Académique Documents

Professionnel Documents

Culture Documents

PCPL 0532 4 407 04 10

Transféré par

tceterexDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PCPL 0532 4 407 04 10

Transféré par

tceterexDroits d'auteur :

Formats disponibles

DOCUMENT No PCPL-0532-4-407-04-10 1.0 1.

1 SCOPE

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 1 of 9

This Specification covers the design, material, construction features, manufacture, inspection and testing at the VENDOR s!his S"#$VENDOR s %or&s, deliver' to Site and performance testing of segregated!non$segregated metal enclosed phase (us ducts. CODES & STANDARDS The design, material, construction, manufacture, inspection, testing and performance of segregated!non$segregated metal enclosed phase (us ducts shall compl' *ith all currentl' applica(le statutes, regulations and safet' codes in the localit' *here the E+uipment *ill (e installed. The E+uipment shall also conform to the latest applica(le standards. Nothing in this Specification shall (e construed to relieve the VENDOR of this responsi(ilit'. E+uipment shall conform to the latest applica(le standards as mentioned in Data Sheets. ,n case of conflict (et*een the standards - this Specification, this Specification shall govern. DEFINITION / Non$Segregated 0hase #us Duct is one in *hich all phase conductors *ith its associated connections, 1oints, accessories and insulating supports are enclosed in an earthed metal enclosure *ithout an' metal or insulation (arrier (et*een the phases.

).0 ).1

).)

..0

2.0 2.1

BUS ENCLOSURE 3aterial The enclosure shall (e made of sheet steel or aluminium allo' as specified in Data Sheet$ /. The grade of sheet steel or aluminium allo' shall (e indicated (' the #,DDER in his #id and shall (e su(1ect to the 0"R45/SER s approval.

2.)

Shape E6cept as noted other*ise in Data Sheet$/, the section of the (us duct enclosure shall (e s+uare or rectangular.

2.. 2...1

3echanical Strength The design of the (us duct enclosure shall (e such that it *ill *ithstand the internal or e6ternal pressures resulting from the follo*ing7 a8 Normal operating conditions (8 3omentar' short$circuit currents 90ea&8 c8 Rigorous adverse *eather conditions, and d8 com(ination of the a(ove

2...) 2.2

The housings shall (e of sturd' construction to have inherent strength to *ithstand the a(ove forces. 4onstruction

DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 2 of 9

The entire (us duct shall (e designed for indoor installation as specified in Data Sheet$/, *ith a dust and vermin$proof construction. #us duct installations meant for outdoor application shall (e of *eatherproof construction and shall have degree of protection (etter than or e+ual to ,0$:; and shall (e indicated (' the #,DDER in Data Sheet$#. 2.< 2.<.1 0ainting The inside of the (usduct enclosure shall (e treated *ith a matt finish paint of dar& colour, prefera(l' (lac& to facilitate efficient heat dissipation. The (are enclosure *ith a(ove painting shall (e designed so as not to e6ceed the temperature specified in 4lause 2.: *hen the conductor is carr'ing rated current. The #,DDER shall su(mit supporting test certificates. The outside of the enclosure shall (e given a finish as per the 0"R45/SER s re+uirement specified in Data Sheet$/. Temperature Rise "nder normal operating conditions, the hot spot temperature of the enclosure shall not e6ceed ;0O4. 2.; #ello* =oints =oints consisting of ru((er (ello*s shall (e provided on the (us enclosure at follo*ing points7 a8 Terminations at transformers (8Terminations at s*itchgear cu(icles 2.> ?le6i(le E6pansion =oints 2.>.1. ?le6i(le e6pansion 1oints for the enclosure shall (e provided *herever deemed necessar' (' the VENDOR. The fle6i(le 1oints shall ta&e care of e6pansion and contraction due to temperature variations on fault conditions. 2.@ #onding Necessar' (onding shall (e provided at the a(ove e6pansion 1oints if made of insulating material. 2.10 Terminal Enclosures and ?langes 2.10.1 Three$phase terminal enclosures shall (e provided *ith flanged ends *ith drilling dimensions to suit the flanges at e+uipment terminals. 2.10.) The flanges shall (e provided *ith gas&ets, nuts, (olts etc. 2.10.. ,t shall (e the responsi(ilit' of the VENDOR of the (us duct to co$ordinate *ith various e+uipment 9(' OT5ERS8 to *hich his (us duct has to (e terminated to ensure proper alignment of the (us duct *ith these e+uipment. 2.11 ,nspection 4overs 0rovision shall (e made for periodic inspection of insulators (' means of inspection covers. The inspection covers shall (e provided *ith +uic& acting stainless steel clamps and shall have gas&ets.

