Académique Documents

Professionnel Documents

Culture Documents

Arc Strike

Transféré par

Bulut YildizTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Arc Strike

Transféré par

Bulut YildizDroits d'auteur :

Formats disponibles

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

TABLE OF CONTENTS

Volume 2, WELDING FABRICATION PROCEDURE

WFP 2-07 AWS D1.6, STRUCTURAL STAINLESS STEEL................................................................. 2 1.0 PURPOSE AND SCOPE ....................................................................................................................... 2 2.0 REFERENCES .................................................................................................................................... 2 3.0 WELDER QUALIFICATION ................................................................................................................ 2 4.0 WELDING PREREQUISITES................................................................................................................ 2 5.0 MATERIALS ...................................................................................................................................... 2 6.0 BASE MATERIAL JOINT PREPARATION ............................................................................................ 2 7.0 BASE MATERIAL JOINT CLEANING .................................................................................................. 3 8.0 JOINT FIT-UP AND ALIGNMENT ....................................................................................................... 3 9.0 PREHEAT .......................................................................................................................................... 4 10.0 TACK WELDS ................................................................................................................................... 4 11.0 BACKPURGE OR BACKING GAS ....................................................................................................... 4 12.0 INTER-PASS TEMPERATURE ............................................................................................................. 4 13.0 WELD TECHNIQUE ........................................................................................................................... 5 14.0 INSPECTOR QUALIFICATION ............................................................................................................. 6 15.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS .......................................................................... 6 16.0 WELD REPAIRS................................................................................................................................. 8 17.0 POST WELD HEAT TREATMENT ....................................................................................................... 9 18.0 ATTACHMENT WELDS ...................................................................................................................... 9 19.0 ATTACHMENTS................................................................................................................................. 9

RECORD OF REVISIONS

Rev 0 1 Date 8/16/04 10/27/06 Initial issue. Administrative changes only. Organization and contract reference updates from LANS transition. IMP and ISD number changes based on new Conduct of Engineering IMP 341. Other administrative changes. Description POC Kelly Bingham, FWO-DECS Kelly Bingham, FM&E-DES OIC Gurinder Grewal, FWO-DO Kirk Christensen, CENG

Contact the Welding Standards POC for upkeep, interpretation, and variance issues Welding POC/Committee WFP 2-07

Page 1 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

WFP 2-07 AWS D1.6, STRUCTURAL STAINLESS STEEL 1.0 PURPOSE AND SCOPE

A. This welding procedure shall govern the welding of components to the requirements of AWS D1.6 (Reference 1). The Code edition and addenda for this procedure shall be the latest in effect or as otherwise specified by engineering requirements. B. The use of AWS Standard Welding Procedure Specifications (WPS) shall be in accordance with GWS 1.02, Administrative Control of Welding.

2.0 3.0

REFERENCES

1. AWS D1.6, Structural Welding of Stainless Steel

WELDER QUALIFICATION

A. Welder/welding operators shall be currently certified, having performed qualification tests in accordance with GWS 1-05, Welder Performance Qualification & Certification.

4.0

WELDING PREREQUISITES

A. All welding shall comply with the requirements specified in the Welding Procedure Specification (WPS) or Welding Technique Sheet (WTS). B. Welding shall not be performed when the ambient temperature in the immediate vicinity of the weld is lower than 0 F or when surfaces are wet or exposed to rain, snow, dust, or high wind that would adversely affect the shielding properties of the welding process used. The specific preheat and inter-pass temperature are largely dependent on the material types and thickness being welded. Both preheat and inter-pass temperatures shall be in accordance with the approved WPS or WTS.

5.0

MATERIALS

A. Base Materials 1. Only the materials specified in the WPS or WTS may be welded using this procedure. B. Filler Materials 1. Welding filler materials to be used with this procedure are specified in the WPS or WTS. A listing of applicable welding filler materials is provided in GWS 1-07, Material Specifications. 2. Requirements for the purchase and control of welding filler material shall be in accordance with GWS 1-03, Welding and Brazing Material Procurement and Control. 3. Welding filler materials (electrodes, bare filler wire, or consumable inserts) must be utilized by welders making weldments with this procedure. Welders shall not perform welds autogenously.

