Académique Documents

Professionnel Documents

Culture Documents

Drying Agents

Transféré par

Ayush GuptaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Drying Agents

Transféré par

Ayush GuptaDroits d'auteur :

Formats disponibles

Drying Agents Many organic solvents are immiscible with aqueous solutions, but they are able to dissolve

significant amounts of water because of their polarity i.e., diethyl ether dissolves 7% of its weight in water while tetrahydrofuran is completely miscible with water (Why?). Unfortunately, water is a compound that is very difficult to remove from many compounds, because they are either holding on to it well (i.e., alcohols) or the compound itself is steam volatile. Bottom-line is that the more polar the solvent is, the more hygroscopic it will usually be because it dissolves the water better. Thus, removing water and other impurities from a solution can become an arduous task but is necessary if the reagents are also sensitive towards water i.e., Grignard reagents or in cases where water has a detrimental effect on the yield or rate of the reaction. In those cases, drying agents like calcium hydride (CaH2), sodium metal (in combination with benzophenone) or lithium aluminum hydride (LiAlH4) are used to chemically destroy the water in the solvent. Those compounds are relatively reactive and difficult to handle and usually not used in lower division undergraduate laboratories (see below). Use of conventional drying agents Commonly used drying agents in organic laboratories are calcium chloride (CaCl2), sodium sulfate (Na2SO4) calcium sulfate (CaSO4, also known as Drierite) and magnesium sulfate (MgSO4), all in their anhydrous form. How do they work? All four of them readily form hydrates at low temperatures according to

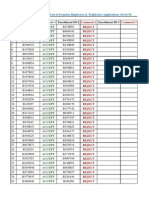

Their efficiency is measured by intensity, capacity and velocity can greatly vary from one solvent to the other. Capacity refers to the maximum numbers of moles of water that the drying agent can bind (n). Another parameter of importance is the efficiency, which refers to the amount of water left in the organic solution after the drying process is completed (e). 1. Calcium chloride (n=6, e=1.5 mg/L) is a very good drying agent for a broad variety of solvents but is generally not compatible with hydroxy (alcohol, phenol), amino (amine, amide) and carbonyl (acid, ketone, ester) functions due to basic impurities such as Ca(OH)2 and CaCl(OH). In addition, it tends to form adducts with those compounds as well. It is often used in drying tubes, since it also is available in granular form. 2. Calcium sulfate (n=0.5, e=0.004 mg/L) is a neutral and good drying agent. However, it does not have a high capacity, which makes it useless for very wet solutions. The commercially available Drierite contains cobalt chloride as indicator (dry: blue, wet: pink), which can be leached out into various solvents i.e. ethanol, DMSO, DMF, ethers, etc. Drierite is often used in desiccators. If the compound is pink, the water can be removed by heating the compound to 210 oC for an hour. 3. Magnesium sulfate (n=7, e=2.8 mg/L) is a slightly acidic drying agent. It works well in solvents like diethyl ether, but not as well for ethyl acetate. A fairly fast drying agent, in part because it comes as a fine powder with a large surface area. 4. Sodium sulfate (n=10, e=25 mg/L) has a very high capacity and is mainly used for very wet solutions. It is very efficient in ethereal solutions, but it also absorbs other polar compounds like alcohols, etc. In addition, it is fairly slow compared to magnesium sulfate, etc. 5. Potassium hydroxide (KOH, n= high, e=0.1 mg/L) and potassium carbonate (K2CO3, n=2, e=moderate) are both of basic nature and often used to dry basic solutions containing amines. They cannot be used to dry acidic compounds since they react with them. 6. Sulfuric acid (H2SO4, e=0.003 mg/L) and phosphorous pentoxide (P4O10) are both acidic drying agents that are mainly used in desiccators and not in direct contact with the solution since they are very aggressive

reagents. Both have a very high capacity. Sulfuric acid forms hydrates while phosphorous pentoxide is ultimately converted into phosphoric acid. P4O10 + 6 H2O ----- > 4 H3PO4 7. Molecular sieves are alumino silicates with a three-dimensional network with different pore sizes (3-5 ). They have to be activated prior use and also can be regenerated at higher temperatures (~180 oC - 260 oC, 1-2 hours). Class of compounds Alkane, alkyl halides Aromatic hydrocarbons, ethers Aldehydes, ketones, esters Alcohols Amines Acidic compounds Recommended drying agent MgSO4, CaCl2, CaSO4, H2SO4, P4O10 MgSO4, CaCl2, CaSO4, P4O10, Na-metal Na2SO4, MgSO4, K2CO3, CaSO4 MgSO4, K2CO3, CaSO4, CaO, BaO KOH, K2CO3 Na2SO4, MgSO4, CaSO4

