Académique Documents

Professionnel Documents

Culture Documents

04 Section 3 Flowcharts (E)

Transféré par

Namelezz ShadowwTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

04 Section 3 Flowcharts (E)

Transféré par

Namelezz ShadowwDroits d'auteur :

Formats disponibles

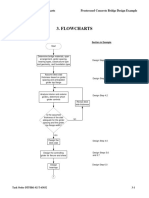

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

3. FLOWCHARTS

Main Design Steps

Section in Example Start

Determine bridge materials, span arrangement, girder spacing, bearing types, substructure type and geometry, and foundation type

Design Step 2.0

Assume deck slab thickness based on girder spacing and anticipated girder top flange

Design Step 4.2

Analyze interior and exterior girders, determine which girder controls

Design Step 4.2 Revise deck slab thickness

Is the assumed thickness of the slab adequate for the girder spacing and the girder top flange width?

NO

YES

Design the deck slab

Design Step 4.0

Design the controlling girder for flexure and shear

Design Steps 5.6 and 5.7

Design bearings

Design Step 6.0

Task Order DTFH61-02-T-63032

3-1

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Main Design Steps (cont.)

Section in Example

Design integral abutments

Design Step 7.1

Design intermediate pier and foundation

Design Step 7.2

End

Task Order DTFH61-02-T-63032

3-2

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Deck Slab Design

Section in Example Start

Assume a deck slab thickness based on girder spacing and width of girder top flange

Design Step 4.2

Determine the location of the critical section for negative moment based on the girder top flange width (S4.6.2.1.6)

Design Step 4.6

Determine live load positive and negative moments (A4)

Design Step 4.7

Determine dead load positive and negative moment

Design Steps 4.8 and 4.9

Determine factored moments (S3.4)

Design Step 4.8

Design main reinforcement for flexure (S5.7.3)

Determine longitudinal distribution reinforcement (S9.7.3.2)

Design Step 4.12

Task Order DTFH61-02-T-63032

3-3

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Deck Slab Design (cont.)

1 Section in Example

For Slabs on Continuous Beams: Steel beam - Determine area of longitudinal reinforcement in the deck in negative moment regions of the girders (S6.10.3.7) Concrete Simple Spans Made Continuous for Live Load Determine the longitudinal slab reinforcement at intermediate pier areas during the design of the girders (S5.14.1.2.7b)

Determine strip width for overhang (S4.6.2.1.3) or where applicable, use S3.6.1.3.4

Design Step 4.10

Determine railing load resistance and rail moment resistance at its base (S13.3)

Design overhang reinforcement for vehicular collision with railing + DL (Case 1 and Case 2 of SA13.4.1)

Determine factored moments from DL + LL on the overhang (Case 3 of SA13.4.1)

Design overhang reinforcement for DL + LL

Determine the controlling case for overhang reinforcement, Case 1, Case 2 or Case 3 Detail reinforcement

Design Step 4.11

End

Task Order DTFH61-02-T-63032

3-4

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

General Superstructure Design (Notice that only major steps are presented in this flowchart. More detailed flowcharts of the design steps follow this flowchart)

Section in Example Start

Assume girder size based on span and girder spacing 2 Determine noncomposite dead load (girder, haunch and deck slab) for the interior and exterior girders

Design Step 2.0

Design Step 5.2

Determine composite dead load (railings, utilities, and future wearing surface) for the interior and exterior girders

Design Step 5.2

Determine LL distribution factors for the interior and exterior girders

Design Step 5.1

Determine unfactored and factored force effects

Design Step 5.3

Determine the controlling girder (interior or exterior) and continue the design for this girder

Task Order DTFH61-02-T-63032

3-5

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

General Superstructure Design (cont.)

1 Section in Example

Determine long-term and short-term prestressing force losses

Design Step 5.4

Design for flexure under Service Limit State

Design Step 5.6

Design for flexure under Strength Limit State

Design for shear under Strength Limit State

Design Step 5.7

Check longitudinal reinforcement for additional forces from shear 2

Did the girder pass all design checks and the calculations indicate the selected girder size leads to an economical design?

NO

Select a different girder size or change strand arrangement

YES

End

Task Order DTFH61-02-T-63032

3-6

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Live Load Distribution Factor Calculations

Section in Example Start

Determine the type of crosssection, Table S4.6.2.2.1-1

Design Step 5.1

Determine the Kg factor (S4.6.2.2.1)

Design Step 5.1.3

For skewed bridges, determine the skew correction factor for moment (if allowed by the owner) (S4.6.2.2.2e) and for shear (S4.6.2.2.3c)

Design Step 5.1.6

Determine LL distribution factors for moment for the interior girder under single lane and multi-lane loading (S4.6.2.2.2b)

Design Step 5.1.5

Determine LL distribution factor for shear for the interior girder under single lane and multi-lane loading (S4.6.2.2.3a)

Design Step 5.1.7

Apply the skew correction factor

Design Step 5.1.8

Task Order DTFH61-02-T-63032

3-7

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Live Load Distribution Factor Calculations (cont.)