6.0

BASE MATERIAL JOINT PREPARATION

A. Surfaces and edges to be welded shall be smooth, uniform, and free from fins, tears, cracks,

Page 2 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

and other discontinuities that would adversely affect the quality or strength of the weld. Surface oxides may be removed mechanical methods, chemical cleaning, or other means approved by the engineer. Grinding disks, saw blades, files or other cutting tools that have been used on carbon steel shall not be used on stainless steel material. It is suggested that tools be color coded for use on stainless steel. B. Members to be joined may be cut to shape and size by machining, shearing, chipping, grinding, thermal cutting, or air carbon arc gouging. Notches, gouges or other material discontinuities may be repaired by grinding provided the depth does not exceed the lesser of 1 /8 in. or 20% of the material thickness. Welding repairs to joint surfaces shall be made with the WPS or WTS.

7.0

BASE MATERIAL JOINT CLEANING

A. Prior to welding, surfaces for welding shall be clean and free from paint, oil, rust, scale, slag, grease, and other foreign materials that are detrimental to welding. It may be necessary to remove surface oxides from the base material prior to welding. B. Solvents approved for use on the base material and weld materials are methyl alcohol, ethyl alcohol, isopropyl alcohol, acetone, methyl ethyl ketone, toluene, Varson 4, Dowanol EB, and Stoddard solvents. C. Stainless steel material shall not come in contact with lead, zinc, or lead or zinc compounds due to potential for hot cracking. If contact has occurred between stainless steel and lead or zinc compounds the base material must be cleaned in accordance with an approved cleaning procedure.

8.0

JOINT FIT-UP AND ALIGNMENT

A. Full and complete information regarding the location, type, size, and extent of all welds shall be clearly shown on the drawing. The drawing shall distinguish between shop and field welds and provide any postweld heat treatment information where required. B. The root opening and fit-up tolerances shall be as specified in GWS 1-06, Weld Joint Design. If the tolerances cannot be achieved, the end preparations may be built up by welding or prepared by machining or grinding. Welding repairs to joint surfaces shall be made in accordance with a WPS or WTS. C. The parts to be joined by a tee or fillet weld shall be brought into as close contact as is practicable. The maximum gap between these parts shall not exceed 3/16 in. If the separation is greater than 1/16 in., then each leg of the fillet weld shall be increased by the amount of separation. D. The gap between faying surfaces of lap joints, plug, slot or butt welds landing on a backing shall not exceed 1/16 in.).

Page 3 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

E. Parts to be joined by butt welding shall be carefully aligned to maintain an offset not exceeding 10 % of the thickness of the thinner part joined, but in no case more than 1/8 in. shall be permitted as a departure from the theoretical alignment. In correcting misalignment in such cases, the parts shall not be drawn into a greater slope than inch in 12 in. of length. Measurement of offset shall be based upon centerline of parts unless otherwise shown on the drawing. The degree of angle on the perpendicular member of the joint shall be as specified in engineering standards/documents or drawings. F. Root openings greater than those permitted in AWS D1.6 pre-qualified weld joints or the WPS or WTS, but not greater than twice the thickness of the thinner part or in. which ever is less. Joints may be corrected by welding to acceptable dimensions prior to joining the parts by welding.

9.0

PREHEAT

A. When the base material temperature is below the minimum preheat temperature specified in the WPS or WTS the base material shall be heated such that the surfaces to be welded are at or above the minimum preheat temperature prior to welding. B. The preheat temperature shall be maintained for a distance of at least 3 in. or thickness of the thicker part being joined, on each side of the weld joint and in advance of the welding. C. Preheat temperature above 125 F shall be checked by a surface pyrometer, Tempilstik, or nonmercury-type thermometer. Temperature indicating crayons shall not be used directly in the weld zone.

10.0 TACK WELDS

A. Tack welds shall be subject to the same quality requirements as the final welds. B. Tack welds shall be made by a qualified welder in accordance with an approved Welding WPS or WTS. C. Tack welds to be incorporated into the final weld shall be made with filler material meeting the requirements of the WPS or WTS. D. Defective tack welds shall be removed or repaired prior to welding.

11.0 BACKPURGE OR BACKING GAS

Not applicable.

12.0 INTER-PASS TEMPERATURE

A. Inter-pass temperature shall not exceed 350 F or the maximum value specified in the WPS or WTS and shall be checked on the surface of the component using a surface pyrometer, Tempilstick, or non-mercury-type thermometer. Temperature indicating crayons shall not be used directly in the weld zone. B. If the temperature of the weld is above 350 F or the maximum inter-pass temperature specified in the WPS or WTS, the weld shall be allowed to cool down below the maximum inter-pass temperature, but not below the minimum preheat temperature, prior to resumption of welding. Deminerialized water and clean lint free rags may be used to reduce the temperature to below 350 F or the maximum inter-pass temperature.