2.<.) 2.:

DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10 2.1) Drain 0lugs and Vents

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 3 of 9

?ilter t'pe drain plugs shall (e installed at lo* points along the run of the (us duct to drain out automaticall' an' moisture condensing *ithin the (us enclosure. The drain plugs shall (e fitted *ith porous filter elements, *hich *ill permit the escape of moisture (ut prevent the ingress of dust. The filter elements shall (e easil' remova(le for cleaning purposes. 2.1. Aas&ets 2.1..1 The gas&et material and thic&ness shall (e so selected as to satisf' the operating conditions imposed (' temperature, *eathering dura(ilit' etc. 4are shall (e e6ercised to ensure that covers fit easil', that the re+uired compression of the gas&ets can (e o(tained *ithout damage to the inspection covers (' (olts and that covers do not (end after this compression has (een applied. Over$compression of the gas&ets shall (e avoided. 2.1..) The material of the gas&et shall prefera(l' (e neoprene closed$cell sponge ru((er or e+uivalent. 2.1... ?langes gas&ets shall (e provided at the e+uipment terminal connections. 2.12 3iscellaneous 5ard*are The (us duct shall not have an' through (olts. /ll nuts and (olts shall (e mild steel hot dip galvanised. 3.S. spring *ashers shall (e provided for ma&ing satisfactor' 1oints. 4lamps, splice plates etc. shall (e provided *herever necessar'. 2.1< Earthing Necessar' earthing arrangement as applica(le shall (e provided *ith clamps to receive the 0"R45/SER s station earthing (us. /ll accessories and hard*are re+uired for the earthing arrangement should (e provided (' the VENDOR. <.0 <.1 BUS CONDUCTOR 3aterial The material of the conductor shall (e aluminium allo' or copper as specified in Data Sheet$/. The grade of aluminium allo' or copper shall (e indicated (' the #,DDER in his #id and shall (e su(1ect to the 0"R45/SER s approval. <.) Rating The (us conductor shall (e designed to carr' the rated current under normal Site operating conditions *ithout e6ceeding a hot spot temperature of >< O4. /lso, the temperature of the (us surface shall not e6ceed )<0O4 *hile carr'ing the specified short circuit current for one second *hen a fault occurs at the operating temperature. ?or a forced$cooled (us, the ratings under self$cooled and forced cooled conditions for same temperature rise shall (e given. <.. Shape E6cept as noted other*ise in Data Sheet$/, the section of the (us conductors used shall (e rectangular, tu(ular, hollo* s+uare, hollo* rectangular, dou(le channel or hollo* he6agonal!octagonal t'pe (ased on the current rating.

DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10 <.2 3echanical Strength

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 4 of 9

The (us conductors and insulated supports shall *ithstand *ithout permanent deformation, deterioration of conductor material and reduction in the #,B value of the (us duct, the stresses consistent *ith the momentar' short circuit current specified in this Specification. <.< 0ainting The (us conductor ma' (e given a coat of matt finish (lac& paint to facilitate heat dissipation. The (are conductor *ith a(ove painting shall (e designed to carr' the normal rated current *ithout e6ceeding temperature rise as specified in 4lause <.) a(ove. The VENDOR shall su(mit supporting test certificate. <.: Bosses The losses in the conductor shall (e limited to such a value that the temperature rise of the conductor does not e6ceed the specified values. The losses should (e such that an optimal operating cost is o(tained. <.; <.;.1 =oints /d1acent sections of the (us conductors shall (e (olted or *elded as specified in Data Sheet$/ to provide an efficient, electricall' continuous and mechanicall' strong connection. %elded Rigid =oints7 =oints shall (e highest +ualit' done as per the proven methods of *elding practice. Suita(le aluminium or copper connectors shall (e provided *herever the (us sections changes. <.;.. %elded E6pansion =oints7 ?le6i(le aluminium or copper connectors *elded to the main (us(ars shall (e provided *herever deemed necessar'. <.;.2 #olted Rigid =oints7 The connectors shall (e of the same material as the conductor and these shall (e silver$ plated for contact surface to ensure an efficient connection. The (olting schedule and contact pressures shall conform to accepted codes of practice. <.;.< #olted ?le6i(le =oints7 ?le6i(le (raided copper connections shall (e provided at the e+uipment terminal connections. #imetallic connectors shall (e provided (et*een the (us(ar and the copper fle6i(le if the (us conductor is of aluminium allo'. The 1oints shall (e capa(le of )<$mm settlement of the e+uipment mounting pads. The 1oints shall (e suita(l' designed to ta&e care of the vi(ration at the terminals as *ell as the e6pansion and contraction of the (us(ars. <.;.: #olted E6pansion =oints7

