Académique Documents

Professionnel Documents

Culture Documents

Metrohm - Titrimetric Analysis of Biofuels

Transféré par

Daniel LieDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metrohm - Titrimetric Analysis of Biofuels

Transféré par

Daniel LieDroits d'auteur :

Formats disponibles

Titrimetric analysis of biofuels

C. Haider and G. Spinnler

Summary

The DIN EN 14214 biodiesel standard stipulates a non-aqueous potentiometric acid-base titration for determining the acid number and a redox titration with sodium thiosulfate solution for the determination of the iodine number. While in the first case the equivalence point is detected by the Solvotrode, the iodine number is determined using a Pt Titrode. Both methods are very user-friendly and characterized by high accuracy and precision. With an acid number of 0.202 mg/g and a iodine number of 114.4 g I2/100 g, the investigated biodiesel sample complies with the limits of 0.5 mg/g and 120 g I2/100g stipulated in DIN EN 14214. According to ASTM D 4806, potentiometric titration of total sulfate in bioethanol with lead nitrate can be performed using a Pb-selective working electrode and a double-junction Ag/AgCl or a glassy-carbon-rod reference electrode. Although both reference electrodes show comparable recovery rates, the latter needs lower maintenance. For both electrodes the ideal operating range is between 1 and 20 ppm sulfate. Corresponding recovery rates are 98109%. Increasing the sulfate standard and the perchloric acid content in commercial bioethanol blends (E85) allows to monitor sulfate contents in the sub-ppm range.

Acid number in biodiesel (EN 14104)

Between 14 and 15 g of the biodiesel sample are dissolved in 50 mL of a bioethanol/diethyl ether mixture (1:1). The titrant is an alcoholic solution of potassium hydroxide (0.1 mol/L). After each titration the Solvotrode is thoroughly rinsed with isopropyl alcohol. The regeneration of the membrane is achieved by immersing the electrode in water for at least three minutes.

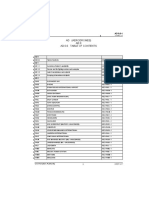

Titer Number of determinations n Mean value Standard deviation Relative standard deviation 3 0.987 0.003 0.34% Acid number 9 0.202 mg/g 0.002 mg/g 0.94%

Sulfate content in bioethanol (ASTM D 7318)

ASTM D 7318 in ASTM D 4806 prescribes a potentiometric titration procedure for the determination of sulfate. 100 g of the bioethanol sample is spiked with known amounts of a sulfate standard. After the addition of 1 mL of 0.1 mol/L perchloric acid the sulfate is precipitated with a lead nitrate solution. The Pb-selective electrode detects the first excess of lead ions at the equivalence point. A double-junction Ag/AgCl or a glassy-carbon-rod electrode are used as the reference electrode.

The acid number determined in the biodiesel sample, in terms of mg KOH per g biodiesel, is 0.202 mg/g. This value complies with the requirements of ASTM D 6751 and EN 14214, which both stipulate a maximal acid number of 0.50 mg/g.

Iodine number in biodiesel (EN 14111)

For the titer determination 50 mg potassium iodate, oven-dried overnight, is dissolved in 80 mL distilled water. After the addition of approximately 1 g of 228.545 potassium iodide and 10 mL of sulfuric acid, the released elemental iodine is titrated with 0.1 mol/L sodium thiosulfate solution. Potentiometric endpoint detection occurs with a Pt Titrode.