Page 4 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

13.0 WELD TECHNIQUE

A. Welding voltage and amperage shall be in accordance with the limits specified in the WPS or WTS. Voltage and amp range gages located on the welding power supply are for reference only and are not mandatory check or hold points. Voltage and amp range checks for documentation purposes shall be performed by a qualified (CWI or equivalent) inspector using calibrated voltage and amp meters or approved welding parameter recording equipment. B. Cracks or blowholes that appear on the surface of a weld bead shall be removed by filing, grinding, chipping, or air carbon arc gouging before depositing the next bead. Oxygen gouging shall not be used on quenched and tempered steel. C. Before welding over previously deposited material, all slag and flux shall be removed, and the weld and at least 1 on either side of adjacent base material shall be brushed clean. This requirement shall apply not only to successive beads but also to the crater area when welding is resumed after any interruption. D. For double-welded butt joints, before applying weld material on the second side to be welded, the root shall be prepared by suitable methods such as chipping, grinding, or air carbon arc gouging to ensure sound material prior to welding. E. The minimum size of a root pass shall be sufficient to prevent cracking, but not less that 1/8. F. The maximum thickness of root passes with SMAW in groove welds shall be in. G. The maximum size of SMAW process single-pass fillet welds and root passes of multiplepass fillet welds shall be:

3 5

/8 in. in the flat position /16 in. in the horizontal and overhead positions

in. in the vertical position.

H. The maximum thickness of SMAW process layers subsequent to root passes of groove and fillet welds shall be: I. J.

1 3

/8 in. for the flat position /16 in. for vertical, overhead, and horizontal positions.

The maximum thickness of weld deposit using the SAW, GMAW, FCAW or GTAW process is identified in the pre-qualified WPS requirements in Table 3.5. of AWS D1.6. When approved by the engineer, peening may be used on intermediate weld layers to mechanically reduce and control distortion or relieve residual stresses created by welding. Peening shall not be performed until 3/8 in. depth of weld has been deposited. Peening shall not be applied to the root, or cover passes, base material, or weld layers requiring nondestructive examination. 1. In assembling and joining parts of a structure or of built-up members and in welding reinforcing parts to members, the procedure and sequence shall be minimize distortion and shrinkage.

K. Control of Distortion and Shrinkage

Page 5 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

2. Insofar as practicable, welds shall be deposited in a sequence that will balance the applied heat of welding while the welding progresses. 3. The welding sequence applied, in conjunction with the WPS or WTS and overall fabrication methods, shall produce members or structures meeting the specified quality requirements. 4. The direction of the general progression in welding on a member shall be from points where the parts are relatively fixed in position with respect to each other toward points where they have a greater relative freedom of movement. 5. Joints expected to have significant shrinkage should usually be welded before joints expected to have lesser shrinkage. Such joints should be welded with as little restraint as possible. 6. Welds under conditions of severe external shrinkage restraint, shall be performed continuous to completion or to a point that will ensure freedom from cracking before the joint is allowed to cool below the minimum specified preheat temperature. 7. If heat straightening is used the procedure must be approved by the engineer. When used, temperatures should not exceed 600 F for ferritic, martensitic, or duplex steels, or 800 F for austenitic stainless steel. L. All welding processes may be single pass or multiple passes per side unless otherwise specified in the WPS or WTS. M. Welding shall be performed single arc unless otherwise specified in the WPS or WTS.

14.0 INSPECTOR QUALIFICATION

A. The Inspector who performs welding inspection for acceptance to this procedure shall be an AWS-CWI, and authorized by the LANL WPA.

15.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS

A. Butt Welds-Statically Loaded 1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, and valleys. 2. The surface condition of the finished welds shall be suitable for the proper interpretation of radiographic and other nondestructive examinations when nondestructive examinations are required. In those cases where there is a question regarding the surface condition on the interpretation of a radiographic film, the film shall be compared to the actual weld surface for interpretation and determination of acceptability. 3. Undercut shall not exceed the following: 0.01 in. for material less than 3/16 in

1 1

/32 in. for material equal to 3/16 in. and less than 1 in.

