Académique Documents

Professionnel Documents

Culture Documents

A Rational Approach To Control Valve Sizing

Transféré par

cymyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Rational Approach To Control Valve Sizing

Transféré par

cymyDroits d'auteur :

Formats disponibles

700

I n d . Eng. Chem. Res. 1990, 29, 700-703

A Rational Approach to Control Valve Sizing

T h e sizing of control valves usually involves a trade-off between pump head and control valve size: the bigger the valve, the smaller t h e pressure drop across the valve and t h e lower the pump head. Thus, large valves are desirable from a steady-state energy-consumption viewpoint. However, dynamic rangeability is improved by designing the system for small, high pressure drop control valves. Control valves are often sized on the basis of heuristics, the most common one being t o make the pressure drop over the control valve a t design conditions one-third of the total system pressure drop. In some applications, this rule-of-thumb works well, but in others it is totally inadequate. A more rational procedure is presented in this paper. T h e idea is to specify the maximum and minimum flow rates required. Then the sizes of both the pump and the control valve can be directly calculated. In a majority of chemical engineering processes, the final control element is an automatic control valve which throttles the flow of a manipulated variable. Sizing of control valves is one of the more controversial subjects in process control. The flow rate through a control valve depends on the size of the valve, the pressure drop over the valve, the stem position, and the fluid properties. The design equation for liquids (nonflashing) is design. In case 2 we will size the valve so that it takes a 80 psi pressure drop a t design. Now a higher head pump will be needed: 150 + 40 + 80 = 270 psi. By use of eq 1, both control valves can be sized. Case 1: (design valve AP = 20 psi)

100 = ~,1(o.5)(20)'/2

=j

c,, = 44.72

Case 2: (design valve 1p = 80 psi)

100 = C,2(0.5)(80)'/2* C,, = 22.36

where F is the flow rate in gpm, C, is the valve size coefficient, x is the valve stem position (fraction of wide open), is the fraction of total flow area (from valve flow characteristic curve), sp.gr. is the specific gravity (relative to water), and AI', is the pressure drop over the valve in psi. More detailed equations are available in publications of the control valve manufacturers (for example, the Masonielan Handbook for Control Valve Sizing (1977)) that handle flows of gases, flashing liquids, and critical flows with either English or SI units. The sizing of control valves is a good example of one of the many engineering trade-offs that must be made in designing a plant. Connell (1987) gives a good description of the problem. Consider the process sketched in Figure 1. The engineer's job is to size both the centrifugal pump and the control valve. The bigger the control valve, the less pressure drop it will take. This means a lower head pump can be used and energy costs will be lower because the power consumed by the motor driving the pump will be less. So from a steady-state energy viewpoint, the pressure drop over the control valve at design conditions should be low and the valve should be big. However, from a dynamic control point of view, the pressure drop over the valve should be large and the valve should be small, as will be illustrated below. This type of design gives a system with more rangeability; i.e., the magnitudes of both the positive and negative changes that can be made in the flow rates are increased. Example These effects are most easily seen in a specific example. Suppose the flow rate a t design conditions is 100 gpm, the pressure in the feed tank is atmospheric, the pressure drop over the heat exchanger (A&,) a t the design flow rate is 40 psi, and the pressure in the final tank is 150 psig. Let us assume that we will have the control valve half open ( f ( x , = 0.5) at the design flow and that the specific gravity of the liquid is 1. Two different designs will be examined to show why it is desirable from a dynamic point of view to take more pressure drop over the control valve. In case 1 we will size the valve so that it takes a 20 psi pressure drop a t design flow when it is half open. This means that the pump must produce a differential head of 150 + 40 + 20 = 210 psi at

0888-5885/90/ 2629-0700$02.50/0

Naturally the control valve in case 2 is smaller than that in case 1. A. Maximum Capacity. Now let us see what happens in the two cases when we open the control valve all the way: = 1. Certainly the flow rate will increase, but how much? From a control point of view, we may want to be able to increase the flow substantially. This unknown maximum flow rate is F,,. As the flow rate is increased through the system, the pressure drop over the heat exchanger increases as the square of the flow rate:

APH = 40(Fmax/F~,,)2 = 40(Fm,x/100)2 (2)

