Académique Documents

Professionnel Documents

Culture Documents

Project Profile ON Mango Processing & Canning Unit

Transféré par

Khánh NgânDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Profile ON Mango Processing & Canning Unit

Transféré par

Khánh NgânDroits d'auteur :

Formats disponibles

PROJECT PROFILE ON MANGO PROCESSING & CANNING UNIT

PRODUCT : MANGO PULP

1. INTRODUCTION Mango Pulp is the concentrated mango juice obtained on processing of various varieties of mangoes. The processed mango pulp has enhanced shelf life and has significant export potential. The mango pulp can further be used to produce downstream products like mango jelly. The canned mango pulp has about 2 years of shelf life without using a cold storage. Canned Mango pulp is consumed as a fruit juice and in the processing of mango jelly.

2. MARKET POTENTIAL Food processing sector of India plays a vital role in improving the value addition opportunities and creating surplus food for agro-food products. Presently, a mere 2.2 per cent of fruits and vegetables are processed The National policy of India aims to increase the percentage of food being processed in the country to 10 per cent by 2010 and 25 per cent by 2025. Food processing adds value, enhances shelf life of the perishable agro-food products and encourages crop diversification. 3. MANUFACTURING PROCESS: The technology for the manufacture of various canned and bottled fruits and vegetable products is well established. The harvested mangoes are put in ripening chambers or sheds and are periodically checked for further processing. The mangoes are selected, graded, washed and cleaned. The pre-treatment process consists of peeling, deseeding, trimming, sizing and blanching. The ingredients of mango pulp are mangoes, sugar, pectin, potassium meta bisulphite and flavoring agents. The material is then sent to coarse pulper and then to fine pulper. The pulp is pasteurized and filled into tins or glass containers, which are subjected to exhausting, vacuumising, retorting and cooling. 4. TECHNOLOGY: The technology required for the canning unit are washer, fruit crusher, pulper, pasteurizer, packing machine, cap sealing machine, boiler, generator, laboratory equipment and other accessories etc

5. INVESTMENT: The investment cost for setting up a canning unit with a capacity of 4 MTPH will be around Rs. 5.10 Crores and the break up of the cost is tabulated below. The land requirement will be around 3 Acres. The Preliminary & Preoperative Expenses includes interest during construction works out to Rs 0.20 Crores. Plant & Machinery including testing equipment works out to Rs. 2.0 Crores and the cost of Misc. Fixed Assets works out to Rs. 0.30 Crores. Buildings and civil works are estimated to Rs. 0.60 Crores. A technology transfer fee is also considered in the project cost. Working capital is estimated to be Rs. 1.5 Crores.

PROJECT COST

Sl..No Description

1 2 3 Land Buildings (including AC Sheds) Plant & Machinery (including test equipment)

Rs. in Crores

0.45 0.6

2.0 4 5 6 7 Misc. Fixed Assets. 0.30 Preliminary & Preoperative Expenses Technology Transfer Fees Working capital 1.50 TOTAL 5.10 0.20 0.05

PROFITABILITY ASSUMPTIONS:

Particulars Plant Capacity (TPH) Number of Working Hours Number of Days Annual requirement (in MT)

Requirements 4 16 125 8000

Yield: The yield of pulp from mango is about 55% The canning unit can work at 40% of installed capacity for the initial year and increases by 10% YoY and will get stagnate in fifth year of operation.

Vous aimerez peut-être aussi

- What Additives Are in Bottled Water?: Magnesium SulfateDocument7 pagesWhat Additives Are in Bottled Water?: Magnesium Sulfateasifiqbal87Pas encore d'évaluation

- Processing of Milk and Milk Products-88350 PDFDocument73 pagesProcessing of Milk and Milk Products-88350 PDFSameer SippyPas encore d'évaluation

- Detailed Project Report For Biscuit Manufacturing Plant: Naganu Foods Pvt. LTDDocument21 pagesDetailed Project Report For Biscuit Manufacturing Plant: Naganu Foods Pvt. LTDGavin MathewPas encore d'évaluation

- Bread Manufacturing Plant Rs. 28.57 Million Jun-2017Document33 pagesBread Manufacturing Plant Rs. 28.57 Million Jun-2017ТаймурАбдуллах75% (4)

- Food Processing Plant DesignDocument2 pagesFood Processing Plant DesignBanupriyaPas encore d'évaluation

- Dry Fruits Marketing Ideas PDFDocument36 pagesDry Fruits Marketing Ideas PDFGhouse BaigPas encore d'évaluation

