Académique Documents

Professionnel Documents

Culture Documents

Polycoat Rbe

Transféré par

jovindhaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Polycoat Rbe

Transféré par

jovindhaDroits d'auteur :

Formats disponibles

POLYCOAT RBE

R ubbe ri ze d bi tu me n em ul si o n

CHARACTERISTICS

TDS_Polycoat-RBE_GCC_0910

POLYCOAT RBE is an emulsified rubber modified bitumen coating, which dries to form a tough, seamless, flexible vapor proof protective coating. Cold applied Single component, easy to apply Can be applied on damp substrates Dual advantage of curing as well as protection of concrete Can be applied in closed or confined areas. Water based Good resistance against chloride and sulphate ions Has good adhesion to most building substrates Seamless/joint free Priming It is highly recommended to apply a priming coat prior to the application of the POLYCOAT RBE coating on the substrate. The primer can be prepared in the site by diluting POLYCOAT RBE with 20% water and applying this diluted coat as the primer. For very dry and porous substrates apply two coats of this primer. The primer can be applied to damp or freshly cast concrete surfaces also. However, it should not be applied on waterlogged or flowing water areas. Further coats shall be applied only after the primer coat dries off completely. In case of delay in application of the top coat for more than 24 hours, a fresh coat of primer shall be re-applied.

Can be used for a wide variety of applications, which includes the following: Protective coating on concrete foundations Curing compound on freshly cast concrete structures Dampproof membrane in sandwich constructions Vapor proof barrier coating for interior & exterior floors & walls The application temperature should be between 4C to 45C. Application procedures may vary slightly depending upon site conditions. The general recommended guidelines for the application of the bitumen coating system is as follows:

FIELDS OF APPLICATION

APPLICATION INSTRUCTIONS

Surface preparation The surface shall be cleaned thoroughly of all contaminants like dust, traces of curing compound, oil and grease. Light mechanical grinding/grit blasting/high pressure water jet may be used to clean the surface of all the contaminants depending on the degree of contamination on the surface to be coated. All surface imperfections and protrusions shall be removed and repaired. Structurally unsound and friable concrete must be removed and repaired with a suitable POLYCRETE* concrete repair mortar.

Protection POLYCOAT RBE coating should be protected from getting damaged due to the ongoing site activities and during backfilling. Coating laid on horizontal surfaces can be protected either by a cement sand screed (50mm thick) or by an asphaltic protection

Foundation Dampproofing Stir the contents of the drum thoroughly before application to remove all sediments. Depending on the dry film thickness required, apply the rubberized bitumen coating @14m/lt./coat. On vertical areas, it is recommended to apply the coating in multiple layers in order to avoid sagging of the heavy bodied coating. Subsequent coats shall be applied only after the previous coat dries off completely and shall be applied at right angles to the previous coat. Clean dry sand may be broadcasted onto the wet coating to provide a key for the subsequent coats and achieve a greater dry film thickness. The coating should be applied and finished up to the DPC level. If a plaster or cement render is to be applied on the bitumen coated surface, clean dry sand shall be broadcasted on to the coating whilst it is still wet. Leave the coating for curing for a minimum period of 48 hours before applying any protection board or backfilling. Care shall be taken to ensure that the first coat is not punctured during the application of the second coat. However, if the coating is damaged, the area can be readily over coated provided the surface preparation is done properly.

BITUBOARD)*. On vertical surfaces the memboard (B brane has to be protected with BIT UBOAR D. BITUBOARD can be fixed on the membrane by a douBITUTAPE TS)*. ble sided bitumen adhesive tape (B The coverage varies depending on the type of use: General Use : 4 m2/lt/coat Curing Compound : 5 m2/lt/coat Clean all tools immediately after use with water. Hardened material can be cleaned with a solvent. The drums must be stored in a covered area, away from direct sunlight, UV and other sources of heat. The shelf life of the product is up to 12 months if stored as per the recommendations. Excessive exposure to sunlight and UV will result in the deterioration of the product and reduce its shelf life. As with all bitumen products, caution should always be exercised. Protective clothing such as gloves and goggles should be worn. (See packing for specific instructions). Treat any splashes to the skin or eyes with fresh water immediately. Should any of the products be accidentally swallowed, do not induce vomiting. Call for medical help immediately. Ensure that the container is available for medical attendant to examine any relevant instructions and content details.

