Académique Documents

Professionnel Documents

Culture Documents

How To Troubleshoot Ecu Controlled Systems: Repair Manual System

Transféré par

Oscar AcevedoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

How To Troubleshoot Ecu Controlled Systems: Repair Manual System

Transféré par

Oscar AcevedoDroits d'auteur :

Formats disponibles

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN13

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

A large number of ECU controlled systems are used in the TACOMA. In general, the ECU controlled system is considered to be a very intricate system requiring a high level of technical knowledge and expert skill to troubleshoot. However, the fact is that if you proceed to inspect the circuits one by one, troubleshooting of these systems is not complex. If you have adequate understanding of the system and a basic knowledge of electricity, accurate diagnosis and necessary repair can be performed to locate and fix the problem. This manual is designed through emphasis of the above standpoint to help service technicians perform accurate and effective troubleshooting, and is compiled for the following major ECU controlled systems:

Repair Manual Vol. 1 System 2RZFE, 3RZFE Engine 5VZFE Engine 2. A340E, A340F Automatic Transmission Vol. 2 3. AntiLock Brake 4. Supplemental Restraint System 5. Cruise Control Page EG1188 EG2216 AT242 BR51 RS25 BE96

The troubleshooting procedure and how to make use of it are described on the following pages.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN14

HOW TO PROCEED WITH TROUBLESHOOTING

Carry out troubleshooting in accordance with the procedure on the following page. Here, only the basic proce dure is shown. Details are provided in each section, showing the most effective methods for each circuit. Confirm the troubleshooting procedures first for the relevant circuit before beginning troubleshooting of that circuit.

Vehicle Brought to Workshop

Customer Problem Analysis

1 Ask the customer about the conditions and the environment when the problem occurred.

Symptom Confirmation and Diagnostic Trouble Code Check

Symptom Simulation

Confirm the symptoms and the problem condi tions, and check the diagnostic trouble codes. (When the problem symptoms do not appear dur ing confirmation, use the symptom simulation method described later on.)

Diagnostic Trouble Code Chart

Matrix Chart of Problem Symptoms

Check the results obtained in Step 2 , then con firm the inspection procedure for the system or the part which should be checked using the diagnostic trouble code chart or the matrix chart of problem symptoms.

Circuit Inspection or Parts Inspection

Check and repair the affected system or part in accordance with the instructions in Step 6 .

Repair

Confirmation Test

End

After completing repairs, confirm that the problem has been eliminated. (If the problem is not reproduced, perform the con firmation test under the same conditions and in the same environment as when it occurred for the first time.)

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN15

1 CUSTOMER PROBLEM ANALYSIS In troubleshooting, the problem symptoms must be confirmed accurately and all preconceptions must be cleared away in order to give an accurate judgement. To ascertain just what the problem symptoms are, it is extremely important to ask the customer about the problem and the conditions at the time it occurred. Important Points in the Problem Analysis The following 5 items are important points in the problem analysis. Past problems which are thought to be unrelated and the repair history, etc. may also help in some cases, so as much information as possible should be gathered and its relationship with the problem symptoms should be correctly ascertained for reference in troubleshooting. A customer problem analysis table is provided in the troubleshooting section for each system for your use. Important Points in the Customer Problem Analysis What Vehicle model, system name When Date, time, occurrence frequency Where Road conditions Under what conditions? Running conditions, driving conditions, weather conditions How did it happen? Problem symptoms (Sample) Engine control system check sheet.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN16

Code Check in which a malfunction in the signal circuits to the ECU is stored in code in the ECU memory at the time of occurrence, to be output by the technician during troubleshooting. Another function is the Input Signal Check which checks if the signals from various switches are sent to the ECU correctly. The air condi tioner system has an Actuator Check function whereby the ECU automatically operates the actuators of the damper and blowermotor, etc. to check the operation. By using these check functions, the problem areas can be narrowed down quickly and troubleshooting can be performed effectively. Diagnostic functions are incorporated in the following systems in the TACOMA.

