Académique Documents

Professionnel Documents

Culture Documents

Petrochm PPAH

Transféré par

Chau MaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Petrochm PPAH

Transféré par

Chau MaiDroits d'auteur :

Formats disponibles

As of April 30 2007, this document is NO LONGER IN USE by the Pollution Prevention and Abatement Handbook World Bank Group.

The new versions of the World Bank Group WORLD BANK GROUP Environmental, Health, and Safety Guidelines are available at Effective July 1998 http://www.ifc.org/ifcext/enviro.nsf/Content/EnvironmentalGuidelines

Petrochemicals Manufacturing

Industry Description and Practices

Natural gas and crude distillates such as naphtha from petroleum refining are used as feedstocks to manufacture a wide variety of petrochemicals that are in turn used in the manufacture of consumer goods. The description of petrochemical processes and products presented here is for illustrative purposes only. The basic petrochemicals manufactured by cracking, reforming, and other processes include olefins (such as ethylene, propylene, butylenes, and butadiene) and aromatics (such as benzene, toluene, and xylenes). The capacity of naphtha crackers is generally of the order of 250,000750,000 metric tons per year (tpy) of ethylene production. Some petrochemical plants also have alcohol and oxo-compound manufacturing units on site. The base petrochemicals or products derived from them, along with other raw materials, are converted to a wide range of products. Among them are:

Resins and plastics such as low-density poly-

A number of alternative methods for manufacturing the desired products are available. Details on typical processes and products are provided in the Annex.

Waste Characteristics

Fugitive air emissions from pumps, valves, flanges, storage tanks, loading and unloading operations, and wastewater treatment are of greatest concern. Some of the compounds released to air are carcinogenic or toxic. Ethylene and propylene emissions are of concern because their release can lead to the formation of extremely toxic oxides. Compounds considered carcinogenic that may be present in air emissions include benzene, butadiene, 1,2-dichloroethane, and vinyl chloride. A typical naphtha cracker at a petrochemical complex may release annually about 2,500 metric tons of alkenes, such as propylenes and ethylene, in producing 500,000 metric tons of ethylene. Boilers, process heaters, flares, and other process equipment (which in some cases may include catalyst regenerators) are responsible for the emission of particulates, carbon monoxide, nitrogen oxides (200 tpy), based on 500,000 tpy of ethylene capacity, and sulfur oxides (600 tpy). The release of volatile organic compounds (VOCs) into the air depends on the products handled at the plant. VOCs released may include acetaldehyde, acetone, benzene, toluene, trichloroethylene, trichlorotoluene, and xylene. VOC emissions are mostly fugitive and depend on the production processes, materials-handling and effluent-treatment procedures, equipment maintenance, and climatic conditions. VOC emissions from a naphtha cracker range from 0.6 to 10 kilograms per metric ton (kg/t) of ethylene pro-

ethylene (LDPE), high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), polypropylene, polystyrene, and polyvinyl chloride (PVC) Synthetic fibers such as polyester and acrylic Engineering polymers such as acrylonitrile butadiene styrene (ABS) Rubbers, including styrene butadiene rubber (SBR) and polybutadiene rubber (PBR) Solvents Industrial chemicals, including those used for the manufacture of detergents such as linear alkyl benzene (LAB) and of coatings, dyestuffs, agrochemicals, pharmaceuticals, and explosives.