<.;.)

DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 5 of 9

E6pansion 1oints made of aluminium or copper strips shall (e provided *herever deemed necessar' (' the VENDOR, to ta&e care of e6pansion and contraction of the (us(ars under normal operating conditions. <.;.; /ll the a(ove 1oints shall (e tested for temperature rise to prove the ade+uac' of the design. The ma6imum temperature rise at the 1oints shall (e less than the specified temperature rise for the (us(ars. 4lamps and 5ard*are The (us(ar clamps at support insulators shall (e designed to *ithstand the forces due to momentar' short circuit current. The' shall permit free longitudinal movement of the (us(ars during e6pansion and contraction. The material of the clamps shall (e aluminium allo'. Suita(le copper or aluminium spacers shall (e provided *herever necessar'. /ll (olts, nuts and loc&ing *ashers used in the (us assem(l' shall (e of high tensile steel, plated for corrosion resistance. Spring *ashers of C#ellevilleD t'pe or e+uivalent shall (e used. Suita(le splice plates and (imetallic connectors shall (e provided *herever necessar'. Disconnecting Bin&s Disconnecting lin&s *ith rating same as that of the main (us(ars shall (e provided in the run of the (us duct at the points as specified in Data Sheet$/ to facilitate disconnection of the (us(ars during testing and maintenance. The separation of the (us(ar sections *ith the (olted lin&s removed shall (e sufficient to *ithstand the rated voltage of the (us duct. <.10 Shorting Bin&s <.10.1 Shorting 1umpers, for the purpose of dr'ing out the e+uipment (efore commissioning or for carr'ing out short circuit test on the e+uipment, rated for the main (us current shall (e supplied for shorting the (us duct at a location, ad1acent to the disconnecting lin&s or as specified in Data Sheet$/. <.10.) The shorting lin&s shall have drilling dimensions matching those of the main (us disconnecting lin&s. Suita(le supporting structures and supports insulators for the shorting lin&s if necessar' shall also (e offered. :.0 :.1 :.) :.).1 :.).) :.. BUS SUPPORT INSULATORS %ithin the (us duct the (us shall (e mounted and supported on insulators. The insulators shall (e mounted on resilient pads provided in the (us enclosure. 3aterial The insulators shall (e prefera(l' made of porcelain. ?or (us ducts *ith voltage rating up to 1100 volt, E0ER3/B, *ood or e+uivalent t'pe of non$h'groscopic insulating supports are accepta(le. 3echanical Strength The insulators shall possess sufficient mechanical strength to *ithstand the forces due to momentar' short circuit currents of magnitude detailed in this Specification. The spacing of the (us insulators shall (e decided giving due factor of safet'. DATE:22-0 -200 ISSUE No: P0

<.> <.>.1

<.>.)