PROPERTIES Color Form

TECHNICAL SPECIFICATION

VALUES Dark Brown -

COVERAGE

T E ST STANDARDS

Density, [g/cc]

Thixotrophic Viscous Liquid 605 approx > 30 > 10 1.050.02

ASTM D 2939

CLEANING

Solid Content, [%] Elongation, [%] Flash point

Rubber Content, [%] Adhesion strength, [N/mm2] Drying Time [min] Application temp, [C]

ASTM D 2939 ASTM D 412 BS 1881 -

STORAGE & SHELF LIFE

> 0.75 Non flamabble < 0.50 5 to 45 60

Curing efficiency [kg/m3] (water loss) Service temp, [C]

ASTM C 309

HEALTH & SAFETY

All values given are subject to 5-10% variation

-5 to 75

POLYCOAT RBE BITUBOARD

SUPPLY

3.2 mm

BITUTAPE TS

6.0 mm

2m x 1m,

2m x 0.95m,

20 lt pail & 200 lt drum

*Refer to website for TDS # Approximate weight

10mm x 50mm, wt 0.60 kg#

wt 12.5 kg#

wt 6.65 kg#

Apart from the information given here it is also important to observe the relevant guidelines and regulations of various organisations and trade associations as well as the respective standards. The aforementioned characteristics are based on practical experience and applied testing. Warranted properties and possible uses which go beyond those warranted in this information sheet require our written confirmation. All data given was obtained at an ambient and material temperature of +23C and 50 % relative air humidity unless specified otherwise. Please note that under other climatic conditions hardening can be accelerated or delayed.

The information contained herein, particularly recommendations for the handling and use of our products, is based on our professional experience. As materials and conditions may vary with each intended application, and thus are beyond our sphere of influence, we strongly recommend that in each case sufficient tests are conducted to check the suitability of our products for their intended use. Legal liability cannot be accepted on the basis of the contents of this data sheet or any verbal advice given, unless there is a case of wilful misconduct or gross negligence on our part. This technical data sheet supersedes all previous editions relevant to this product. Manufactured in G.C.C.

P .O. Box 48539, Sharjah, United Arab Emirates Sales Tel:+971 6 572 2282, Fax:+971 6 572 2289 Factory Tel:+971 6 767 0777, Fax:+971 6 767 1669

Henkel Polybit Industries Ltd.

P .O. Box 2230, Al Khobar 31952, K.S.A Tel:+9663 8894110, Fax:+9663 8995313

Henkel Polybit Industries Ltd.(Branch)

Internet: www.henkelpolybit.com E-mail: polybit@henkelpolybit.com

Quality for Professionals

Vous aimerez peut-être aussi

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- Salesforce Platform Developer 1Document15 pagesSalesforce Platform Developer 1Kosmic PowerPas encore d'évaluation

- Detailers Dictionary Volume 2: The Industry StandardD'EverandDetailers Dictionary Volume 2: The Industry StandardPas encore d'évaluation

- TT S 00227eDocument25 pagesTT S 00227eJesse JamesPas encore d'évaluation

- PSISA Free Practice Exams TestsDocument2 pagesPSISA Free Practice Exams TestsGoodmanBeguel50% (2)

- Motion For Bill of ParticularsDocument3 pagesMotion For Bill of ParticularsPaulo Villarin67% (3)

- 91 SOC Interview Question BankDocument3 pages91 SOC Interview Question Bankeswar kumarPas encore d'évaluation

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyePas encore d'évaluation

- Business Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaDocument49 pagesBusiness Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaInfiniteKnowledge100% (9)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- POLYCOATDocument2 pagesPOLYCOATGeorge TsiamtsourisPas encore d'évaluation

- Polypoxy FC(S)Document2 pagesPolypoxy FC(S)Sam AhmedPas encore d'évaluation

- BITUSTICK - XL-Tecnical Data SheetDocument2 pagesBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- Polyguard PEDocument2 pagesPolyguard PEabcd1860100% (1)

- Highly Chemical Resistant Epoxy CoatingDocument2 pagesHighly Chemical Resistant Epoxy Coatingsudhialakkal0% (1)

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aPas encore d'évaluation

- Dimetcote 9 PDS AIDocument3 pagesDimetcote 9 PDS AIAmer Y KPas encore d'évaluation