371

372

PROJECT GUIDELINES: INDUSTRY SECTOR GUIDELINES

duced. Of these emissions, 75% consists of alkanes, 20% of unsaturated hydrocarbons, about half of which is ethylene, and 5% of aromatics. For a vinyl chloride plant, VOC emissions are 0.022.5 kg/t of product; 45% is ethylene dichloride, 20% vinyl chloride, and 15% chlorinated organics; for an SBR plant, VOC emissions are 3 10 kg/t of product; for an ethyl benzene plant, 0.1-2 kg/t of product; for an ABS plant, 1.427 kg/t of product; for a styrene plant, 0.2518 kg/t of product; and for a polystyrene plant, 0.25 kg/t of product. Petrochemical units generate wastewaters from process operations such as vapor condensation, from cooling tower blowdown, and from stormwater runoff. Process wastewaters are generated at a rate of about 15 cubic meters per hour (m3/hr), based on 500,000 tpy ethylene production, and may contain biochemical oxygen demand (BOD) levels of 100 mg/l, as well as chemical oxygen demand (COD) of 1,500 6,000 mg/l, suspended solids of 100400 mg/l, and oil and grease of 30600 mg/l. Phenol levels of up to 200 mg/l and benzene levels of up to 100 mg/l may also be present. Petrochemical plants generate solid wastes and sludges, some of which may be considered hazardous because of the presence of toxic organics and heavy metals. Spent caustic and other hazardous wastes may be generated in significant quantities; examples are distillation residues associated with units handling acetaldehyde, acetonitrile, benzyl chloride, carbon tetrachloride, cumene, phthallic anhydride, nitrobenzene, methyl ethyl pyridine, toluene diisocyanate, trichloroethane, trichloroethylene, perchloroethylene, aniline, chlorobenzenes, dimethyl hydrazine, ethylene dibromide, toluenediamine, epichlorohydrin, ethyl chloride, ethylene dichloride, and vinyl chloride. Accidental discharges as a result of abnormal operation, especially from polyethylene and ethylene-oxide-glycol plants in a petrochemical complex, can be a major environmental hazard, releasing large quantities of pollutants and products into the environment. Plant safety and fire prevention and control procedures should be in place.

cesses are usually specific to the characteristics of the products manufactured. Specific pollution prevention or source reduction measures are best determined by technical staff. However, there are a number of broad areas where improvements are often possible, and site-specific emission reduction measures in these areas should be designed into the plant and targeted by plant management. Areas where efforts should be concentrated are discussed below. Reduction of Air Emissions

Minimize leakages of volatile organics, includ-

ing benzene, vinyl chloride, and ethylene oxide, from valves, pump glands (through use of mechanical seals), flanges, and other process equipment by following good design practices and equipment maintenance procedures. Use mechanical seals where appropriate. Minimize losses from storage tanks, product transfer areas, and other process areas by adopting methods such as vapor recovery systems and double seals (for floating roof tanks). Recover catalysts and reduce particulate emissions. Reduce nitrogen oxide (NOx) emissions by using low-NOx burners. Optimize fuel usage.

In some cases, organics that cannot be recovered are effectively destroyed by routing them to flares and other combustion devices. Elimination or Reduction of Pollutants

Use nonchrome-based additives in cooling

water.

Use long-life catalysts and regeneration to ex-

tend the cycle. Recycling and Reuse

Recycle cooling water and treated wastewa-

ter to the extent feasible.

Recover and reuse spent solvents and other

chemicals to the extent feasible. Improved Operating Procedures

Segregate process wastewaters from storm-

Pollution Prevention and Control

Petrochemical plants are typically large and complex, and the combination and sequence of pro-

water systems.

Petrochemicals Manufacturing

373

Optimize the frequency of tank and equipment

cleaning.

Prevent solids and oily wastes from entering

the drainage system.

Establish and maintain an emergency pre-

paredness and response plan.