The higher flow rate might also reduce the head that the centrifugal pump produces if we are out on the pump curve where head is dropping significantly with throughput. For simplicity, let us assume for the moment that the pump curve is flat. This means that the total pressure drop (APT) across the heat exchanger and the control valve is constant. Therefore, the pressure drop over the control valve must decrease as the pressure drop over the heat exchanger increases:

2, APT

-p

(3)

Substituting in the appropriate numbers for the two cases yields the following results. Case 1: (20 psi design with C,, = 44.72) APT = l p $ e s + 1pp = 20 + 40 = 60 psi

Fmax,l = (44.72)(1.0)[60- 40(F,,,,~/100)~]"~ (4)

Solving for Fmax,, gives 115 gpm. So the maximum flow through the valve is only 15% more than the design flow rate if a 20 psi pressure drop over the valve is used a t design flow rate. The valve pressure drop at Fmax,, is

LPT? = 60 - 40(115/100)2 = 7.1 psi

Note that the pressure drop through the valve at the maximum flow rate is less than a t the design flow rate. Case 2: (80 psi design with C,, = 22.36) APT = 80 + 40 = 120 psi

Fmax,:! = (22.38)(1.0)[120- 40(Fm,x,~/100)2]"2 (5)

Solving for Fmax,2 yields 141 gpm. So the maximum flow

C) 1990 American Chemical Society

Ind. Eng. Chem. Res., Vol. 29, No. 4, 1990 701

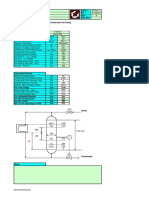

H e a t

E x c hangpr

Feed

To-k

Pump

Con t r o

Va h

Figure 1. Process for pump and control valve design.

through this valve, which has been designed for a higher pressure drop, is over 40% more than design. The valve pressure drop at Fmax,2 is

AP;y = 120 - 40(141/100)2 = 40.5 psi

We can see from the results above that the valve that has been designed for the larger pressure drop can produce more of an increase in the flow rate at its maximum capacity. B. Minimum Turndown. Now consider what happens when we want to reduce the flow. Control valves do not work too well when they are less than about 10% open. They can become mechanically unstable, shutting off completely and then popping partially open. The resulting fluctuations in flow are undesirable. Therefore, we want to design for a minimum valve opening of 10%. Let us see what the minimum flow rates will be in the two cases considered above when the two valves are pinched down so that f ( x , = 0.1. In this case, the lower flow rate will mean a decrease in the pressure drop over the heat exchanger and therefore an increase in the pressure drop over the control valve. Case 1: (20 psi design)

A. Common Heuristic. A commonly used heuristic recommends that the pressure drop over the control valve at design should be 50% of the total pressure drop through the system. Although widely used, this procedure often leads to poorly controlled processes. In the numerical example considered above, if the heat-exchanger pressure drop is 40 psi, the control valve pressure drop at design would be set at 20 psi. This is case 1 considered above. The results showed that the maximum increase in the flow rate was only 15%, and the minimum flow rate was one-third of the design. In some situations, this amount of rangeability is perfectly acceptable, e.g., for a feed flow rate into a process unit. However, in other situations it is very important to be able to substantially increase the flow rate above the design conditions. For example, the cooling water to the jacket of an exothermic chemical reaction may have to be doubled or tripled to handle dynamic upsets. B. Connell Procedure. Connell (1987) proposed a method for determining the design pressure drop over a control valve that used the maximum flow rate and some heuristic safety factors. These factors provide additional valve pressure drop to compensate for possible uncertainty in pressure drops through process equipment and changes in the pressure levels in the vessels a t the inlet or exit of the pump/valve circuit. Connell did not consider the turndown problem. A comparison of valve and pump designs using Connells method and using the proposed procedure will be given later in this paper.

Recommended Design Procedure A more logical approach is to base the design of the control valve and the pump on producing a process that can attain both the maximum and the minimum flow conditions. The design flow conditions are only used to get the pressure drop over the heat exchanger (or fixed resistance part of the process). The designer must specify the maximum flow rate that is required under the worst conditions and the minimum flow rate that is required. Then the valve flow equations for the maximum and minimum conditions give two equations and two unknowns: the pressure head of the centrifugal pump (Up) and the control valve size (CJ. To illustrate the procedure, consider the design a control valve for admitting cooling water to a cooling coil in an exothermic chemical reactor. The normal flow rate is 50 gpm. To prevent reactor runaways, the valve must be able to provide 3 times the design flow rate. Because the sales forecast could be overly optimistic, a minimum flow rate of 50% of the design flow rate must be achieveable. The pressure drop through the cooling coil is 10 psi at a design flow rate of 50 gpm. The cooling water is to be pumped from an atmospheric tank. The water leaving the coil runs into a pipe in which the pressure is constant at 2 psig. The pressure drop through the coil depends on the flow rate (F):