/16 in. is permitted for an accumulated length of 2 inches in any 12 in., in material greater than in.

1

/16 in. for material equal to or greater than 1 in.

4. Reinforcement should not exceed 1/8 in. in height and shall have gradual transition (not less than 3:1) to the plane of the base material surface.

Page 6 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

5. Complete joint penetration groove welds in butt joints transverse to the direction of computed tensile stress shall have no visible piping porosity. For all other groove welds, the sum of the visible piping porosity 1/32 in. or greater in diameter shall not exceed 3/8 in. in any linear inch of weld and shall not exceed in. in any 12 in. length of weld. 6. Groove welds shall be terminated at the ends of a joint in a manner that will ensure sound welds. This shall be done by use of extension bars or runoff plates or by grinding starts and stops. After the weld is completed, the extension bars or runoff plates shall be removed and the junction ground flush. B. Fillet Welds-Statically Loaded 1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, and valleys. 2. The surface condition of the finished welds shall be suitable for the proper interpretation of nondestructive examinations. 3. Fillet welds may vary from convex to concave. The size of a fillet weld is determined as shown in AWS D1.6. 4. Weld beads shall be continuous through high stress areas such as corners. 5. The minimum fillet weld size, except for fillet welds used to reinforce groove welds, shall be in accordance with AWS D1.6. 6. The weld undercut criteria in 15.A.3 shall be applied to fillet welds 7. The sum of diameters of visible piping porosity 1/32 in. or greater in diameter shall not exceed 3/8 inch in any linear inch of weld and shall not exceed in. in any 12 in. length of weld. 8. The fillet weld in any single continuous weld may be less than the specified fillet size by up to and including 1/16 in.) with correction, provided that the undersized portion of the weld does not exceed 10% of the length of the weld. On web-to-flange welds on girders, fillet weld sizes less than the specified size shall be prohibited at the end for a length equal to twice the width of the flange. C. Butt Welds-Cyclically Loaded 1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, and valleys. 2. The surface condition of the finished welds shall be suitable for the proper interpretation of radiographic and other nondestructive examinations when nondestructive examinations are required. In those cases where there is a question regarding the surface condition on the interpretation of a radiographic film, the film shall be compared to the actual weld surface for interpretation and determination of acceptability. 3. In primary members, as defined in the contract documents, undercut shall be no more than 0.01 in. deep when the weld is transverse to tensile stress under any design loading condition, as shown on the drawings. Undercut shall be no more than 1/32 in. deep for all other applications. 4. Reinforcement should not exceed 1/8 in. in height and shall have gradual transition (equal to or less than 3:1) to the plane of the base material surface.

Page 7 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

5. Complete joint penetration groove welds in butt joints transverse to the direction of computed tensile stress shall have no visible piping porosity. For all other groove welds, the frequency of visible piping porosity shall not exceed one in 4 in. of length of weld and the maximum diameter shall not exceed 3/32 in. 6. Groove welds shall be terminated at the ends of a joint in a manner that will ensure sound welds. This shall be done by use of extension bars or runoff plates or by grinding starts and stops. After the weld is completed, the extension bars or runoff plates shall be removed and the junction ground flush. D. Fillet Welds- Cyclically loaded 1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, and valleys. 2. The surface condition of the finished welds shall be suitable for the proper interpretation of nondestructive examinations. 3. Fillet welds may vary from convex to concave. The size of a fillet weld is determined as shown in AWS D1.6. 4. Weld beads shall be continuous through high stress areas such as corners. 5. The minimum fillet weld size, except for fillet welds used to reinforce groove welds, shall be in accordance with AWS D1.6. 6. The weld undercut criteria in 15.C.3 shall be applied to fillet welds 7. The frequency of visible piping porosity in fillet welds shall not exceed one in 4 in. length of weld and maximum diameter shall not exceed 3/32 in. However for fillet welds connecting stiffeners to web, the sum of the diameter of piping porosity shall not exceed 3 /8 in. in any linear inch of weld and shall not exceed in. in any 12 in. length of weld. 8. The fillet weld in any single continuous weld may be permitted to under-run the nominal fillet weld size specified by 1/16 in. without correction, provided that the undersize portion of the weld does not exceed 10% of the length of the weld. On web-to-flange welds on girders, no under-run is permitted at the ends for a length equal to twice the width of the flange. E. Arc Strikes 1. Grinding or other suitable means may used to remove arc strikes. Cracks or blemishes outside of the area of permanent welds resulting from arc strikes shall also be ground to a smooth contour and examined visually to assure complete removal. Care shall be taken to avoid infringement of the base material thickness.