densation, absorption, adsorption (using activated carbon, silica gel, activated alumina, and zeolites), and, in some cases, biofiltration and bioscrubbing (using peat or heather, bark, composts, and bioflora to treat biodegradable organics), and thermal decomposition. Liquid Effluents Petrochemical wastewaters often require a combination of treatment methods to remove oil and other contaminants before discharge. Separation of different streams (such as stormwater) is essential to minimize treatment requirements. Oil is recovered using separation techniques. For heavy metals, a combination of oxidation/reduction, precipitation, and filtration is used. For organics, a combination of air or steam stripping, granular activated carbon, wet oxidation, ion exchange, reverse osmosis, and electrodialysis is used. A typical system may include neutralization, coagulation/flocculation, flotation/sedimentation/filtration, biodegradation (trickling filter, anaerobic, aerated lagoon, rotating biological contactor, and activated sludge), and clarification. A final polishing step using filtration, ozonation, activated carbon, or chemical treatment may also be required. Examples of pollutant loads that can be achieved are: COD, less than 1 kg per 100 tons of ethylene produced; suspended solids, less than 0.4 kg/100 t; and dichloroethane, than 0.001 kg/100 t. Solid and Hazardous Wastes Combustion (preceded in some cases by solvent extraction) of toxic organics is considered an effective treatment technology for petrochemical organic wastes. Steam stripping and oxidation are also used for treating organic waste streams. Spent catalysts are generally sent back to the suppliers. In some cases, the solid wastes may require stabilization to reduce the leachability of toxic metals before disposal of in an approved, secure landfill.

Target Pollution Loads

Implementation of cleaner production processes and pollution prevention measures can yield both economic and environmental benefits. The following production-related targets can be achieved by measures such as those described in the previous section. The figures relate to the production processes before the addition of pollution control measures. A good practice target for petrochemical complex is to reduce total organic emissions (including VOCs) from the process units to 0.6% of the throughput. Target maximum levels for air releases, per ton of product, are, for ethylene, 0.06 kg; for ethylene oxide, 0.02 kg; for vinyl chloride, 0.2 kg; and for 1,2-dichloroethane, 0.4 kg. Methods of estimating these figures include ambient and emissions monitoring, emission factors, and inventories of emissions sources. Design assumptions should be recorded to allow for subsequent computation and reduction of losses. Vapor recovery systems to control losses of VOCs from storage tanks and loading areas should achieve close to 100% recovery. A wastewater generation rate of 15 cubic meters per 100 tons of ethylene produced is achievable with good design and operation; and new petrochemical complexes should strive to achieve this.

Treatment Technologies

Air Emissions Control of air emissions normally includes the capturing and recycling or combustion of emissions from vents, product transfer points, storage tanks, and other handling equipment. Catalytic cracking units should be provided with particulate removal devices. Particulate removal technologies include fabric filters, ceramic filters, wet scrubbers, and electrostatic precipitators. Gaseous releases are minimized by con-

Emissions Guidelines

Emissions levels for the design and operation of each project must be established through the environmental assessment (EA) process on the

374

PROJECT GUIDELINES: INDUSTRY SECTOR GUIDELINES

basis of country legislation and the Pollution Prevention and Abatement Handbook, as applied to local conditions. The emissions levels selected must be justified in the EA and acceptable to the World Bank Group. The guidelines given below present emissions levels normally acceptable to the World Bank Group in making decisions regarding provision of World Bank Group assistance. Any deviations from these levels must be described in the World Bank Group project documentation. The emissions levels given here can be consistently achieved by well-designed, well-operated, and well-maintained pollution control systems. The guidelines are expressed as concentrations to facilitate monitoring. Dilution of air emissions or effluents to achieve these guidelines is unacceptable. All of the maximum levels should be achieved for at least 95% of the time that the plant or unit is operating, to be calculated as a proportion of annual operating hours. Air Emissions The emissions levels presented in Table 1 should be achieved. Liquid Effluents The effluent levels presented in Table 2 should be achieved.

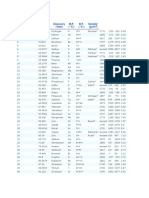

Table 1, Emissions from Petrochemicals Manufacturing and Target Ambient Levels

(miligrams per normal cubic meter)

Table 2. Effluents from Petrochemicals Manufacturing

(milligrams per liter, except for pH and temperature)

Parameter

pH BOD COD TSS Oil and grease Cadmium Chromium (hexavalent) Copper Phenol Benzene Vinyl chloride Sulfide Nitrogen (total) Temperature increase

Maximum value

69 30 150 30 10 0.1 0.1 0.5 0.5 0.05 0.05 1 10 3Ca

Note: Effluent requirements are for direct discharge to surface waters. a. The effluent should result in a temperature increase of no more than 3 C at the edge of the zone where initial mixing and dilution take place. Where the zone is not defined, use 100 meters from the point of discharge.

