasound in Organic SynthesisLav VarmaPas encore d'évaluation

- A Survey of Dusty Plasma Physics PDFDocument13 pagesA Survey of Dusty Plasma Physics PDFAjit Upadhyay100% (1)

- Models - Aco.piezoacoustic TransducerDocument14 pagesModels - Aco.piezoacoustic Transducerkiran kumar kPas encore d'évaluation

- The Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Document3 pagesThe Use of Ultrasonic Cleaning in Dairy Industry: How Does It Work?Vetz clubPas encore d'évaluation

- Radionics Radiestesia and Physics DR William A TillerDocument24 pagesRadionics Radiestesia and Physics DR William A TillerRicardo GuimarãesPas encore d'évaluation

- The Electromagnetic Bio-Field - Clinical Experiments and InterferencesDocument6 pagesThe Electromagnetic Bio-Field - Clinical Experiments and InterferencesKevin Steeven Delgado MarinPas encore d'évaluation

- Cai2009 PDFDocument5 pagesCai2009 PDFLeon Blažinović100% (1)

- 4th Class EVS 9Document4 pages4th Class EVS 9surya_kotniPas encore d'évaluation

- 7 Teaching Learning MaterialDocument6 pages7 Teaching Learning Materialsurya_kotniPas encore d'évaluation

- Bhagavad GeethaDocument381 pagesBhagavad GeethaVenu GadadasuPas encore d'évaluation

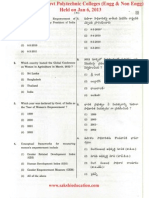

- Jan6-2012 Poly Technic Exam PaperDocument32 pagesJan6-2012 Poly Technic Exam PaperNooruddin SheikPas encore d'évaluation

- Hindu Calender 2015Document12 pagesHindu Calender 2015pravin2projectsPas encore d'évaluation

- Psychology Definitions1Document3 pagesPsychology Definitions1surya_kotniPas encore d'évaluation

- Engineering Physics Sem - 1Document349 pagesEngineering Physics Sem - 1Andrew NelsonPas encore d'évaluation

- 10th Physical Science Bit BankDocument7 pages10th Physical Science Bit Banksurya_kotniPas encore d'évaluation

- Seagate Dashboard User Guide UsDocument20 pagesSeagate Dashboard User Guide UsPranav VyasPas encore d'évaluation

- I YearDocument28 pagesI Yearsurya_kotniPas encore d'évaluation

- 10th Class Bit Bank Physic (T.M)Document16 pages10th Class Bit Bank Physic (T.M)Rajasekhar ParaPas encore d'évaluation

- 10th Chemistry Bit Bank EMDocument6 pages10th Chemistry Bit Bank EMsurya_kotniPas encore d'évaluation

- Magnetism ContentsDocument6 pagesMagnetism Contentssurya_kotniPas encore d'évaluation

- 9th Beejiya SamasaluDocument31 pages9th Beejiya Samasalusurya_kotniPas encore d'évaluation

- Results of 2nd Stage Exam For NTPC (UG) (DOE-19.01.14)Document4 pagesResults of 2nd Stage Exam For NTPC (UG) (DOE-19.01.14)surya_kotniPas encore d'évaluation

- 10 Science English 2013Document204 pages10 Science English 2013surya_kotniPas encore d'évaluation

- 12Document1 page12surya_kotniPas encore d'évaluation

- Engbooklet (1) 2014Document23 pagesEngbooklet (1) 2014surya_kotniPas encore d'évaluation

- AP X Physics EMDocument352 pagesAP X Physics EMsurya_kotniPas encore d'évaluation

- 12Document1 page12surya_kotniPas encore d'évaluation

- Sakshi: ÑÐ) L ) Lä Æ ) L Ð) Låð) LçüDocument4 pagesSakshi: ÑÐ) L ) Lä Æ ) L Ð) Låð) LçümooorthuPas encore d'évaluation

- 12Document1 page12surya_kotniPas encore d'évaluation

- Path A Jali Yoga Sutra MuluDocument58 pagesPath A Jali Yoga Sutra MuluKovvuri Vnlnsrinivas100% (5)

- Magnetism 06Document8 pagesMagnetism 06surya_kotniPas encore d'évaluation

- Ãt Ûäyês¡+ 2 - Òæáãe) 2011: Á - Üc Nqtã+ Ûä+Document1 pageÃt Ûäyês¡+ 2 - Òæáãe) 2011: Á - Üc Nqtã+ Ûä+surya_kotniPas encore d'évaluation

- Èlç (™èlìz Ð) L Qå Çü Çœ$R ) Lë$: SakshiDocument4 pagesÈlç (™èlìz Ð) L Qå Çü Çœ$R ) Lë$: SakshiJagadeesh SaragadamPas encore d'évaluation

- Electromagnetism 8Document9 pagesElectromagnetism 8surya_kotniPas encore d'évaluation

- Electricity 7Document13 pagesElectricity 7surya_kotniPas encore d'évaluation

- Pragnaa File FromDocument1 pagePragnaa File Fromsurya_kotniPas encore d'évaluation

- Mahaprasthanam in TeluguDocument54 pagesMahaprasthanam in TeluguTelugu Telugu100% (1)

- ALL ANSWERS Numbered-CompressedDocument80 pagesALL ANSWERS Numbered-CompressedBoston KarymshakovPas encore d'évaluation

- Complex Engineering Problem: Mohammad Hussain Submitted To: BSME: 18-22 Roll: 19 Dr. Rab NawazDocument11 pagesComplex Engineering Problem: Mohammad Hussain Submitted To: BSME: 18-22 Roll: 19 Dr. Rab NawazMohammad HussainPas encore d'évaluation