One of the main problems in the drying process is that the equilibrium above is shifted to the left if the mixture is heated (increase in entropy!) in most cases unless the water is chemically destroyed. Therefore, the drying agent has to be removed (by filtration or decanting) from the dry solution prior to removal of the solvent. Drying agents like Drierite or molecular sieves can be recycled several times by heating them to an appropriate temperature (see above). Example: Reversibility of drying process

Vous aimerez peut-être aussi

- 03 Budget Casseroles - Betty Crocker Recipe Card LibraryDocument58 pages03 Budget Casseroles - Betty Crocker Recipe Card LibraryKenneth83% (12)

- Raw Foods On A Budget - IndbDocument302 pagesRaw Foods On A Budget - Indbiamelizah100% (5)

- 5meo SynthesisDocument2 pages5meo SynthesisLuis López PiñeresPas encore d'évaluation

- Extraction of Alkaloids From Medicinal PlantsDocument7 pagesExtraction of Alkaloids From Medicinal PlantsSneha PatelPas encore d'évaluation

- Cacao Powder Recipes: 1 Espresso Brownie Chocolate SmoothieDocument18 pagesCacao Powder Recipes: 1 Espresso Brownie Chocolate SmoothieHaithamPas encore d'évaluation

- Tier 3 Chocolate Spider Web Mirror GlazeDocument9 pagesTier 3 Chocolate Spider Web Mirror GlazeQuang Lê MinhPas encore d'évaluation

- 9: Multistep Synthesis (Experiment) : Step 1: Synthesis of BenzoinDocument4 pages9: Multistep Synthesis (Experiment) : Step 1: Synthesis of BenzoinNaveed SajidPas encore d'évaluation

- Purification of Organic CompoundsDocument14 pagesPurification of Organic Compoundsmaria theresa fortuna100% (1)

- Digital Printmaking: Pixels, Dots, and Ink JetsDocument9 pagesDigital Printmaking: Pixels, Dots, and Ink JetssoujanaPas encore d'évaluation

- A New Species of Blue PoppyDocument6 pagesA New Species of Blue PoppyBhutan CanadaPas encore d'évaluation

- An Artist PDFDocument12 pagesAn Artist PDFPepabuPas encore d'évaluation

- 2 Paths To Enlightenment by Ven Maha PrasertDocument14 pages2 Paths To Enlightenment by Ven Maha PrasertBro CheahPas encore d'évaluation

- Recrystallization: Methods of PurificationDocument9 pagesRecrystallization: Methods of PurificationMuhammed_Sulim_3079Pas encore d'évaluation

- Phase Three: Applying The Art of Dream ControlDocument19 pagesPhase Three: Applying The Art of Dream ControlJosé GabrielPas encore d'évaluation

- Silvering and ReDocument4 pagesSilvering and RetumadrepuesPas encore d'évaluation

- Experiment 1: Thin Layer ChromatographyDocument9 pagesExperiment 1: Thin Layer Chromatographyzynab123Pas encore d'évaluation

- Aldol CondensationDocument3 pagesAldol CondensationDaniel McDermottPas encore d'évaluation

- Carbon RSDocument15 pagesCarbon RSSandra SinuésPas encore d'évaluation

- Psychedelic LichensDocument4 pagesPsychedelic LichensJon. . .Pas encore d'évaluation

- Lab 03 Crystallization of An UnknownDocument7 pagesLab 03 Crystallization of An UnknownReyPas encore d'évaluation

- AR 001 2020 Chromatography Natural Compounds enDocument5 pagesAR 001 2020 Chromatography Natural Compounds enmppatilmayurPas encore d'évaluation

- Arclightshroom's 4 Aco DMT WorkDocument6 pagesArclightshroom's 4 Aco DMT Workj.pedrogomes84Pas encore d'évaluation

- Crystallization: A. BackgroundDocument8 pagesCrystallization: A. Backgroundchamp delacruzPas encore d'évaluation

- Exp 8 CaffeineDocument6 pagesExp 8 Caffeinek0% (1)

- Wet Method ProcedureDocument2 pagesWet Method ProcedureKelly CantagalliPas encore d'évaluation

- It ReportDocument24 pagesIt ReportTobenna Alan Ndu0% (1)

- The Production of Psilocybin in Submerged Culture by Psilocybe Cubensis (Psilosophy - Info)Document9 pagesThe Production of Psilocybin in Submerged Culture by Psilocybe Cubensis (Psilosophy - Info)luke100% (1)

- Kash's A - B Mescaline Extraction - DMT-Nexus WikiDocument6 pagesKash's A - B Mescaline Extraction - DMT-Nexus WikiDanyLarocquePas encore d'évaluation

- Lab 2 - Extraction and RecrystallizationDocument4 pagesLab 2 - Extraction and RecrystallizationJoshua Smith100% (2)