Solid Wastes and Sludges Wherever possible, generation of sludges should be minimized. Sludges must be treated to reduce toxic organics to nondetectable levels. Wastes containing toxic metals should be stabilized before disposal. Ambient Noise Noise abatement measures should achieve either the levels given below or a maximum increase in background levels of 3 decibels (measured on the A scale) [dB(A)]. Measurements are to be taken at noise receptors located outside the project property boundary.

Maximum allowable log equivalent (hourly measurements), in dB(A) Day Night (07:0022:00) (22:0007:00)

Parameter

PM Nitrogen oxides Hydrogen chloride Sulfur oxides Benzene 1,2-dichloroethane Vinyl chloride Ammonia

Maximum value

20 300 10 500 5 mg/m3 for emissions; 0.1 ppb at the plant fence 5 mg/m3 for emissions; 1.0 ppb at the plant fence 5 mg/m3 for emissions; 0.4 ppb at the plant fence 15 mg/m3

Receptor

Residential, institutional, educational Industrial, commercial

Note: Maximum ambient levels for ethylene oxide are 0.3 parts per billion (ppb) at the plant fence. Maximum total emissions of the VOCs acetaldehyde, acrylic acid, benzyl chloride, carbon tetrachloride, chlorofluorocarbons, ethyl acrylate, halons, maleic anhydride, 1, 1, 1 trichlorethane, trichloroethylene, and trichlorotoluene are 20 mg/Nm 3. Maximum total heavy metals emissions are 1.5 mg/Nm3.

55 70

45 70

Petrochemicals Manufacturing

375

Monitoring and Reporting

Frequent sampling may be required during startup and upset conditions. Once a record of consistent performance has been established, sampling for the parameters listed in this document should be as described below. Air emissions from stacks should be visually monitored for opacity at least once every eight hours. Annual emissions monitoring of combustion sources should be carried out for sulfur oxides, nitrogen oxides, and the organics listed above, with fuel sulfur content and excess oxygen maintained at acceptable levels during normal operations. Leakages should be visually checked every eight hours and at least once a week using leak detection equipment. Liquid effluents should be monitored at least once every eight hours for all the parameters cited above except metals, which should be monitored at least monthly. Each shipment of solid waste going for disposal should be monitored for toxics. Monitoring data should be analyzed and reviewed at regular intervals and compared with the operating standards so that any necessary corrective actions can be taken. Records of monitoring results should be kept in an acceptable format. The results should be reported to the responsible authorities and relevant parties, as required.

Use nonchrome-based additives in cooling

water.

Design and practice emergency preparedness

and prevention measures.

Annex. Typical Processes and Products in Petrochemical Manufacturing

C1 compounds (with one carbon atom in their molecule) manufactured at petrochemical plants include methanol, formaldehyde, and halogenated hydrocarbons. Formaldehyde is used in the manufacture of plastic resins, including phenolic, urea, and melamine resins. Halogenated hydrocarbons are used in the manufacture of silicone, solvents, refrigerants, and degreasing agents. Olefins (organics having at least one double bond for carbon atoms) are typically manufactured from the steam cracking of hydrocarbons such as naphtha. Major olefins manufactured include ethylene (C2, since it has two carbon atoms), propylene (C3), butadiene (C4), and acetylene. The olefins manufactured are used in the manufacture of polyethylene, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE), and for polystyrene, polyvinyl chloride, ethylene glycol (used along with dimethyl terphthalate, DMT, as feedstock to the polyester manufacturing process), ethanol amines (used as solvents), polyvinyl acetate (used in plastics), polyisoprene (used for synthetic rubber manufacture), polypropylene, acetone (used as a solvent and in cosmetics), isopropanol (used as a solvent and in pharmaceuticals manufacturing), acrylonitrile (used in the manufacture of acrylic fibers and nitrile rubber), propylene glycol (used in pharmaceuticals manufacturing), and polyurethane. Butadiene is used in the manufacture of polybutadiene rubber (PBR) and styrene butadiene rubber (SBR). Other C4 compounds manufactured include butanol, which is used in the manufacture of solvents such as methyl ethyl ketone. The major aromatics (organics having at least one ring structure with six carbon atoms) manufactured include benzene, toluene, xylene, and naphthalene. Other aromatics manufactured include phenol, chlorobenzene, styrene, phthalic and maleic anhydride, nitrobenzene, and aniline. Benzene is generally recovered from cracker streams at petrochemical plants and is used for