Fmin,l = (0.1)(44.72)[60 - 40(Fmin,1/100)2]z (6)

Solving gives Fmin,l = 33.3 gpm. Case 2: (80 psi design)

Fmin,P = (0.1)(22.36)[120 - 40(Fmin,z/100)2]1iz (7)

Solving gives Fmin,P = 24.2 gpm. These results show that the minimum flow rate is lower for the valve that was designed for a larger pressure drop. So not only can we increase the flow more but we also can to reduce it more. Thus, the turndown (the ratio of Fmax Fminj of the big A I valve is larger: turndown ratio for 20 psi design valve = 115/33.3 = 3.46 turndown ratio for 80 psi design valve = 141/24.2 = 5.83 This specific example demonstrates the increase in rangeability provided by designing for higher pressure drops over control valves. It should be noted that this problem of control valve and pump sizing is independent of considerations of types of control valve trim (linear or equal percentage) and installed versus inherent valve characteristics. These aspects, which are discussed in many of the standard texts (for example, Shinskey (1979)), affect how the flow changes as stem position is changed over its entire range, but they do not affect the maximum and minumum flows through the system.

A I , = 10(F/50)2

(8)

Existing Methods Two methods have been proposed to resolve this conflict between the steady-state energy consumption and rangeability.

The pressure drop over the control valve is the total pressure drop available (which we dont know yet) minus the pressure drop over the coil. We will consider three cases: the first when the pump curve is flat, the second when the pump head decreases linearly with flow rate, and the third when the pump curve is parabolic. A. Flat Pump Curve. If the pump curve is flat, APT is constant:

702 Ind. Eng. Chem. Res., Vol. 29, No. 4, 1990

We can write two equations, one for the maximum flow conditions and one for the minimum flow conditions. At the maximum conditions, 150 = C,(l.o)[flT - 10(150/50)2]"2 (10)

A t the minimum conditions, 25 = c v ( o . l ) [ f l T- 10(25/50)2]"2

(11)

I

Solving simultaneously for the two unknowns yields the control valve size (C, = 21.3) and the pump head ( P p = APT + 2 = 139.2 + 2 = 141.2 psi). A t the design conditions (50 gpm), the valve fraction open (fdes)will be given by 50 = 21.3fdes(139.2* fdes = 0.206

@_ . 5 r_ oe, ~ ~ _ _ _ _

'Pi

F-Jh F?-E

3;'

Figure 2. Parabolic pump curve

(12)

The pressure drop over the valve at design conditions is 129.2 psi, a t maximum flow is 49.2 psi, and at minimum flow is 136.7 psi. This example illustrates how the proposed method determines simultaneously both the control valve size and the pump head. B. Linear Pump Curve. To illustrate the effect of changing centrifugal pump head with flow rate on control valve design, consider the example discussed above but now assume that the pump curve drops off with a constant slope of -0.1 psi/gpm. This means that there is more pressure drop available over the valve at low flow rates and less pressure drop at high rates: PT=APB-0.1F-2 is the pump head at zero flow. where Now the pressure drop over the control valve is (13)

To take a specific case, assume that the pump curve drops 2.5 psi from zero flow to half design flow (50 gpm in our numerical example) and 10 psi from zero flow to design flow (100 gpm). Evaluation of the constants gives a, = 0 and a2 = -0.001. For this case, the pump head is given by u p = AP$ - 0.001F2 (20)

A t the maximum conditions, 150 = C,(l.O)[APOp - 0.001(150)2- 2 - 10(150/50)2]'~2 (21) A t the minimum conditions, 25 = C,(O.l)[APO, - 0.001(25)2- 2 - 10(25/50)2]'/2 (22)

Solving simultaneously for the two unknowns yields the control valve size (C, = 19.1) and the pump head at zero flow (P$ = 176.0 psi). The valve pressure drop at design is 154 psi. Thus, the effect of a variable pump head is to require a larger pressure drop over the valve at design conditions and a smaller control valve. The method discussed above produces designs for both the control valve and the pump. A similar procedure was used by Papastathopoulou and Luyben (1988) for the simultaneous design of the control valve and the heat-exchanger area in the design of flooded-reboiler systems.

