Académique Documents

Professionnel Documents

Culture Documents

17 Inspissator Finthfhg

Transféré par

ArchieDuqueDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

17 Inspissator Finthfhg

Transféré par

ArchieDuqueDroits d'auteur :

Formats disponibles

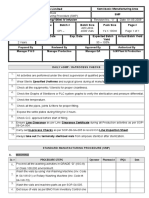

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page: 1 of 6

Content

1. 2. 3. Scope Definitions and abbreviations Personnel qualifications #!$ %edical fitness #!& 'ducation and training Procedure (!$ Principle (!& Samples (!# ')uipment and materials (!( Reagents and solutions (!* "etailed instructions for use (!+ Recording and reporting (!, -ualit. control (!/ Safet. precautions !elated documents

4.

"nne# 1. $nspissator lo%boo& "nne# 2. 'aintenance lo%boo&

Compiled b. 3ame "ate Signature Laborator. area:

'0amined b.

1ppro2ed b.

Replaced Code:

3e4 2ersion Code:

3o of copies:

Reason for c5ange:

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page: 2 of 6

1.

Scope

65is SOP describes t5e optimal operation of an inspissator t5roug5 regular ser2icing and pre2enti2e maintenance! 65e SOP must be adapted for different t.pes of inspissator t.pes according to t5e manufacturer7s instructions!

2.

8C: 31:

Definitions and abbreviations

degrees Celsius not applicable

3.

Personnel qualifications

3.1 Medical fitness

31

3.2 Education and training 'ducation and training must be gi2en on t5e follo4ing topics: 5.giene re)uirements9 4earing and use of protecti2e e)uipment and clot5ing9

pre2ention of incidents and steps to be ta:en b. 4or:ers in t5e case of incidents (bio5a;ard incidents< c5emical< electrical and fire 5a;ards)9 good laborator. practice9 organi;ation of 4or: flo49 use of e)uipment (operation< identification of malfunctions< maintenance)! 65e training s5all be: gi2en before a staff member ta:es up 5is/5er post9 strictl. super2ised9 adapted to ta:e account of ne4 or c5anged conditions9 and repeated periodicall.< preferabl. e2er. .ear!

4.

Procedure

4.1 Principle 65e inspissator (coagulator) is intended for batc5 production of egg=based culture medium (L>4enstein?@ensen< Oga4a and ot5er modified egg=based media) 4it5 or 4it5out t5e addition of drugs! 12ailable inspissators differ in si;e and in t5e t.pe of 5eater: some :eep t5e temperature 5omogeneous and stable b. means of a 4ater= bat5 and ot5ers b. forced air circulation! 4.2 Samples

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page: 3 of 6

31 4.3 Equipment and materials Inspissator< properl. maintained and installed according to t5e manufacturerAs manual (specific to eac5 inspissator)! Calibrated t5ermometer 6imer Remo2able tube rac:s 4it5 appropriate tubes or bottles for culture 65ermoresistant glo2es 4.4 Reagents and solutions "istilled 4ater< obtained from ion=e0c5ange s.stems t5at do not use salt bac:=flus5ing to regenerate t5e ion=e0c5ange cartridge (sodium ions are 2er. corrosi2e to t5e stainless steel tan:)! 4.5 Detailed instructions for use 4.5.1 Check before use Replace inspissator 4ater 4it5 fres5 distilled 4ater once a 4ee: to pre2ent corrosion of t5e stainless steel tan:! 'nsure t5at t5e element is submerged belo4 t5e 4ater le2el at all times< to pre2ent o2er5eating and damage of t5e element! 4.5.2 Loading the inspissator Heat t5e inspissator to /B 8C! Place t5e bottles/tubes in a slanted position in t5e inspissator! Co2er 4it5 a blan:et< if recommended b. t5e manufacturer! Coagulate t5e medium for (* minutes at /B?/* 8C! (65e medium 5as been prepared asepticall. and t5is 5eating is t5erefore designed to solidif. t5e medium< not to sterili;e it!) 65e )ualit. of egg=based media deteriorates if coagulation is performed at too 5ig5 a temperature or for too long! Heating for a second or t5ird time 5as a detrimental effect! C5ec: t5e )ualit. of t5e medium once cooled (see section (!, belo4)! 4.5.3 Cleaning Clean t5e inspissator 4it5 a damp clot5 after disconnecting t5e inspissator from t5e electricit. suppl.! 12oid t5e use of sol2ents for cleaning! Clean t5e immersed parts using proprietar. 5eating element cleaners! Note Follow the manufacturers instructions carefull ! as these cleaners ma be to"ic. 4.! Recording and reporting