Key Issues

The key production and control practices that will lead to compliance with emissions guidelines can be summarized as follows:

Implement an equipment maintenance pro-

gram that minimizes releases of volatile organics, including ethylene oxide, benzene, vinyl chloride, and 1,2-dichloroethane. Install vapor recovery systems to reduce VOC emissions. Use low-NOx burners. Optimize fuel usage. Regenerate and reuse spent catalysts, solvents, and other solutions to the extent feasible. Recycle cooling water and reuse wastewaters. Segregate stormwater from process wastewater.

376

PROJECT GUIDELINES: INDUSTRY SECTOR GUIDELINES

the manufacture of phenol, styrene, aniline, nitrobenzene, sulfonated detergents, pesticides such as hexachlorobenzene, cyclohexane (an important intermediate in synthetic fiber manufacture), and caprolactam, used in the manufacture of nylon. Benzene is also used as a solvent. The main uses of toluene are as a solvent in paints, rubber, and plastic cements and as a feedstock in the manufacture of organic chemicals, explosives, detergents, and polyurethane foams. Xylenes (which exist as three isomers) are used in the manufacture of DMT, alkyd resins, and plasticizers. Naphthalene is mainly used in the manufacture of dyes, pharmaceuticals, insect repellents, and phthalic anhydride (used in the manufacture of alkyd resins, plasticizers, and polyester). The largest user of phenol in the form of thermosetting resins is the plastics industry. Phenol is also used as a solvent and in the manufacture of intermediates for pesticides, pharmaceuticals, and dyestuffs. Styrene is used in the manufacture of synthetic rubber and polystyrene resins. Phthalic anhydride is used in the manufacture of DMT, alkyd resins, and plasticizers such as phthalates. Maleic anhydride is used in the manufacture of polyesters and, to some extent, for alkyd resins. Minor uses include the manufacture of malathion and soil conditioners. Nitrobenzene is used in the manufacture of aniline, benzidine, and dyestuffs and as a solvent in polishes. Aniline is used in the manufacture of dyes, including azo dyes, and rubber chemicals such as vulcanization accelerators and antioxidants.

