Académique Documents

Professionnel Documents

Culture Documents

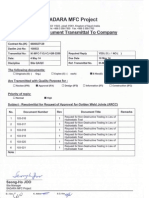

Rtip - LSTK - Ik - Schedule Q - 0

Transféré par

Siddiqui Abdul KhaliqDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rtip - LSTK - Ik - Schedule Q - 0

Transféré par

Siddiqui Abdul KhaliqDroits d'auteur :

Formats disponibles

CONTRACT NO.

6600027129

RTIP IN KINGDOM

LSTK CONTRACT SCHEDULE Q QUALITY REQUIREMENTS

Revision 3

SCHEDULE Q SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

QUALITY REQUIREMENTS TABLE OF CONTENTS

1. 2. 3. 4. 5. 6. 7.

General ............................................................................................................... 1 Quality Management System Requirements ..................................................... 2 Documentation Requirements ............................................................................ 2 Management Responsibility ............................................................................... 3 Resource Management ...................................................................................... 3 Project Execution/Process Realization .............................................................. 5 Measurement, Analysis and Improvement ......................................................... 6 Contractor and Subcontractor Quality Personnel Qualification Requirements Company Standards and Procedures with Applicable Quality Requirements Quality Requirements for Contractor Materials and Equipment Quality Requirements for the Construction Phase Summary of Quality Management System Deliverables Project Specific Quality Requirements

ATTACHMENT I ATTACHMENT II ATTACHMENT III ATTACHMENT IV ATTACHMENT V ATTACHMENT VI

Revision 3

Q-i

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

1. 1.1 1.2

GENERAL This Schedule Q describes Companys minimum requirements for Contractors Quality Management System (QMS). Contractor will be fully responsible for the quality of the Work. Contractor must inspect, test and accept all parts of the Work, including all Work performed by Subcontractors and Vendors, to ensure the Work complies with all applicable drawings, specifications and standards. Company will be entitled to have the Company Representative or a nominee present at any time at all Work Sites where Contractor or its Subcontractors and Vendors are engaged in the performance of the Work, to review all aspects of Contractor's quality activities and to witness whatever inspection and testing is required by the Contract. Company retains the right to conduct whatever additional tests or inspections it deems necessary to ensure that all materials and equipment meet the requirements of the Contract and the applicable Purchase Orders. Contractor must not refuse Company or its nominee access to technical or other data which Contractor considers proprietary or confidential, and which is reasonably required to inspect Contractor's performance of the Work. Company retains the right to conduct additional tests or inspections as it deems necessary to ensure all Work conforms to the Contract. Company will complete its review of Contractors quality documents (e.g., Quality Plan, procedures, Inspection & Test Plans, etc.) and Contractor Personnel qualifications within thirty (30) days from initial submission of such quality documents and Contractor Personnel qualifications. Following such review, Company must Approve, provisionally Approve or reject with comments the submitted quality documents and/or Contractor Personnel qualifications. Contractor must not commence any Work related to engineering, procurement or construction of the Facilities prior to obtaining Approval of the Quality Plan in accordance with paragraph 3.1 of this Schedule Q. For any inspection or any test required to be witnessed by Company and/or required by the applicable Laws of the Kingdom of Saudi Arabia, Contractor must provide notice of such inspection or test as specified in the Approved ITPs to enable the Company Representative or delegate to attend. If any part of the Work or Facilities is closed or covered without Approval before the required inspection or witnessing has been performed, at Companys request Contractor must open or uncover the Work or Facilities for inspection or witnessing and re-close or recover at Contractors expense. If any inspection or test directed or performed by Company, or by another party at the direction of Company, reveals any defect in any Contractor Materials or Equipment or in the Work, Contractor shall bear