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page: 4 of 6

Record data in t5e logboo: after preparation of eac5 batc5 of medium! Record details of t5e loading and operation of t5e inspissator in t5e inspissator logboo: (1nne0 $)! Incidents< accidents and/or mec5anical problems must also be recorded (1nne0 &)! 4." #ualit$ control isuall. c5ec: t5e )ualit. of t5e medium once it 5as cooled! It s5ould not be li)uid< and s5ould not release large 2olumes of 4ater! "iscolouration of t5e coagulated medium ma. be due to e0cessi2e 5eating! 65e appearance of small 5oles or bubbles on t5e surface of t5e medium also indicates fault. coagulation procedures< especiall. 45ere t5e medium is in contact 4it5 t5e glass (internal 4all of t5e tube)! If t5e medium is li)uid or disintegrates easil.< t5e inspissation temperature mig5t 5a2e been too lo4! 65is can be detected b. tapping (on t5e 5and) one or t4o tubes randoml. c5osen from t5e inspissated batc5! Poor )ualit. media s5ould be discarded! #terilit check 1fter inspissation< t5e 45ole media batc5 s5ould be incubated at #*?#, 8C for &( 5ours and tubes c5ec:ed for t5e appearance of contamination! 1lternati2el.< a randoml. selected sample of tubes is incubated at #*?#, 8C for &(?(/ 5ours! 65e batc5 is used onl. after a negati2e test result (2erif.ing t5e absence of contamination)! 4.% Safet$ precautions Use thermoresistant glo$es to protect from 5eat! Ce careful of steam 45en opening t5e inspissator! Dor ser2ice or repairs< onl. t5e control unit ? not t5e tan: or bridge plate ? is remo2ed! Ser2ice and repair s5ould be performed b. a )ualified ser2ice tec5nician! Refer to t5e manufacturerAs manual for safe 5andling of t5e inspissator!

!elated documents

%anufacturerAs manual< specific to eac5 inspissator

Laborator ser$ices in tuberculosis control. %art &&&' Culture! Eene2a< Forld Healt5 Organi;ation< $GG/ (FHO/6C/G/!&*/)!

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page : of 6

"nne# 1. $nspissator lo%boo&

Date (ime )perator *olume of load +no. of vials,tubes'edium type L. L./pyr )%a0a L. $12 L. !$3 L. 4'5 L. S'

Institution Laboratory name Location Head/Responsible person

Standard Operating Procedure (SOP) Use and maintenance of an inspissator

Code: ersion: no! "ate: of release Page: 6 of 6

"nne# 2. 'aintenance lo%boo&

$(4' $D41($3$C"($)1 Crand name: %odel/t.pe: Serial no! 6el: 6el:

')uipment: I3SPISS16OR Purc5ase date: Location 4it5in laborator.: Farrant. e0pir. date: %anufacturer: 1ddress:! Contact person: 6ec5nical ser2ice representati2e:

P4!$)D$C$(67 "ate %aintenance operation Operator

"ate

'2ent

3"$L8!4 4*41(S Correcti2e action ta:en

Operator

Vous aimerez peut-être aussi

- Content: Standard Operating Procedure (SOP) Use and Maintenance of An IncubatorDocument7 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of An IncubatorEndo LPas encore d'évaluation

- Content: Standard Operating Procedure (SOP) Use and Maintenance of Class I and Class II Biological Safety CabinetsDocument15 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of Class I and Class II Biological Safety CabinetsReni LenggogeniPas encore d'évaluation

- 05 BSC Fumigation FinDocument6 pages05 BSC Fumigation FinRaj KumarPas encore d'évaluation

- 34 Catalase Test FinDocument5 pages34 Catalase Test FinMeenachi ChidambaramPas encore d'évaluation

- Content: Standard Operating Procedure (SOP) Use and Maintenance of An Electromagnetic BalanceDocument5 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of An Electromagnetic BalancebsreegiriprasadPas encore d'évaluation