Sources

Bounicore, Anthony J., and Wayne T. Davis, eds. 1992. Air Pollution Engineering Manual. New York: Van Nostrand Reinhold. Cortes, Mariluz, and Peter Bocock. 1984. North-South Technology Transfer: A Case Study of Petrochemicals in Latin America. Baltimore, Md.: The John Hopkins University Press Langley, Roger. 1991. Petrochemicals: An Industry and Its Future. Special Report 2067. London: Economist Intelligence Unit. National Swedish Environmental Protection Board. 1987. Focus on Environmental Impacts of Petrochemical Plants in Stenungsund. SNV. Report 3209. Solna. UNIDO (United Nations Industrial Development Organization). 1994. Report on Consultation on Downstream Petrochemical Industries in Developing Countries in Tehran, Islamic Republic of Iran during November 7 through 11, 1993. Vienna. United Kingdom, Her Majestys Inspectorate of Pollution. 1993. Chief Inspectors Guidance to Inspectors, Environmental Protection Act 1990. Process Guidance Note IPR 4/1: Petrochemical Processes. London: Her Majestys Stationery Office. Vergara, Walter, and Dominique Babelon. 1990. The Petrochemical Industry in Developing Asia: A Review of the Current Situation and Prospects for Development in the 1990s. World Bank Technical Paper 113. Washington, D.C.: World Bank. Vergara, Walter, and Donald Brown. 1988. The New Face of the World Petrochemical Sector: Implications for Developing Countries. World Bank Technical Paper 84. Washington, D.C.: World Bank.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- 2014 Tungsten Carbides As Selective Deoxygenation Catalysts Experimental and Computational Studies of Converting C3 Oxygenates To PropeneDocument9 pages2014 Tungsten Carbides As Selective Deoxygenation Catalysts Experimental and Computational Studies of Converting C3 Oxygenates To PropeneChau MaiPas encore d'évaluation

- Kinetic Modeling of Aqueous-Phase Glycerol Hydrogenolysis in A Batch SlurryDocument10 pagesKinetic Modeling of Aqueous-Phase Glycerol Hydrogenolysis in A Batch SlurryChau MaiPas encore d'évaluation

- 1993 Fuzzy Gain Scheduling of PID Controllers PDFDocument7 pages1993 Fuzzy Gain Scheduling of PID Controllers PDFChau MaiPas encore d'évaluation

- 25 08 16 Developing A Practical Framework For ERP Readiness Assessment Using Fuzzy Analytic Network ProcessDocument11 pages25 08 16 Developing A Practical Framework For ERP Readiness Assessment Using Fuzzy Analytic Network ProcessChau MaiPas encore d'évaluation

- Synthesis of Poly (L-Lactide) and Polyglycolide by PDFDocument5 pagesSynthesis of Poly (L-Lactide) and Polyglycolide by PDFChau MaiPas encore d'évaluation

- Sliding Mode Control Design Based On Ackermann's Formula PDFDocument4 pagesSliding Mode Control Design Based On Ackermann's Formula PDFChau MaiPas encore d'évaluation

- Synthesis of Poly (L-Lactide) and Polyglycolide by PDFDocument5 pagesSynthesis of Poly (L-Lactide) and Polyglycolide by PDFChau MaiPas encore d'évaluation

- Catalytic Conversion of Glycerol To Propylene GlycolDocument215 pagesCatalytic Conversion of Glycerol To Propylene Glycolbarbara_ropePas encore d'évaluation

- 21 2011 Direct Hydrogenolysis of Highly Concentrated Glycerol SolutionsDocument10 pages21 2011 Direct Hydrogenolysis of Highly Concentrated Glycerol SolutionsChau MaiPas encore d'évaluation

- Catalyst Characterization by A Probe Reaction Effect of Tin Addition in PtSnAl2O3Document8 pagesCatalyst Characterization by A Probe Reaction Effect of Tin Addition in PtSnAl2O3Chau MaiPas encore d'évaluation

- 1990 Catalyst Characterization by A Probe Reaction The Number of Active HydrogenDocument13 pages1990 Catalyst Characterization by A Probe Reaction The Number of Active HydrogenChau MaiPas encore d'évaluation

- 08 16 A Comparative Study of Production-Inventory Model For Determining Effective Production Quantity and Safety Stock Level PDFDocument16 pages08 16 A Comparative Study of Production-Inventory Model For Determining Effective Production Quantity and Safety Stock Level PDFChau MaiPas encore d'évaluation

- 08 16 A Serial Inventory System With Supplier Selection and Order Quantity Allocation Considering Transportation CostsDocument23 pages08 16 A Serial Inventory System With Supplier Selection and Order Quantity Allocation Considering Transportation CostsChau MaiPas encore d'évaluation

- 01 09 16 The Current State of Control Loop Performance Monitoring - A Survey PDFDocument10 pages01 09 16 The Current State of Control Loop Performance Monitoring - A Survey PDFChau MaiPas encore d'évaluation