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocument7 pagesPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDPas encore d'évaluation

- BITUBOARDDocument2 pagesBITUBOARDjovindhaPas encore d'évaluation

- Bitustick XLS HynkleDocument2 pagesBitustick XLS HynkleMohamed ShehataPas encore d'évaluation

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Cold Applied Waterproofing MembraneDocument2 pagesCold Applied Waterproofing MembraneSyed ShahbazPas encore d'évaluation

- Don't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiDocument2 pagesDon't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiLion YangPas encore d'évaluation

- POLYTEXDocument2 pagesPOLYTEXDon AlexPas encore d'évaluation

- Proofex GPXDocument2 pagesProofex GPXVenkata RaoPas encore d'évaluation

- Epoxy Resin Mortar for Concrete ProtectionDocument2 pagesEpoxy Resin Mortar for Concrete ProtectionsudhialakkalPas encore d'évaluation

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidPas encore d'évaluation

- GCPAT Bituthene 3000 and Bituthene Low Temperature Membranes Us 65576Document7 pagesGCPAT Bituthene 3000 and Bituthene Low Temperature Membranes Us 65576sameerace.kolonPas encore d'évaluation

- Brush BondDocument4 pagesBrush BondVenkata RaoPas encore d'évaluation

- Crack Bridging Elastomeric PaintDocument3 pagesCrack Bridging Elastomeric PaintMearg NgussePas encore d'évaluation

- Epoxy Floor Coating Technical Data SheetDocument4 pagesEpoxy Floor Coating Technical Data SheetMohamed FaragPas encore d'évaluation

- Jotaguard 630Document4 pagesJotaguard 630Christine HermawanPas encore d'évaluation

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- TDS 0004 FlexoPrime 202003Document3 pagesTDS 0004 FlexoPrime 202003Mearg NgussePas encore d'évaluation

- RBE Coating Application GuideDocument1 pageRBE Coating Application GuideMang JosePas encore d'évaluation

- Coal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Document3 pagesCoal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- PdsDocument3 pagesPdsEnrico SaviraPas encore d'évaluation

- Jet Mastic 800Document3 pagesJet Mastic 800jopersa9Pas encore d'évaluation

- Bitustick XLSDocument2 pagesBitustick XLSAbed DaherPas encore d'évaluation

- SikaTop Seal 107 PDS (CE) PDFDocument4 pagesSikaTop Seal 107 PDS (CE) PDFSed BeelzePas encore d'évaluation

- TDS Levelling - PlasterDocument3 pagesTDS Levelling - PlasterNandhagopal DhandapaniPas encore d'évaluation

- Jotun Epoxy Filler: Technical Data Sheet Application GuideDocument5 pagesJotun Epoxy Filler: Technical Data Sheet Application GuidekajaqcPas encore d'évaluation

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekPas encore d'évaluation

- Jotafloor TopcoatDocument4 pagesJotafloor TopcoatrogandatambunanPas encore d'évaluation

- Nitocote cm210Document4 pagesNitocote cm210Venkata RaoPas encore d'évaluation

- TDS - 0063 CapaFilex - 202003Document3 pagesTDS - 0063 CapaFilex - 202003Mearg NgussePas encore d'évaluation

- Naviguard ME - English (Uk) - Issued.06.12.2007Document3 pagesNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Renderoc Plug: Uses SpecificationDocument2 pagesRenderoc Plug: Uses SpecificationVenkata RaoPas encore d'évaluation

- Fosroc Renderoc CS PuneDocument2 pagesFosroc Renderoc CS Punealdred_chezkaPas encore d'évaluation

- CapaStucco Interior Filler Technical Data SheetDocument3 pagesCapaStucco Interior Filler Technical Data SheetMearg NgussePas encore d'évaluation

- Proofex 12Document2 pagesProofex 12kalidindivenkatarajuPas encore d'évaluation

- Pilot II: Technical Data Sheet Application GuideDocument6 pagesPilot II: Technical Data Sheet Application Guidendt stanleyPas encore d'évaluation

- Nitomortar TC2000Document3 pagesNitomortar TC2000MuhammedHafis100% (1)