- Step by Step Action Plan For A Mineral Water PlantDocument3 pagesStep by Step Action Plan For A Mineral Water PlantSoumitra GhotikarPas encore d'évaluation

- SMEDA Mini Flour MillDocument30 pagesSMEDA Mini Flour MillMuaz AhmedPas encore d'évaluation

- 1 Food Processing PDFDocument102 pages1 Food Processing PDFjitendra panigrahiPas encore d'évaluation

- Potato Processing For Powder and Flakes PDFDocument7 pagesPotato Processing For Powder and Flakes PDFManish MotwaniPas encore d'évaluation

- Tomato Paste and Fruit PulpDocument26 pagesTomato Paste and Fruit Pulppradip_kumarPas encore d'évaluation

- Feasibility of Rice Bran Oil PDFDocument248 pagesFeasibility of Rice Bran Oil PDFSajidur Rehman Syed100% (1)

- Project Report On King Chilli Processing UnitDocument39 pagesProject Report On King Chilli Processing UnitPrakash Pokhrel0% (1)

- SMEDA Fruit Juice ProcessingDocument41 pagesSMEDA Fruit Juice ProcessingImran Qasim Jora100% (1)

- Name of Project Facility For Manufacturing of Disposable SyringesDocument1 pageName of Project Facility For Manufacturing of Disposable SyringesEyock PierrePas encore d'évaluation

- Detailed Project Report On Rice Milling Unit at GelephuDocument19 pagesDetailed Project Report On Rice Milling Unit at GelephuHarpy happyPas encore d'évaluation

- Detailed Business Plan On Stationary Market in IndiaDocument13 pagesDetailed Business Plan On Stationary Market in IndiaVikky SinghPas encore d'évaluation

- Packaging of BeveragesDocument31 pagesPackaging of BeveragesThe Second Life Gaming100% (2)

- Mahajan Mini Flour Mill, UdhampurDocument24 pagesMahajan Mini Flour Mill, UdhampurMj PayalPas encore d'évaluation

- Business Plan: Branding of Sugarcane JuiceDocument27 pagesBusiness Plan: Branding of Sugarcane JuiceKamran Siddiqui100% (1)

- Business Plan - Bangla DrinksDocument17 pagesBusiness Plan - Bangla DrinksDipto Rzk100% (1)

- Questionnaire For Tomato Paste LineDocument6 pagesQuestionnaire For Tomato Paste LineDidier Sanon0% (2)

- Required Documents To Start A Mineral Water Plant in IndiaDocument2 pagesRequired Documents To Start A Mineral Water Plant in IndiaSoumitra Ghotikar100% (1)

- My Food Roller Flour Factory PVT - LTDDocument54 pagesMy Food Roller Flour Factory PVT - LTDSandeep Nair67% (3)

- Customer Attitude Towards RTE Food IndustryDocument83 pagesCustomer Attitude Towards RTE Food Industry14441Pas encore d'évaluation

- Coffee Database in Nepal 2014 PDFDocument66 pagesCoffee Database in Nepal 2014 PDFAnonymous tlMW8s0% (1)

- Mango Pulp RefinerDocument7 pagesMango Pulp RefinerAmzad DPPas encore d'évaluation

- SSG Agro: Dry Fish Market AssessmentDocument26 pagesSSG Agro: Dry Fish Market AssessmentmasudPas encore d'évaluation

- Fruit ProcessingDocument31 pagesFruit ProcessingFekadie TesfaPas encore d'évaluation

- Profile On Processing of TurmericDocument13 pagesProfile On Processing of TurmericBaldev Singh100% (1)

- Project Report On Namkeen and Chips ManufactureDocument8 pagesProject Report On Namkeen and Chips ManufactureSachin SharmaPas encore d'évaluation

- Bicycle Parts Manufacturing Unit CarrierDocument17 pagesBicycle Parts Manufacturing Unit CarrierAftabunarPas encore d'évaluation

- The Carbonated Soft Drink IndustryDocument15 pagesThe Carbonated Soft Drink IndustryBhushan LumanPas encore d'évaluation

- Fruit Juicer To PublishDocument20 pagesFruit Juicer To Publishmm patraPas encore d'évaluation

- Pickle Production Processing Packaging and MarketingDocument32 pagesPickle Production Processing Packaging and MarketingvermanavalPas encore d'évaluation