AP, = A I ' $

- 0.1F - 2

- 10(F/50)'

(14)

A t the maximum conditions,

150 = C,(l.O)[fl#! - 0.1(150) - 2 - 10(150/50)2]'/2 (15) A t the minimum conditions, 25 = C , ( O . l ) [ f l ~ - 0.1(25) - 2 - 10(25/50)2]'/2 (16) Solving simultaneously for the two unknowns yields the control valve size (C, = 20.0) and the pump head CAP$ = 163.2 psi). The valve pressure drop at design is now 146.2 psi, compared to the flat pump curve valve pressure drop of 129.2 psi. C. Parabolic Pump Curve. To be more realistic, let us consider a pump curve that is parabolic. As a specific example, suppose we can describe the curve by a secondorder polynomial that goes through three points: zero flow, half design flow, and desi n flow. We define the pump head at zero flow to be Up, which we have to determine. We assume that the shape of the pump curve is known so that the change in pump head from zero flow to design flow is @des and the change in pump head from zero flow to half of design flow is A P d e s 1 2 . See Figure 2. The equation giving the pump head at any flow rate (F) is

Comparison with Connell's Method One of the examples given by Connell (1987) was a process that had three heat exchangers, orifice, piping, and a furnace. The total pressure drop of this fixed resistance part of the process a t design flow rate was 124 psi. The maximum flow rate was set a t 1.2 times the design flow rate. Connell recommended a 76 psi valve pressure drop at design flow rate. Assuming a flat pump curve, the total pressure drop available for the process equipment and the control valve was 200 psi. At the maximum flow rate, the equipment pressure drop was 124(1.2)2= 178.6 psi. Thus, the valve pressure drop at maximum flow was 21.4 psi. The valve (C,) can be calculated for this maximum condition: c, = 1.2Fdes/ 21.4'1'. The valve fraction open at design is

= APg

+ a1F + a2F'

(17)

where the constants a, and a2 can be calculated from the known drop-off in the pump curve as flow changes from zero to half design to design:

a' =

*des

4pdes/2

(18)

pdes)

Fdes

The ratio of the minimum flow rate to the design flow rate can be found by solving the equation given below: F,i, = 0.1[ 1.2Fdes/21.41/2] [ 200 - 124(Fmin /FdeS)'] '1' (24) F m i n / F d e s = 0.352 Thus, the Connell procedure for this process gives a system in which the flow can be increased to 120% and reduced to 35% of the design.

2(2apdes/2

a2 =

(19)

Fdes2

Ind. Eng. Chem. Res., Vol. 29, No. 4, 1990 703 In the proposed method, the desired minimum flow must be explicitly specified. If the minimum flow rate were set a t 35% of the design, the two methods would give identical results. If, however, the minimum flow rate were given as 60% of the design, the results from the Connell method would not change since it does not consider turndown. However, the proposed method would give a design that required only a 60.2 psi pressure drop over the valve a t design flow rate. be accomplished by using two control valves in parallel (one large valve and one small valve) that are set up in a split-range configuration. The small valve opens first and then the large valve opens as the signal to the two valve changes over its full range.

Limitations The control valve/pump sizing procedure proposed above is not without its limitations. The two design equations for the maximum and minimum conditions in general terms (for a flat pump curve) are

Conclusion A simple procedure is proposed that provides a rational approach to the problem of designing control valve and pumping systems. The method is based on guaranteeing that both maximum and minimum flow rates can be attained by the system. The designer does not have to rely on heuristics but must define the largest and the smallest flow rates required. Nomenclature ai = coefficients in parabolic pump curve C, = control valve sizing coefficient fdes = fraction of valve opening at design flow rate fma, = fraction of valve opening at maximum flow rate fmin = fraction of valve opening at minimum flow rate Fdes = design flow rate, gpm Fmax = maximum flow rate, gpm Fmin = minimum flow rate, gpm f ( x ) = fraction of valve opening R = rangeability index x = valve stem position (fraction open) @des = change in pump head from zero flow to design flow, PS h p d , / z = change in pump head from zero flow to half of design flow, psi APH = pressure drop over heat exchanger, psi A P T = total pressure drop over heat exchanger and control valve, psi AP, = pressure drop over control valve, psi A P p = pressure head produced by pump, psi 2 0 ,= pressure head produced by pump at zero flow, psi Literature Cited