- Florgard EsdDocument3 pagesFlorgard Esddox4printPas encore d'évaluation

- Durathane TdsDocument3 pagesDurathane TdsSyawaluddin Fitri AwangPas encore d'évaluation

- Penguard HB 2005 PDFDocument4 pagesPenguard HB 2005 PDFMuthuKumarPas encore d'évaluation

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Document3 pagesChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Uzin KE 603Document2 pagesUzin KE 603FloorkitPas encore d'évaluation

- Eco-friendly protective coatingDocument2 pagesEco-friendly protective coatingRaed Naim KhammashPas encore d'évaluation

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 pagesPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- 629 PDFDocument2 pages629 PDFMikePas encore d'évaluation

- Penguard HBDocument4 pagesPenguard HBhedisanjayaPas encore d'évaluation

- Sikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsDocument4 pagesSikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsSholikhinIbnuRamadhanPas encore d'évaluation

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionD'EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionPas encore d'évaluation

- EIS Meadows Fee Policy For The Year 2021 2022Document2 pagesEIS Meadows Fee Policy For The Year 2021 2022jovindhaPas encore d'évaluation

- Project: Subject: Reply Date: Product ADM COMMENTS (Application No: 202200286578)Document6 pagesProject: Subject: Reply Date: Product ADM COMMENTS (Application No: 202200286578)jovindhaPas encore d'évaluation

- 07 31.10.2022 - October 2022 Commission Monthly Progress Report (63) UpdatedDocument2 pages07 31.10.2022 - October 2022 Commission Monthly Progress Report (63) UpdatedjovindhaPas encore d'évaluation

- Vehicle License DetailsDocument1 pageVehicle License DetailsjovindhaPas encore d'évaluation

- Sandeep Singh: Contact No.: +971-508637292/ +91-9417177292Document2 pagesSandeep Singh: Contact No.: +971-508637292/ +91-9417177292jovindhaPas encore d'évaluation

- Asphalt Mix Design Submittal: Project DescriptionDocument11 pagesAsphalt Mix Design Submittal: Project DescriptionjovindhaPas encore d'évaluation

- Health CertificateDocument1 pageHealth CertificatejovindhaPas encore d'évaluation

- Inspection-Certificate 2Document1 pageInspection-Certificate 2jovindhaPas encore d'évaluation

- Flexible Sheets For Waterproofing Ð Determination of Resistance To Tearing (Nail Shank) ÐDocument10 pagesFlexible Sheets For Waterproofing Ð Determination of Resistance To Tearing (Nail Shank) ÐjovindhaPas encore d'évaluation

- DSF-CRS-0952-02 Technical Submittal For Cement Lining of CS Pipes FittingsDocument3 pagesDSF-CRS-0952-02 Technical Submittal For Cement Lining of CS Pipes FittingsjovindhaPas encore d'évaluation

- Bicycle Track Coating SystemDocument3 pagesBicycle Track Coating SystemjovindhaPas encore d'évaluation

- LHC Congress 2003 FinalDocument13 pagesLHC Congress 2003 FinaljovindhaPas encore d'évaluation

- Asjad CVDocument2 pagesAsjad CVjovindhaPas encore d'évaluation

- Page 5 From BS EN 1344Document1 pagePage 5 From BS EN 1344jovindhaPas encore d'évaluation

- Failures in Wearing Course For The Cycle TrackDocument4 pagesFailures in Wearing Course For The Cycle TrackjovindhaPas encore d'évaluation

- MAT-MEP-0827 FIRE WATER TANK - ADM Comments - Returned For ModificationDocument1 pageMAT-MEP-0827 FIRE WATER TANK - ADM Comments - Returned For ModificationjovindhaPas encore d'évaluation

- Failures in Wearing Course For The Cycle Track1Document1 pageFailures in Wearing Course For The Cycle Track1jovindhaPas encore d'évaluation

- CICONDocument1 pageCICONjovindhaPas encore d'évaluation

- Development of Roads Network at Mina Zayed Phase 1 Main TunnelDocument3 pagesDevelopment of Roads Network at Mina Zayed Phase 1 Main TunneljovindhaPas encore d'évaluation

- 16.consultant Technical Evalution ReportsDocument1 page16.consultant Technical Evalution ReportsjovindhaPas encore d'évaluation