- 01 09 16 A Simple Method For Detection of Stiction in Control ValvesDocument11 pages01 09 16 A Simple Method For Detection of Stiction in Control ValvesChau MaiPas encore d'évaluation

- 01 09 16 A Simple Method For Detecting Valve Stiction in Oscillating Control Loops PDFDocument12 pages01 09 16 A Simple Method For Detecting Valve Stiction in Oscillating Control Loops PDFChau MaiPas encore d'évaluation

- 25 08 16 The Role of Readiness For Change in ERP Implementation Theoretical Bases and Empirical Validation PDFDocument8 pages25 08 16 The Role of Readiness For Change in ERP Implementation Theoretical Bases and Empirical Validation PDFChau MaiPas encore d'évaluation

- 08 16 Economic Order Quantity and Purchasing Price For Items With Imperfect Quality When Inspection Shifts From Buyer To SupplierDocument8 pages08 16 Economic Order Quantity and Purchasing Price For Items With Imperfect Quality When Inspection Shifts From Buyer To SupplierChau MaiPas encore d'évaluation

- 08 16 A Comparative Study of Production-Inventory Model For Determining Effective Production Quantity and Safety Stock Level PDFDocument16 pages08 16 A Comparative Study of Production-Inventory Model For Determining Effective Production Quantity and Safety Stock Level PDFChau MaiPas encore d'évaluation

- 1993 Fuzzy Gain Scheduling of PID Controllers PDFDocument7 pages1993 Fuzzy Gain Scheduling of PID Controllers PDFChau MaiPas encore d'évaluation

- 1999 Effect of The Alumina Phase and Its Modification On NiAl2O3 Catalysts For The Hydrodechlorination of 1,2,4-TrichlorobenzeneDocument13 pages1999 Effect of The Alumina Phase and Its Modification On NiAl2O3 Catalysts For The Hydrodechlorination of 1,2,4-TrichlorobenzeneChau MaiPas encore d'évaluation

- 2012 Aqueous Phase Hydrogenolysis of Glycerol To Bio-Propylene Glycol Over PT SN CatalystsDocument4 pages2012 Aqueous Phase Hydrogenolysis of Glycerol To Bio-Propylene Glycol Over PT SN CatalystsChauPas encore d'évaluation

- Heterogeneous Catalysts Supported On Chiral CarriersDocument13 pagesHeterogeneous Catalysts Supported On Chiral CarriersChau MaiPas encore d'évaluation

- 2007 Heterogeneously Catalysed Partial Oxidation of Acrolein To AcrylicDocument13 pages2007 Heterogeneously Catalysed Partial Oxidation of Acrolein To AcrylicChau MaiPas encore d'évaluation

- 1990 Catalyst Characterization by A Probe Reaction The Number of Active HydrogenDocument13 pages1990 Catalyst Characterization by A Probe Reaction The Number of Active HydrogenChau MaiPas encore d'évaluation

- 2011 Development of Sodium Alkoxide Catalysts From PolyolsDocument169 pages2011 Development of Sodium Alkoxide Catalysts From PolyolsChau MaiPas encore d'évaluation

- 1 s2.0 S0960852411008935 MainDocument5 pages1 s2.0 S0960852411008935 MainChau MaiPas encore d'évaluation

- WO2013008279A1 Process For Preparing Catalyst Used in Production of Acrolein andDocument25 pagesWO2013008279A1 Process For Preparing Catalyst Used in Production of Acrolein andChau MaiPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Recipes For MilletsDocument20 pagesRecipes For MilletsRavi TejaPas encore d'évaluation

- Test 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsDocument7 pagesTest 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsChrisPas encore d'évaluation

- Atp InvetigationDocument6 pagesAtp InvetigationHussain IbrahimPas encore d'évaluation