Connell, J. R. Realistic Control-Valve Pressure Drops. Chem. Eng. 1987, Sept 28, 123. Papastathopoulou, H. S.; Luyben, W. L. Design and Control of Condensate-Throttling Reboilers. Ind. Eng. Chem. Res. 1988,27, 2293-2304. Masonielan Handbook for Control Value Sizing, 6th ed.; Dresser Industries: Houston, TX, 1977. Shinskey, F. G. Process-Control Systems, 2nd ed.; McGraw-Hill: New York, 1979.

Fm, =

Fmin

cv[@T

- (@H),es(Fm,,/Fd,~)~l~/~

(25)

(26) = f m i n c v [ u T - (aPH)de~(Fmin/Fdes)~I~~

where A P T is the total pressure drop through the system a t design flow rates, ( @ + ) d e is the pressure drop through the fixed resistances in the system a t design flow, fmin is the minimum valve opening, and F d e s is the flow rate a t design. Solving these two equations for UT gives

F m a 1 2 - FminZ

It is clear from eq 27 that as the second term in the denominator approaches unity, the required pressure drop goes to infinity! So there is a limit to the achievable rangeability of a system. Let us define this term as the rangeability index of the system, 2:

fminFmax 3%Fmin

The parameters on the right side of eq 28 must be chosen such that R is less than unity. This can be illustrated using the numbers from the example above. If the minimum flow rate is reduced from 50% of the design (where APT was 139.2 psi) to 40%, the is reduced further to new A P T becomes 202 psi. If Fmin 35% of the design, APT is 335 psi. In the limit as F- goes to 30% of the design, the rangeability index becomes

William L. Luyben

Process Modeling and Control Center Department of Chemical Engineering Lehigh University, 111 Research Drive Bethlehem, Pennsylvania 18015 Receiued for reuiew November 3, 1989 Accepted November 17, 1989

Rr-

fminFmax Fmin

(0.1)(150) =1

15

and the total pressure drop required goes to infinity. This limitation can be reduced, if a larger turndown ratio is required, by using a value of fmin below 0.1. This can

Vous aimerez peut-être aussi

- Allowable Vapor Control ValveDocument9 pagesAllowable Vapor Control Valvejohn VilladaPas encore d'évaluation

- Control Valve DPDocument8 pagesControl Valve DPAmit SawantPas encore d'évaluation

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationD'EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationPas encore d'évaluation

- Pumping TrapsDocument36 pagesPumping TrapsjonathanyflorenciaPas encore d'évaluation

- Relief SystemDocument24 pagesRelief SystemFarhanSaatPas encore d'évaluation

- PRV ScenariosDocument5 pagesPRV Scenariosaugur886Pas encore d'évaluation

- Gas Blow-By From A Production Separator To Tank PDFDocument7 pagesGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- BDVDocument3 pagesBDVJason ThomasPas encore d'évaluation

- Traditional Plate Exchanger CalculationDocument3 pagesTraditional Plate Exchanger CalculationAlexander DavidPas encore d'évaluation

- How To Use Vertical Thermosyphon Reboiler CalculatorDocument2 pagesHow To Use Vertical Thermosyphon Reboiler CalculatorMahesh KumarPas encore d'évaluation

- CHEMCAD 7 User Guide PDFDocument154 pagesCHEMCAD 7 User Guide PDFadfPas encore d'évaluation

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsPas encore d'évaluation

- IMTPDocument16 pagesIMTPDHAVALESH AMPas encore d'évaluation

- FluidFlow QuestionsDocument2 pagesFluidFlow Questionssonaldiv100% (2)

- ChemEngReliefPaper2005 PDFDocument34 pagesChemEngReliefPaper2005 PDFNoirchevalPas encore d'évaluation

- Vent Sizing Applications For Reactive SystemsDocument10 pagesVent Sizing Applications For Reactive SystemsAritraDalalPas encore d'évaluation

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 pagesThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaPas encore d'évaluation

- PSV For Super Critical FluidDocument10 pagesPSV For Super Critical FluidMubarik AliPas encore d'évaluation

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884Pas encore d'évaluation

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592Pas encore d'évaluation

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 pagesCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberPas encore d'évaluation