1 Section in Example

Determine the controlling (larger) distribution factors for moment and shear for the interior girder

Design Step 5.1.9

Divide the single lane distribution factors by the multiple presence factor for one lane loaded,1.2, to determine the fatigue distribution factors (Notice that fatigue is not an issue for conventional P/S girders. This step is provided here to have a complete general reference for distribution factor calculations.)

Repeat the calculations for the exterior girder using S4.6.2.2.2d for moment and S4.6.2.2.3b for shear

Design Step 5.1.10

Additional check for the exterior girder for bridges with rigidly connected girders

Design Step 5.1.15

End

Task Order DTFH61-02-T-63032

3-8

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Creep and Shrinkage Calculations

Section in Example Start

Calculate the creep coefficient, (t, ti), for the beam at infinite time according to S5.4.2.3.2.

Design Step C1.2

Calculate the creep coefficient, (t,ti), in the beam at the time the slab is cast according to S5.4.2.3.2.

Design Step C1.3

Calculate the prestressed end slope, .

Design Step C1.4

Calculate the prestressed creep fixed end actions

Design Step C1.5

Calculate dead load creep fixed end actions

Design Step C1.6

Determine creep final effects

Design Step C1.7

Task Order DTFH61-02-T-63032

3-9

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Creep and Shrinkage Calculations (cont.)

Section in Example 1

Calculate shrinkage strain in beam at infinite time according to S5.4.2.3.3.

Design Step C2.1

Calculate shrinkage strain in the beam at the time the slab is cast (S5.4.2.3.3).

Design Step C2.2

Calculate the shrinkage strain in the slab at infinite time (S5.4.2.3.3).

Design Step C2.3

Calculate the shrinkage driving end moment, Ms

Design Step C2.5

Analyze the beam for the shrinkage fixed end actions

Design Step C2.6

Calculate the correction factor for shrinkage

Design Step C2.7

Calculate the shrinkage final moments

Design Step C2.8

End

Task Order DTFH61-02-T-63032

3-10

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Prestressing Losses Calculations

Section in Example Start

Determine the stress limit immediately prior to transfer in the prestressing strands for the prestressing steel used (S5.9.3)

Design Step 5.4.2

Determine Instantaneous Losses (S5.9.5.2) for pretensioned members, only Elastic Shortening (S5.9.5.2.3a) is considered

Design Step 5.4.3

Lump Sum

Will the lump sum method or the refined method for time-dependent losses be used?

Refined

Determine the lump sum timedependent losses (S5.9.5.3)

Determine shrinkage loss (S5.9.5.4.2)

Design Step 5.4.6.1

Determine creep loss (S5.9.5.4.3)

Design Step 5.4.6.2

Task Order DTFH61-02-T-63032

3-11

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Prestressing Losses Calculations (cont.)

1 2 Section in Example

Determine relaxation loss at transfer (S5.9.5.4.4b)

Determine losses due to relaxation after transfer (S5.9.5.4.4c)

Design Step 5.4.6.3

Determine time-dependent losses after transfer as the total time-dependent losses minus relaxation losses at transfer

Determine total time-dependent losses after transfer by adding creep, shrinkage and relaxation losses

Design Step 5.4.7

Determine stress in strands immediately after transfer as the stress prior to transfer minus instantaneous losses

Design Step 5.4.4

Determine final stress in strands as stress immediately prior to transfer minus sum of instantaneous loss and timedependent losses after transfer

Design Step 5.4.8

End

Task Order DTFH61-02-T-63032

3-12

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Flexural Design

Section in Example Start

Design controlling girder (interior)

Determine compression and tension stress limits at transfer

Design Step 5.6.1.1

Determine final compression and tension stress limits

Design Step 5.6.2.1

Calculate initial service moment stress in the top and bottom of the prestressed girder

Design Step 5.6.1.2

Calculate final service moment stress in the top and bottom of the prestressed girder Select a different girder size or change strand arrangement Are service stresses within stress limits?