- Misonix Sonicator BrochureDocument15 pagesMisonix Sonicator BrochureMilad MiladPas encore d'évaluation

- Natural Products ChemistryDocument80 pagesNatural Products ChemistrychimnecheremukachukwuPas encore d'évaluation

- Ultra Stable Process InstructionsDocument5 pagesUltra Stable Process InstructionstdptdpPas encore d'évaluation

- AP Chemistry Properties of Solutions: Important TermsDocument17 pagesAP Chemistry Properties of Solutions: Important TermsLuc LePas encore d'évaluation

- Transfer of Divine EnergyDocument2 pagesTransfer of Divine EnergyHarshadRathodPas encore d'évaluation

- Recrystallization of Benzoic Acid PDFDocument7 pagesRecrystallization of Benzoic Acid PDFericaPas encore d'évaluation

- GeohuascaDocument17 pagesGeohuascaAlexander PeevPas encore d'évaluation

- Ultrasonic EmulsificationDocument11 pagesUltrasonic EmulsificationPatel dharmendraPas encore d'évaluation

- Meditation Mastery: Embrace Mindfulness To Transform Your LifeDocument58 pagesMeditation Mastery: Embrace Mindfulness To Transform Your LifeAditya trimukhePas encore d'évaluation

- Muladhara Chakra (Root Chakra) - Complete Guide: The Earth Element - PrithviDocument19 pagesMuladhara Chakra (Root Chakra) - Complete Guide: The Earth Element - Prithvisandhya vPas encore d'évaluation

- Livret 6 AnglaisDocument11 pagesLivret 6 AnglaisJenniDelgado88% (8)

- Friendship JokesDocument74 pagesFriendship Jokeslinh_tran6634100% (1)

- 3D & 5D Chakra Systems: Lada Ray Quantum CalibrationsDocument12 pages3D & 5D Chakra Systems: Lada Ray Quantum Calibrationsrashmi chauhanPas encore d'évaluation

- Mba Operations Project in Process ManagementDocument66 pagesMba Operations Project in Process ManagementSushant Gage100% (4)

- Screenprint Induction Workshop EnglishDocument28 pagesScreenprint Induction Workshop EnglishAugusto GrasselliPas encore d'évaluation

- 3 14 Revision Guide Organic SynthesisDocument6 pages3 14 Revision Guide Organic SynthesisCin D NgPas encore d'évaluation

- Extraction of A Three Component Mixture-750mgDocument3 pagesExtraction of A Three Component Mixture-750mgDaniel McDermottPas encore d'évaluation

- What Are The Short-Term Effects of Cocaine?Document3 pagesWhat Are The Short-Term Effects of Cocaine?Adriana CamposPas encore d'évaluation

- Drying SolventsDocument2 pagesDrying SolventsCatenanePas encore d'évaluation

- Experiment #1:: Purification of Benzoic Acid by RecrystallizationDocument51 pagesExperiment #1:: Purification of Benzoic Acid by RecrystallizationStephanie Ann Marie DueñasPas encore d'évaluation

- 1-Ae15 Masuda 1-11Document12 pages1-Ae15 Masuda 1-11Gaby ZgubyutzaPas encore d'évaluation

- Process of MeditationDocument2 pagesProcess of MeditationTimes SquarePas encore d'évaluation

- Solutions and SolubilityDocument28 pagesSolutions and SolubilityMhimi ViduyaPas encore d'évaluation

- Training Camp 08 ProgramDocument4 pagesTraining Camp 08 ProgramChetanya MundachaliPas encore d'évaluation

- Teacher Training Manual: Lesson 05 - Raja Yoga: ObjectivesDocument3 pagesTeacher Training Manual: Lesson 05 - Raja Yoga: ObjectivesParameshwaran IyerPas encore d'évaluation

- DHATURADocument3 pagesDHATURAXee JayPas encore d'évaluation

- Exp 6 - Extraction+ Question 2 PDFDocument9 pagesExp 6 - Extraction+ Question 2 PDFAseel MohammedPas encore d'évaluation

- Chem Lab 2 For The Ib DiplomaDocument3 pagesChem Lab 2 For The Ib DiplomaZoravar Sher Singh KalsiaPas encore d'évaluation

- How To DMT From FrogsDocument4 pagesHow To DMT From FrogsJeremai BuenoPas encore d'évaluation

- Erowid EVR Proper Use of Acorus Calamus (Sweet Flag Obligeana)Document4 pagesErowid EVR Proper Use of Acorus Calamus (Sweet Flag Obligeana)musicadsPas encore d'évaluation

- Preparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneDocument22 pagesPreparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneYami BaudelairePas encore d'évaluation

- Alphabet of LoveDocument9 pagesAlphabet of LoveVasugi KuppanPas encore d'évaluation