- Tutorial PipeFLoDocument1 pageTutorial PipeFLohel hel100% (1)

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 pagesEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddPas encore d'évaluation

- Reboiler HydraulicDocument3 pagesReboiler Hydraulic54yreyePas encore d'évaluation

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Pas encore d'évaluation

- Flare System DesignDocument2 pagesFlare System Designomar alnasserPas encore d'évaluation

- IVPL Control Valve Sizing ManualDocument20 pagesIVPL Control Valve Sizing ManualGanesh YadavPas encore d'évaluation

- Control Valve Sizing: How to Identify and Troubleshoot Problems On-LineDocument42 pagesControl Valve Sizing: How to Identify and Troubleshoot Problems On-LineSalim AhamedPas encore d'évaluation

- Vessel Depressurization ModelingDocument14 pagesVessel Depressurization ModelingemaengPas encore d'évaluation

- Design of Bubble Cap TrayDocument5 pagesDesign of Bubble Cap TrayVirendra BhagatPas encore d'évaluation

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićPas encore d'évaluation

- PSV Sizing - Blocked Outlet GasDocument1 pagePSV Sizing - Blocked Outlet GasSilas Onyekwe100% (1)

- Steam Condensate Pot Sizing PDFDocument1 pageSteam Condensate Pot Sizing PDFjittshong8072Pas encore d'évaluation

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicsMichael HaisePas encore d'évaluation

- Infytq With SolutionsDocument37 pagesInfytq With SolutionsÃbhilâśh Rêddÿ100% (1)

- Demister DatasheetDocument1 pageDemister Datasheetdeion29Pas encore d'évaluation

- Optimizing Pressure Relief SystemsDocument6 pagesOptimizing Pressure Relief SystemsKimberly ConleyPas encore d'évaluation

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksPas encore d'évaluation

- Steam Control Valve Sizing for Tag PV123Document2 pagesSteam Control Valve Sizing for Tag PV123dilip matalPas encore d'évaluation

- Design of Valve TrayDocument4 pagesDesign of Valve TrayVirendra BhagatPas encore d'évaluation

- Simulation Compresseur PDFDocument85 pagesSimulation Compresseur PDFyamakunPas encore d'évaluation

- Advanced Heat Exchanger Design TechniquesDocument9 pagesAdvanced Heat Exchanger Design Techniquesjdgh1986Pas encore d'évaluation

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32Pas encore d'évaluation

- Improved Control Valve Sizing For Multiphase FlowDocument10 pagesImproved Control Valve Sizing For Multiphase FlowThitikorn WassanarpheernphongPas encore d'évaluation

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarPas encore d'évaluation

- CFD predictions on Liquid Pressure Recovery Factor (FL) for control valvesDocument9 pagesCFD predictions on Liquid Pressure Recovery Factor (FL) for control valvesAshok SureshPas encore d'évaluation

- Ejector technology for efficient and cost effective flare gas recoveryDocument10 pagesEjector technology for efficient and cost effective flare gas recoverySdadPas encore d'évaluation

- Dynamic SimulationDocument22 pagesDynamic SimulationUsama IqbalPas encore d'évaluation

- Consequence AnalyserDocument23 pagesConsequence AnalyserGlacier RamkissoonPas encore d'évaluation

- Relief Load CalculationDocument8 pagesRelief Load CalculationMuthuKumar ArunachalamPas encore d'évaluation

- Tank CalcDocument21 pagesTank CalcInggitPas encore d'évaluation

- Stripping Notes PDFDocument28 pagesStripping Notes PDFnimi khalidPas encore d'évaluation

- Selection, Sizing, and Operation of Control Valves For Gases and LiquidsDocument7 pagesSelection, Sizing, and Operation of Control Valves For Gases and LiquidsAshish ShahPas encore d'évaluation

- Vacuum Distillation in Petroleum RefineryDocument3 pagesVacuum Distillation in Petroleum RefineryAdelmo FilhoPas encore d'évaluation

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentD'EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentPas encore d'évaluation

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesD'EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesPas encore d'évaluation

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7D'EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Pas encore d'évaluation

- A Rational Approach To Control Valve Sizing PDFDocument4 pagesA Rational Approach To Control Valve Sizing PDFDaniaMartínezPas encore d'évaluation