System 2RZFE, 3RZFE Engine 5VZFE Automatic Transmission Supplemental Restraint System Diagnostic Trouble Code Check Input Signal Check (Sensor Check)

2 SYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE CHECK The diagnostic system in the TACOMA fulfills various functions. The first function is the Diagnostic Trouble

Other Diagnosis Function Diagnostic Test Mode Diagnostic Test Mode Diagnostic Test Mode

O (with Check Mode) O (with Check Mode) O (with Check Mode)

In diagnostic trouble code check, it is very important to determine whether the problem indicated by the diagnostic trouble code is still occurring or occurred in the past but returned to normal at present. In addi tion, it must be checked in the problem symptom check whether the malfunction indicated by the diagnostic trouble code is directly related to the problem symptom or not. For this reason, the diagnostic trouble codes should be checked before and after the symptom confirmation to determine the current condi tions, as shown in the table below. If this is not done, it may depending on the case, result in unnecessary troubleshooting for normally operating systems, thus making it more difficult to locate the problem, or in repairs not pertinent to the problem. Therefore, always follow the procedure in correct order and perform the diagnostic trouble code check. DIAGNOSTIC TROUBLE CODE CHECK PROCEDURE

Diagnostic Trouble Code Check (Make a note of and then clear) Diagnostic Trouble Code Display Confirmation of Symptoms Problem symptoms exist Diagnostic Trouble Code Check Same diagnostic trouble code is displayed Normal code is displayed Problem Condition

Problem is still occurring in the diagnostic circuit. The problem is still occurring in a place other than in the diagnostic circuit. (The diagnostic trouble code displayed first is either for a past problem or it is a secondary problem.) The problem occurred in the diagnostic circuit in the past.

No problem symptoms exist Normal Code Display Problem symptoms exist No problem symptoms exist Normal code is displayed Normal code is displayed

The problem is still occurring in a place other than in the diagnostic circuit. The problem occurred in a place other than in the diagnostic circuit in the past.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN17

Taking into account the above points, a flow chart showing how to proceed with troubleshooting using the diagnostic trouble code check is shown below. This flow chart shows how to utilize the diagnostic trouble code check effectively, then by carefully checking the results, indicates how to proceed either to diagnostic trouble code troubleshooting or to troubleshooting of problem s^mptoms.

Diagnostic trouble code check

Making a note of and clearing of the diagnostic trouble codes displayed

Symptom confirmation Problem symptoms exist No problem symptoms exist

Simulation test using the symptom simulation methods

Diagnostic trouble code check

Diagnostic trouble code displayed Problem symptoms exist

Normal code displayed Problem symptoms exist

Normal code displayed No problem symptoms exist

System Normal Troubleshooting of problem indicated by diagnostic trou ble code Troubleshooting of each problem symptom If a diagnostic trouble code was dis played in the initial diagnostic trouble code check, it indicates that the trouble may have occurred in a wire harness or connector in that circuit in the past. Therefore, check the wire harness and connectors (see page IN24).

IN18

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

3 SYMPTOM SIMULATION The most difficult case in troubleshooting is when there are no problem symptoms occurring. In such cases, a thorough customer problem analysis must be carried out, then simulate the same or similar conditions and environment in which the problem occurred in the customers vehicle. No matter how much experience a technician has, or how skilled he may be, if he proceeds to troubleshoot without confirming the problem symptoms he will tend to overlook something important in the repair operation and make a wrong guess somewhere, which will only lead to a standstill. For example, for a problem which only occurs when the engine is cold, or for a problem which occurs due to vibration caused by the road during driving, etc., the problem can never be determined so long as the symptoms are confirmed with the engine hot condition or the vehicle at a standstill. Since vibration, heat or water penetration (moisture) are likely causes for problems which are difficult to reproduce, the symptom simulation tests introduced here are effective measures in that the external causes are applied to the vehicle in a stopped condition. Important Points in the Symptom Simulation Test In the symptom simulation test, the problem symptoms should of course be confirmed, but the problem area or parts must also be found out. To do this, narrow down the possible problem circuits according to the symptoms before starting this test and connect a tester beforehand. After that, carry out the symptom sim ulation test, judging whether the circuit being tested is defective or normal and also confirming the problem symptoms at the same time. Refer to the matrix chart of problem symptoms for each system to narrow down the possible causes of the symptom. VIBRATION METHOD: When vibration seems to be the major cause. CONNECTORS Slightly shake the connector vertically and horizontally.