NO

Design Step 5.6.2.2

YES

Task Order DTFH61-02-T-63032

3-13

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

1 2 Section in Example

Design the longitudinal steel at top of girder

Design Step 5.6.3

Calculate factored flexural resistance, Mr, at points of maximum moment (S5.7.3.1)

Design Step 5.6.4

Check the nominal capacity versus the maximum applied factored moment

NG

Select a different girder size or change strand arrangement

OK

Check the maximum and minimum reinforcement (S5.7.3.3.2)

NG

Select a different girder size or change strand arrangement

Design Step 5.6.4.1 and 5.6.4.2

OK Check negative moment connection at intermediate pier

Design Step 5.6.5.1

Task Order DTFH61-02-T-63032

3-14

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

3 Section in Example

Check moment capacity versus the maximum applied factored moment at the critical location for negative moment.

Design Step 5.6.5.1

Check service crack control in negative moment region (S5.5.2)

Design Step 5.6.5.1

Check positive moment connection at intermediate pier

Design Step 5.6.5.2

Check fatigue in prestressed steel (S5.5.3) (Notice that for conventional prestressed beams, fatigue does not need to be checked)

Design Step 5.6.6

Calculate required camber in the beams to determine bearing seat elevations

Design Step 5.6.7.1

Determine the haunch thickness

Design Step 5.6.7.2

Calculate required camber in the beams to determine probable sag in bridge

Design Step 5.6.7.3

Task Order DTFH61-02-T-63032

3-15

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

4 Section in Example

Optional live load deflection check (S2.5.2.6.2)

Design Step 5.6.8

End

Task Order DTFH61-02-T-63032

3-16

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 1, Assumed Angle

Start Section in Example

Determine bv and dv Eq. S5.8.2.9

Design Step 5.7.2.1

Calculate Vp

Calculate shear stress ratio, vu/f'c

Design Step 5.7.2.2

If the section is within the transfer length of any strands, calculate the average effective value of fpo

Design Step 5.7.2.5

If the section is within the development length of any reinforcing bars, calculate the effective value of As

Design Step 5.7.2.5

Assume value of shear crack inclination angle

Design Step 5.7.2.5

Calculate x using Eq. S5.8.3.4.2-1

Task Order DTFH61-02-T-63032

3-17

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 1, Assumed Angle

1

(cont.)

2 Section in Example

Is assumed value of greater than the value determined based on calculated x?

NO

Use the value last determined for

YES

Is assumed value of too conservative, i.e., too high?

YES

NO

Determine transverse reinforcement to ensure Vu <= Vn Eq. S5.8.3.3

Design Step 5.7.2.5

Check minimum and maximum transverse reinforcement requirements S5.8.2.5 and S5.8.2.7

Design Step 5.7.2.3 and 5.7.2.4

Can longitudinal reinforcement resist required tension? Eq. S5.8.3.5

NO

Design Step 5.7.6

YES

Task Order DTFH61-02-T-63032

3-18

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 1, Assumed Angle

3

(cont.)

4 Section in Example

Check bursting resistance (S5.10.10.1)

Design Step 5.7.4

YES

Can you use excess shear capacity to reduce the longitudinal steel requirements in Eq. S5.8.3.5-1?

Choose values of and corresponding to larger x, Table S5.8.3.4.2-1

NO

6 Check confinement reinforcement (S5.10.10.2)

Provide additional longitudinal reinforcement Design Step 5.7.5

Check horizontal shear at interface between beam and deck (S5.8.4)

Design Step 5.7.7

End

Task Order DTFH61-02-T-63032

3-19

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 2, Assumed Strain

Start

Section in Example

Determine bv and dv Eq. S5.8.2.9

Design Step 5.7.2.1

Calculate Vp

Calculate shear stress ratio, vu/f'c

Design Step 5.7.2.2

If the section is within the transfer length of any strands, calculate the average effective value of fpo

Design Step 5.7.2.5

If the section is within the development length of any reinforcing bars, calculate the effective value of As

Design Step 5.7.2.5

Assume value of x and take and from corresponding cell of Table S5.8.3.4.2-1

Calculate x using Eq. S5.8.3.4.2-1

Design Step 5.7.2.5

Task Order DTFH61-02-T-63032

3-20

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 2, Assumed Strain

2 1

(cont.)

3 Section in Example

NO

Is calculated x less than assumed value?

YES

Is assumed value of too conservative, i.e., too high?

YES

NO

Determine transverse reinforcement to ensure Vu <= Vn Eq. S5.8.3.3

Design Step 5.7.2.5

Check minimum and maximum transverse reinforcement requirements S5.8.2.5 and S5.8.2.7

Design Step 5.7.2.3 and 5.7.2.4

Can longitudinal reinforcement resist required tension? Eq. S5.8.3.5

NO

Design Step 5.7.6

YES

Task Order DTFH61-02-T-63032

3-21

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Shear Design Alternative 2, Assumed Strain

4

(cont.)