- Avoiding Cavitation in Control Valves: ASHRAE JournalDocument4 pagesAvoiding Cavitation in Control Valves: ASHRAE JournalTONPas encore d'évaluation

- Installed Flow CharacteristicsDocument4 pagesInstalled Flow CharacteristicscymyPas encore d'évaluation

- Counter Current Heat Exchanger CarnahanDocument4 pagesCounter Current Heat Exchanger CarnahancymyPas encore d'évaluation

- Live Solution Tank ExampleDocument6 pagesLive Solution Tank ExamplecymyPas encore d'évaluation

- Nox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetDocument13 pagesNox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetcymyPas encore d'évaluation

- Combustion Equilibrium Calculations: A1 A2 A3 A4Document6 pagesCombustion Equilibrium Calculations: A1 A2 A3 A4cymyPas encore d'évaluation

- Nox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetDocument13 pagesNox Kinetics Calculations - : Cvode Starts at Line 100 On Excel SheetcymyPas encore d'évaluation

- Heat Transfer FinDocument10 pagesHeat Transfer FincymyPas encore d'évaluation

- Example 8.5a (Vapor Ethane)Document4 pagesExample 8.5a (Vapor Ethane)cymyPas encore d'évaluation

- Numerical Solution Economizer Tubes Temperature ProfileDocument2 pagesNumerical Solution Economizer Tubes Temperature ProfilecymyPas encore d'évaluation

- Problem 8.6 DewDocument10 pagesProblem 8.6 DewcymyPas encore d'évaluation

- Air Standard Cycle - Off Design 2: W - AC (KJ/S)Document8 pagesAir Standard Cycle - Off Design 2: W - AC (KJ/S)cymyPas encore d'évaluation

- Problem 8.6 BubbleDocument10 pagesProblem 8.6 BubblecymyPas encore d'évaluation

- Air Standard Cycle - Design Conditions: W - AC (KJ/S)Document6 pagesAir Standard Cycle - Design Conditions: W - AC (KJ/S)cymyPas encore d'évaluation

- Mass Flowrates and Weight %: Styrene FlowsheetDocument1 pageMass Flowrates and Weight %: Styrene FlowsheetcymyPas encore d'évaluation

- Example 6.16aDocument1 pageExample 6.16acymyPas encore d'évaluation

- Example 8.6c (Vapor Condenser)Document2 pagesExample 8.6c (Vapor Condenser)cymyPas encore d'évaluation

- Problem 8.6 L (160.67F)Document3 pagesProblem 8.6 L (160.67F)cymyPas encore d'évaluation

- Linear Data Reconciliation: Narasimhan and Jordache (2000)Document1 pageLinear Data Reconciliation: Narasimhan and Jordache (2000)cymyPas encore d'évaluation

- Example 2.16 ADocument1 pageExample 2.16 AcymyPas encore d'évaluation

- Air Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodDocument6 pagesAir Standard Cycle With HRSG Supplemental Firing: Overall Energy Balance MethodcymyPas encore d'évaluation

- SI - Real Gas - Design: VariablesDocument9 pagesSI - Real Gas - Design: VariablescymyPas encore d'évaluation

- Example 2.17 BDocument2 pagesExample 2.17 BcymyPas encore d'évaluation

- Air Standard Cycle - Design Conditions: W - AC (KJ/S)Document6 pagesAir Standard Cycle - Design Conditions: W - AC (KJ/S)cymyPas encore d'évaluation

- Example 2.17 ADocument2 pagesExample 2.17 AcymyPas encore d'évaluation

- X (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodeDocument1 pageX (0) X (1) X (2) RHS X X X: Newton-Raphson Method All VBA CodecymyPas encore d'évaluation

- Example 2.16 BDocument1 pageExample 2.16 BcymyPas encore d'évaluation

- Ammonia Material Balance using Gauss Jordan and NewtonDocument1 pageAmmonia Material Balance using Gauss Jordan and NewtoncymyPas encore d'évaluation

- Example 2.14Document1 pageExample 2.14cymyPas encore d'évaluation

- Ammonia Material Balances VBA ProgramDocument1 pageAmmonia Material Balances VBA ProgramcymyPas encore d'évaluation

- Styrene Production Alternative Specification SolverDocument1 pageStyrene Production Alternative Specification SolvercymyPas encore d'évaluation

- ppts-ppt-9. AdsorptionDocument35 pagesppts-ppt-9. Adsorptionryu rayPas encore d'évaluation