Introduction

The interest in biofuels obtained from renewable vegetable sources has greatly increased in recent years. The reasons are the increasing demand for mineral oil as well as the environmental problems linked with burning fossil fuels. In order to avoid disturbances in the injection system and in the engine itself, vehicle and biofuel manufacturers have developed quality standards that define testing methods and specifications for biofuels. While there are two major biodiesel standards, the European EN 14214 and the American ASTM D 6751, there currently exists only one major bioethanol standard, the ASTM D 4806. Its European equivalent, the EN 15376, is currently under development. The determination of the water content of biogenic engine fuels is beyond the scope of this work and is presented under http://products.metrohm.com (search for 8.000.6030EN). Acid number in biodiesel according to EN 14104 The acid number is a sum parameter comprising all acidic components; it serves as a measure for the long-term stability and corrosiveness of the biofuel. The smaller the value, the higher the quality. Standard EN 14104 in DIN EN 14214 stipulates a non-aqueous potentiometric acid-base titration for determining the acid number. Iodine number in biodiesel according to EN 14111 The iodine number is a measure for the number of double bonds in a sample. It specifies the amount of iodine in g that are consumed by 100 g of the biodiesel sample under the given conditions. The determination of the iodine number by redox titration with a solution of sodium thiosulfate is described by the European standard EN 14111. Sulfate content in bioethanol according to ASTM D 7318 Potentiometric titration with lead nitrate is a proven method for sulfate determination, a Pb ISE serving as the indicator electrode. The latter detects the first excess of lead ions at the equivalence point.

Download a copy of this poster from http://products.metrohm.com (search for 8.000.6020EN).

Conc. [ppm] 0.998 4.989 9.978 19.965

a

Double-Junction Ag/AgCl Reference Electrode Sulfate conc.a RSDb nc Recovery rate [%] [%] [ppm] 0.978 5.229 10.047 21.627 0.81 0.41 0.52 1.08 3 4 4 5 98.0 104.8 100.7 108.3

Glassy-Carbon-Rod Electrode Sulfate conc.a RSDb nc Recovery rate [%] [%] [ppm] 1.063 5.268 10.063 21.735 1.46 0.23 0.24 0.75 3 3 3 4 106.5 105.6 100.9 108.9

Determinations n 1 2 3 Mean value Standard deviation Relative standard deviation

Titer 1.0155 1.0188 1.0210 1.0184 0.0027 0.27%

sulfate concentrations determined by potentiometric titration, brelative standard deviation, cnumber of determinations

While sulfate concentrations between 5 and 10 ppm result in recovery rates of 100.7...105.6%, sulfate contents of 1 and 20 ppm provide recovery rates of 98.0...106.5% and 108.3...108.9%, respectively. Sulfate content of an E85 bioethanol sample The low sulfate content in commercial bioethanol fuel blends results in a marginal consumption of lead nitrate, thus impairing the standard deviation. Moreover, a possible lead carbonate formation and weighing errors from evaporation losses falsify the results. In the following, we evaluate the influence of increased sulfate standard and perchloric acid addition on the method precision.

Bioethanol sample E 85 + 0.2 mL sulfate standard (blank) + 1.0 mL perchloric acid (0.1 mol/L) + 0.4 mL sulfate standard (blank) + 2.0 mL perchloric acid (0.1 mol/L)

a

0.15 g of the biodiesel sample is dissolved in 20 mL glacial acetic acid and treated with 25 mL Wijs reagent. After 5 minutes, 15 mL potassium iodide is added. The released elemental iodine is then titrated with 0.1 mol/L sodium thiosulfate solution up to the first end point.

Blank Number of determinations n Mean value thiosulfate consumption [mL] Iodine number [g iodine/100 g sample] Standard deviation Relative standard deviation [%] 3 47.71 Biodiesel 7 33.79 114.40 0.50 0.44

na 3 3

Concentration [mg sulfate/kg sample] 0.348 2.087

RSDb [%] 4.81 0.27

number of titrimetric analyses, brelative standard deviation

The investigated biodiesel sample has a iodine value of 114.4 and thus meets the requirements of EN 14111, which allows a maximal value of 120 g iodine per 100 g sample.

The precision of the determinations is significantly improved by dublicating the content of perchloric acid and sulfate standard. The observed sulfate concentration of 2.087 ppm is below the limit of 4 pm stipulated by ASTM D 4806.