Section in Example

Check bursting resistance (S5.10.10.1)

Design Step 5.7.4

YES

Can you use excess shear capacity to reduce the longitudinal steel requirements in Eq. S5.8.3.5-1?

Choose values of and corresponding to larger x, Table S5.8.3.4.2-1

NO

7 Check confinement reinforcement (S5.10.10.2)

Provide additional longitudinal reinforcement Design Step 5.7.5

Check horizontal shear at interface between beam and deck (S5.8.4)

Design Step 5.7.7

End

Task Order DTFH61-02-T-63032

3-22

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design Method A (Reference Only)

Start Section in Example

Determine movements and loads at pier support (S14.4)

Calculate required plan area based on compressive stress limit (S14.7.6.3.2)

Determine dimensions L and W of the bearing, W is taken to be slightly less than the width of the girder bottom flange (S14.7.5.1)

Determine the shape factor for steelreinforced elastomeric bearings according to S14.7.5.1

Determine material properties (S14.7.6.2)

Check compressive stress. Determine the maximum allowed shape factor using total load and live load stresses for the assumed plan area (S14.7.6.3.2)

Assume elastomer layer maximum thickness and number of layers

Task Order DTFH61-02-T-63032

3-23

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design Method A (Reference Only) (cont.)

1 Section in Example

Recalculate the shape factor

Determine maximum stress associated with the load conditions inducing the maximum rotation (S14.7.6.3.5)

Check stability of the elastomeric bearing (S14.7.6.3.6)

Reinforcement for steel-reinforced elastomeric bearings is designed according to S14.7.5.3.7

Did bearing pass all checks?

NO

Change plan dimensions, number of layers, and/or thickness of layers

YES

Check if the bearing needs to be secured against horizontal movement (S14.7.6.4)

End

Task Order DTFH61-02-T-63032

3-24

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design Method B

Start Section in Example

Determine movements and loads at pier support (S14.4)

Design Step 6.1

Calculate required plan area of the elastomeric pad based on compressive stress limit (S14.7.5.3.2)

Design Step 6.1.1

Determine dimensions L and W of the bearing, W is taken to be slightly less than the width of the girder bottom flange (S14.7.5.1)

Design Step 6.1.1

Determine material properties (S14.7.5.2)

Check compressive stress. Determine the maximum allowed shape factor using total load and live load stresses for the assumed plan area (S14.7.5.3.2)

Design Step 6.1.2.1

Calculate maximum elastomer interior layer thickness, hri. (S14.7.5.1)

Design Step 6.1.2.1

Task Order DTFH61-02-T-63032

3-25

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design Method B (cont.)

1 Section in Example

Recalculate the shape factor (S14.7.5.1)

Design Step 6.1.2.1

Check compressive deflection if there is a deck joint at the bearing location (S14.7.5.3.3)

Design Step 6.1.2.2

Check shear deformation (S14.7.5.3.4)

Design Step 6.1.2.3

Check combined compression and rotation (S14.7.5.3.5)

Design Step 6.1.2.4

Check stability of elastomeric bearings (S14.7.5.3.6)

Design Step 6.1.2.5

Did bearing pass all checks?

NO

Change plan dimensions, number of layers, and/or thickness of layers

YES

Determine steel reinforcement thickness, hs (S14.7.5.3.7)

Design Step 6.1.2.6

End

Task Order DTFH61-02-T-63032

3-26

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

SUBSTRUCTURE Integral Abutment Design

Start Section in Example

Generate applied dead load and live load for the abutment components.

Design Step 7.1.1

Determine controlling limit state. Factor the loads according to Table S3.4.1-1 to be applied for pile design

Design Step 7.1.2

Check pile compressive resistance (S6.15 and S6.9.2). Determine number of piles and corresponding spacing.

Design Step 7.1.3.1

Design pile cap reinforcement. Check flexure and shear.

Design Step 7.1.4

Check the flexure and shear resistance of the backwall.

Design Step 7.1.4.1

Design wingwall

Design Step 7.1.5

Design approach slab for flexure

Design Step 7.1.6

End

Task Order DTFH61-02-T-63032

3-27

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Intermediate Bent Design

Start Section in Example

Generate the loads applied to the intermediate bent components.