1.3

1.4

1.5

1.6

1.7

Revision 3

Q-1

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

the cost of such inspection and testing and must promptly correct such defect at Contractor's expense. 1.8 If Contractor does not adhere to the quality requirements of this Schedule Q, Company may, upon providing fourteen (14) days advance notification to Contractor, supply sufficient inspection and testing services to ensure the Work is being performed as required by the Contract. Contractor shall bear the cost of such inspection and testing. QUALITY MANAGEMENT SYSTEM REQUIREMENTS Contractor must implement a Project-specific QMS in compliance with this Schedule Q and based on the latest version of ISO 9001 (Quality Management Systems - Requirements). Definitions contained in the latest version of ISO 9000 (Quality Management Systems Fundamentals and Vocabulary) will apply to this Schedule Q. In case of conflict between ISO 9001 and this Schedule Q, the requirements of this Schedule Q shall take precedence, unless otherwise Approved. 3. 3.1 DOCUMENTATION REQUIREMENTS Contractor must prepare a Project-specific Quality Plan in accordance with this Schedule Q and the latest version of ISO 10005 (Quality Management Systems - Guidelines for Quality Plans) covering, as applicable, engineering, procurement, construction and Precommissioning activities and submit it to the Company for review and Approval within thirty (30) days from the Effective Date. Contractor must organize, execute and control all Work in accordance with the Quality Plan, ITPs and specified procedures. The Quality Plan must ensure Contractor processes, including those of Subcontractors, will be effective and the Work will be completed in strict compliance with all provisions of the Contract and the applicable Purchase Orders. Contractor must prepare ITPs and supporting checklists in accordance with Attachment IV to this Schedule Q and must not commence associated Work prior to Approval of the applicable ITPs. Contractor must submit Vendors ITPs in accordance with Attachment III to this Schedule Q. Pending Approval of the ITPs, Contractor must not permit fabrication to begin on any item required to have ITPs. Contractor must modify its Quality Plans and ITPs to reflect any changes identified by Contractor or Company. Contractor must incorporate any changes and resubmit the revised Quality Plans or ITPs for Approval within seven (7) days from identification of the changes. Contractor shall make the latest revision of Contractors quality manual, applicable Quality Plans and all referenced documentation available for Company use at Contractor's Work Site(s). Reference documents include all those contained in drawings, specifications and procedures for the

2.

3.2

3.3

3.4

3.5

3.6

Revision 3

Q-2

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

inspection of equipment and materials to be fabricated or constructed at the applicable Work Site. 3.7 Contractor must identify and maintain quality records to demonstrate specified quality requirements are implemented and achieved. Records must support all activities related to the QMS to verify conformance to the quality requirements. MANAGEMENT RESPONSIBILITY 4.1 Contractor's top management shall conduct management reviews of the Project-specific QMS to ensure it is suitable, adequate and effective, as indicated in ISO 9001 (Quality Management Systems Requirements). The schedule for the management reviews must be provided to the Company Representative for review. Within fourteen (14) days from the management reviews described in paragraph 4.1 above, Contractor must advise the Company Representative in writing of the results and recommended actions arising from the reviews. Contractor must incorporate any changes to the QMS resulting from the reviews, with the Approval of the Company Representative, into the Quality Plans as necessary. RESOURCE MANAGEMENT 5.1 5.2 Contractor must provide resources to implement the QMS as set forth in the Contract. Within seven (7) days from the Effective Date, Contractor must designate the Quality Assurance (QA) Manager, who shall be assigned to the Work through to Work completion. At least thirty (30) days prior to the start of fabrication, Contractor must designate the Construction Quality Control (QC) Manager, who shall be assigned to the Work through to Work completion. Within thirty (30) days from the Effective Date, Contractor must designate the Procurement QC Supervisor, who shall be assigned to the Work through to Work completion of all procurement activities. Contractor, Subcontractor and third party agency quality personnel assigned to the Work must meet the minimum qualification requirements of Attachment I to this Schedule Q and must be technically competent to perform their duties. Contractor shall provide to Company resums and all associated certifications of all Contractor, Subcontractor and third party agency quality personnel for review and Approval prior to each individual starting work on the Project. Company shall have the right to interview and/or test such personnel and to reject proposed candidates if they do not comply with the

4.

4.2

5.

5.3

5.4

5.5

5.6

Revision 3

Q-3

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

requirements in Attachment I to this Schedule Q or if Company has had prior poor experience with such candidates. 5.7 If Work includes welding and non-destructive testing (NDT) and exceeds two thousand (2000) groove/butt weld joints, Contractor must designate an NDT coordinator a minimum of thirty (30) days prior to the start of welding. Contractor may subcontract inspection services subject to Company Approval. Contractors quality personnel will be dedicated to perform and complete all quality functions as described in this Schedule Q. Contractors quality personnel shall have sufficient and well defined responsibilities, qualifications, authority, and organizational freedom to identify quality problems and areas of non-conformance and to initiate, recommend and substantiate corrective actions. During all phases of the Work, Contractors QC Managers/Supervisors must functionally report to the Contractor QA Manager. QA/QC Managers/Supervisors must not functionally or administratively report to the Construction Manager. Within sixty (60) days from the Effective Date, Contractor must submit to the Company Representative as part of the monthly Quality Management Report (see paragraph 7.5 below) a summary sorted by discipline of quality personnel forecast to be mobilized or demobilized within the next sixty (60) days. Such forecasts shall include information pertaining to Contractors and Subcontractors construction personnel loading/unloading, as applicable. Contractor must include and maintain current in its Quality Plans or as an attachment, its organization charts clearly showing assignments of personnel including: 5.12.1 all planned quality personnel, including Subcontractor personnel, for the Project in accordance with Attachment VI to this Schedule Q; reporting relationships from inspector to the level above Contractors Project Manager; internal and external lines of communication; interfaces between Contractor and its Subcontractors and Vendors, and between Contractor and Company; and Mobilization and de-mobilization dates for all planned quality personnel.