WIRE HARNESS Slightly shake the wire harness vertically and horizon tally. The connector joint, fulcrum of the vibration, and body through portion are the major areas to be checked thoroughly.

PARTS AND SENSORS Apply slight vibration with a finger to the part of the sen

sor considered to be the problem cause and check if the malfunction occurs. HINT: Applying strong vibration to relays may result in open relays.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN19

HEAT METHOD: When the problem seems to occur when the suspect area is heated. Heat the component that is the likely cause of the malfunc tion with a hair dryer or similar object. Check to see if the malfunction occurs. NOTICE: (1) Do not heat to more than 60C (140F). (Tempera ture limit that no damage is done to the component). (2) Do not apply heat directly to parts in the ECU.

WATER SPRINKLING METHOD: or in a highhumidity condition. Sprinkle water onto the vehicle and check to see if the malfunction occurs. NOTICE: (1) Never sprinkle water directly into the engine compart

ment, but indirectly change the temperature and hu midity by applying water spray onto the radiator front surface. (2) Never apply water directly onto the electronic com ponents.

When the malfunction seems to occur on a rainy day

(Service hint) If a vehicle is subject to water leakage, the leaked water may contaminate the ECU. When testing a vehicle with a water leakage problem, special caution must be used. OTHER: When a malfunction seems to occur when electrical load is excessive.

Turn on all electrical loads including the heater blower, head lights, rear window defogger, etc. and check to see if the malfunction occurs.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN20

4 DIAGNOSTIC TROUBLE CODE CHART The inspection procedure is shown in the table below. This table permits efficient and accurate troubleshooting using the diagnostic trouble codes displayed in the diagnostic trouble code check. Proceed with troubleshooting in accordance with the inspection procedure given in the diagnostic chart correspon ding to the diagnostic trouble codes displayed. The engine diagnostic trouble code chart is shown below as an example.

DTC No. Indicates the diagnostic trouble code. Detection Item Indicates the system of the pro blem or contents of the problem.

Diagnostic Trouble Code Detecting Condition Indicates the diagnostic trouble code set parameter.

Trouble Area Indicates the suspect area of the pro blem.

Page or Instructions Indicates the page where the inspection pro cedure for each circuit is to be found, or gives in structions for checking and repairs.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN21

5 MATRIX CHART OF PROBLEM SYMPTOMS The suspect circuits or parts for each problem symptom are shown in the table below. Use this table to troubleshoot the problem when a Normal code is displayed in the diagnostic trouble code check but the problem is still occurring. Numbers in the table indicate the inspection order in which the circuits or parts should be checked. HINT: when the problem is not detected by the diagnostic system even though the problem symptom is

present, it is considered that the problem is occurring outside the detection range of the diagnostic system, or that the problem is occurring in a system other than the diagnostic system. Page Indicates the page where the flow chart for each circuit is located. Circuit or Part Name Indicates the circuit or part which needs to be checked.

Problem Symptom

Circuit Inspection, Inspection Order Indicates the circuit which needs to be checked for each problem symptom. Check in the order in dicated by the numbers.

IN22

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

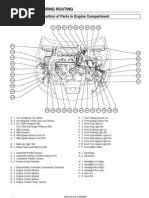

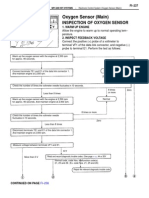

[6] CIRCUIT INSPECTION How to read and use each page is shown below.

Diagnostic Trouble Code No. and Detection Item

Circuit Description The major role and operation, etc. of the cir cuit and its component parts are explained.