- Chemistry Project On Analysis of FertilizersDocument12 pagesChemistry Project On Analysis of FertilizersRitik ShankarPas encore d'évaluation

- MST, Module 1, NotesDocument22 pagesMST, Module 1, NotesChandrashekhar KulkarniPas encore d'évaluation

- Graph - BJH Method Adsorption DV (R) - 20191213 SAMPEL 2Document1 pageGraph - BJH Method Adsorption DV (R) - 20191213 SAMPEL 2amanda A9lenoPas encore d'évaluation

- GS14 Industrial Geophone - GeoSpace TechnologiesDocument1 pageGS14 Industrial Geophone - GeoSpace TechnologieshectorPas encore d'évaluation

- NEET - Physics # DPP (Motion in 1D) - 05.04.2017Document7 pagesNEET - Physics # DPP (Motion in 1D) - 05.04.2017Sankar KumarasamyPas encore d'évaluation

- Bernoullis EquationDocument45 pagesBernoullis EquationEunicePas encore d'évaluation

- Contributions of Indian Physicists in ScienceDocument42 pagesContributions of Indian Physicists in ScienceblahPas encore d'évaluation

- Grade 9 Science UP 4Document30 pagesGrade 9 Science UP 4MR. BEST100% (1)

- 5 1doneDocument3 pages5 1doneeperlaPas encore d'évaluation

- Physics Division: Phys 141 Syllabus, PGDocument7 pagesPhysics Division: Phys 141 Syllabus, PGJun YoutubePas encore d'évaluation

- MCQ Questions On Set TheoryDocument34 pagesMCQ Questions On Set TheoryShubham PardeshiPas encore d'évaluation

- Plasma AntennaDocument9 pagesPlasma Antennaleena999Pas encore d'évaluation

- M-TECH Machine Design Kerala University SYLLABUSDocument71 pagesM-TECH Machine Design Kerala University SYLLABUSMathew JohnPas encore d'évaluation

- AIK (Screening) 2Document26 pagesAIK (Screening) 2anisaPas encore d'évaluation

- Earthing System JKR PDFDocument19 pagesEarthing System JKR PDFameera nabihaPas encore d'évaluation

- Rotational MechanicsDocument6 pagesRotational MechanicsHemant KumarPas encore d'évaluation

- Abstract-Piezoelectric Energy HarvestingDocument2 pagesAbstract-Piezoelectric Energy HarvestingGanesh Venugopal100% (5)

- Strength of Materials PDFDocument139 pagesStrength of Materials PDFBrajnandan AryaPas encore d'évaluation

- NEET 2021 - 20 Practice Sets (I - GK PublicationsDocument65 pagesNEET 2021 - 20 Practice Sets (I - GK PublicationsPushparaj Thangaraj100% (1)

- Chapter 10 Relative Equilibrium On FluidsDocument42 pagesChapter 10 Relative Equilibrium On FluidsJubillee Magsino0% (1)

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSPas encore d'évaluation

- ME 423 Finals Formula SheetDocument2 pagesME 423 Finals Formula SheetNicolai CeloPas encore d'évaluation

- Architectural Acoustic: Prepared By:-Rushit PatelDocument32 pagesArchitectural Acoustic: Prepared By:-Rushit PatelSaurabh SinghPas encore d'évaluation

- Column DesignDocument4 pagesColumn DesignArnel Dodong83% (6)

- Useful Information: Bending Ratio of Rope (D/D)Document2 pagesUseful Information: Bending Ratio of Rope (D/D)علي الزغلPas encore d'évaluation

- Crystal DefectsDocument2 pagesCrystal DefectsVictory OkwuPas encore d'évaluation

- One Marks Questions: NumericalsDocument2 pagesOne Marks Questions: NumericalsKumar SushilPas encore d'évaluation

- 4.26μm sensor CO2Document9 pages4.26μm sensor CO2JindraPas encore d'évaluation

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherD'EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherPas encore d'évaluation

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticD'EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticÉvaluation : 3.5 sur 5 étoiles3.5/5 (10)

- The Importance of Being Earnest: Classic Tales EditionD'EverandThe Importance of Being Earnest: Classic Tales EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (44)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedD'EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- The Inimitable Jeeves [Classic Tales Edition]D'EverandThe Inimitable Jeeves [Classic Tales Edition]Évaluation : 5 sur 5 étoiles5/5 (3)

- The Comedians in Cars Getting Coffee BookD'EverandThe Comedians in Cars Getting Coffee BookÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyD'EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- The Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoD'EverandThe Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoD'EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoÉvaluation : 3.5 sur 5 étoiles3.5/5 (1428)

- 100 Bible Verses Everyone Should Know by HeartD'Everand100 Bible Verses Everyone Should Know by HeartÉvaluation : 4.5 sur 5 étoiles4.5/5 (20)

- 1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderD'Everand1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderÉvaluation : 3.5 sur 5 étoiles3.5/5 (48)

- Cats On The Run: a wickedly funny animal adventureD'EverandCats On The Run: a wickedly funny animal adventureÉvaluation : 4 sur 5 étoiles4/5 (8)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverD'EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Spoiler Alert: You're Gonna Die: Unveiling Death One Question at a TimeD'EverandSpoiler Alert: You're Gonna Die: Unveiling Death One Question at a TimeÉvaluation : 4 sur 5 étoiles4/5 (58)

- Electronics All-in-One For Dummies, 3rd EditionD'EverandElectronics All-in-One For Dummies, 3rd EditionÉvaluation : 5 sur 5 étoiles5/5 (2)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)