<.>.. <.@

DOCUMENT No PCPL-0532-4-407-04-10 :.2 Electrical Strength

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: of 9

/s a conse+uence of current loading and variation in e6ternal temperatures in the e6ternal sections of the (us duct, condensation of moisture ma' ta&e place on the surface of the insulators. 5ence the insulators shall have a high creepage distance and a *ithstand voltage rating sufficient to provide specified insulation under highl' humid conditions. ;.0 ;.1 !ALL FRAME ASSEMBL" & SEAL-OFF BUS#INGS %all ?rame /ssem(l' %herever the (us duct passes through the plant (uilding *all, from indoors to outdoors, a *all frame assem(l' *ith seal$off (ushings shall (e provided to prevent an' lea&age of rain *ater, infiltration of dust and air temperature variations from indoors to outdoors. The *all frame shall (e fa(ricated out of aluminium angles and sheet and shall (e suita(le for grouting in the *all. ,t shall (e provided *ith flanges on (oth sides to receive the (us duct flanges. ;.) Seal$off #ushings The (us duct shall (e e+uipped *herever necessar' *ith (affle or seal$off (ushings to prevent interchange of air at different temperatures. The seal$off (ushings shall (e flanged t'pe. ;.. 3aterial The insulator for *all frame assem(l' and seal$off (ushings shall (e of porcelain. /lso the (ushings shall (e designed for thermal e6pansion!contraction due to temperature differential for outdoor!indoor use. ;.2 3echanical Strength The insulator shall *ithstand the ma6imum short circuit forces under fault conditions specified in this specification. The insulator material shall not deteriorate under normal operating temperatures or due to temperature rise under fault conditions. ;.< >.0 >.1 @.0 @.1 Electrical Strength The electrical properties of the insulator shall (e in conformit' *ith this specification. P#ASE CLEARANCES The minimum phase to phase and phase to earth clearances of (us(ars *ithin the enclosures shall (e as specified in Data Sheet$/. BUS DUCT SUPPORTS 3aterial The supporting structure shall (e fa(ricated from standard steel sections and shall (e hot dip galvanised after fa(rication. The hot dip galvanising shall (e in accordance *ith standards listed in Data Sheet$/. @.) 3echanical Strength The supporting structures shall (e designed to *ithstand the dead *eight of the (us duct and also the short circuit forces under ma6imum fault conditions and also the *ind load DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 7 of 9

and forces due to seismic accelerations *hich are specified in Data Sheet$/ and!or Section$# entitled E0ro1ect ,nformation . 4alculations shall (e furnished to su(stantiate the a(ove and shall (e su(1ect to the 0"R45/SER s approval. @.. /ccessories and 5ard*are The supporting structures shall include supporting mem(ers, (rac&ets, hangers, longitudinal (eams, channels, nuts, (olts, insulating pads, insulating *ashers and all other hard*are *hich are necessar' for the erection and support of the entire (us duct installation. /ll the accessories and hard*are of ferrous material shall (e hot dip galvanised. @.2 @.2.) @.2.. @.< 3ethods of Support ,ndoor portion of the (us duct ma' (e supported from the floor or ceiling (eams. Outdoor portion of the (us duct shall (e supported from ground (elo* on suita(le foundations in the ground. The foundations and structures in outdoor area shall clear the transformers, transformer foundations, ca(le trenches etc. Earthing Each supporting structure shall (e securel' - electricall' connected from t*o points to the 0"R45/SER s station earthing (us. /ll necessar' hard*are, such as clamps, connectors etc., Re+uired for this purpose shall (e furnished (' the VENDOR. 10.0 MAR$INGS /ll components of the (us duct along *ith the supporting structure shall (e distinctl' mar&ed for erection in accordance *ith the erection dra*ings to (e prepared - furnished (' the VENDOR. These mar&s shall (e made in a manner as not to (e o(literated and erased in transit or to damage the galvanising of the (us duct enclosure or the supporting structure. 11.0 11.1 11.) MISCELLANEOUS Studs, nuts, (olts and tapped holes shall conform to the relevant standards. Onl' he6agonal nuts shall (e used. /ll (olt holes shall (e spot faced for nuts. 4astings and forging shall conform to respective material specifications and shall (e free from fla*s. The' shall (e machined true as per good *or&shop practice. %elding shall (e performed in accordance *ith relevant esta(lished standards. /ll threaded pipe connections and fittings, pipe flanges and tu(e fittings shall compl' *ith relevant standards. DESIGN RE%UIREMENTS OF BUS DUCT T&' B() *&+,, -o./+(. )'*(0. -+,-1,+/(o. (. *122o3/ of the follo*ing parameters of the (us duct design7 a8 SiFing of the (us(ars, vis$G$vis thermal capa(ilit' to *ithstand rated continuous current and one second short time current.