- Cocks and Valves ProductionDocument28 pagesCocks and Valves ProductionYohannes Woldekidan100% (1)

- Dimma HoneyASDocument50 pagesDimma HoneyASAnonymous h2hxB1Pas encore d'évaluation

- List of Profitable Business Ideas in Production of Soy and Soya Based Food Products. - 969297 PDFDocument50 pagesList of Profitable Business Ideas in Production of Soy and Soya Based Food Products. - 969297 PDFRamling PatrakarPas encore d'évaluation

- Water PlanDocument42 pagesWater PlanvspcmPas encore d'évaluation

- Business Plan of "Package Drinking Water" byDocument33 pagesBusiness Plan of "Package Drinking Water" byNIKHIL_SPas encore d'évaluation

- Baseline Survey On Competition and Markets in EthiopiaDocument112 pagesBaseline Survey On Competition and Markets in Ethiopiaasfawm3Pas encore d'évaluation

- Milk Powder ProductionDocument28 pagesMilk Powder Productionabel_kayel100% (2)

- Sem ProjDocument92 pagesSem ProjJiyaul Haque100% (1)

- KUNAP'S Final Feasibility StudyDocument51 pagesKUNAP'S Final Feasibility StudyMelat MakonnenPas encore d'évaluation

- Mini ProjectDocument19 pagesMini ProjectLuv Singh100% (1)

- Project Profile On The Production of Beverage Cap-Corwn CorkDocument5 pagesProject Profile On The Production of Beverage Cap-Corwn CorkSuleman100% (1)

- Small Industry Set Up and Costing - Biscuit Factory Set UpDocument3 pagesSmall Industry Set Up and Costing - Biscuit Factory Set UpNipun ShahPas encore d'évaluation

- Bhushan Flour Mill A9-B9 Live ProjectDocument39 pagesBhushan Flour Mill A9-B9 Live ProjectABHIRUP ANANDPas encore d'évaluation

- Egg Processing Guide BookDocument31 pagesEgg Processing Guide BookClaudia Melissa Orlandini MendozaPas encore d'évaluation

- Profile On The Setup of Poultry FeedDocument26 pagesProfile On The Setup of Poultry FeedMOHIT KHATWANIPas encore d'évaluation

- SMEDA Honey ProcessingDocument33 pagesSMEDA Honey ProcessingranaisbpkPas encore d'évaluation

- Project Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)Document6 pagesProject Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)EIRI Board of Consultants and PublishersPas encore d'évaluation

- Confectionery Industry: Submitted By: M. Waqas Mahomood Roll No. 3236Document15 pagesConfectionery Industry: Submitted By: M. Waqas Mahomood Roll No. 3236Muhammad Sohail AkramPas encore d'évaluation

- Pre Feasibility Study WATER BOTTLING PLADocument29 pagesPre Feasibility Study WATER BOTTLING PLAHenok MesfinPas encore d'évaluation

- SWOT Analysis Chemical IndustryDocument45 pagesSWOT Analysis Chemical IndustryAditya Singh100% (3)

- Extruded Pellets From Maida For FryingDocument14 pagesExtruded Pellets From Maida For Frying124swadeshiPas encore d'évaluation

- Food Outlook: Biannual Report on Global Food Markets May 2019D'EverandFood Outlook: Biannual Report on Global Food Markets May 2019Pas encore d'évaluation

- Mango Processing & Canning UnitDocument5 pagesMango Processing & Canning UnitHemanth Kumar RamachandranPas encore d'évaluation

- Project Report Preparation FOR EntrepreneursDocument12 pagesProject Report Preparation FOR EntrepreneursAlokPas encore d'évaluation

- DGA Methoden Der ZukunftDocument46 pagesDGA Methoden Der Zukunftjoaquin65Pas encore d'évaluation

- DGA Diagnostic MethodsDocument12 pagesDGA Diagnostic Methodslbk50Pas encore d'évaluation

- 4 CsapoDocument19 pages4 CsapoKhánh NgânPas encore d'évaluation

- Packaging ResearchDocument281 pagesPackaging Researchwasim_it100% (3)

- Contherm® Core Scraped-Surface Heat ExchangerDocument2 pagesContherm® Core Scraped-Surface Heat ExchangerKhánh NgânPas encore d'évaluation

- 445e TDS Varitube EDocument4 pages445e TDS Varitube EKhánh NgânPas encore d'évaluation

- Principles and Practices - FAO 2001Document221 pagesPrinciples and Practices - FAO 2001sami_bulut542Pas encore d'évaluation

