Académique Documents

Professionnel Documents

Culture Documents

CISC 95 Example 002

Transféré par

Bùi Văn HợpDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CISC 95 Example 002

Transféré par

Bùi Văn HợpDroits d'auteur :

Formats disponibles

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 1

CISC 95 Example 002

WIDE FLANGE MEMBER UNDER COMPRESSION & BENDING

EXAMPLE DESCRIPTION

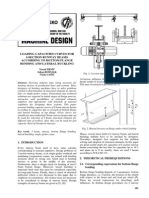

The frame object axial and moment strengths are tested in this example.

In this example a continuous column is subjected factored loads and moments Cf

= 2000 kN; Mfx-top= 200 kN-m; Mfx-bottom= 300 kN-m. This example was tested

using theCSA S16-01 (CISC 95) steel frame design code. The design capacities

are compared with Handbook of Steel construction (6

th

Edition) results.

GEOMETRY, PROPERTIES AND LOADING

2000 kN

TECHNICAL FEATURES TESTED

Section Compactness Check (Compression & Bending)

Member Compression Capacity

Member Bending Capacity with no Mid-Span Loading

Material Properties

E = 200,000 MPa

= 0.3

G= 76,923.08 MPa

Loading Design Properties

fy = 300 MPa

Cf = 2000 kN

Mfx-top = 200 kN-m

Mfx-bottom = 300 kN-m

A

3.7 m

A

Mxf= 200 kN-m

Mxf= 300 kN-m

Section A-A

W310x129

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 2

RESULTS COMPARISON

Independent results are taken from Example 1 on page 4-108 of the Hand Book

of Steel Construction to CSA S16-94 published by Canadian Institute of Steel

Construction..

Output Parameter SAP2000 Independent

Percent

Difference

Compactness Class 1 Class 1 0.00%

Axial Capacity, Cr (kN) 3797.3 3797.3 0.00%

Bending Capacity, Mr33

(kN-m)

583.2 583.2 0.00%

COMPUTER FILE: CISC 95 EX002

CONCLUSION

The results show an acceptable comparison with the independent results.

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 3

HAND CALCULATION

Properties:

Material: CSA G40.21 Grade 300W

fy = 300 MPa

E = 200,000 MPa

G = 76923.08 MPa

Section: W310x129

bf = 308 mm, tf = 20.6 mm, d = 318 mm, tw = 13.1 mm

2 318 2 20.6 276.8

f

h d t mm = = - =

Ag = 16500 mm

2

r33 = 136.626 mm, r22 = 77.8499 mm

I22 = 100,000,000 mm

4

Z33 = 2,160,000 mm

3

J = 2,130,000 mm

4

12 6

2.211 10

w

C mm = -

Member:

lz= le33 = le22 = 3700 mm (unbraced length)

kz=k33 = k22 =1.0

0.9 | =

Loadings:

2000

f

C kN =

,

200

a xf top

M M kN m = =

,

300

b xf bottom

M M kN m = =

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 4

Section Compactness:

Localized Buckling for Flange:

.1

145 145

8.37

300

Cl

y

F

= = =

308

7.48

2 2 20.6

f

f

b

t

= = =

-

.1 Cl

< , No localized flange buckling

Flange is Class 1.

Localized Buckling for Web:

300 16500

4950

1000

y y g

C f A kN

-

= = =

.1

1100 1100 2000

1 0.39 1 0.39 53.50

4950 300

f

Cl

y y

C

C F

| |

| |

= = =

|

|

|

\ .

\ .

276.8

21.13

13.1

w

h

t

= = =

.1 Cl

< , No localized web buckling

Web is Class 1.

Section is Class 1

Member Compression Capacity:

Flexural Buckling

n = 1.34 (wide flange section)

22 22

22 33 22

22

1.0 3700 300

max( , ) 0.5859

77.8499 200000

y

f

k l

r E

t

-

= = = = =

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 5

( ) ( )

1 1

2 2 1.34

1.34

1 0.9 16500 300 1 0.5859

n

n

r g y

C A F |

-

= + = - - - +

3797.3

r

C kN =

Section Bending Capacity:

33 33

2,160, 000 300 648

p y

M Z F kN m = = - =

Member Bending Capacity:

2

2

1.75 1.05 0.3 2.5

a a

b b

M M

M M

e

| | | |

= + + s

| |

\ . \ .

2

2

200 200

1.75 1.05 0.3 2.583 2.5

300 300

e

| | | |

= + + = s

| |

\ . \ .

So

2

2.5 e =

2

2

22 22

22 22

u w

E

M EI GJ I C

l l

e t t | |

= +

|

\ .

2

5

5 8 6 8 12

2.5 2 10

2 10 1 10 76923.08 2.13 10 1 10 2.211 10

3700 3700

u

M

t t | | - - -

= - - - - - - + - - -

|

\ .