- Landsat8 Referat EnglDocument45 pagesLandsat8 Referat EnglAlinutza StancescuPas encore d'évaluation

- Drag Force in Flow Over A BodyDocument11 pagesDrag Force in Flow Over A Bodyamin67% (3)

- SAP HPM - Hydrocarbon Product ManagementDocument36 pagesSAP HPM - Hydrocarbon Product ManagementIsaac Andrade100% (3)

- Civil Engineering JournalDocument11 pagesCivil Engineering JournalBiswajit SahooPas encore d'évaluation

- Refining Precious Metals Wastes by CM. HokeDocument369 pagesRefining Precious Metals Wastes by CM. HokeadamdwaldropPas encore d'évaluation

- SPE Method DevelopmentDocument22 pagesSPE Method Developmentalchemist90Pas encore d'évaluation

- Column/Wall Modelling and Finite Element AnalysisDocument7 pagesColumn/Wall Modelling and Finite Element AnalysisA KPas encore d'évaluation

- Qiu Et Al PDFDocument22 pagesQiu Et Al PDFAlejandro Serrano ChavezPas encore d'évaluation

- COLUMN CHROMATOGRAPHY SEPARATES PLANT PIGMENTSDocument4 pagesCOLUMN CHROMATOGRAPHY SEPARATES PLANT PIGMENTSJoshua L. De JesusPas encore d'évaluation

- Maxwell-Boltzmann Velocity DistributionDocument16 pagesMaxwell-Boltzmann Velocity DistributionSheelaPas encore d'évaluation

- Stepan Formulation 149Document2 pagesStepan Formulation 149Suraj PetkarPas encore d'évaluation

- Exercise - Moon MissionDocument14 pagesExercise - Moon Missional3ssi086Pas encore d'évaluation

- Solu of Assignment 4Document8 pagesSolu of Assignment 4dontstopmePas encore d'évaluation

- Re Zuma Teart I Cole 201105Document56 pagesRe Zuma Teart I Cole 201105kevin smithPas encore d'évaluation

- PTI AnchorageDocument18 pagesPTI AnchorageMG Kim100% (1)

- SAGE Profile V6.3.2 User Manual - Volume 3Document55 pagesSAGE Profile V6.3.2 User Manual - Volume 3GodwinPas encore d'évaluation

- Ftre 2014 Sample Paper Class 8 Paper 1Document13 pagesFtre 2014 Sample Paper Class 8 Paper 1Shailendra Walia77% (97)

- Electric Field of Dipole ConfigurationDocument7 pagesElectric Field of Dipole Configurationld393563Pas encore d'évaluation

- Heat Equation Fourier Series SolutionDocument20 pagesHeat Equation Fourier Series SolutionSwen Moreno RosalesPas encore d'évaluation

- Directional Drilling Survey Calculations PDFDocument39 pagesDirectional Drilling Survey Calculations PDFSig BahaPas encore d'évaluation

- A Disc To Produce Subjective Colors.-english-Gustav Theodor Fechner.Document3 pagesA Disc To Produce Subjective Colors.-english-Gustav Theodor Fechner.gabriel brias buendiaPas encore d'évaluation

- D 6520 - 00 Rdy1mjaDocument6 pagesD 6520 - 00 Rdy1mjaFer RomPas encore d'évaluation

- Organic 2 PDFDocument864 pagesOrganic 2 PDFaisyahPas encore d'évaluation

- Daylight Factor: Prasented byDocument8 pagesDaylight Factor: Prasented byDebayan dasPas encore d'évaluation

- 2010 Paper 2 H2 QN PaperDocument20 pages2010 Paper 2 H2 QN PaperHee Jing ShenPas encore d'évaluation

- The Speed and Lifetime of Cosmic Ray Muons: Lululiu@mit - EduDocument6 pagesThe Speed and Lifetime of Cosmic Ray Muons: Lululiu@mit - Edujohnsmith37758Pas encore d'évaluation

- UmbraDocument3 pagesUmbramaplecookiePas encore d'évaluation

- Mechanical ToyDocument10 pagesMechanical ToyPaul Lau100% (1)

- Analyzing Simple Structures in Engineering Mechanics (CENG1041Document9 pagesAnalyzing Simple Structures in Engineering Mechanics (CENG1041nvnrevPas encore d'évaluation