- Sor FiskDocument46 pagesSor FiskKhánh NgânPas encore d'évaluation

- Physical Education and Health 11Document2 pagesPhysical Education and Health 11maePas encore d'évaluation

- ABM Topaz Business Plan TemplateDocument6 pagesABM Topaz Business Plan TemplateJulia Mae AlbanoPas encore d'évaluation

- Modified and Controlled AtmospheDocument610 pagesModified and Controlled AtmospheAnchieta100% (1)

- Common Procurement Vocabulary (CPV)Document434 pagesCommon Procurement Vocabulary (CPV)Mising TesingPas encore d'évaluation

- Your NAET Information GuideDocument8 pagesYour NAET Information GuideRicard Revuelto Orengo50% (2)

- Riddles Guess The Fruit or VegetableDocument2 pagesRiddles Guess The Fruit or VegetablegufeoPas encore d'évaluation

- UAE Food Import RequirementsDocument13 pagesUAE Food Import Requirementssabir21Pas encore d'évaluation

- Name: - Date: - Junk Food and Real Food'Document1 pageName: - Date: - Junk Food and Real Food'Aleksandra Krstovska100% (1)

- Food Guide PyramidDocument16 pagesFood Guide PyramidKing Emmanuel JavierPas encore d'évaluation

- Metis Cookbook and Guide To Healthy Living - Second EditionDocument112 pagesMetis Cookbook and Guide To Healthy Living - Second EditionRecipeRain100% (4)

- Empowering Musahar Community Women Through Kitchen GardensDocument2 pagesEmpowering Musahar Community Women Through Kitchen Gardenspvchr.india9214Pas encore d'évaluation

- KPDS - (Kasim) 1992Document16 pagesKPDS - (Kasim) 1992Onur KafalıPas encore d'évaluation

- Production of Pharmaceuticals in A Specially Designed Plant FactoryDocument7 pagesProduction of Pharmaceuticals in A Specially Designed Plant FactoryGutierrez MartinPas encore d'évaluation

- Indian Food Processing Industry SnapshotDocument11 pagesIndian Food Processing Industry Snapshotswapnil118Pas encore d'évaluation

- 2015 FOOD SECURITY SURVEY - PhilippinesDocument116 pages2015 FOOD SECURITY SURVEY - PhilippinesAgape BlissPas encore d'évaluation

- Tomato PasteDocument45 pagesTomato Pastebharat.tumuluru2431100% (4)

- Complementary Feeding - GIDocument27 pagesComplementary Feeding - GIokwadha simionPas encore d'évaluation

- Hope 1 Q1 M6Document14 pagesHope 1 Q1 M6Jessica BihasaPas encore d'évaluation

- Last Minutes Note 1Document64 pagesLast Minutes Note 1iman ghoshPas encore d'évaluation

- Survival Gardening With Heirlooms PDFDocument81 pagesSurvival Gardening With Heirlooms PDFeuqehtb100% (2)

- In Summary:: Ash SprayDocument6 pagesIn Summary:: Ash SprayJovita D. SaraosPas encore d'évaluation

- Food SpoilageDocument5 pagesFood SpoilageRajaDeepak VermaPas encore d'évaluation

- Fish Haccp Model 2 - enDocument14 pagesFish Haccp Model 2 - enTRANDAFPas encore d'évaluation

- FDA-3537 Stat Sec Ext 01-04-23Document10 pagesFDA-3537 Stat Sec Ext 01-04-23Erick BellidoPas encore d'évaluation

- RRL SquashDocument2 pagesRRL SquashTrisha Nicole Salazar ApuadoPas encore d'évaluation

- 1572245905more VegetablescDocument236 pages1572245905more VegetablescAbdullah Hashemi100% (1)

- Winter Season Essay 4 (250 Words)Document3 pagesWinter Season Essay 4 (250 Words)Haris ArshadPas encore d'évaluation

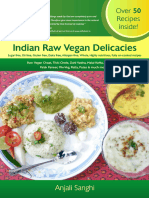

- Raw Vegan IndianDocument57 pagesRaw Vegan IndianallyaPas encore d'évaluation

- Food Consumption Behavior of People Living in Rural NepalDocument19 pagesFood Consumption Behavior of People Living in Rural NepalSagar SunuwarPas encore d'évaluation

- ChefSteps SousVideReferenceDocument7 pagesChefSteps SousVideReferenceQueezle_SisterPas encore d'évaluation