5.8 5.9 5.10

5.11

5.12

5.12.2 5.12.3 5.12.4 5.12.5 5.13

Planned staffing levels must comply with Attachment VI to this Schedule Q. Any planned reduction from the required levels must be approved.

Revision 3

Q-4

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

5.14

Contractor shall make quality personnel changes required due to resignations, temporary assignments, vacations, or other reasons as necessary to maintain required quality coverage. Contractor must advise the Company Representative at least thirty (30) days in advance of scheduled absences or changes to personnel and quality coverage or within seventy-two (72) hours for unscheduled changes including illness and emergency leave. Contractor shall implement and maintain an ongoing program to introduce and familiarize all Contractor Personnel and Subcontractor personnel with the Project quality requirements for their area of responsibility.

5.15

6. 6.1

PROJECT EXECUTION/PROCESS REALIZATION Engineering Phase Quality Activities 6.1.1 6.1.2 Contractor shall comply with the engineering requirements of the Quality Plan and scope of Work. phase

Contractor shall perform engineering reviews at appropriate stages during the engineering phase according to the Approved engineering execution plan. Contractor must maintain records of such Contractor engineering reviews in accordance with the Quality Plan, including solicitation, recording, tracking and resolution of all comments.

6.2

Procurement Phase Quality Activities Contractor must comply with the procurement phase requirements of the Quality Plan and Attachment III to this Schedule Q.

6.3

Construction Phase Quality Activities Contractor must comply with the construction phase requirements of the Quality Plan and Attachment IV to this Schedule Q.

6.4

Pre-commissioning Phase Quality Activities 6.4.1 6.4.2 Contractor must comply with the Pre-commissioning phase requirements of the Quality Plan and Schedule B. Prior to completion of Work, Contractor shall, at Contractors own expense, perform the inspections required by Schedule B to complete Pre-commissioning activities and document and correct any non-conformances. Contractor must submit a copy of the inspection results and status of the correction of non-conformances to the Company Representative each week until acceptance of the outstanding items.

Revision 3

Q-5

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

7. 7.1

MEASUREMENT, ANALYSIS AND IMPROVEMENT Internal Assessments 7.1.1 Contractor must conduct internal quality assurance/quality control assessments for contracts or work phases with a duration of six (6) months or longer. This shall include assessments of Contractor's quality functions and obligations as described in the Contract, Quality Plans, and ISO 9001 (Quality Management Systems - Requirements). This shall also include scheduled QMS assessments for all Subcontractors and Vendors carrying out Work which is scheduled to exceed six (6) months in duration. Contractor must submit a quality assessment schedule to the Company Representative for review and approval within thirty (30) days from the Effective Date. As a minimum, full QMS assessments shall be carried out at fifteen percent (15%) and sixty percent (60%) of completion of the engineering, procurement, and construction phases. Contractors assessments may be rescheduled only with the Approval of the Company Representative and the revised schedule must be submitted to the Company Representative within seven (7) days of the Approved rescheduling. All assessments must be executed by quality system assessors (qualified in accordance with Attachment I to this Schedule Q) not directly responsible for the area being assessed, or by an Approved third party agency. Contractor shall initiate corrective actions, at the Contractors own expense, to prevent recurrence of nonconformities identified in each assessment. Contractor must verify implementation and effectiveness of any corrective actions before closing. Contractor must submit to the Company Representative a copy of each assessment report within fourteen (14) days of its completion. The Company Representative or nominee shall be invited to participate in all assessments. Assessment notifications and agendas must be submitted to the Company Representative fourteen (14) days in advance of the planned assessment. Company will be entitled to have the Company Representative or nominees schedule and conduct quality assessments of Contractors quality functions and obligations as outlined in this Schedule Q. Company shall communicate the quality assessment schedule to Contractor at least fourteen (14) days prior to the assessment.