- Instructions For Use CRP: VITROS Chemistry Products CRP SlidesDocument12 pagesInstructions For Use CRP: VITROS Chemistry Products CRP SlidesKemal MuratspahicPas encore d'évaluation

- SMP 200mgDocument7 pagesSMP 200mgTahir IbrahimPas encore d'évaluation

- Nnaca Sop 304Document9 pagesNnaca Sop 304Somnis VeritasPas encore d'évaluation

- Chemical Cleaning of BoilerDocument27 pagesChemical Cleaning of BoilerlrpatraPas encore d'évaluation

- As-200 服务手册 v1.0 en PDFDocument6 pagesAs-200 服务手册 v1.0 en PDF袁崇山Pas encore d'évaluation

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugeDocument9 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugenazmiPas encore d'évaluation

- Gauging Manual Rev 1.6Document22 pagesGauging Manual Rev 1.6ابوالحروف العربي ابوالحروفPas encore d'évaluation

- SolasDocument2 pagesSolasmy printPas encore d'évaluation

- M10002 AG480 SDocument23 pagesM10002 AG480 SsupravietuirePas encore d'évaluation

- TS TVS TFS ProtocolsDocument16 pagesTS TVS TFS ProtocolsTaulehia Pulefou SemisiPas encore d'évaluation

- Content: Standard Operating Procedure (SOP) Use and Maintenance of An InspissatorDocument6 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of An InspissatornazmiPas encore d'évaluation

- Gas ChromatographyDocument34 pagesGas ChromatographyReverse FlashPas encore d'évaluation

- Ascott Manual S Ip RangeDocument80 pagesAscott Manual S Ip Rangejeremias100% (1)

- HACCP PLAN APPROVED 11 26 2012 Páginas 5Document25 pagesHACCP PLAN APPROVED 11 26 2012 Páginas 5jerco27Pas encore d'évaluation

- Sop of Disinfection, CoatingDocument27 pagesSop of Disinfection, CoatingAhmed Quadri0% (1)

- Iso 7937 1985Document8 pagesIso 7937 1985Alnoor LabPas encore d'évaluation

- 1220Infinity-Infinity2-LC Preventive Maintenance ChecklistDocument8 pages1220Infinity-Infinity2-LC Preventive Maintenance ChecklistYudi - PT. Laborindo SaranaPas encore d'évaluation

- Procedure: Non-SMILE Created Resources Author: N/A: Coulter A T 5 Diff Cap Pierce (CP) Operations ProcedureDocument12 pagesProcedure: Non-SMILE Created Resources Author: N/A: Coulter A T 5 Diff Cap Pierce (CP) Operations ProcedureLuis Ferdinand Dacera-Gabronino Gamponia-NonanPas encore d'évaluation

- RCPT Apparatus With 4 CellsDocument17 pagesRCPT Apparatus With 4 CellsDRAWINGPas encore d'évaluation

- RCPT Apparatus With 4 CellsDocument17 pagesRCPT Apparatus With 4 CellsDRAWINGPas encore d'évaluation

- Pi300142 Covid 19 QPCR I Kit 11 20200624 - Ce IvdDocument13 pagesPi300142 Covid 19 QPCR I Kit 11 20200624 - Ce IvdJason YanPas encore d'évaluation

- ABO & Acid CleaningDocument38 pagesABO & Acid Cleaningsrigirisetty208100% (1)

- Manual Detector de GasesDocument221 pagesManual Detector de GasesjimenezjacoboPas encore d'évaluation

- Equ10-05 CO2 Incubator FYRITE SOPDocument5 pagesEqu10-05 CO2 Incubator FYRITE SOPQuality Control BiochemPas encore d'évaluation

- HS-1607BLe 1501Document60 pagesHS-1607BLe 1501Ngô ĐôngPas encore d'évaluation

- EQ-17 StackDocument6 pagesEQ-17 StackSangam SharmaPas encore d'évaluation

- Bioreactor Sartorius Biostat Cplus (5L) InstructionsDocument8 pagesBioreactor Sartorius Biostat Cplus (5L) Instructionshulki özelPas encore d'évaluation

