Académique Documents

Professionnel Documents

Culture Documents

Welding Standard

Transféré par

Sowmen ChakrobortyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welding Standard

Transféré par

Sowmen ChakrobortyDroits d'auteur :

Formats disponibles

Welding Standard for Telcon

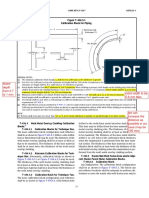

Sl.No. Weld Inspection Items Tolerance Limitation Sketch

Date:

01.09.2010 Rev - 1

Counter Action Against Defect

Missing weld

NOT ACCEPTED

Complete the weld.

Leg Length( L )

L - 1.2 L

INCASE OF DEFECT: Repair by grinding. (Without affecting weld toe) .

Weld under-fill

NOT ACCEPTABLE

Fill it by weld bead.

4(a) Under Cutting 4(b)

Under cut tolerance is 0.4mm (For less than 6 mm plate thickness) Under cut tolerance is 0.5mm For more than 6 mm plate thickness) (

INCASE OF DEFECT: Weld the groove and smooth grinding.

Overlap

The overlap tolerance is 0.3 mm .

IF OVERLAP EXCEED 0.3MM: Excess weld metal must be removed by grinding

6(a)

Bead Surface Blow Holes

Size of blow holes: even one blow hole more than 2mm -- NOT ACCEPTED

Redone by gauging and bead replacement

6(b)

Bead Surface Blow Holes

Number of blow holes: 4 nos/

500 length

IF IT IS MORE THAN 4 NOS / 500 LENGTH: Redone by gauging and bead replacement

Page 1 of 4

Welding Standard for Telcon

Date:

01.09.2010 Rev - 1

6(c)

Bead Surface Blow Holes

Density: 2 NOS within area of

500 mm 2

ACCEPTED.

6(d)

Bead Surface Blow Holes

Density: 3 nos or more within 2 area of 500 mm -- NOT ACCEPTED

Redone by gauging and bead replacement

Crater

Crater depth exceeding 1mm --

REJECTED

a) If no cracks exist, simply fill the crater. b) In case of crater crack, remove and reweld

Grinding mark(W eld finish)

0.1 mm deep within 10mm length -- ACCEPTABLE

If exceeds, weld it followed by smooth grinding.

9(a)

Reinforcement Height

Less than 1.5mm(for less than 12 mm thickness of plate)

IF HEIGHT > 1.5MM: Remove by grinding.

9(b)

Reinforcement Height

Less than 2.5mm(for 12 to 25 mm thickness of plate)

IF HEIGHT > 2.5MM: Remove by dressing.

9(c)

Reinforcement Height

Less than 3mm(for more than 25 mm)

IF HEIGHT > 3 MM: Remove by grinding.

10

Dent / Scratch marks

NO DENT marks are accepted.

Repair by welding and smooth grinding.

Page 2 of 4

Welding Standard for Telcon

Bead width varies, weld bead not straight, ripples are not consistent and spatter --NOT ACCEPTABLE

Date:

01.09.2010 Rev - 1

11

Weld appearance

Remove the bead by gauging and reweld it.

12

Spatter removal

Spatter more than 0.5 mm dia in the area of 300 mm sqr. -- NOT

Remove by grinding/chiseling.

ACCEPTABLE

13

Weld Cracks

Not accepted ( All items with a welding Cracks are rej ected).

Remove the crack completely and Reweld.

14

Bead Shape

Reinforcement angle less than 60 degree)

IF ANGLE EXCEEDS 60 : Remove by dressing.

15

Uneven Bead Width

Bead Width difference Less than 4 mm acceptable in a length of 50mm

IF BEAD WIDTH DIFFERENCE EXCEEDS 4MM: Remove by

grinding.

16

Bead Extension Edge

The bead extension edge shall be smooth.( It is desirable that finger nail is not caught in the extension direction.

Smooth grinding at weld toe region.

17

Bead joint

Bead joint section shall smoothly connected with less bead pile. Bead pile more than 2mm ----

REJECTED Repair the bead with grinder.

Page 3 of 4

Welding Standard for Telcon

Date:

01.09.2010 Rev - 1

18

Lack of fusion

NOT ACCEPTABLE

Remove the bead by gauging and weld caref ully

19

Lack of fusion

NOT ACCEPTABLE

Remove the bead by gauging and weld caref ully

20

Plate 1.6~4.5 mm: Both side

weld (No back-up bar used) 45� + /- 2.5 � Within 1 mm (Plate thickness 4.5 Gap between 28 mm, Groove angle 45 � +/ Backup bar and 2.5 �) Plate joint IF EXCEED 1 MM: Maintain 1mm by hammering to back up bar.