Design Step 7.2.1

Determine maximum loads transferred from the superstructure

Analyze the pier cap. Determine the locations of maximum positive moment, negative moment and shear

Design Step 7.2.2

Design flexural and shear reinforcement in the pier cap

Check limits of reinforcement (S5.7.3.3)

Check flexural reinforcement distribution (S5.7.3.4)

Check minimum temperature and shrinkage steel (S5.10.8)

Design Step 7.2.2.4

Task Order DTFH61-02-T-63032

3-28

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Intermediate Bent Design (cont.)

1 Section in Example

Check skin reinforcement in components where de exceeds 3.0 ft. (S5.7.3.4)

Design Step 7.2.2.5

Design the columns. Determine the maximum moments and shears in the column

Design Step 7.2.3

Check limits for reinforcement in compression members (S5.7.4.2)

Develop the column interaction curve

Check slenderness provisions for concrete columns (S5.7.4.3)

Design Step 7.2.3.1

Determine transverse reinforcement for a compressive member (S5.10.6)

Design Step 7.2.3.2

Design the footing. Determine applied moments and shears transmitted from the columns

Design Step 7.2.4

Task Order DTFH61-02-T-63032

3-29

Design Step 3 Design Flowcharts

Prestressed Concrete Bridge Design Example

Intermediate Bent Design (cont.)

2 Section in Example

Check flexural resistance (S5.7.3.2)

Design Step 7.2.4.1

Check maximum and minimum reinforcement (S5.7.3.3)

Design Step 7.2.4.2

Check distribution of reinforcement for cracking in the concrete (S5.7.3.4)

Design Step 7.2.4.3

Design footing for maximum shear in the longitudinal and transverse directions (one-way shear and punching (two-way) shear)

Design Step 7.2.4.4

Foundation soil resistance at the Strength Limit State (S10.6.3)

Design Step 7.2.4.5

End

Task Order DTFH61-02-T-63032

3-30

Vous aimerez peut-être aussi

- NR 410110 Prestressed ConcreteDocument8 pagesNR 410110 Prestressed ConcreteSrinivasa Rao G100% (2)

- 425-Chp7-Bond Development Length SplicesDocument41 pages425-Chp7-Bond Development Length SplicesAhsan BuriroPas encore d'évaluation

- Prestressed ConcreteDocument154 pagesPrestressed ConcretejohnnPas encore d'évaluation

- No.1 PrestressedDocument10 pagesNo.1 PrestressedKristin ArgosinoPas encore d'évaluation

- Module 4 - QuantityDocument12 pagesModule 4 - QuantityKimberly Wealth Meonada MagnayePas encore d'évaluation

- Methods For Inelastic Analysis of BridgesDocument44 pagesMethods For Inelastic Analysis of BridgesPrijeSamZnaoCitatiPas encore d'évaluation

- Prestress Concrete (24-30)Document33 pagesPrestress Concrete (24-30)Prantik Adhar SamantaPas encore d'évaluation

- Design of Columns Subject To Axial Load and BendingDocument10 pagesDesign of Columns Subject To Axial Load and BendingWilbert ReuyanPas encore d'évaluation

- Module 3 Compression Members Lec #1Document5 pagesModule 3 Compression Members Lec #1k. NotujPas encore d'évaluation

- An Assessment of The Efficiency of RetaiDocument32 pagesAn Assessment of The Efficiency of RetaiWella Wella WellaPas encore d'évaluation

- Ch3 Lateral Earth Pressure 230109Document92 pagesCh3 Lateral Earth Pressure 230109azuan wahariPas encore d'évaluation

- Introduction To Prestressed Concrete Design PDFDocument43 pagesIntroduction To Prestressed Concrete Design PDFMarkVincentTulinaoPas encore d'évaluation

- Notes Ce Laws, Contracts and ObligationsDocument5 pagesNotes Ce Laws, Contracts and ObligationsWilliam LimPas encore d'évaluation

- Analysis of Prestress and Bending Stress: Force 170 KNJ.)Document5 pagesAnalysis of Prestress and Bending Stress: Force 170 KNJ.)Kim JunmyeonPas encore d'évaluation

- A. Read The Following Book Chapters and Other Readings For ReferenceDocument4 pagesA. Read The Following Book Chapters and Other Readings For ReferenceJomar LampitokPas encore d'évaluation

- Two Way Slab AnalysisDocument58 pagesTwo Way Slab AnalysisBaloch Khan100% (1)

- TimberDocument6 pagesTimberzmejiePas encore d'évaluation

- No.2 PrestressedDocument8 pagesNo.2 PrestressedMaria Anthony Macatangay OriolaPas encore d'évaluation