Indicates the diagnostic trouble code, diagnostic trouble code set parameter and suspect area of the problem.

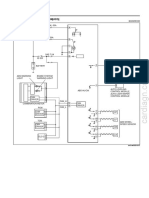

WIRING DIAGRAM

Wiring Diagram This shows a wiring diagram of the circuit. Use this diagram together with ELECTRICAL WIRING DIAGRAM to thoroughly understand the circuit.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN23

Indicates the position of the ignition switch during the check. Ignition Switch LOCK (OFF) Ignition Switch ON Ignition Switch START

Ignition Switch ACC

Inspection Procedure

Use the inspection pro cedure to determine if the circuit is normal or abnor mal, and, if it is abnormal, use it to determine whether the problem is located in the sensors, actuators, wire harness or ECU.

Preparation Check

Indicates the place to check the voltage or resistance. Indicates the connector position to be checked, from the front or back side.

Check from the connector back side. (with harness)

Check from the connector front side (without harness) In this case, care must be taken not to bend the ter minals.

Indicates the condition of the connector of ECU during the ckeck.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN24

HOW TO USE THE DIAGNOSTIC CHART AND INSPECTION PROCEDURE

1. For troubleshooting, diagnostic trouble code charts or problem symptom charts are provided for each circuit with detailed inspection procedures on the following pages. 2. When all the component parts, wire harnesses and connectors of each circuit except the ECU are found to be normal in troubleshooting, then it is determined that the problem is in the ECU. Accordingly, if diagnosis is performed without the problem symptoms occurring, the instruction will be to check and replace the ECU, even if the problem is not in the ECU. So, always confirm that the pro blem symptoms are occurring, or proceed with inspection while using the symptom simulation method. 3. The instructions Check wire harness and connector and Check and replace ECU which appear in the inspection procedure, are common and applicable to all diagnostic trouble codes. Follow the pro cedure outlined below whenever these instructions appear.

Check Wire Harness and Connector

The problem in the wire harness or connector is an open circuit or a short circuit.

OPEN CIRCUIT:

This could be due to a disconnected wire harness, faulty contact in the connector, a connector terminal pull ed out, etc.

HINT: 1. It is rarely the case that a wire is broken in the middle of it. Most cases occur at the connector. In par ticular, carefully check the connectors of sensors and actuators. 2. Faulty contact could be due to rusting of the connector terminals, to foreign materials entering ter minals or a drop in the contact pressure between the male and female terminals of the connector. Simp ly disconnecting and reconnecting the connectors once changes the condition of the connection anc may result in a return to normal operation. Therefore, in troubleshooting, if no abnormality is found in the wire harness and connector check, but the problem disappears after the check, then the cause is considered to be in the wire harness or con. nectors.

SHORT CIRCUIT:

This could be due to a short circuit between the wire harness and the body ground or to a short inside the switch, etc. HINT: When there is a short between the wire harness and body ground, check thoroughly whether the wire

harness is caught in the body or is clamped properly.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN25

1. CONTINUITY CHECK (OPEN CIRCUIT CHECK) (1) Disconnect the connectors at both ECU and sensor

sides. (2) Measure the resistance between the applicable ter minals of the connectors. Resistance: 1W or less HINT: Measure the resistance while lightly shaking the wire harness vertically and horizontally. When tester probes are inserted into a connector, insert the probes from the back. For waterproof connectors in which the probes cannot be inserted from the back, be careful not to bend the termianls when inserting the tester probes.

2. RESISTANCE CHECK (SHORT CIRCUIT CHECK) (1) Disconnect the connectors at both ends.

12y Measure the resistance between the applicable ter minals of the connectors and body ground. Be sure to carry out this check on the connectors on both ends. Resistance: 1 MW or higher HINT: Measure the resistance while lightly shaking the wire harness vertically and horizontally.