16.0 WELD REPAIRS

A. Weld repairs shall be performed using the original WPS or WTS or an approved alternate WTS specific to repair, to restore a weld to an acceptable condition. B. The removal of weld material or portions of the base material may be done by machining, grinding, chipping, or air carbon arc gouging. It shall be done in such a manner that the remaining weld material or base material is not nicked or undercut. Unacceptable portions of the weld shall be removed without substantial removal of the base material. The surfaces shall be cleaned thoroughly before welding. Additional weld material shall be deposited using an electrode preferably smaller than that used for making the original weld.

Page 8 of 9

LANL Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure WFP 2-07 AWS D1.6, Structural Stainless Steel

Chapter 13, Welding & Joining Rev. 1, 10/27/06

C. The repaired areas shall be examined visually and where required by the appropriate NDE method. The acceptance criteria applied shall be per the applicable material specification, contract requirement and or Section 6 of AWS D1.6 (Reference 1)

17.0 POST WELD HEAT TREATMENT

A. Post weld heat treatment, when indicated in the engineering specification or in the WPS or WTS, shall be performed in accordance with GWS 1-08, Post Weld Heat Treatment. B. When welds are subject to PWHT, the weld and base material shall be cleaned and visually examined after heat treatment unless otherwise specified. C. When applying PWHT to materials of different thicknesses, the PWHT requirements of the thicker material shall be observed.

18.0 ATTACHMENT WELDS

A. Attachment welds shall be performed in accordance with an approved WPS or WTS. B. Materials used for welded attachments shall be compatible with the base material. C. When applying attachments to materials of different thicknesses, the preheat requirements of the thicker material shall be observed. D. When the specification requires temporary attachments to be removed, a method of removal that will not damage the base material shall be utilized; i.e., grind, or air carbon arc gouge the attachment off and grind the area flush. Welding repairs to material surfaces shall be made with the original WPS or WTS. E. As a minimum, visual examination shall be performed of the area where the temporary attachment was removed to assure permanent materials have not been gouged, nicked or otherwise damaged.

19.0 ATTACHMENTS

None

Page 9 of 9

Vous aimerez peut-être aussi

- Heat Input Calculation From WeldingDocument9 pagesHeat Input Calculation From Weldingemmanuilmoulos6339Pas encore d'évaluation

- Syarikat Kejuruteraan Sistematik Sendirian BerhadDocument3 pagesSyarikat Kejuruteraan Sistematik Sendirian BerhadPat Lim100% (1)

- Cigweld-Deposited Rates PDFDocument7 pagesCigweld-Deposited Rates PDFNam_HitechPas encore d'évaluation

- DVS 2207-3Document12 pagesDVS 2207-3gura9054Pas encore d'évaluation

- PPSC - Product Data Sheet Fusion Bonded EpoxyDocument1 pagePPSC - Product Data Sheet Fusion Bonded EpoxyjulianpirahPas encore d'évaluation

- 00-V016 Quality EHS Record Control Procedure Rev 180311Document5 pages00-V016 Quality EHS Record Control Procedure Rev 180311Tuong NguyenPas encore d'évaluation

- Flame Arrester Installation and Maintenance Instructions ForDocument3 pagesFlame Arrester Installation and Maintenance Instructions Forhk168Pas encore d'évaluation

- Ss Pipe WeldingDocument3 pagesSs Pipe WeldingshridharbshenoyPas encore d'évaluation

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينPas encore d'évaluation

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaPas encore d'évaluation

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Aggregate Sieve Analysis Quality Control and Inspection Report FormDocument1 pageAggregate Sieve Analysis Quality Control and Inspection Report FormMOST PASONPas encore d'évaluation

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Pas encore d'évaluation

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarPas encore d'évaluation

- Flange Tracking LogDocument5 pagesFlange Tracking Logcorey jacobsPas encore d'évaluation

- 13.api 570 Open BookDocument60 pages13.api 570 Open BookAMAL VISHNUPas encore d'évaluation

- Quad Pipe Hydrotest Procedure Rev1Document16 pagesQuad Pipe Hydrotest Procedure Rev1Trust EmmaPas encore d'évaluation

- Pictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Document2 pagesPictures Related To NCR NO.100: Picture 1 (B667) Picture 2 (B642)Mohamed Reda HusseinPas encore d'évaluation

- AKP Storage TanksDocument51 pagesAKP Storage Tankscris_2010Pas encore d'évaluation

- CV - Fabio Madeira en - 082018Document3 pagesCV - Fabio Madeira en - 082018inspetorfabiomadeiraPas encore d'évaluation

- Effect Analysis of An Arc-strike-Induced Defect On The Failure of A Post-Tensioned ThreadbarDocument9 pagesEffect Analysis of An Arc-strike-Induced Defect On The Failure of A Post-Tensioned ThreadbarnaderbahramiPas encore d'évaluation

- Saudi Aramco Standards: WeldingDocument12 pagesSaudi Aramco Standards: WeldingGEORGE IVANPas encore d'évaluation

- Welding TerminologyDocument18 pagesWelding Terminologymahi1437100% (1)

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- I Object: Repair Procedure For Tank BottomDocument6 pagesI Object: Repair Procedure For Tank BottomZouhair BenmabroukPas encore d'évaluation

- Ansi-Aws A5 - 18-93Document37 pagesAnsi-Aws A5 - 18-93skrkulachiPas encore d'évaluation

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandePas encore d'évaluation

- WPS & PQR Review Check List: Asme Sec. Ix Ed.2007Document2 pagesWPS & PQR Review Check List: Asme Sec. Ix Ed.2007KyPas encore d'évaluation

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganPas encore d'évaluation

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDocument7 pagesHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- Welding Inspector: Weld Repairs Section 16Document20 pagesWelding Inspector: Weld Repairs Section 16manojballaPas encore d'évaluation

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarPas encore d'évaluation

- Annex BDocument14 pagesAnnex BPercy Junior Berrios Muñoz100% (1)

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaPas encore d'évaluation

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 pagesInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiPas encore d'évaluation

- Highlights-ASME Guides Preheat-PWHT-VIII PDFDocument5 pagesHighlights-ASME Guides Preheat-PWHT-VIII PDFEr Manish JadaunPas encore d'évaluation

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpPas encore d'évaluation

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariPas encore d'évaluation

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaPas encore d'évaluation

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaPas encore d'évaluation

- API 570 Daily ExamDocument3 pagesAPI 570 Daily Examalouis100% (1)

- P91 MaterialDocument15 pagesP91 MaterialelrajilPas encore d'évaluation

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoPas encore d'évaluation

- Electrode SelectionDocument1 pageElectrode SelectionMel gibsonPas encore d'évaluation

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormMd Shariful IslamPas encore d'évaluation

- Difference Between Wrought Fittings and Forged Fittings - Google GroupsDocument1 pageDifference Between Wrought Fittings and Forged Fittings - Google Groupsim4uim4uim4uPas encore d'évaluation

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasPas encore d'évaluation

- Evaluation of 8090 and Weldalite-049 Aluminum-Lithium AlloysDocument39 pagesEvaluation of 8090 and Weldalite-049 Aluminum-Lithium Alloysskylancer-3441Pas encore d'évaluation

- List of Qualified Welder Summary BLCPDocument2 pagesList of Qualified Welder Summary BLCPpstechnical_43312697Pas encore d'évaluation

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothPas encore d'évaluation

- Pigging TerminologyDocument90 pagesPigging TerminologyNaveen TripuraneniPas encore d'évaluation

- Repair WpsDocument2 pagesRepair WpsyogacruisePas encore d'évaluation

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaPas encore d'évaluation

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument9 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJovanni RodriguezPas encore d'évaluation

- Volume 2, Welding Fabrication ProcedureDocument7 pagesVolume 2, Welding Fabrication ProcedurealouisPas encore d'évaluation

- WFP 2 01 Procedure R1Document8 pagesWFP 2 01 Procedure R1leodavid87Pas encore d'évaluation

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013Pas encore d'évaluation

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument11 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJaveed A. Khan100% (1)

- Fabrication Weld ManualDocument12 pagesFabrication Weld ManualChaidir Transmission100% (2)

- Deltagulf 1559.Document15 pagesDeltagulf 1559.Bulut YildizPas encore d'évaluation

- Princeton Project Management OverviewDocument1 pagePrinceton Project Management OverviewBulut YildizPas encore d'évaluation