- NSCPDocument1 pageNSCPAngelique EsquillaPas encore d'évaluation

- Steel Module 2 Part 2Document41 pagesSteel Module 2 Part 2Pyro VillanuevaPas encore d'évaluation

- RCD 1Document25 pagesRCD 1Niña Amethyst AlivioPas encore d'évaluation

- Network Diagram Group 6Document8 pagesNetwork Diagram Group 6Klent Evran JalecoPas encore d'évaluation

- Clave, Artemio John C./ 1512117 CE513/ Prestresessed Concrete Design Bsce/ 5 Year/ CE52S2/ Assignment No. 2 Engr. Adams Royce A. DionisioDocument3 pagesClave, Artemio John C./ 1512117 CE513/ Prestresessed Concrete Design Bsce/ 5 Year/ CE52S2/ Assignment No. 2 Engr. Adams Royce A. DionisioDaniel DomingoPas encore d'évaluation

- Shear and Diagonal TensionDocument21 pagesShear and Diagonal TensionJohnvirgo Corpuz0% (1)

- Lecture 6.0 - Analysis and Design For TorsionDocument22 pagesLecture 6.0 - Analysis and Design For TorsionRonnie BarreraPas encore d'évaluation

- Lecture 8 - Design of Short Columns Subject To Axial and BendingDocument39 pagesLecture 8 - Design of Short Columns Subject To Axial and BendingMarcelo AbreraPas encore d'évaluation

- Introduction To Timber DesignnDocument32 pagesIntroduction To Timber DesignnnurulselangorPas encore d'évaluation

- RC Design Lecture 1Document18 pagesRC Design Lecture 1Katherine Shayne Yee100% (1)

- MANUAL - DaMPeR MODULE 8A PRE-EARTHQUAKE RAPID EVALUATION Rev2019 0115Document13 pagesMANUAL - DaMPeR MODULE 8A PRE-EARTHQUAKE RAPID EVALUATION Rev2019 0115Mars TinPas encore d'évaluation

- Chapter 5-Prestressed Concrete DesignDocument51 pagesChapter 5-Prestressed Concrete DesignAzrai AzizPas encore d'évaluation

- Plate No.1 - Autor JoyDocument6 pagesPlate No.1 - Autor JoyJoy lauriaPas encore d'évaluation

- 9 Shear Design LectureDocument31 pages9 Shear Design LectureChristinePas encore d'évaluation

- The NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsDocument33 pagesThe NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsFritze Hansteen OngPas encore d'évaluation

- 18 Structural Engineering ConstructionDocument2 pages18 Structural Engineering ConstructionDex To JarPas encore d'évaluation

- Prestressed Concrete Design: A. Reference: NSCP 2015 and AASHTO 2007 (SI Edition) Philosophy of Prestressed ConcreteDocument15 pagesPrestressed Concrete Design: A. Reference: NSCP 2015 and AASHTO 2007 (SI Edition) Philosophy of Prestressed ConcreteJon SnowPas encore d'évaluation

- 425-Doubly Reinforced Beam Design-S11Document45 pages425-Doubly Reinforced Beam Design-S11Kaye MamisaoPas encore d'évaluation

- Deflection Prestressed ConcreteDocument48 pagesDeflection Prestressed Concreteajith chandranPas encore d'évaluation

- Instructions: General Instructions:: Asia Pacific College of Advanced StudiesDocument2 pagesInstructions: General Instructions:: Asia Pacific College of Advanced StudiesJoshua John JulioPas encore d'évaluation

- Structural Steel Design by Besavilla Download PDFDocument2 pagesStructural Steel Design by Besavilla Download PDFJefferd PaetPas encore d'évaluation

- T Beams 1Document27 pagesT Beams 1Jonniel De GuzmanPas encore d'évaluation

- Review of Related LiteratureDocument14 pagesReview of Related LiteratureDennis LundayPas encore d'évaluation

- General Information: Years Experience: 3 Yrs. Education: Degree Holder ObjectiveDocument4 pagesGeneral Information: Years Experience: 3 Yrs. Education: Degree Holder ObjectiverrpenolioPas encore d'évaluation

- Footing On PilesDocument12 pagesFooting On PilesRey Dominique VillarPas encore d'évaluation

- Gillmore Needle ApparatusDocument14 pagesGillmore Needle ApparatusDRAWINGPas encore d'évaluation

- Elementary Theory of StructuresDocument112 pagesElementary Theory of StructuresGodwin AcquahPas encore d'évaluation

- Ce Laws - Section1.ppsxDocument27 pagesCe Laws - Section1.ppsxniel paulPas encore d'évaluation