3842.7039

u

M kN m =

Since

33

0.67

u p

M M > -

33

33 33 33

1.15 1 0.28

p

r p p

u

M

M M M

M

| |

(

= s

(

33

648

1.15 0.9 648 1 0.28 0.9 648

3842.7039

r

M

(

= - - s -

(

Software Verification

PROGRAM NAME:

SAP2000

REVISION NO.:

0

CISC 95 Example 002 - 6

33

639 583.2

r

M = s

33

583.2

r

M kN m =

Vous aimerez peut-être aussi

- CSA S16-01 Example 001Document7 pagesCSA S16-01 Example 001Bùi Văn HợpPas encore d'évaluation

- Design of Crane Runway Beam With ChannelDocument9 pagesDesign of Crane Runway Beam With Channellatyrniang100% (3)

- MonorailDocument13 pagesMonorailleodegarioporralPas encore d'évaluation

- Design Concepts For Jib Cranes PDFDocument12 pagesDesign Concepts For Jib Cranes PDFanthony cordovaPas encore d'évaluation

- CMAA No.70 (2000)Document90 pagesCMAA No.70 (2000)jsyun0831100% (10)

- Lecture 14.4: Crane Runway Girders: Objective/ScopeDocument22 pagesLecture 14.4: Crane Runway Girders: Objective/ScopeScooby DooPas encore d'évaluation

- Spreader Beam DesignDocument5 pagesSpreader Beam DesigntndeshmukhPas encore d'évaluation

- Triangle Plates & Cantilever Beams: Applications, Design, Construction & TestingDocument68 pagesTriangle Plates & Cantilever Beams: Applications, Design, Construction & TestingTatak Bay AhmedPas encore d'évaluation

- Design and Behavior of Jib CranesDocument20 pagesDesign and Behavior of Jib Cranesdicktracy1180% (5)

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISPas encore d'évaluation

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Monorail CalculationDocument10 pagesMonorail CalculationMiftakhu ZaimPas encore d'évaluation

- Introduction To Work Station Cranes (Gobel)Document16 pagesIntroduction To Work Station Cranes (Gobel)Yadi KusmayadiPas encore d'évaluation

- Crane DesignDocument18 pagesCrane DesignSina Enteshari100% (4)

- Tips For Avoiding Crane Runway Problems PDFDocument25 pagesTips For Avoiding Crane Runway Problems PDFLCSPas encore d'évaluation

- KBK Brochure PDFDocument12 pagesKBK Brochure PDFMahendran KuppusamyPas encore d'évaluation

- 181-186 For Web PDFDocument6 pages181-186 For Web PDFdiego.peinado8856100% (1)

- Crane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Document38 pagesCrane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005yercPas encore d'évaluation

- Crane Runway Beam Design Using CSA S16-14 CodeDocument3 pagesCrane Runway Beam Design Using CSA S16-14 CodesergiooiPas encore d'évaluation

- Design Concept For Jib CraneDocument12 pagesDesign Concept For Jib Cranevish5610100% (3)

- Jibcrane 2Document14 pagesJibcrane 2exlexzonPas encore d'évaluation

- ProgressiveCrane E Book OverheadCranesToptoBottomDocument57 pagesProgressiveCrane E Book OverheadCranesToptoBottomsamdol619100% (1)

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraPas encore d'évaluation

- CSA Beam Column DesignDocument21 pagesCSA Beam Column DesignOvidiu PetruescuPas encore d'évaluation

- Calculation DesignDocument25 pagesCalculation DesignMuhammad Fadzil100% (1)

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanPas encore d'évaluation

- GORBEL Jib and Gantry BrochureDocument16 pagesGORBEL Jib and Gantry Brochureaiyubi2Pas encore d'évaluation

- Jib Crane Example ProblemDocument7 pagesJib Crane Example Problemearthboy2u100% (1)

- Conveyor BeltDocument13 pagesConveyor BeltRajesh KumarPas encore d'évaluation

- Jib Crane Design SellDocument13 pagesJib Crane Design Selljafary100% (3)

- Cranerunwayloads bk105 PDFDocument6 pagesCranerunwayloads bk105 PDFmaxamaxaPas encore d'évaluation

- Design of Concentrically Braced FramesDocument22 pagesDesign of Concentrically Braced FramesAnonymous iS33V5100% (1)

- Maintenance and Inspection of BTH LiftersDocument8 pagesMaintenance and Inspection of BTH Liftersrpatel12Pas encore d'évaluation

- Gantry GirderDocument5 pagesGantry GirderDas TadankiPas encore d'évaluation

- Structural and Crane Load Design CriteriaDocument13 pagesStructural and Crane Load Design CriteriaMontoya SantiagoPas encore d'évaluation