21

22

Plate beyond 28 mm : Both side welding (No back-up bar

used) -- Double V joint.

23

Corner welding

Weld start and stop should be 50mm away from corner j oint.

Acceptable

24

Welding at bead No weld joint is allowed within 50 intersection mm area from bead intersection.

Stress Concentration occurs where weld beads intersect. Accordingly, starting and ending of weld beads (craters) shall not be positioned in this area.

Page 4 of 4

Vous aimerez peut-être aussi

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafiePas encore d'évaluation

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsD'EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsPas encore d'évaluation

- Solution of 5817 Standard PDFDocument37 pagesSolution of 5817 Standard PDFRajesh KumarPas encore d'évaluation

- Appendix 3 Example Report E9Document3 pagesAppendix 3 Example Report E9Laith SalmanPas encore d'évaluation

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocument7 pagesA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekPas encore d'évaluation

- Radiography BookDocument40 pagesRadiography BookBijo Mathew100% (1)

- ISO 5817 Chennai 2011 Pres PDFDocument17 pagesISO 5817 Chennai 2011 Pres PDFcesargamboaPas encore d'évaluation

- Quality Level CDocument17 pagesQuality Level CUgonnaPas encore d'évaluation

- User Guide: API 653 Inspectors ToolboxDocument4 pagesUser Guide: API 653 Inspectors ToolboxBùi Văn HợpPas encore d'évaluation

- CSWIP 3.1U RevisionDocument12 pagesCSWIP 3.1U Revisionayman corePas encore d'évaluation

- API Acceptance CriteriaDocument1 pageAPI Acceptance CriteriaravigurajapuPas encore d'évaluation

- M2.2.3 Visual InspectionDocument11 pagesM2.2.3 Visual InspectionAldy Bagus PratamaPas encore d'évaluation

- Selected Questions From General MechanicalDocument5 pagesSelected Questions From General MechanicalEhab Harb100% (1)

- What Is NDT ?: Detection of Damage Before BreakdownDocument40 pagesWhat Is NDT ?: Detection of Damage Before BreakdownAnik hasan BadhonPas encore d'évaluation

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayPas encore d'évaluation

- A SeriesDocument18 pagesA SeriesĐỗ Thị HuyềnPas encore d'évaluation

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Document29 pagesVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- RT Sensitivity Calculation - TwiDocument2 pagesRT Sensitivity Calculation - TwiTomy GeorgePas encore d'évaluation

- Catalog Fabricante TechnipDocument9 pagesCatalog Fabricante Technipjimy GutiérrezPas encore d'évaluation

- Cordon Off - 4 (00000003)Document1 pageCordon Off - 4 (00000003)Anonymous PlyxbQ3tPas encore d'évaluation

- Helling Katalog NDTDocument43 pagesHelling Katalog NDTjeyaselvanmPas encore d'évaluation

- MR Zubair - NotesDocument39 pagesMR Zubair - NotesAnjali Singh100% (1)

- Quality Level BDocument17 pagesQuality Level BUgonnaPas encore d'évaluation

- Selenium 75Document0 pageSelenium 75vrapciudorianPas encore d'évaluation

- ButtWelding Is 11790 1986Document11 pagesButtWelding Is 11790 1986kathir1965Pas encore d'évaluation

- 00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysDocument14 pages00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysStevanNikolicPas encore d'évaluation

- WIS 5 EOCA QuestionsDocument31 pagesWIS 5 EOCA QuestionsAli ClubistPas encore d'évaluation

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedPas encore d'évaluation

- Cswip DocumentDocument23 pagesCswip DocumentAmit KumarPas encore d'évaluation

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Document4 pagesCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Ahmed Hassan100% (1)

- WIS5 PRO NDocument71 pagesWIS5 PRO NRob WillestonePas encore d'évaluation

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroPas encore d'évaluation

- Acceptance CriteriaDocument19 pagesAcceptance CriteriaAnonymous 5iv0i3cZPas encore d'évaluation

- NDT Code Book Made Easy For AsmeDocument398 pagesNDT Code Book Made Easy For AsmeJosé Pablo Espinoza SolísPas encore d'évaluation

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamPas encore d'évaluation

- Piping TCG Caliberation BlockDocument1 pagePiping TCG Caliberation BlockAhmed Abd ElmegeedPas encore d'évaluation