7.1.2

7.1.3

7.1.4

7.1.5

7.1.6

7.1.7

Revision 3

Q-6

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129

7.2

Monitoring and Measuring of Processes Contractor must continually monitor and measure Contractor and Subcontractor critical processes throughout the Work. The Quality Plan must include suitable measurement methods to evaluate the ability of the process to achieve planned results. As a minimum, Contractor must evaluate the processes shown in paragraph 2.1 of Attachment IV to this Schedule Q as appropriate, in accordance with the scope of Work in Schedule B.

7.3

Control of Non-conformance and Corrective and Preventive Action 7.3.1 In the Quality Plan, Contractor shall address procedures to prevent inadvertent use of engineering documents, materials, parts, components, equipment or services not conforming to requirements of the Contract. The Quality Plan shall require the identification and recording of all non-conformances, corrective actions and preventive actions. Contractor shall be responsible for all Contractor Materials, Equipment and portions of the Work that do not conform to the requirements of the Contract and in such circumstances, shall ensure the processes and procedures prescribed in paragraphs 7.3.3 to 7.3.6 (inclusive) below are followed. Contractor shall establish and maintain controls to restrict further processing or installation of nonconforming or defective items, pending decisions on disposition. When practical, Contractor shall segregate all nonconforming Contractor Materials and Equipment to a clearly designated hold area. Contractor, Subcontractors, and/or Vendors must record all non-conformances to Contract requirements, Quality Plans, ITPs, and procedures. Contractor shall forward records of all non-conformances to Company within forty-eight (48) hours of issue. Contractor shall initiate corrective actions to prevent recurrence of non-conformances a maximum of fourteen (14) days from the issue date of the non-conformance. Contractor shall provide the Company Representative with an explanation for non-conformances that will require more than fourteen (14) days to resolve. Contractor shall maintain a summary of the status of non-conformances and include this summary in the monthly Quality Management Report as indicated in paragraph 7.5 below. Contractor shall respond in writing, including proposed corrective action, to all non-conformances issued by Company within three (3) Business Days of receiving notification of the non-

7.3.2

7.3.3

7.3.4

7.3.5

7.3.6

Revision 3

Q-7

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129 conformance. Contractor shall, at Contractors own expense, promptly rework or repair and re-inspect all non-conforming items in accordance with Approved procedures and notify the Company Representative for verification prior to closure that such rework/repair is satisfactory.

7.3.7

Contractors procedures for preventive action must describe the requirements for evaluating the need for actions to prevent occurrence of potential non-conformances and for the implementation of applicable lessons learned from previous projects.

7.4

Variances Contractor shall maintain a log detailing all variances from Company standards obtained during all phases of the Work, including those initiated by Company (during or prior to the start of Work) or Contractor. This log must indicate the status of the variance and include a brief description and details of the applicable Purchase Order and equipment or construction process.

7.5

Analysis of Data Contractor shall prepare and submit within sixty (60) days from the Effective Date, a monthly Quality Management Report in a format acceptable to Company to demonstrate effective implementation of Contractor's QMS. The Quality Management Report must include the following items, as a minimum: 7.5.1 General Items: (a) summary of quality assessments completed (internal, Subcontractors and Vendors), in progress, and planned for the next month; status of corrective actions from non-conformance reports, assessments and management reviews; quality personnel summary/forecast by discipline as specified in paragraph 5.11 above; and Status of engineering variances requested.

(b) (c) (d)

7.5.2 Engineering and Procurement Phase Items: (a) (b) listing of Vendor assessments performed with results and those planned for the next month; listing of pre-inspection meetings conducted and those planned for the next month;

Revision 3

Q-8

SCHEDULE Q

RTIP LSTK IK CONTRACT NO. 6600027129 (c) (d) listing of Vendor inspections performed with results and those planned for the next month; and Listing and disposition of all defective or rejected material or equipment.

7.5.3 Construction Phase Items: (a) listing and disposition of all defective or rejected material or equipment received at Construction Site by Contractor and Subcontractors; and welding rejection rate reported in accordance with the Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects A554-O-PRG-QA-GENPRO013 document, including the historical performance during the Project.