11.. 1).0 1).1

DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 4 of 9

(8 Spacing of the insulators vis$G$vis mechanical strength to *ithstand forces due to 3omentar' short$circuit current. c8 5eat loss and temperature rise calculations for conductor and enclosure. %herever Rain hood is provided the effects of solar radiation ma' (e neglected *hile calculating temperature rise. 1).) 1..0 1..1 T&' B() *&+,, 5' -o62,'/' 7(/& +,, &'+/ ,o** -+,-1,+/(o.* . /ll formulae and other information from *hich the heat losses have (een derived shall (e enlisted. SPACE #EATERS The (us duct shall (e provided *ith space heaters of ade+uate capacit' to maintain the internal temperature a(ove the de* point to prevent moisture condensation *ithin the (us duct. The space heaters shall (e rated for >0%, )20V single phase, <0 5F. /4 suppl'. The space heater shall (e automaticall' controlled (' differential thermometers. TESTS & TEST REPORTS The follo*ing t'pe and routine tests shall (e conducted on representative section of the (us assem(l'. The (us assem(l' tested shall include (olted connections and fle6i(le connections. The tests shall (e conducted as per standards indicated in these specifications. T'pe Tests

1480 12.1

12.)

12.).1 One$minute po*er fre+uenc' *ithstand voltage test. 12.).) ,mpulse voltage *ithstand test. 12.).. Temperature rise test of (are (lac& matt finish painted conductors and enclosures. 12.).2 D'namic *ithstand test. 12.).< %ater tightness test. 12.).: /ir tightness tests. 12.. Routine Tests 12...1 One$minute po*er fre+uenc' *ithstand voltage test. 12...) %ater tightness test 12.... /ir tightness test 12.2 Test Report for 4omponents 3anufacturer s t'pe and routine test certificates shall (e su(mitted for tests conducted as per relevant standards for the follo*ing components7 a8 ,nsulators (8 Seal$off (ushings c8 #olted and fle6i(le 1oints d8 #us(ars e8 Enclosure material DATE:22-0 -200 ISSUE No: P0

DOCUMENT No PCPL-0532-4-407-04-10

NON SEGRAGATED BUSDUCTS

SECTION - 4 PAGE: 9 of 9

f8 Aalvanising of support structures g8 ?uses if an'. 1580 SPARES %hether included in the #,DDER s recommendation or not, unit prices of the follo*ing items or the items recommended (' them shall (e +uoted together *ith their suggested +uantities and catalogue num(ers7 a8 #us support insulators (8 ?le6i(le connector c8 ,solating lin& d8 Different t'pe of gas&ets

DATE:22-0 -200 ISSUE No: P0

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Spec - Earthing & BondingDocument15 pagesSpec - Earthing & BondingcklconPas encore d'évaluation

- The IEE Wiring Regulations Explained and IllustratedD'EverandThe IEE Wiring Regulations Explained and IllustratedÉvaluation : 4 sur 5 étoiles4/5 (14)

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedDocument13 pagesAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Beautiful Sanskrit Names For Boy Baby, Ancient Hindu Boy Names, Sanskrit Name MeaningDocument10 pagesBeautiful Sanskrit Names For Boy Baby, Ancient Hindu Boy Names, Sanskrit Name MeaningtceterexPas encore d'évaluation

- Piping Joint HandbookDocument66 pagesPiping Joint HandbookPuiu VoicuPas encore d'évaluation

- Kagga MankuthimmaDocument29 pagesKagga MankuthimmatceterexPas encore d'évaluation

- Material Specification - 077154C-000-JSS-1700-009 - DDocument13 pagesMaterial Specification - 077154C-000-JSS-1700-009 - DStructures ProductionPas encore d'évaluation

- 12 Key Principles On Bhava AnalysisDocument28 pages12 Key Principles On Bhava AnalysisDhineshPas encore d'évaluation

- Material SpecificationsDocument27 pagesMaterial Specificationssat palPas encore d'évaluation

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06Pas encore d'évaluation

- Therapeutic Nutrition: Khien S. Sasi, RN, ManDocument33 pagesTherapeutic Nutrition: Khien S. Sasi, RN, ManKhien Sasi100% (4)

- 15 TMSS 02 R0Document0 page15 TMSS 02 R0renjithas2005Pas encore d'évaluation

- Ancient Names, Mythological Names, Hindu Epics Mythology Names, Vedic Names ADocument5 pagesAncient Names, Mythological Names, Hindu Epics Mythology Names, Vedic Names AtceterexPas encore d'évaluation

- JRC JFE-680 Instruct ManualDocument86 pagesJRC JFE-680 Instruct ManualMark Dominic FedericoPas encore d'évaluation