- Sample For A Design ProposalDocument7 pagesSample For A Design ProposalSuresh Gunasekara100% (2)

- Elements of Roads and Highways by Max Fajardo 2nd EditionDocument2 pagesElements of Roads and Highways by Max Fajardo 2nd Editionjohnnoe delosreyes0% (1)

- Module 5 - Design of Isolated Spread FootingDocument21 pagesModule 5 - Design of Isolated Spread FootingRVPas encore d'évaluation

- Concrete Design Flowcharts 3-14-17Document38 pagesConcrete Design Flowcharts 3-14-17MY NamePas encore d'évaluation

- ES 13 1920A Problem Set 2Document5 pagesES 13 1920A Problem Set 2Charmaine ColetaPas encore d'évaluation

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- 04 - Section 3 - Flowcharts (E)Document30 pages04 - Section 3 - Flowcharts (E)Mutiara Puspahati CripstyaniPas encore d'évaluation

- Camber and Deflection CalculationDocument5 pagesCamber and Deflection CalculationCaesarAbdullahPas encore d'évaluation

- 09 - Section 5.4 - Loss of Prestress (E)Document10 pages09 - Section 5.4 - Loss of Prestress (E)Desak Nyoman Deasi TrianiPas encore d'évaluation

- PSC I-Girder Bridge Design in AASHTO-LRFDDocument99 pagesPSC I-Girder Bridge Design in AASHTO-LRFDSANDIPPas encore d'évaluation

- LRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFDocument61 pagesLRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFSomi Khan100% (1)

- Wing WallDocument135 pagesWing WallPanca AtmajatamaPas encore d'évaluation

- Sam Eurocode UK Pretressed Beam Sample ReportDocument176 pagesSam Eurocode UK Pretressed Beam Sample Reportdragos_bogdan1974Pas encore d'évaluation

- c05 Proe wf2.0Document69 pagesc05 Proe wf2.0Namelezz ShadowwPas encore d'évaluation

- 1996 DanielsonDocument21 pages1996 DanielsonNamelezz ShadowwPas encore d'évaluation

- c10 Proe wf2.0Document40 pagesc10 Proe wf2.0Namelezz ShadowwPas encore d'évaluation

- 1993 Helnwein A New 3-D Finite Element Model For Cord-Reinforced Rubber CompositesDocument16 pages1993 Helnwein A New 3-D Finite Element Model For Cord-Reinforced Rubber CompositesNamelezz ShadowwPas encore d'évaluation

- Böhm 1996 Dynamic Rolling ProcDocument9 pagesBöhm 1996 Dynamic Rolling ProcNamelezz ShadowwPas encore d'évaluation

- 1996 NoorDocument11 pages1996 NoorNamelezz ShadowwPas encore d'évaluation

- 1994 Meschke Helnwein Large Strain 3D Analysis of Fibre Reinforced CompositesDocument15 pages1994 Meschke Helnwein Large Strain 3D Analysis of Fibre Reinforced CompositesNamelezz ShadowwPas encore d'évaluation

- AC7122.2 Rev A - 1Document46 pagesAC7122.2 Rev A - 1Namelezz ShadowwPas encore d'évaluation

- AC7122.4 Rev ADocument20 pagesAC7122.4 Rev ANamelezz ShadowwPas encore d'évaluation

- Letterhead Kittigorn ChalernphonDocument1 pageLetterhead Kittigorn ChalernphonNamelezz ShadowwPas encore d'évaluation

- Midterm Examination (Kittigorn) Ver01Document10 pagesMidterm Examination (Kittigorn) Ver01Namelezz ShadowwPas encore d'évaluation

- AC7101.1 Rev G 2Document37 pagesAC7101.1 Rev G 2Namelezz ShadowwPas encore d'évaluation

- The Chains That RustDocument1 pageThe Chains That RustNamelezz ShadowwPas encore d'évaluation

- ASTM International Standards Committee On Homeland Security Applications Response Robots (E54.09)Document28 pagesASTM International Standards Committee On Homeland Security Applications Response Robots (E54.09)Namelezz ShadowwPas encore d'évaluation

- Audit Criteria: Rev. DDocument24 pagesAudit Criteria: Rev. DNamelezz ShadowwPas encore d'évaluation

- AC7101.2 Rev E 1 FinalDocument27 pagesAC7101.2 Rev E 1 FinalNamelezz ShadowwPas encore d'évaluation

- Bio-Epoxy For Aerospace Applications - Summary 22 June 2021Document6 pagesBio-Epoxy For Aerospace Applications - Summary 22 June 2021Namelezz ShadowwPas encore d'évaluation