- NDT of Welded Steel Tanks1 PDFDocument4 pagesNDT of Welded Steel Tanks1 PDFBulut Yildiz100% (1)

- Infiltration Ventilation LeakageDocument42 pagesInfiltration Ventilation LeakageBulut YildizPas encore d'évaluation

- Coating StandardDocument40 pagesCoating Standardkendo_qn100% (8)

- Unit 1Document29 pagesUnit 1Biswajit MishraPas encore d'évaluation

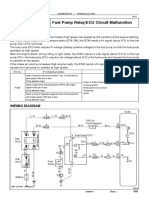

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealPas encore d'évaluation

- Compre Queation PaperDocument6 pagesCompre Queation PaperGanesh DharmireddyPas encore d'évaluation

- Critically Reviewing The Literature ClassDocument32 pagesCritically Reviewing The Literature ClassSoman Rajpoot100% (1)

- CDB Aia - Data Integration - Internship - Detailed HandbookDocument3 pagesCDB Aia - Data Integration - Internship - Detailed HandbookRama KrishnanPas encore d'évaluation

- Infinix NOTE 5 Stylus Quick Guide: Together We Can!Document16 pagesInfinix NOTE 5 Stylus Quick Guide: Together We Can!LescribeurPas encore d'évaluation

- Codigo Ficheros PHPDocument33 pagesCodigo Ficheros PHPm_montielPas encore d'évaluation

- Active Mathematics PDFDocument22 pagesActive Mathematics PDFgoingforward77Pas encore d'évaluation

- Automatic Fruit Image Recognition System Based On Shape and Color FeaturesDocument2 pagesAutomatic Fruit Image Recognition System Based On Shape and Color FeaturesakshayPas encore d'évaluation

- MSC Academic Guide - Admission Test PDFDocument13 pagesMSC Academic Guide - Admission Test PDFTonoy Peter CorrayaPas encore d'évaluation

- TH 2100Document67 pagesTH 2100KI TechnologiesPas encore d'évaluation

- 1.basic Electrical Engineering Lecture Part-1Document17 pages1.basic Electrical Engineering Lecture Part-1jimvalenciaPas encore d'évaluation

- Vector AlgebraDocument7 pagesVector AlgebraDeeePas encore d'évaluation

- Microstructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringDocument5 pagesMicrostructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringLeidy Silvana Chacón VelascoPas encore d'évaluation

- Fatigue Life Prediction - An Overview - ScienceDirect TopicsDocument14 pagesFatigue Life Prediction - An Overview - ScienceDirect TopicsMohamed AlaaElDinPas encore d'évaluation

- Proportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammeDocument66 pagesProportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammealeksandrPas encore d'évaluation

- B28 VivaDocument27 pagesB28 VivashubhamPas encore d'évaluation

- Pseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in ADocument3 pagesPseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in AChristian Doson EstillorePas encore d'évaluation

- AssignmentDocument9 pagesAssignmentRazi BaigPas encore d'évaluation

- Astm Parte 5Document5 pagesAstm Parte 5Jimmy David Espinoza MejiaPas encore d'évaluation

- Science 3 PDFDocument12 pagesScience 3 PDFJelyn CandoPas encore d'évaluation

- IC Project Report Dashboard 10673 0Document6 pagesIC Project Report Dashboard 10673 0Anonymous Sls6WCF100% (2)

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteDocument4 pagesStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniPas encore d'évaluation

- H2 Math PracticeDocument7 pagesH2 Math PracticePhoebe Heng100% (2)

- Direct Synthesis of Sodalite From Kaolin: The Influence of AlkalinityDocument7 pagesDirect Synthesis of Sodalite From Kaolin: The Influence of AlkalinityIsye RahmaenaPas encore d'évaluation

- Evaluating Capital ProjectsDocument254 pagesEvaluating Capital Projectsariff_sodriPas encore d'évaluation

- High-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsDocument3 pagesHigh-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsakhileshPas encore d'évaluation

- Whitepaper 10G Ethernet 10-08Document16 pagesWhitepaper 10G Ethernet 10-08Bogdan IhnatiucPas encore d'évaluation

- Modern Age Waste Water ProblemsDocument364 pagesModern Age Waste Water Problemsromaehab201912Pas encore d'évaluation

- MMW (Data Management) - Part 2Document43 pagesMMW (Data Management) - Part 2arabellah shainnah rosalesPas encore d'évaluation