3. VISUAL CHECK AND CONTACT PRESSURE CHECK (1) Disconnect the connectors at both ends.

(2) Check for rust or foreign material, etc. on the termi nals of the connectors. (3) Check crimped portions for looseness or damage and check if the terminals are secured in the lock position. HINT: The terminals should not come out when pulled lightly.

(4) Prepare a test male terminal and insert it in the female terminal, then pull it out. HINT: When the test terminal is pulled out more easily than others, there may be poor contact in that section.

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN26

Actual examples of the inspection method for open circuit and short circuit are explained below. 1. OPEN CIRCUIT CHECK

For the open circuit in the wire harness in Fig. 1, perform (a) Continuity Check or (b) Voltage Check to locate the section.

(a) Continuity Check

(1) Disconnect connectors (A) and (C) and measure the resistance between them. In the case of Fig. 2, Between terminal 1 of connector (A) and terminal 1 of connector (C) No continuity (open) Between terminal 2 of connector (A) and terminal 2 of connector (C) Continuity Therefore, it is found out that there is an open circuit between terminal 1 of connector (A) and terminal 1 of connector (C) .

(2) Disconnect connector B and measure the resistance between connectors (A) and (B), (B) and (C). In the case of Fig. 3, Between terminal 1 of connector (A) and terminal 1 of connector (B) Continuity Between terminal 1 of connector (B) and terminal 1 of connector (C) No continuity (open) Therefore, it is found out that there is an open circuit between terminal 1 of connector S and terminal 1 of connector (C).

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN27

(b) Voltage Check

In a circuit in which voltage is applied (to the ECU connector terminal), an open circuit can be checked for by conducting a voltage check. (1) As shown in Fig. 4, with each connector still connected, measure the voltage between body ground and terminal 1 of connector (A) at the ECU 5 V output terminal, terminal 1 of connector (B), and terminal 1 of connector (C), in that order. If the results are: 5 V: Between Terminal 1 of connector (A) and Body Ground 5 V: Between Terminal 1 of connector (B) and Body Ground 0 V: Between Terminal 1 of connector (C) and Body Ground then it is found out that there is an open circuit in the wire harness between terminal 1 of (B) and terminal 1 of (C).

2. SHORT CIRCUIT CHECK

If the wire harness is ground shorted as in Fig. 5, locate the section by conducting a continuity check with ground.

IN28

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

(a) Continuity Check with Ground (1) Disconnect connectors (A) and (C) and measure the resistance between terminals 1 and 2 of connec tor (A) and body ground. In the case of Fig. 6, Between terminal 1 of connector (A) and body ground Continuity Between terminal 2 of connector (A) and body ground No continuity (open) Therefore, it is found out that there is a short circuit between terminal 1 of connector (A) and terminal 1 of connector (C).

(2) Disconnect connector (B) and measure the resistance between terminal 1 of connector (A) and body ground, and terminal 1 of connector (B) and body ground. Between terminal 1 of connector (A) body ground No continuity (open)

Between terminal 1 of connector (B) and body ground Continuity Therefore, it is found out that there is a short circuit between terminal 1 of connector (B) and terminal 1 of connector (C).

INTRODUCTION

HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN29

Check and Replace ECU First check the ECU ground circuit. If it is faulty, repair it. If it is normal, the ECU could be faulty, so replace the ECU with a known good one and check if the symptoms appear.

(1) Measure the resistance between the ECU ground ter minal and the body ground.

Resistance: 1W or less

(2) Disconnect the ECU connector, check the ground ter minals on the ECU side and the wire harness side for bend and check the contact pressure.