- TS - 400kVA Earthing TransformerDocument8 pagesTS - 400kVA Earthing TransformerViswanathan VPas encore d'évaluation

- Napoleonic WargamingDocument13 pagesNapoleonic WargamingandyPas encore d'évaluation

- Construction Standard FOR Electrical Installation Original Edition DEC. 1997Document9 pagesConstruction Standard FOR Electrical Installation Original Edition DEC. 1997cherif yahyaouiPas encore d'évaluation

- Cecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Document19 pagesCecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Jose SanchezPas encore d'évaluation

- Standard Data Electrical Items For Buildings Preamble: Chapter 1: Conduit LayingDocument4 pagesStandard Data Electrical Items For Buildings Preamble: Chapter 1: Conduit Laying79LiterPas encore d'évaluation

- Cross Talk Details and RoutingDocument29 pagesCross Talk Details and RoutingRohith RajPas encore d'évaluation

- Dry Type Transformer Spec in Word FormatDocument25 pagesDry Type Transformer Spec in Word Formatarulraj1971Pas encore d'évaluation

- Honeycomb Kevlar 49 (Hexcel)Document3 pagesHoneycomb Kevlar 49 (Hexcel)Julia GarciaPas encore d'évaluation

- FEWA HV Joints & TerminationsDocument29 pagesFEWA HV Joints & TerminationsMuhammad RazaPas encore d'évaluation

- Spec For High MastDocument61 pagesSpec For High MastVenkatRaghavendarPas encore d'évaluation

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcPas encore d'évaluation

- Norsok M-503 Cathodic ProtectionDocument14 pagesNorsok M-503 Cathodic ProtectionbreeeeezzzzzePas encore d'évaluation

- 1970 - Transformer FMEA PDFDocument7 pages1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- 5G Transport Slice Control in End-To-End 5G NetworksDocument19 pages5G Transport Slice Control in End-To-End 5G NetworksmorganPas encore d'évaluation

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaPas encore d'évaluation

- Cathodic Protection: Foreword 1 Scope 2 Normative References 3 Definitions 4 Cathodic Protection DesignDocument11 pagesCathodic Protection: Foreword 1 Scope 2 Normative References 3 Definitions 4 Cathodic Protection Designvvraghu12Pas encore d'évaluation

- DO Fuse UnitDocument8 pagesDO Fuse UnitImran KhanPas encore d'évaluation

- PCPL 0532 4 407 04 11Document7 pagesPCPL 0532 4 407 04 11tceterexPas encore d'évaluation

- DB Tech Specs - BDDocument5 pagesDB Tech Specs - BDDarshit VyasPas encore d'évaluation

- specSPCT00rev01 PDFDocument10 pagesspecSPCT00rev01 PDFharsh_1582Pas encore d'évaluation

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilPas encore d'évaluation

- Tech. Specs. For 11 KV DP StructureDocument7 pagesTech. Specs. For 11 KV DP StructureSaraswatapalitPas encore d'évaluation

- Specification ElectricalDocument14 pagesSpecification Electrical2003_335Pas encore d'évaluation

- Hvac Ductwork: SECTION 15/1/2Document15 pagesHvac Ductwork: SECTION 15/1/2Ahmed Yousri AhmedPas encore d'évaluation

- Medium Voltage Composite InsulatorsDocument14 pagesMedium Voltage Composite Insulatorsdeepthik27Pas encore d'évaluation

- Section - 9 Main L.T. Switchboard: 9.1 GeneralDocument4 pagesSection - 9 Main L.T. Switchboard: 9.1 GeneralHusnain AssociatesPas encore d'évaluation

- Piping Shop Fabrication SpecificationDocument20 pagesPiping Shop Fabrication SpecificationAnonymous NIICRJPas encore d'évaluation

- 7.4. UPVC Pipes & FittingsDocument3 pages7.4. UPVC Pipes & FittingsKrishna SankarPas encore d'évaluation

- L s8 Lightning Protection System Using Stranded G.I. WiresDocument4 pagesL s8 Lightning Protection System Using Stranded G.I. WiresTan Kang YaoPas encore d'évaluation

- TES-P-104.04-R0 Splices and Termination of Power CablesDocument9 pagesTES-P-104.04-R0 Splices and Termination of Power CablesSalmanEjazPas encore d'évaluation