Metrohm AG, CH-9101 Herisau/Switzerland, hc@metrohm.com, phone +41 71 353 86 52

Titration

Vous aimerez peut-être aussi

- 2 ChlorobutaneDocument5 pages2 ChlorobutaneDaniel LiePas encore d'évaluation

- Edwin EmulsificationDocument3 pagesEdwin EmulsificationDaniel LiePas encore d'évaluation

- Goal Seek 2Document1 pageGoal Seek 2Daniel LiePas encore d'évaluation

- PRD Calculation Report - Fire Load CaseDocument1 pagePRD Calculation Report - Fire Load CaseDaniel LiePas encore d'évaluation

- Grands Evenements - EnglDocument14 pagesGrands Evenements - EnglDaniel LiePas encore d'évaluation

- PSV Calculation Report - 2-Phase - Direct Method Sizing CaseDocument1 pagePSV Calculation Report - 2-Phase - Direct Method Sizing CaseDaniel LiePas encore d'évaluation

- Mechanism of Cannizzaro ReactionDocument8 pagesMechanism of Cannizzaro ReactionDaniel LiePas encore d'évaluation

- Imr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDocument2 pagesImr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDaniel LiePas encore d'évaluation

- Material Safety Data Sheet U.S. Department of Labor: Section IDocument2 pagesMaterial Safety Data Sheet U.S. Department of Labor: Section IDaniel LiePas encore d'évaluation

- LucasDocument1 pageLucasDaniel LiePas encore d'évaluation

- How Clothing Evolves: Daniel-XII IPA 3-7Document4 pagesHow Clothing Evolves: Daniel-XII IPA 3-7Daniel LiePas encore d'évaluation

- Aluminum Alkyl HalidesDocument6 pagesAluminum Alkyl HalidesDaniel LiePas encore d'évaluation

- Implementation XBar-R ChartDocument10 pagesImplementation XBar-R ChartDaniel LiePas encore d'évaluation

- 2.c.5.a Copper Production GB2009Document20 pages2.c.5.a Copper Production GB2009Daniel LiePas encore d'évaluation

- Brown Stock WashingDocument5 pagesBrown Stock WashingDaniel LiePas encore d'évaluation

- Experiment PDFDocument4 pagesExperiment PDFDaniel LiePas encore d'évaluation

- Ekstraksi Senyawa Organik Asam, Basa, NetralDocument6 pagesEkstraksi Senyawa Organik Asam, Basa, NetralDaniel LiePas encore d'évaluation

- Basic Troubleshooting (Disc Saveall)Document7 pagesBasic Troubleshooting (Disc Saveall)Daniel Lie100% (1)

- Log Portrait Letter 0x1Document1 pageLog Portrait Letter 0x1Daniel LiePas encore d'évaluation

- NUS Math SyllabusDocument11 pagesNUS Math SyllabusAgus LeonardiPas encore d'évaluation

- Vertical Termosyphon Reboiler: Light Naphtha (XDocument1 pageVertical Termosyphon Reboiler: Light Naphtha (XDaniel LiePas encore d'évaluation

- 5 - I - C - Finding Laplace Transform Examples IIDocument2 pages5 - I - C - Finding Laplace Transform Examples IIDaniel LiePas encore d'évaluation

- Blanco 1989 JoCEDocument3 pagesBlanco 1989 JoCEDaniel LiePas encore d'évaluation

- DI Bio GMP Education ITB Apr 01 2014Document50 pagesDI Bio GMP Education ITB Apr 01 2014Daniel LiePas encore d'évaluation

- Freeness of Pulper Test Method t227Document9 pagesFreeness of Pulper Test Method t227sjvpdktPas encore d'évaluation

- Modelo Doble Helice Watson y CrickDocument2 pagesModelo Doble Helice Watson y Crickangelferp100% (2)

- Enthalpy of Vaporization LabDocument5 pagesEnthalpy of Vaporization LabDaniel LiePas encore d'évaluation

- Lanjutan FileDocument14 pagesLanjutan FileavcjhavcjkvakxPas encore d'évaluation

- M.S - C P I E F: Name First Name Student Number SignatureDocument6 pagesM.S - C P I E F: Name First Name Student Number SignatureDaniel LiePas encore d'évaluation

- Postgraduate Prospectus For 2014 EntryDocument296 pagesPostgraduate Prospectus For 2014 EntryDaniel LiePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Brochure 7900E EN PDFDocument16 pagesBrochure 7900E EN PDFabvs97Pas encore d'évaluation

- Android OpenGL 2.0 PDFDocument14 pagesAndroid OpenGL 2.0 PDFdalaran34100% (1)

- Summer Training ReportDocument133 pagesSummer Training ReportRitesh Meena100% (3)