Vous aimerez peut-être aussi

- Ecu Support ListDocument15 pagesEcu Support Listrozy100% (1)

- Toyota - Diagnostic Trouble CodesDocument5 pagesToyota - Diagnostic Trouble Codesfostech91% (22)

- Vehicle Sensors WiringDocument8 pagesVehicle Sensors WiringAudrick RussellPas encore d'évaluation

- Engine Control UnitDocument0 pageEngine Control UnitDixit UdayakumarPas encore d'évaluation

- Manual Pajero 4x4 GeneralDocument30 pagesManual Pajero 4x4 GeneralGIAN CARLO MAMANI GILES.Pas encore d'évaluation

- Techstream Ecu Flash Reprogramming Procedure Ts-ss002-07Document23 pagesTechstream Ecu Flash Reprogramming Procedure Ts-ss002-07pepeladazo100% (1)

- EcuFlash TutorialDocument11 pagesEcuFlash Tutorialfrancisca19100% (1)

- Atc NissanDocument150 pagesAtc NissanAldo Llerena100% (1)

- EI - Engine Immobiliser PDFDocument100 pagesEI - Engine Immobiliser PDFMugiraneza100% (1)

- PE3 Series ManualDocument149 pagesPE3 Series Manualdebendra128nitrPas encore d'évaluation

- DTC Check ClearDocument2 pagesDTC Check ClearDaniel Mamani ParedezPas encore d'évaluation

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualD'EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualPas encore d'évaluation

- Camshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementDocument17 pagesCamshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementMusat Catalin-Marian100% (5)

- Body + ElectricalDocument259 pagesBody + Electricalnels26Pas encore d'évaluation

- Engine D-4S. LexusDocument59 pagesEngine D-4S. LexusThanh DanhPas encore d'évaluation

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezPas encore d'évaluation

- X431 Diagnostic Coverage DetailsDocument64 pagesX431 Diagnostic Coverage Detailsengineer_mohamed_wahieb100% (1)

- Ecu TestDocument1 pageEcu TestMirancea VioPas encore d'évaluation

- Ems-Pro Tuning GuideDocument52 pagesEms-Pro Tuning GuideHenry CastellanosPas encore d'évaluation

- Toyota Yaris Ecu ImmoDocument2 pagesToyota Yaris Ecu Immogryzzly50% (2)

- EPS ReportDocument58 pagesEPS ReportAyush GhoshPas encore d'évaluation

- A32 at PDFDocument293 pagesA32 at PDFOmar RodriguezPas encore d'évaluation

- 2JZ-GTE VVti Aristo ECU PINOUTDocument11 pages2JZ-GTE VVti Aristo ECU PINOUTDoichin Mitov100% (1)

- Guidebook Efiscan 1.5 eDocument47 pagesGuidebook Efiscan 1.5 equangvunvcPas encore d'évaluation

- Pages From Toyota Hilux Wiring Diagrams-EngineDocument10 pagesPages From Toyota Hilux Wiring Diagrams-EnginePoon Electronic Training CentrePas encore d'évaluation

- Alarm System AlphardDocument10 pagesAlarm System AlphardAiman HafidzPas encore d'évaluation

- Introduction To Engine Control System Processes and Diagnostic ToolsDocument27 pagesIntroduction To Engine Control System Processes and Diagnostic Toolssungjoo75Pas encore d'évaluation

- Immobilizer ReprogramDocument3 pagesImmobilizer ReprogramKhairul Izwan Che Soh100% (1)

- Ground-Mounted Verticals: Dispelling Radial Misconceptions and Looking at The New 43ft Multiband VerticalsDocument38 pagesGround-Mounted Verticals: Dispelling Radial Misconceptions and Looking at The New 43ft Multiband VerticalsCKJJ55@hotmail.cmPas encore d'évaluation

- 2008 Mazda MPV - Brake - Symptom Troubleshooting (ABS)Document15 pages2008 Mazda MPV - Brake - Symptom Troubleshooting (ABS)lo mio es mioPas encore d'évaluation

- 2007 Honda Civic Hybrid - Engine CoolingDocument19 pages2007 Honda Civic Hybrid - Engine Coolingangelvalladares100% (1)

- Ecu Manual PDFDocument23 pagesEcu Manual PDFFERNANDO ANDRIOTTI VICENTIN0% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusD'EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusPas encore d'évaluation

- Key Maker For EWS (ENG)Document16 pagesKey Maker For EWS (ENG)BOBMALIK100% (1)