- 9Document25 pages9pcelisPas encore d'évaluation

- 220kV Cable Accessory Technical SpecificationDocument9 pages220kV Cable Accessory Technical Specificationanurag_pugaliaaPas encore d'évaluation

- 12 SDMS 01rev1Document16 pages12 SDMS 01rev1sardarmkhanPas encore d'évaluation

- AZZ Non-Segregated Phase Bus Technical Spec - 2016Document8 pagesAZZ Non-Segregated Phase Bus Technical Spec - 2016Ganesh KumarPas encore d'évaluation

- F 708 - 92 R97 - Rjcwoc05mli5nw - PDFDocument13 pagesF 708 - 92 R97 - Rjcwoc05mli5nw - PDFRománBarciaVazquezPas encore d'évaluation

- 12SDMS01Document14 pages12SDMS01hafezasadPas encore d'évaluation

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundPaulo GalvãoPas encore d'évaluation

- 76 Vol II SEC - STR - 04 PDFDocument10 pages76 Vol II SEC - STR - 04 PDFPremBhushanPas encore d'évaluation

- Technical Specification Section: StructureDocument10 pagesTechnical Specification Section: StructurePremBhushanPas encore d'évaluation

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalPas encore d'évaluation

- C 1460 - 04 - Qze0njaDocument4 pagesC 1460 - 04 - Qze0njaSamuel EduardoPas encore d'évaluation

- Antifog Disc InsulatorDocument35 pagesAntifog Disc InsulatorJayant Kumar DasPas encore d'évaluation

- P-90-82 F - CT's 33 To 132 KVDocument13 pagesP-90-82 F - CT's 33 To 132 KVHasnain AwanPas encore d'évaluation

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundFernando Da RosPas encore d'évaluation

- Electrical Specification Division 16, Section 16116Document4 pagesElectrical Specification Division 16, Section 16116eng_asayedPas encore d'évaluation

- Electricity Board DocsDocument41 pagesElectricity Board DocsM_D_MendisPas encore d'évaluation

- Review of Method Statement For Underground (Carbon Steel) Piping Construction and InstallationDocument22 pagesReview of Method Statement For Underground (Carbon Steel) Piping Construction and InstallationBenjamin HoltPas encore d'évaluation

- Job Procedure 03 For EARTHINGDocument5 pagesJob Procedure 03 For EARTHINGSoumik KarPas encore d'évaluation

- Fasteners Test Report DHBVNDocument114 pagesFasteners Test Report DHBVNvelu.gPas encore d'évaluation

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Document25 pagesTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoPas encore d'évaluation

- Low and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Document5 pagesLow and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Bayu Suryo WirantoPas encore d'évaluation

- P 8-96 Disc Porcelain InsulatorsDocument14 pagesP 8-96 Disc Porcelain InsulatorsSyed Oon Haider ZaidiPas encore d'évaluation

- Checklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingDocument4 pagesChecklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- 1212.03 15kV Submersible Transformer SpecificationDocument8 pages1212.03 15kV Submersible Transformer SpecificationurramarianiPas encore d'évaluation

- Ips C El 115Document9 pagesIps C El 115kazemi.1991Pas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Indian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter EDocument2 pagesIndian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter EtceterexPas encore d'évaluation

- UPS Application Guide: 16 Neutral SystemsDocument9 pagesUPS Application Guide: 16 Neutral SystemstceterexPas encore d'évaluation

- Micro 5PXN CatalogDocument2 pagesMicro 5PXN CatalogtceterexPas encore d'évaluation

- Knowledge Management in ADBDocument20 pagesKnowledge Management in ADBtceterexPas encore d'évaluation

- Indian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter ODocument1 pageIndian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter OtceterexPas encore d'évaluation

- Indian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter UDocument4 pagesIndian Baby Names, Hindu Baby Names, Indian Boy Names, Hindu Boy Names, Hindu Baby Boy Names - Names Starting With Letter UtceterexPas encore d'évaluation

- TRistile ODocument4 pagesTRistile OtceterexPas encore d'évaluation

- Aviation LampDocument1 pageAviation LamptceterexPas encore d'évaluation

- Low Voltage Products: Price ListDocument66 pagesLow Voltage Products: Price ListRavi ShankerPas encore d'évaluation