- Intertek Confinement ASHRAE 110 1995Document31 pagesIntertek Confinement ASHRAE 110 1995Linh NgoPas encore d'évaluation

- Voltatex 4130Document5 pagesVoltatex 4130mouds22Pas encore d'évaluation

- AgraQuantAflaMethod 4-40-020108Document4 pagesAgraQuantAflaMethod 4-40-020108Muchlas AkbarPas encore d'évaluation

- Schlumberger Dowell Lab ManualDocument76 pagesSchlumberger Dowell Lab ManualmenocaPas encore d'évaluation

- SOP For Laminar Air Flow Workbench - PharmaguidelineDocument2 pagesSOP For Laminar Air Flow Workbench - PharmaguidelineGopi NathPas encore d'évaluation

- Installation Qualification Protocol Agilent Capillary Electrophoresis SystemDocument20 pagesInstallation Qualification Protocol Agilent Capillary Electrophoresis SystemThanh Thanh Hai LePas encore d'évaluation

- Manual Syp2001-V-DestiladorDocument15 pagesManual Syp2001-V-DestiladorVictor fajardoPas encore d'évaluation

- TextDocument17 pagesTextsinghminakshi721Pas encore d'évaluation

- Maintenance Checklist BA400Document5 pagesMaintenance Checklist BA400Labor PrimaPas encore d'évaluation

- Environmentally Safe Refrigerant ServiceDocument71 pagesEnvironmentally Safe Refrigerant ServiceStevenSilvaPas encore d'évaluation

- Laboratory Cleaning and MaintenanceDocument8 pagesLaboratory Cleaning and MaintenanceJenner ButlongPas encore d'évaluation

- Well Testing Systems: Norsok StandardDocument40 pagesWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- 3.5 Testing For Syphilis (VDRL)Document3 pages3.5 Testing For Syphilis (VDRL)BALAJIPas encore d'évaluation

- 11 Autoclave FinDocument10 pages11 Autoclave FinTawanda Precious SingiziPas encore d'évaluation

- Standard Operating Procedure To Learn How To Behave in Quality Control Laboratory in PharmaceuticalsDocument38 pagesStandard Operating Procedure To Learn How To Behave in Quality Control Laboratory in PharmaceuticalsYulis AdrianaPas encore d'évaluation

- 660 MW, BHEL, Chemical CleaningDocument24 pages660 MW, BHEL, Chemical CleaningHoncho Abhi SinhaPas encore d'évaluation

- Trace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFDocument22 pagesTrace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFHassan Houdoud100% (1)

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A FreezerDocument7 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of A FreezerPrincess PiaPas encore d'évaluation

- Pexp5 TOPO User ManualDocument53 pagesPexp5 TOPO User Manualsam0214100% (1)

- CD4% Counting With CyFlow Counter - 2011-11-03 - Rev007Document6 pagesCD4% Counting With CyFlow Counter - 2011-11-03 - Rev007Dinesh SreedharanPas encore d'évaluation

- US Environmental Protection Agency Office of Pesticide ProgramsDocument20 pagesUS Environmental Protection Agency Office of Pesticide Programsanandhra2010Pas encore d'évaluation

- Instructivo MesofilosDocument97 pagesInstructivo MesofilosYERIS RINALDY MOJICAPas encore d'évaluation

- SM - SOPs - Autoclave SOP-good ExampleDocument6 pagesSM - SOPs - Autoclave SOP-good ExamplesonnydominicPas encore d'évaluation

- IPC TM 650 Solder Ball TestDocument3 pagesIPC TM 650 Solder Ball TestJonas Ricafrente MojicaPas encore d'évaluation

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Distillation: Operation and ApplicationsD'EverandDistillation: Operation and ApplicationsAndrzej GorakÉvaluation : 4 sur 5 étoiles4/5 (10)

- Organizing and Organization: Chapter Highlights and Glossary of Key TermsDocument29 pagesOrganizing and Organization: Chapter Highlights and Glossary of Key TermsArchieDuquePas encore d'évaluation

- 2.1 Describing Motion (1) KgugkDocument8 pages2.1 Describing Motion (1) KgugkArchieDuquePas encore d'évaluation

- Change Management-A ProcessDocument16 pagesChange Management-A ProcessArchieDuquePas encore d'évaluation