- King (1983) PDFDocument19 pagesKing (1983) PDFNamelezz ShadowwPas encore d'évaluation

- Nov15 cs533d SlidesDocument8 pagesNov15 cs533d SlidesNamelezz ShadowwPas encore d'évaluation

- 2019 Book QuickStartGuideToVerilog PDFDocument195 pages2019 Book QuickStartGuideToVerilog PDFNamelezz ShadowwPas encore d'évaluation

- UBC97 Seismic Design PresentationDocument55 pagesUBC97 Seismic Design Presentationmario_gPas encore d'évaluation

- Calculation of Dynamic Forces and AnalysDocument6 pagesCalculation of Dynamic Forces and AnalysSARATH RAJ KKVPas encore d'évaluation

- Earthquake Safety Evaluation of Gravity DamsDocument12 pagesEarthquake Safety Evaluation of Gravity DamsNguyenPas encore d'évaluation

- Solucionario Charter 15 Pag 11-20Document10 pagesSolucionario Charter 15 Pag 11-20web SoftNert ChilePas encore d'évaluation

- Teacher Notes and Answers 17 Electrical Energy and CurrentDocument3 pagesTeacher Notes and Answers 17 Electrical Energy and CurrentMona Mohamed Safwat100% (1)

- Generate Column Interaction DiagramDocument88 pagesGenerate Column Interaction DiagramSaad SekkatePas encore d'évaluation

- AP Physics 1 02DynamicsMCQ Quiz1Document28 pagesAP Physics 1 02DynamicsMCQ Quiz1SoulArcher23Pas encore d'évaluation

- Chap4 3Document8 pagesChap4 3AhmedSeragPas encore d'évaluation

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSPas encore d'évaluation

- Energy and HeadDocument9 pagesEnergy and Headdritz tevesPas encore d'évaluation

- 2010 - A Biomechanical Evaluation of ResistanceDocument24 pages2010 - A Biomechanical Evaluation of ResistanceBruno MontoroPas encore d'évaluation

- Ch21 Fundamentals of CuttingDocument56 pagesCh21 Fundamentals of CuttingImGlobalCitizenPas encore d'évaluation

- 1 s2.0 S0924424721002065 MainDocument23 pages1 s2.0 S0924424721002065 MainPN VinodPas encore d'évaluation

- Face Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsDocument14 pagesFace Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsRonald Cornejo MarmanilloPas encore d'évaluation

- Mechanical Sciences: W. JohnsonDocument6 pagesMechanical Sciences: W. JohnsonSaeed GhaffariPas encore d'évaluation

- Unit 8 - Week 7: Assignment 07Document3 pagesUnit 8 - Week 7: Assignment 07Anand KesarkarPas encore d'évaluation

- Conception Aero Aero Dynamism e 2015Document97 pagesConception Aero Aero Dynamism e 2015mechmaster4uPas encore d'évaluation

- ASSIGNMENT1Document1 pageASSIGNMENT1harekrishnaiitkanpur2004Pas encore d'évaluation

- BRIDON BAC TechnicalDocument25 pagesBRIDON BAC TechnicalMohamed SidatePas encore d'évaluation

- Shear Force and Bending Moment: Learning ObjectivesDocument29 pagesShear Force and Bending Moment: Learning ObjectivesBoopathi YoganathanPas encore d'évaluation

- Eddy Current Damping Review SVDDocument10 pagesEddy Current Damping Review SVDbeladelPas encore d'évaluation

- Module 4. Bernoulli's EquationDocument4 pagesModule 4. Bernoulli's EquationKenneth Roy MatuguinaPas encore d'évaluation

- Stress-Strain Relationship For Reinforced Concrete in TensionDocument8 pagesStress-Strain Relationship For Reinforced Concrete in TensionManprit SinghPas encore d'évaluation

- Internal Loadings Develpoed in Structural MembersDocument17 pagesInternal Loadings Develpoed in Structural MembersEboO QQPas encore d'évaluation

- Hse Blast LoadsDocument80 pagesHse Blast LoadsAbhijeet KulkarniPas encore d'évaluation

- Scalars and Vectors: PHY111: Mechanics and Thermo Properties of MatterDocument21 pagesScalars and Vectors: PHY111: Mechanics and Thermo Properties of MatterStudent 365Pas encore d'évaluation

- Modeling and Control of Flexible Link Robots - 48628966Document153 pagesModeling and Control of Flexible Link Robots - 48628966GIYEONGPas encore d'évaluation

- VRSF SeriesDocument12 pagesVRSF SeriesBerkah PowerindoPas encore d'évaluation