- MAT-0010-Precast Concrete Kerbs - ADM Comments - RejectedDocument1 pageMAT-0010-Precast Concrete Kerbs - ADM Comments - RejectedjovindhaPas encore d'évaluation

- Text For UplodingDocument1 pageText For UplodingjovindhaPas encore d'évaluation

- Rev. 00Document1 pageRev. 00jovindhaPas encore d'évaluation

- IRI CommentsDocument1 pageIRI CommentsjovindhaPas encore d'évaluation

- Pitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemDocument9 pagesPitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemjovindhaPas encore d'évaluation

- Soil Analysis Services: World Class Geotechnical TestingDocument10 pagesSoil Analysis Services: World Class Geotechnical TestingjovindhaPas encore d'évaluation

- ASTM PageDocument1 pageASTM PagejovindhaPas encore d'évaluation

- Action Plan For Close Out - 19122020Document5 pagesAction Plan For Close Out - 19122020jovindhaPas encore d'évaluation

- CICON - AUH Commercial License 2015Document1 pageCICON - AUH Commercial License 2015jovindhaPas encore d'évaluation

- Superelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDocument7 pagesSuperelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDavid C HouserPas encore d'évaluation

- Grid Xtreme VR Data Sheet enDocument3 pagesGrid Xtreme VR Data Sheet enlong bạchPas encore d'évaluation

- Daftar Pustaka Marketing ResearchDocument2 pagesDaftar Pustaka Marketing ResearchRiyan SaputraPas encore d'évaluation

- How To Generate Your First 20,000 Followers On InstagramDocument44 pagesHow To Generate Your First 20,000 Followers On InstagramAdrian Pratama100% (1)

- AX CLI Ref v2 4 3-20100621Document718 pagesAX CLI Ref v2 4 3-20100621VisiGodPas encore d'évaluation

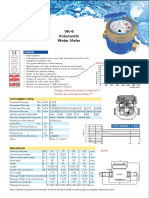

- Baylan: VK-6 Volumetric Water MeterDocument1 pageBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaPas encore d'évaluation

- Chrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDocument4 pagesChrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDalton WisePas encore d'évaluation

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pages(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetPas encore d'évaluation

- Basic Concept of EntrepreneurshipDocument12 pagesBasic Concept of EntrepreneurshipMaria January B. FedericoPas encore d'évaluation

- TV/VCR Tuner Ic With DC/DC Converter: FeaturesDocument21 pagesTV/VCR Tuner Ic With DC/DC Converter: FeaturesEdsel SilvaPas encore d'évaluation

- Chilled Beam SystemsDocument3 pagesChilled Beam SystemsIppiPas encore d'évaluation

- MACROECONOMICSDocument95 pagesMACROECONOMICSClaudine Jeanne NillamaPas encore d'évaluation

- Matching a Vendor's HRSG in THERMOFLEXDocument30 pagesMatching a Vendor's HRSG in THERMOFLEXRafraf EzdinePas encore d'évaluation

- BR18 Mechanical Engineering Robotics Semester VIDocument2 pagesBR18 Mechanical Engineering Robotics Semester VIPRAVEePas encore d'évaluation

- Flex VPNDocument3 pagesFlex VPNAnonymous nFOywQZPas encore d'évaluation

- Carbon Trust Certification OverviewDocument2 pagesCarbon Trust Certification OverviewMatt MacePas encore d'évaluation

- Ganbare Douki Chan MALDocument5 pagesGanbare Douki Chan MALShivam AgnihotriPas encore d'évaluation

- Assignment # 4 26 CH 22Document6 pagesAssignment # 4 26 CH 22Ibrahim AbdallahPas encore d'évaluation

- BS 00011-2015Document24 pagesBS 00011-2015fazyroshan100% (1)

- Private Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleDocument3 pagesPrivate Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleijustyadavPas encore d'évaluation

- ID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFDocument11 pagesID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFAmelia AmelPas encore d'évaluation

- Distribution Requirements PlanningDocument8 pagesDistribution Requirements PlanningnishantchopraPas encore d'évaluation

- ITC Report and Accounts 2016Document276 pagesITC Report and Accounts 2016Rohan SatijaPas encore d'évaluation

- Timesheet 2021Document1 pageTimesheet 20212ys2njx57vPas encore d'évaluation

- Sahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Document1 pageSahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Rohit raagPas encore d'évaluation