- Finals Class TrematodaDocument47 pagesFinals Class TrematodaArchieDuquePas encore d'évaluation

- 001 The Crib SheetDocument13 pages001 The Crib Sheetmoi moiPas encore d'évaluation

- RAW TM & HM Users Manual V 11Document8 pagesRAW TM & HM Users Manual V 11arcangelus22Pas encore d'évaluation

- GRP 15 Property Law Final DDocument15 pagesGRP 15 Property Law Final DBruno OsananPas encore d'évaluation

- Unit 25 Sound Recording Lab LacDocument16 pagesUnit 25 Sound Recording Lab Lacapi-471521676Pas encore d'évaluation

- Dirt Bikes Financial and Sales DataDocument7 pagesDirt Bikes Financial and Sales Datakhang nguyenPas encore d'évaluation

- Constantin Floros, Kenneth Chalmers - New Ears For New Music-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)Document242 pagesConstantin Floros, Kenneth Chalmers - New Ears For New Music-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)paperocamillo100% (3)

- Sow English Year 4 2023 2024Document12 pagesSow English Year 4 2023 2024Shamien ShaPas encore d'évaluation

- Research Poster 1Document1 pageResearch Poster 1api-662489107Pas encore d'évaluation

- 띵동 엄마 영어 소책자 (Day1~30)Document33 pages띵동 엄마 영어 소책자 (Day1~30)Thu Hằng PhạmPas encore d'évaluation

- Playing Djembe PDFDocument63 pagesPlaying Djembe PDFpbanerjeePas encore d'évaluation

- CE GATE'2017 Paper 02 Key Solution PDFDocument29 pagesCE GATE'2017 Paper 02 Key Solution PDFgolaPas encore d'évaluation

- Communique Supply Teacher (Oriental Languages) (Primary) 2021-2022Document4 pagesCommunique Supply Teacher (Oriental Languages) (Primary) 2021-2022nishiPas encore d'évaluation

- BZU Ad 31 12 12Document15 pagesBZU Ad 31 12 12Saleem MirraniPas encore d'évaluation

- 01.performing Hexadecimal ConversionsDocument11 pages01.performing Hexadecimal ConversionsasegunloluPas encore d'évaluation

- EY Global Hospitality Insights 2016Document24 pagesEY Global Hospitality Insights 2016Anonymous BkmsKXzwyKPas encore d'évaluation

- Managerial Accounting 14th Edition Warren Solutions Manual DownloadDocument28 pagesManagerial Accounting 14th Edition Warren Solutions Manual DownloadRose Speers100% (22)

- Modal VerbsDocument2 pagesModal VerbsDICX7770% (1)

- Suspension Mansons 2Document45 pagesSuspension Mansons 2Andres Silva67% (3)

- Tucker ComplaintDocument48 pagesTucker ComplaintMike MarinoPas encore d'évaluation

- Contoh DVDocument5 pagesContoh DVHiruma YoishiPas encore d'évaluation

- 1167 Nine Planets in TamilDocument1 page1167 Nine Planets in TamilmanijaiPas encore d'évaluation

- Prayer Points 7 Day Prayer Fasting PerfectionDocument4 pagesPrayer Points 7 Day Prayer Fasting PerfectionBenjamin Adelwini Bugri100% (6)

- Social Legislation Cases On Kasambahay LawDocument12 pagesSocial Legislation Cases On Kasambahay LawLiee Raine100% (1)

- Physicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)Document11 pagesPhysicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)International Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- ArcSight Profiler IntegrationDocument8 pagesArcSight Profiler IntegrationemvePas encore d'évaluation

- Corporation Tax CT41G-DciDocument1 pageCorporation Tax CT41G-DciHenry HarrodPas encore d'évaluation

- Working Capital Management by Birla GroupDocument39 pagesWorking Capital Management by Birla GroupHajra ShahPas encore d'évaluation

- EpitheliumDocument48 pagesEpitheliumdrpankaj28100% (1)

- DHS/ICE (ICEPIC) Information Sharing Status: Enforcement Systems BranchDocument22 pagesDHS/ICE (ICEPIC) Information Sharing Status: Enforcement Systems BranchImpello_TyrannisPas encore d'évaluation

- Week 4Document5 pagesWeek 4عبدالرحمن الحربيPas encore d'évaluation