- Celica ECM PinoutDocument9 pagesCelica ECM PinoutYen N Chia100% (2)

- Genius ListDocument8 pagesGenius ListBruno MarianoPas encore d'évaluation

- Yaris 1nz-Fe (Engine)Document12 pagesYaris 1nz-Fe (Engine)esquisofPas encore d'évaluation

- Barbarians of The AftermathDocument178 pagesBarbarians of The AftermathTorito Xerezano100% (5)

- 10-6620 For EMS - 30-6620Document14 pages10-6620 For EMS - 30-6620Michael AliPas encore d'évaluation

- VNX - Su Avensis Supplement Chassis Body 2000 rm781 PDFDocument776 pagesVNX - Su Avensis Supplement Chassis Body 2000 rm781 PDFprog-toy75% (4)

- R34 EcuDocument1 pageR34 EcuJamie MacdonaldPas encore d'évaluation

- ECM Input OutputDocument17 pagesECM Input OutputFlorin BodroghinăPas encore d'évaluation

- Diesel Control ECU Operator ManualDocument21 pagesDiesel Control ECU Operator ManualThug LabPas encore d'évaluation

- 09e 5 PDFDocument26 pages09e 5 PDFruslan1580Pas encore d'évaluation

- m1 5 5 PDFDocument5 pagesm1 5 5 PDFEd Aguilar MartinsPas encore d'évaluation

- Sewer and Drainage Facilites Design Manual - City of Portland PDFDocument201 pagesSewer and Drainage Facilites Design Manual - City of Portland PDFgemotorresPas encore d'évaluation

- Indigo InstructionsDocument12 pagesIndigo InstructionsMarina VasxPas encore d'évaluation

- New Fgtech Boot Tricore User Manual 2018Document137 pagesNew Fgtech Boot Tricore User Manual 2018Reginaldo Araujo100% (1)

- OA2 2a VocabularyDocument10 pagesOA2 2a Vocabularymafalda1286Pas encore d'évaluation

- Ignition PDFDocument17 pagesIgnition PDFtavi2mePas encore d'évaluation

- Science6 Q4 Mod3 Seasons of PhilippinesDocument25 pagesScience6 Q4 Mod3 Seasons of Philippinesfiona leigh homerezPas encore d'évaluation

- Var SlidesDocument28 pagesVar SlidespinakimahataPas encore d'évaluation

- 2006 Hyundai H 1 Grand Starex 100720Document284 pages2006 Hyundai H 1 Grand Starex 100720hideki kurosaki100% (1)

- 2jzgte Uk Spec Ecu PinoutDocument2 pages2jzgte Uk Spec Ecu PinoutWilliamPas encore d'évaluation

- Method Statement For Surface Preparation Prtective CoatingDocument10 pagesMethod Statement For Surface Preparation Prtective CoatingJaved MAPas encore d'évaluation

- 1NZ Fe PDFDocument4 pages1NZ Fe PDFVinh PhạmPas encore d'évaluation

- User Manual Abrites Commander For ToyotaDocument27 pagesUser Manual Abrites Commander For ToyotaJame Eduardo100% (1)

- FF EcuDocument9 pagesFF EcuEduardo J CondePas encore d'évaluation

- Toyota YarisDocument5 pagesToyota YarisMohammed Yusuf100% (1)

- Kia Code RetrievalDocument2 pagesKia Code Retrievalandreisim80100% (1)

- Prius C Technical Presentation PowerpointDocument90 pagesPrius C Technical Presentation PowerpointDanny CooperPas encore d'évaluation

- Toytoa Wire DiagramDocument8 pagesToytoa Wire Diagramspybot1331100% (1)

- Ecu Diagram Forester 2002Document7 pagesEcu Diagram Forester 2002Razvan MateiPas encore d'évaluation

- Novedades Jaltest CV en 887Document14 pagesNovedades Jaltest CV en 887Bruce LyndePas encore d'évaluation

- 4afe O2sensor TestDocument3 pages4afe O2sensor Testkkg4782Pas encore d'évaluation