(b)

7.5.4

Narrative Section for Process Improvement Activities: This section of the report shall describe Contractors and Subcontractors activities during the month to continually improve their processes, prevent potential problems, and increase efficiency, and include trend analysis for processes identified in paragraph 7.2 of this Schedule Q. End of Schedule Q

Revision 3

Q-9

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Weekly Welder Repair Rate MonitoringDocument15 pagesWeekly Welder Repair Rate MonitoringSiddiqui Abdul Khaliq100% (1)

- PWHT As Per Asme b31.3Document2 pagesPWHT As Per Asme b31.3Siddiqui Abdul KhaliqPas encore d'évaluation

- API 570 - Daily Exam 5C API-571-577 Questions - PSJDocument4 pagesAPI 570 - Daily Exam 5C API-571-577 Questions - PSJKrishna Moorthy50% (2)

- Mock-Up Block Drawings Fro AUTDocument14 pagesMock-Up Block Drawings Fro AUTSiddiqui Abdul KhaliqPas encore d'évaluation

- Sadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingDocument1 pageSadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingSiddiqui Abdul KhaliqPas encore d'évaluation

- Impact Testing PhotosDocument2 pagesImpact Testing PhotosSiddiqui Abdul KhaliqPas encore d'évaluation

- Sample Welder's JCCDocument1 pageSample Welder's JCCSiddiqui Abdul KhaliqPas encore d'évaluation

- ARCC Hydrotest Packages Summary ReportDocument4 pagesARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqPas encore d'évaluation

- 1401 TamimiDocument1 page1401 TamimiSiddiqui Abdul KhaliqPas encore d'évaluation

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- Figure 323.2 Asme b31.3Document1 pageFigure 323.2 Asme b31.3Siddiqui Abdul KhaliqPas encore d'évaluation

- Sec VIII PagesDocument3 pagesSec VIII PagesSiddiqui Abdul KhaliqPas encore d'évaluation

- SAES W 011 Cover PageDocument1 pageSAES W 011 Cover PageSiddiqui Abdul KhaliqPas encore d'évaluation

- Page From B31.3-2012Document1 pagePage From B31.3-2012Siddiqui Abdul KhaliqPas encore d'évaluation

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqPas encore d'évaluation

- DWG - No Revision Status Joint No. Joint Revision PJ Gen Apply Manual Joint Size Welding Type Line No. Line Class Test Package NoDocument3 pagesDWG - No Revision Status Joint No. Joint Revision PJ Gen Apply Manual Joint Size Welding Type Line No. Line Class Test Package NoSiddiqui Abdul KhaliqPas encore d'évaluation

- Transmittal FormatDocument1 pageTransmittal FormatSiddiqui Abdul KhaliqPas encore d'évaluation

- Sec VIII PagesDocument3 pagesSec VIII PagesSiddiqui Abdul KhaliqPas encore d'évaluation

- ASTM Material Comparison TableDocument1 pageASTM Material Comparison Tabledhasdj100% (1)

- ASME SECTION IX INTERPRETATIONSDocument77 pagesASME SECTION IX INTERPRETATIONSहेमंत कुमार मीणाPas encore d'évaluation

- Islamic Calendar 2014 1435Document12 pagesIslamic Calendar 2014 1435Anupama NagrajPas encore d'évaluation

- Caracteristicas Normas ASME B31Document3 pagesCaracteristicas Normas ASME B31darthneoPas encore d'évaluation

- SS Consumable SelectionDocument1 pageSS Consumable SelectionSiddiqui Abdul KhaliqPas encore d'évaluation

- Dms Go BrochureDocument12 pagesDms Go BrochureSiddiqui Abdul KhaliqPas encore d'évaluation

- High-Pressure Dry Abrasive Blasting Operations at Which PressureDocument2 pagesHigh-Pressure Dry Abrasive Blasting Operations at Which PressureSiddiqui Abdul Khaliq100% (1)

- Engineering Procedure: SAEP-20 28 September 2005 Equipment Inspection Schedule Document Responsibility: Inspection DeptDocument25 pagesEngineering Procedure: SAEP-20 28 September 2005 Equipment Inspection Schedule Document Responsibility: Inspection DeptGritz Kay Labucay MarforiPas encore d'évaluation

- Saf Rad PresentationDocument17 pagesSaf Rad PresentationSiddiqui Abdul KhaliqPas encore d'évaluation

- Contact Nmanpower Supply AgenciesDocument3 pagesContact Nmanpower Supply AgenciesSiddiqui Abdul KhaliqPas encore d'évaluation

- Sample ResumeDocument1 pageSample ResumeSiddiqui Abdul KhaliqPas encore d'évaluation

- Daily Welding Checklist (Sample)Document7 pagesDaily Welding Checklist (Sample)Siddiqui Abdul KhaliqPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DT-1. Familiarization With AIML PlatformsDocument25 pagesDT-1. Familiarization With AIML PlatformsNobodyPas encore d'évaluation