- WeldingDocument21 pagesWeldingprabhatkumar_6657012Pas encore d'évaluation

- Senior Welding Inspection: Weld Procedures Course Reference WIS 10Document21 pagesSenior Welding Inspection: Weld Procedures Course Reference WIS 10Harkynollar HarkyntehyePas encore d'évaluation

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyPas encore d'évaluation

- Scenario 1 S: Lamelar Tearing Occur in Set In? orDocument6 pagesScenario 1 S: Lamelar Tearing Occur in Set In? orBeny ZulPas encore d'évaluation

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayPas encore d'évaluation

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneePas encore d'évaluation

- Technology Multiple Choice Exam 1Document8 pagesTechnology Multiple Choice Exam 1saifullah629Pas encore d'évaluation

- QAPDocument31 pagesQAPlohitha100% (1)

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDocument4 pagesWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedSurendra KamalPas encore d'évaluation

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiPas encore d'évaluation

- CSWIP 3.1 Training Questions For Pipe Butt Weld 3Document5 pagesCSWIP 3.1 Training Questions For Pipe Butt Weld 3ahmad fikriePas encore d'évaluation

- Visual Inspection of Steel Pipes PlatesDocument72 pagesVisual Inspection of Steel Pipes PlatesLiam Choon SengPas encore d'évaluation

- TestDocument6 pagesTestAdil Hasanov100% (2)

- Inconal625 - SAW Study - Final ReportDocument21 pagesInconal625 - SAW Study - Final ReportshibumbPas encore d'évaluation

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Welding Tolerance StandardsDocument6 pagesWelding Tolerance StandardsSowmen_CPas encore d'évaluation

- Comparision of Fabrication TolerancesDocument4 pagesComparision of Fabrication TolerancesSatish Keskar100% (1)

- Standard EN10029Document4 pagesStandard EN10029Florin JipaPas encore d'évaluation

- Tata Steel Bulb Flats BroDocument11 pagesTata Steel Bulb Flats BroMd. Rafique HassanPas encore d'évaluation

- Adhesion Test cc1000 vf1839 d44Document3 pagesAdhesion Test cc1000 vf1839 d44VanesaPas encore d'évaluation

- En 10029Document3 pagesEn 10029Nuran ZorPas encore d'évaluation

- Tolerances As Per Aws D1.1: Structural Welding CodeDocument34 pagesTolerances As Per Aws D1.1: Structural Welding Codeegy purePas encore d'évaluation

- PDS - Duco PU Universal Epoxy Primer SurfacerDocument2 pagesPDS - Duco PU Universal Epoxy Primer SurfacerSowmen ChakrobortyPas encore d'évaluation

- Shot Peening Manual PDFDocument48 pagesShot Peening Manual PDFSowmen Chakroborty100% (1)

- Test Block No. 2 Acc. To EN ISO 3452-3 (Order No. 9992.100) : Description, Application and Handling of TheDocument1 pageTest Block No. 2 Acc. To EN ISO 3452-3 (Order No. 9992.100) : Description, Application and Handling of TheSowmen ChakrobortyPas encore d'évaluation

- Planets and Their EffectsDocument479 pagesPlanets and Their Effectsggajendranath86% (86)

- Iso 8503-1 - 8503-2 - Surface Roughness Comprator PDFDocument4 pagesIso 8503-1 - 8503-2 - Surface Roughness Comprator PDFSowmen ChakrobortyPas encore d'évaluation

- The Scientific Technical Committees (STC'S)Document8 pagesThe Scientific Technical Committees (STC'S)Sowmen ChakrobortyPas encore d'évaluation

- En 1355 K Ed3Document2 pagesEn 1355 K Ed3Sowmen Chakroborty100% (1)

- Us 12e pr1263Document1 pageUs 12e pr1263Janaka MangalaPas encore d'évaluation

- Din en 10293-2005 PDFDocument18 pagesDin en 10293-2005 PDFdepeche1mode100% (1)

- DIN 1690 - 2-TDC of Metallic Casting (Steel Casing)Document16 pagesDIN 1690 - 2-TDC of Metallic Casting (Steel Casing)Sowmen Chakroborty100% (4)

- General Tolerance: Scope of ApplicationDocument1 pageGeneral Tolerance: Scope of ApplicationSowmen ChakrobortyPas encore d'évaluation

- Steel - Equivalent Grades PDFDocument23 pagesSteel - Equivalent Grades PDFSowmen Chakroborty100% (2)