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopMohamed HarbPas encore d'évaluation

- CSSBI-12M-13 - Standard For Composite Steel DeckDocument9 pagesCSSBI-12M-13 - Standard For Composite Steel DeckjulianobiancoPas encore d'évaluation

- BBA3 QT - Time - Series - Unit - 2Document11 pagesBBA3 QT - Time - Series - Unit - 2Deepanshu RajawatPas encore d'évaluation

- Effect of Urban Structure On Thermal Comfort and Walking Comfort in JakartaDocument215 pagesEffect of Urban Structure On Thermal Comfort and Walking Comfort in JakartaF360spiderPas encore d'évaluation

- Venice: Portugal's Eastern Trade: 1508-1595Document5 pagesVenice: Portugal's Eastern Trade: 1508-1595Tay MonPas encore d'évaluation

- Determination of Suitable Thin Layer Drying Curve Model For Apple SlicesDocument6 pagesDetermination of Suitable Thin Layer Drying Curve Model For Apple Slicesvele2ionut100% (1)

- Harmony Air Conditioning Alfords Point 2234 DocumentDocument4 pagesHarmony Air Conditioning Alfords Point 2234 DocumentВелимир КнежевићPas encore d'évaluation

- 2021 EMDAT ReportDocument8 pages2021 EMDAT ReportNirdeshKumarSharmaPas encore d'évaluation

- Starkville Dispatch Eedition 11-19-18Document12 pagesStarkville Dispatch Eedition 11-19-18The DispatchPas encore d'évaluation

- EPDM Geomembrane Installation Guide - 4Document15 pagesEPDM Geomembrane Installation Guide - 4Mukti AwanPas encore d'évaluation

- NTC Thermistors:: Type CLDocument3 pagesNTC Thermistors:: Type CLErnesto Moya-AlborPas encore d'évaluation

- Seasonal Prediction of Crop Yields in Ethiopia Using An Analog ApproachDocument11 pagesSeasonal Prediction of Crop Yields in Ethiopia Using An Analog Approachamandawilliam8060Pas encore d'évaluation

- Carbon Dioxide (Dry-Ice) Blasting: Robert W. FosterDocument7 pagesCarbon Dioxide (Dry-Ice) Blasting: Robert W. FosterRinush Fedrikdo Bushido OdaPas encore d'évaluation

- Bristol Scroll Compressors GuidelinesDocument18 pagesBristol Scroll Compressors GuidelinesBrian DohertyPas encore d'évaluation

- Student: Pavel Mircea Grupa: TA 31 Profesor: Pricop CodrutaDocument51 pagesStudent: Pavel Mircea Grupa: TA 31 Profesor: Pricop CodrutaMircea PavelPas encore d'évaluation

- UD 6-81-7 (E) A Guide To Cold Weather Operations, Booklet 7, Cold Weather Equipment (1988)Document32 pagesUD 6-81-7 (E) A Guide To Cold Weather Operations, Booklet 7, Cold Weather Equipment (1988)Sven Weißenberger100% (1)

- Ehb Ta 072-240 1008 PDFDocument40 pagesEhb Ta 072-240 1008 PDFsaulPas encore d'évaluation

- Bahan Us 2017Document24 pagesBahan Us 2017Ir SuhaeniPas encore d'évaluation

- Gobi-Altai VCA& CP Eng FINAL 070211Document32 pagesGobi-Altai VCA& CP Eng FINAL 070211batmunkh.ePas encore d'évaluation

- Extracted Pages From SAES-Q-006Document2 pagesExtracted Pages From SAES-Q-006Sarah AzizPas encore d'évaluation

- Thermosense: Occupancy Thermal Based Sensing For Hvac ControlDocument8 pagesThermosense: Occupancy Thermal Based Sensing For Hvac ControledgardoboieroPas encore d'évaluation

- First Trainer 2015 Reading and Use of EnglishDocument10 pagesFirst Trainer 2015 Reading and Use of EnglishManuel Lemos100% (2)