- Calculate Design Beam Jib CraneDocument25 pagesCalculate Design Beam Jib Cranejafary100% (14)

- Jib CraneDocument16 pagesJib Cranesuperman3k100% (2)

- Crane Beam DesignDocument4 pagesCrane Beam DesignPat Baker100% (1)

- Steel Structural Design Bolted & Welded Connections RevisedDocument115 pagesSteel Structural Design Bolted & Welded Connections RevisedPratikto WibowoPas encore d'évaluation

- Modeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsDocument8 pagesModeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsAnonymous wWOWz9UnWPas encore d'évaluation

- Design of Lifting Beams PDFDocument10 pagesDesign of Lifting Beams PDFAnonymous x9STa9Pas encore d'évaluation

- 15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneDocument3 pages15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneravirajPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Anitha Hassan KabeerPas encore d'évaluation

- NTC 2008 Example 001Document6 pagesNTC 2008 Example 001Anitha Hassan KabeerPas encore d'évaluation

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerPas encore d'évaluation

- BS 5950-2000 Example 002Document5 pagesBS 5950-2000 Example 002Anitha Hassan KabeerPas encore d'évaluation

- AS 4100-1998 Example 001Document5 pagesAS 4100-1998 Example 001Anitha Hassan KabeerPas encore d'évaluation

- CSA S16 09 Example 001Document7 pagesCSA S16 09 Example 001thanzawtun1981Pas encore d'évaluation

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001thanzawtun1981Pas encore d'évaluation

- NZS-3404-1997 Example 002Document5 pagesNZS-3404-1997 Example 002thanzawtun1981Pas encore d'évaluation

- IS 456-2000 Example 001 PDFDocument4 pagesIS 456-2000 Example 001 PDFwillowdoPas encore d'évaluation

- AS 3600-2009 Ex002Document4 pagesAS 3600-2009 Ex002Antonius AjalahPas encore d'évaluation

- Software Verification: TS 500-2000 Example 002Document4 pagesSoftware Verification: TS 500-2000 Example 002sertackcdgPas encore d'évaluation

- EN 2-2004 Ex002Document4 pagesEN 2-2004 Ex002sertackcdgPas encore d'évaluation

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Win ThanPas encore d'évaluation

- As 3600-01 RC-BM-001Document7 pagesAs 3600-01 RC-BM-001VinnieTranPas encore d'évaluation

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Maribel Isaura Cunurana YapuchuraPas encore d'évaluation

- NTC 2008 Example 002Document14 pagesNTC 2008 Example 002Anitha Hassan KabeerPas encore d'évaluation

- TLDD-0003-2AAT-A03-1005-D1 (Position Layout)Document1 pageTLDD-0003-2AAT-A03-1005-D1 (Position Layout)Bùi Văn HợpPas encore d'évaluation

- Durapac-Cylinder-Single Acting High Tonnage Locking CollarDocument4 pagesDurapac-Cylinder-Single Acting High Tonnage Locking CollarBùi Văn HợpPas encore d'évaluation

- Man TrappedDocument2 pagesMan TrappedBùi Văn HợpPas encore d'évaluation

- MSDS Jotun Jotamastic 80 STD Comp BDocument11 pagesMSDS Jotun Jotamastic 80 STD Comp BBùi Văn HợpPas encore d'évaluation

- 6 - 150 - MQ ModelDocument1 page6 - 150 - MQ ModelBùi Văn HợpPas encore d'évaluation

- Trapped Person Alarm For Cold Room StoresDocument1 pageTrapped Person Alarm For Cold Room StoresBùi Văn HợpPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- Bigos 1954Document22 pagesBigos 1954Bùi Văn HợpPas encore d'évaluation

- Unching OAD Ssignments: T S F P L CDocument4 pagesUnching OAD Ssignments: T S F P L CBùi Văn HợpPas encore d'évaluation

- Proposed Design Criteria For Stiffened Seated Connections To Column WebsDocument25 pagesProposed Design Criteria For Stiffened Seated Connections To Column WebsBùi Văn HợpPas encore d'évaluation

- Thornton 1991Document32 pagesThornton 1991Bùi Văn HợpPas encore d'évaluation

- Aisc Asd-89 Example 002Document5 pagesAisc Asd-89 Example 002Bùi Văn HợpPas encore d'évaluation

- S TN Pun 001Document3 pagesS TN Pun 001Bùi Văn HợpPas encore d'évaluation

- EN 3-2005 Example 002Document5 pagesEN 3-2005 Example 002Bùi Văn HợpPas encore d'évaluation

- Aisc Lrfd-99 Example 002Document7 pagesAisc Lrfd-99 Example 002Bùi Văn HợpPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- AS 4100-1998 Example 003Document6 pagesAS 4100-1998 Example 003Bùi Văn HợpPas encore d'évaluation