- A11yprovider LogDocument260 pagesA11yprovider LogAntonella SalasPas encore d'évaluation

- DBL 5307Document14 pagesDBL 5307Marko SamardžićPas encore d'évaluation

- Alarms and Error Codes 88 SeriesDocument40 pagesAlarms and Error Codes 88 SeriesOzgyur MehmedovPas encore d'évaluation

- PS Series: Robotic Total StationsDocument4 pagesPS Series: Robotic Total StationsAlina Gabriela TodicaPas encore d'évaluation

- Vspace Pro 11 For Windows: (Version 11.1.1)Document20 pagesVspace Pro 11 For Windows: (Version 11.1.1)Bryan LimaPas encore d'évaluation

- Change 19 Key Essays On How Internet Is Changing Our LivesDocument470 pagesChange 19 Key Essays On How Internet Is Changing Our LivesahcaetanoPas encore d'évaluation

- 7.SAP2000 Report With StiffenerDocument36 pages7.SAP2000 Report With StiffenerAlaa Al-habashPas encore d'évaluation

- (!! SPAM) RE - Alphamas Mandiri - Weather Stations QuotationDocument4 pages(!! SPAM) RE - Alphamas Mandiri - Weather Stations QuotationErnest V SPas encore d'évaluation

- Step 4.1 Manage Incoming Data: Resources For Implementing The WWF Project & Programme StandardsDocument9 pagesStep 4.1 Manage Incoming Data: Resources For Implementing The WWF Project & Programme StandardsTran Thi HaiPas encore d'évaluation

- TMEIC Crane Control IndustryDocument32 pagesTMEIC Crane Control IndustryBoy AlfredoPas encore d'évaluation

- Preface 2016 Innovative Bridge Design HandbookDocument2 pagesPreface 2016 Innovative Bridge Design HandbookGroupe MilleniumPas encore d'évaluation

- Digital Physical Design: Hierarchical and Low Power Implementation FlowsDocument37 pagesDigital Physical Design: Hierarchical and Low Power Implementation Flowsprakashthamankar100% (2)

- Nagachethan - Test ManagerDocument1 pageNagachethan - Test ManagerNagachetan SPPas encore d'évaluation

- Control Gear Fluorescent Electronic EB-ECONOMY Electronic Ballasts For TLD LampsDocument6 pagesControl Gear Fluorescent Electronic EB-ECONOMY Electronic Ballasts For TLD LampsGary LauPas encore d'évaluation

- New Office ShredderDocument2 pagesNew Office ShredderR Lilianitha SiboPas encore d'évaluation

- Gda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Document17 pagesGda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Vũ Khánh Trang BùiPas encore d'évaluation

- The Revenue Cycle: Introduction To Accounting Information Systems, 7eDocument47 pagesThe Revenue Cycle: Introduction To Accounting Information Systems, 7eontykerlsPas encore d'évaluation

- AnatomageDocument12 pagesAnatomageapi-446183922Pas encore d'évaluation

- DRF450 Workshop Manual VDRF03 - 02GB PDFDocument128 pagesDRF450 Workshop Manual VDRF03 - 02GB PDFANH LÊ100% (1)

- BGChain WhitepaperDocument31 pagesBGChain WhitepaperJohn DamonPas encore d'évaluation

- CareerPath SupplyChainDocument27 pagesCareerPath SupplyChainShobhit PareekPas encore d'évaluation

- Green IT Project Outline and Practical ApplicationsDocument29 pagesGreen IT Project Outline and Practical ApplicationsRahul Yadav100% (1)

- Cement plant proposalDocument49 pagesCement plant proposalTesfaye Degefa100% (1)

- BWT61 ManualDocument38 pagesBWT61 ManualDMaccPas encore d'évaluation

- G6 Final Transpo-ReportDocument9 pagesG6 Final Transpo-ReportCamille Andrea SequitinPas encore d'évaluation

- The Unified Kill ChainDocument19 pagesThe Unified Kill ChainManuPas encore d'évaluation

- Unit 3 Working With XML Introduction To XMLDocument41 pagesUnit 3 Working With XML Introduction To XMLAishwaryaPas encore d'évaluation

- Curriculum Vitae: Executive Summary & Covering LetterDocument9 pagesCurriculum Vitae: Executive Summary & Covering LetterKhalid MahmoodPas encore d'évaluation

- Bugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateDocument56 pagesBugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateAuttapol TunwilaiPas encore d'évaluation