- Effects of Silicon Surfactant in Rigid Polyurethane FoamsDocument7 pagesEffects of Silicon Surfactant in Rigid Polyurethane Foamsธนพล กัตติยบุตรPas encore d'évaluation

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCPas encore d'évaluation

- Mill Inspection Certificate 質 量 証 明 書: Changshu Walsin Specialty Steel Co.,Ltd. 常熟華新特殊鋼有限公司Document4 pagesMill Inspection Certificate 質 量 証 明 書: Changshu Walsin Specialty Steel Co.,Ltd. 常熟華新特殊鋼有限公司Weipeng LvPas encore d'évaluation

- Organic Chemistry Compounds 9Document30 pagesOrganic Chemistry Compounds 9silvio1980Pas encore d'évaluation

- Dentin Biomodification AgentsDocument56 pagesDentin Biomodification AgentsRevathy M Nair100% (1)

- Chemical Properties of PotassiumDocument4 pagesChemical Properties of PotassiumAfrahSiregarPas encore d'évaluation

- 6.0 ELECTROCHEMISTRYDocument35 pages6.0 ELECTROCHEMISTRYwb4qv7yzvzPas encore d'évaluation

- Composite Propellant 2 PDFDocument9 pagesComposite Propellant 2 PDFAishwarya NPas encore d'évaluation

- Polyester Fiber Production Flow ChartDocument2 pagesPolyester Fiber Production Flow ChartMuhammad Jafor IqbalPas encore d'évaluation

- B183-79 (2014) Standard Practice For Preparation of Low-Carbon Steel For Electroplating PDFDocument3 pagesB183-79 (2014) Standard Practice For Preparation of Low-Carbon Steel For Electroplating PDFdiego rodriguezPas encore d'évaluation

- Ikatan Kovalen Polar Dan Asam Basa - Kimor 2Document29 pagesIkatan Kovalen Polar Dan Asam Basa - Kimor 2akbar_rozaaqPas encore d'évaluation

- CottonDocument16 pagesCottonKushagradhi DebnathPas encore d'évaluation

- Chemical Properties of Soil: pH, CEC & PZCDocument17 pagesChemical Properties of Soil: pH, CEC & PZCHasnat QureshiPas encore d'évaluation

- Busgard Geo 15w40Document2 pagesBusgard Geo 15w40Kaly7Pas encore d'évaluation

- Ultraguard 3% AR-AFFF Foam Concentrate FM Approved: Discharge DevicesDocument2 pagesUltraguard 3% AR-AFFF Foam Concentrate FM Approved: Discharge DevicesPercy Valdera GuerreroPas encore d'évaluation

- General Multi Choice Paper - 3Document4 pagesGeneral Multi Choice Paper - 3Chinni KrishnaPas encore d'évaluation

- 3.2.2 Reaction Rates QPDocument17 pages3.2.2 Reaction Rates QPjasmeet kahlonPas encore d'évaluation

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataPas encore d'évaluation

- Jurnal Arif Algifari 1202072Document15 pagesJurnal Arif Algifari 1202072Minangkabau BreederPas encore d'évaluation

- Subject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. MarksDocument25 pagesSubject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. Markssaeeda shoaibPas encore d'évaluation

- Formulation Development of Albendazole-Loaded Self PDFDocument20 pagesFormulation Development of Albendazole-Loaded Self PDFDiah100% (1)

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document8 pagesAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaPas encore d'évaluation

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταPas encore d'évaluation

- Formula 1955 Organic Hand CreamDocument1 pageFormula 1955 Organic Hand CreamSafiullah KhanPas encore d'évaluation

- Niobium, Titanium AnodizingDocument6 pagesNiobium, Titanium AnodizingCary Brief100% (1)

- Orgo2 Lab Report1Document2 pagesOrgo2 Lab Report1api-382264943Pas encore d'évaluation

- Chapter 2 - The Structure of The Atom p3Document7 pagesChapter 2 - The Structure of The Atom p3lhmooPas encore d'évaluation