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- CISC 95 Example 001Document7 pagesCISC 95 Example 001Bùi Văn HợpPas encore d'évaluation

- Aisc Lrfd-93 Example 001Document7 pagesAisc Lrfd-93 Example 001Bùi Văn HợpPas encore d'évaluation

- Aisc Lrfd-93 Example 001Document7 pagesAisc Lrfd-93 Example 001Bùi Văn HợpPas encore d'évaluation

- BS 5950-1990 Example 001Document5 pagesBS 5950-1990 Example 001Bùi Văn HợpPas encore d'évaluation

- Catalog ASTM A193MDocument2 pagesCatalog ASTM A193MPercy Gonzales LopezPas encore d'évaluation

- Aisc Asd-89 Example 002Document5 pagesAisc Asd-89 Example 002Bùi Văn HợpPas encore d'évaluation

- Aisc Asd-01 Example 001Document5 pagesAisc Asd-01 Example 001Bùi Văn HợpPas encore d'évaluation

- AISC 360-05 Example 002Document6 pagesAISC 360-05 Example 002Bùi Văn HợpPas encore d'évaluation

- AISC 360-10 Example 001Document7 pagesAISC 360-10 Example 001Bùi Văn HợpPas encore d'évaluation

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDocument7 pagesA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiPas encore d'évaluation

- Developments in Prepress Technology (PDFDrive)Document62 pagesDevelopments in Prepress Technology (PDFDrive)Sur VelanPas encore d'évaluation

- Karmex 80df Diuron MsdsDocument9 pagesKarmex 80df Diuron MsdsSouth Santee Aquaculture100% (1)

- Surge Arrester: Technical DataDocument5 pagesSurge Arrester: Technical Datamaruf048Pas encore d'évaluation

- Frito Lay AssignmentDocument14 pagesFrito Lay AssignmentSamarth Anand100% (1)

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandPas encore d'évaluation

- Teralight ProfileDocument12 pagesTeralight ProfileMohammed TariqPas encore d'évaluation

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriPas encore d'évaluation

- Vocabulary Practice Unit 8Document4 pagesVocabulary Practice Unit 8José PizarroPas encore d'évaluation

- scx4521f SeriesDocument173 pagesscx4521f SeriesVuleticJovanPas encore d'évaluation

- Sun Hung Kai 2007Document176 pagesSun Hung Kai 2007Setianingsih SEPas encore d'évaluation

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Document3 pagesSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaPas encore d'évaluation

- Yamaha F200 Maintenance ScheduleDocument2 pagesYamaha F200 Maintenance ScheduleGrady SandersPas encore d'évaluation

- Supply Chain Risk Management: Resilience and Business ContinuityDocument27 pagesSupply Chain Risk Management: Resilience and Business ContinuityHope VillonPas encore d'évaluation

- AdvertisingDocument2 pagesAdvertisingJelena ŽužaPas encore d'évaluation

- Bell WorkDocument26 pagesBell WorkChuột Cao CấpPas encore d'évaluation

- Risk and Uncertainty in Estimating and TenderingDocument16 pagesRisk and Uncertainty in Estimating and TenderingHaneefa ChPas encore d'évaluation

- Atom Medical Usa Model 103 Infa Warmer I - 2 PDFDocument7 pagesAtom Medical Usa Model 103 Infa Warmer I - 2 PDFLuqman BhanuPas encore d'évaluation

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 pagesInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqPas encore d'évaluation

- CoP - 6.0 - Emergency Management RequirementsDocument25 pagesCoP - 6.0 - Emergency Management RequirementsAnonymous y1pIqcPas encore d'évaluation

- Mix Cases UploadDocument4 pagesMix Cases UploadLu CasPas encore d'évaluation

- Resources and Courses: Moocs (Massive Open Online Courses)Document8 pagesResources and Courses: Moocs (Massive Open Online Courses)Jump SkillPas encore d'évaluation

- CNS Manual Vol III Version 2.0Document54 pagesCNS Manual Vol III Version 2.0rono9796Pas encore d'évaluation

- ARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiDocument5 pagesARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiGAURAV DANGARPas encore d'évaluation

- Drug Study TemplateDocument2 pagesDrug Study TemplateKistlerzane CABALLEROPas encore d'évaluation

- Modal Case Data Form: GeneralDocument4 pagesModal Case Data Form: GeneralsovannchhoemPas encore d'évaluation

- On Applied EthicsDocument34 pagesOn Applied Ethicsamanpatel78667% (3)

- Introduction To Radar Warning ReceiverDocument23 pagesIntroduction To Radar Warning ReceiverPobitra Chele100% (1)

- Man Machine Interface SafetyDocument9 pagesMan Machine Interface SafetyVidyesh Viswanathan NairPas encore d'évaluation

- VB 850Document333 pagesVB 850Laura ValentinaPas encore d'évaluation