- Acid, Base & SaltDocument41 pagesAcid, Base & Saltsaadhana elangovanPas encore d'évaluation

- The Synthesis of Ethyl Ethanoate: A2 Experiment 13.5 (3) Teachers' GuideDocument3 pagesThe Synthesis of Ethyl Ethanoate: A2 Experiment 13.5 (3) Teachers' GuideRudyPas encore d'évaluation

- Newer Methods of Preparative Organic Chemistry V2D'EverandNewer Methods of Preparative Organic Chemistry V2Wilhelm FoerstPas encore d'évaluation

- Sir Lucy Lay TekDocument10 pagesSir Lucy Lay TekVee-infinityPas encore d'évaluation

- On Env ProtectionDocument5 pagesOn Env ProtectionHimansu GoswamiPas encore d'évaluation

- Perrins Purification ShortDocument6 pagesPerrins Purification ShortGaveUpOnTVPas encore d'évaluation

- Why Won't A PMOS Pass A Zero and A NMOS Pass A One - VLSI & MSEEDocument4 pagesWhy Won't A PMOS Pass A Zero and A NMOS Pass A One - VLSI & MSEEAyush GuptaPas encore d'évaluation

- B 293 G 24 ApplicationformDocument1 pageB 293 G 24 ApplicationformAyush GuptaPas encore d'évaluation

- 1 0 JOB AID Different Transmission MediaDocument4 pages1 0 JOB AID Different Transmission MediaAyush GuptaPas encore d'évaluation

- Genuine Duplicates Iitr 01 11 Accept RejectDocument2 pagesGenuine Duplicates Iitr 01 11 Accept RejectAyush GuptaPas encore d'évaluation

- SWOT Analysis On Second Cup CoffeeDocument14 pagesSWOT Analysis On Second Cup CoffeeHasibul IslamPas encore d'évaluation

- Halal Food in USADocument5 pagesHalal Food in USAnazienazPas encore d'évaluation

- Đề Thi Lại: 2. I thanked my classmate - - - - - - helping me with my homework. a. for b. about c. of d. witDocument2 pagesĐề Thi Lại: 2. I thanked my classmate - - - - - - helping me with my homework. a. for b. about c. of d. witnguyenanhmaiPas encore d'évaluation

- Ashfaq Nisar Shaikh 1Document4 pagesAshfaq Nisar Shaikh 1Tushaba SayedPas encore d'évaluation

- TurkeyDocument50 pagesTurkeyKaur MandeepPas encore d'évaluation

- Mark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Sentence That Best Completes Each of The Following ExchangesDocument5 pagesMark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Sentence That Best Completes Each of The Following ExchangesBang Bang BuiPas encore d'évaluation

- Funda Drill-007: INSTRUCTIONS: Read and Understand The Questions Properly and SelectDocument9 pagesFunda Drill-007: INSTRUCTIONS: Read and Understand The Questions Properly and SelectWawit A Dela CernaPas encore d'évaluation

- Playbook RestaurantsDocument10 pagesPlaybook RestaurantslawrgeoPas encore d'évaluation

- Verifying The Starting CFU Concentration of EZ-PEC InoculumDocument2 pagesVerifying The Starting CFU Concentration of EZ-PEC Inoculumhoria96Pas encore d'évaluation

- TD Pmo 6000 en 080108Document16 pagesTD Pmo 6000 en 080108Ricardo DávilaPas encore d'évaluation

- Vending Machine Mac 2013Document22 pagesVending Machine Mac 2013Asneeda Ishak0% (1)

- Chemistry ExhibitionDocument2 pagesChemistry ExhibitionHammad SalehinPas encore d'évaluation

- Ethnography PaperDocument19 pagesEthnography Paperapi-248127956Pas encore d'évaluation

- 8liechk-Ssf-Wl Whirlpool Manual EnglishDocument19 pages8liechk-Ssf-Wl Whirlpool Manual EnglishDwane DuncanPas encore d'évaluation

- C S10 26 17Document12 pagesC S10 26 17Chuck ThompsonPas encore d'évaluation

- Science Action - BOOK 2Document46 pagesScience Action - BOOK 2saisssms911650% (2)

- 8080Document212 pages8080Manwinder Singh Gill100% (2)

- Lodge Brochure Ngala Tented CampDocument13 pagesLodge Brochure Ngala Tented CampE-private Tutor TutorPas encore d'évaluation

- CoffeeShopER ModelDocument1 pageCoffeeShopER ModelmePas encore d'évaluation

- Williams, James - Origin of Beverages PDFDocument129 pagesWilliams, James - Origin of Beverages PDFkustad33Pas encore d'évaluation

- Ud1 English Y3 Section ADocument7 pagesUd1 English Y3 Section Azura_kiprawiPas encore d'évaluation