- Bosch PACO ProductDocument8 pagesBosch PACO ProducttceterexPas encore d'évaluation

- Hidprox Cards Chart enDocument1 pageHidprox Cards Chart entceterexPas encore d'évaluation

- Unit Rate Amount Supply Supply Supply of Electrical 1100V Grade Cabels Boq Item No. Description of Work BOQ Qty. UnitDocument1 pageUnit Rate Amount Supply Supply Supply of Electrical 1100V Grade Cabels Boq Item No. Description of Work BOQ Qty. UnittceterexPas encore d'évaluation

- 160KVA Green Power - TransformerlessDocument0 page160KVA Green Power - TransformerlesstceterexPas encore d'évaluation

- File C Users Vanpaq1 AppData Local Temp Out1B5FDocument1 pageFile C Users Vanpaq1 AppData Local Temp Out1B5FtceterexPas encore d'évaluation

- MCB MCCB RCCBDocument0 pageMCB MCCB RCCBtceterexPas encore d'évaluation

- PCPL 0630 4 SLD 003P0Document1 pagePCPL 0630 4 SLD 003P0tceterexPas encore d'évaluation

- 100&160KVA MP Elite TransformerbasedDocument0 page100&160KVA MP Elite TransformerbasedtceterexPas encore d'évaluation

- PCPL 0532 4 407 02Document1 pagePCPL 0532 4 407 02tceterexPas encore d'évaluation

- 40-120KVA Green Power TransformerlessDocument0 page40-120KVA Green Power TransformerlesstceterexPas encore d'évaluation

- Module 4 Active Faults and Other Earthquake Sources: Learning OutcomeDocument3 pagesModule 4 Active Faults and Other Earthquake Sources: Learning OutcomeFatima Ybanez Mahilum-LimbagaPas encore d'évaluation

- 08 Activity 1 (10) (LM)Document2 pages08 Activity 1 (10) (LM)Jhanine Mae Oriola FortintoPas encore d'évaluation

- Kinematics in One DimensionDocument4 pagesKinematics in One DimensionAldrin VillanuevaPas encore d'évaluation

- Curriculum Vitae - RadikaDocument3 pagesCurriculum Vitae - RadikaradikahendryPas encore d'évaluation

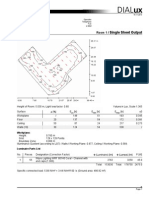

- Indor Lighting DesignDocument33 pagesIndor Lighting DesignRajesh MalikPas encore d'évaluation

- Bible World History Timeline - 4004-3004BCDocument1 pageBible World History Timeline - 4004-3004BCSagitonette DadapPas encore d'évaluation

- Amnaya Sutra (English)Document458 pagesAmnaya Sutra (English)Assam Bhakti SagarPas encore d'évaluation

- Grade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaDocument25 pagesGrade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaPenke Mejado BelenPas encore d'évaluation

- 2022 Audi e Tron 22Document318 pages2022 Audi e Tron 22Alejandro Alberto Robalino MendezPas encore d'évaluation

- AoS Soulbound - Pregens - Skyrigger Malgra DainssonDocument2 pagesAoS Soulbound - Pregens - Skyrigger Malgra DainssonAdrien DeschampsPas encore d'évaluation

- Stalthon Rib and InfillDocument2 pagesStalthon Rib and InfillAndrea GibsonPas encore d'évaluation

- Fig. 4 Phasor Diagram of P.TDocument31 pagesFig. 4 Phasor Diagram of P.Tdon aPas encore d'évaluation

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDocument10 pagesThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaPas encore d'évaluation

- The Light Fantastic by Sarah CombsDocument34 pagesThe Light Fantastic by Sarah CombsCandlewick PressPas encore d'évaluation

- Mahindra & MahindraDocument13 pagesMahindra & MahindraAbhishek DharmadhikariPas encore d'évaluation

- Biology Accel Syllabus 2011-2012Document3 pagesBiology Accel Syllabus 2011-2012Mike DeleonPas encore d'évaluation

- Reviews: The Global Epidemiology of HypertensionDocument15 pagesReviews: The Global Epidemiology of Hypertensionrifa iPas encore d'évaluation

- Math COT 3Document18 pagesMath COT 3Icy Mae SenadosPas encore d'évaluation