- Watershed SegmentationDocument19 pagesWatershed SegmentationSan DeepPas encore d'évaluation

- User Manual: Touch Control LED LampDocument1 pageUser Manual: Touch Control LED LampHector LuisPas encore d'évaluation

- Aerodromes PDFDocument522 pagesAerodromes PDFaditya100% (1)

- 007-012518-001 MobilePASS 8 4 2 For Windows Desktop CRN Rev FDocument6 pages007-012518-001 MobilePASS 8 4 2 For Windows Desktop CRN Rev Fvenkatbv78Pas encore d'évaluation

- Modes in Optical FibersDocument10 pagesModes in Optical FibersAdamStone100% (1)

- Working of Fingerprint ScannerDocument5 pagesWorking of Fingerprint ScannerSahana BalasubramanianPas encore d'évaluation

- PSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Document322 pagesPSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Héctor SánchezPas encore d'évaluation

- Bisskey ThaicomDocument8 pagesBisskey Thaicomazroy86Pas encore d'évaluation

- SR No. Beneficiary Name Scheme Name Purpose Amount Utr No. (Bank TXN Id) Bank TXN Date Status Failure Reason Credit Date Uidasper Bank Acctnumber Asperbank Favoringas Perbank Bankiinas PerbankDocument3 pagesSR No. Beneficiary Name Scheme Name Purpose Amount Utr No. (Bank TXN Id) Bank TXN Date Status Failure Reason Credit Date Uidasper Bank Acctnumber Asperbank Favoringas Perbank Bankiinas PerbankAnand ReddyPas encore d'évaluation

- 24 Plait 8ft Bullwhip RecipeDocument9 pages24 Plait 8ft Bullwhip RecipeTyler RicePas encore d'évaluation

- Saniaccess Pump Product SheetDocument1 pageSaniaccess Pump Product SheetArun UdayabhanuPas encore d'évaluation

- ASOC Exam Study Based On Latest Syllabus IndiaDocument238 pagesASOC Exam Study Based On Latest Syllabus IndiaBiju Gopi ThilakaPas encore d'évaluation

- Serdes HandbookDocument98 pagesSerdes HandbookRamesh YadavPas encore d'évaluation

- A4000 Installation ManualDocument10 pagesA4000 Installation ManualMuti FutiPas encore d'évaluation

- Stageverslag Roelofsen Tcm235 882304Document83 pagesStageverslag Roelofsen Tcm235 882304raptor776Pas encore d'évaluation

- Introduction To Weapon & AmmunitionDocument141 pagesIntroduction To Weapon & Ammunitionk2kkhanna105100% (1)

- 4 Leed Open SpaceDocument6 pages4 Leed Open SpaceswapnilupgadePas encore d'évaluation

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDocument7 pagesErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- Mit PDFDocument113 pagesMit PDFAnonymous WXJTn0Pas encore d'évaluation

- Ladle Cleaning Machine Risk Assessment2Document6 pagesLadle Cleaning Machine Risk Assessment2Edgar PenicelaPas encore d'évaluation

- An Overview of Load Flow Analysis Methods For Electrical Distribution NetworksDocument3 pagesAn Overview of Load Flow Analysis Methods For Electrical Distribution NetworksSantosh Ramana Kumar JogaPas encore d'évaluation

- Boostherm DWV 01 2017 ENDocument6 pagesBoostherm DWV 01 2017 ENCarlos LehmanPas encore d'évaluation

- Euro Ncap Aeb Test Protocol v11 PDFDocument31 pagesEuro Ncap Aeb Test Protocol v11 PDFRTCNPas encore d'évaluation

- 12T0070 Atr Fit12Document16 pages12T0070 Atr Fit12expairtisePas encore d'évaluation

- Customer Interface Publication: KCH CIP015Document8 pagesCustomer Interface Publication: KCH CIP01560360155Pas encore d'évaluation

- C3704 2018 PDFDocument122 pagesC3704 2018 PDFHaileyesus Kahsay100% (1)

- Electrical Equipment in Hazardous LocationsDocument41 pagesElectrical Equipment in Hazardous LocationsSAYEDPas encore d'évaluation