Académique Documents

Professionnel Documents

Culture Documents

Us 61018

Transféré par

asdfasfCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Us 61018

Transféré par

asdfasfDroits d'auteur :

Formats disponibles

tait@ :grafts latrnt @ffice

SIDNEY W., J. FOREMAN, AND NELSON PALMER, OF AUBURN, NEW YORK, ASSIGNORS TO i

Tl-EMSELYES AND DAVID _LYMAN, OF MIDDLEFIELD, CONNECTICUT.

-Ltters .Patent No. 61,018, dated January 8, 1867.

Iurnovsn Miners.

@in rlgctul ttfcrnh tu im their @titers nttnt nrt mating nu uf tigt samt.

To wnorr 1r MAY eoNonRN:

Be it known that we, SIDNEY W., J. FOREMAN, and NELsoN PALMER, of Auburn, in the county of Cayuga, and State of New York, have invented certain new and useful Improvements in Mangles; and we do hereby declare the following to be a fulL'clea-r, and exact description' of the same, reference boing had to the'accorn

panying drawings, in which- ' Y _

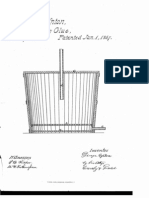

Figure l is a side elevation of a mangle constructed in accordance with our invention.

Figure 2, a transverse vertical section of the mangle rolls; and

Figure 3 is a top or plan view of the machine. l v

Our invention consists, first, in forming the surface of the rolls of a mangle of vulcanite When mangle rolls are made of wood, the moisture which is pressed from the clothes or other between them, soon causes them to lose their polish, and to become rough andl swollen, thus unt for use as mangle or ironing rolls. On the other hand, when metal rolls are employed,

or-hard rubber.` articles passingrendering them the dampness or

moisture of the clothes soon causes them to rust; while the soda or alkalics, which -are used in washing, attack

the metal, and corrode or eat into it. The use of metal in this connection is, therefore, quite as objectionable

as that of wood, and even more so, for the rust on the rolls is apt to mark and stain the articles which are brought _in contact with them. It is, cbnsequcntly, e greatl desideratum to construct rolls of a material which will not

rust or corrode, and which willalways present a hard and smooth surface. To accomplish this, we have made the rolls, or that part of them which comes in contact-With the clothes or other articles to be smoothed, of vul canite or hard rubber, the use of which is attended with none of the disadvantages consequentpon the employ ment of other material, as above mentioned; for it is not affected in any way or degree by water or moisture, and is not attacked by the salts or alkales used in washing, preserving at all times a smooth, hard surface, admirably fitted for mangling purposes. ' Our invention `also consists in the arrangement of the gear for transmitting motion between the rollers, whose axes must necessarily be at variable distances from each other. _ Under this arrangement the gear-wheels, mounted on the ends of the two rollers, do not mesh directly with one another,'but engage with an auxiliary

wheel or pinion; and, while the centres of motion of the two rollers are' at variable distances with respect _to each other, the distance between them and the centre of motion of the auxiliary gear is xed and unchangeable. The latter wheel or pinion constitutes, therefore, the intermediary through which motion is communicated from

one roll to the other, and by means of _which the rollers are revolved at an equal rate of speed, no matter what'

may be the distance between them. `

Our 'invention further consists in'the arrangement and combination, with the adjustable and movable roller of the mangle or other like machine, of a system of levers for regulating and graduating the pressure upon the

article passing between the rolls. To enable those skilled in the art to fully understand and to use our invention, we will now proceed to`

describe it by reference to the accompanying drawings.

y' In fig. 2 is shown the construction of the mangle rolls. They consist each of a. mandrel or shaft, aand ,

of metal or other suitable material, upon which is cemented or otherwise secured a sleeve or casing of Vhard rubber, A and B, of any desired or suitable thickness. These rollers are provided at their ends with journals,

which have their bearings in the machine, as shown in iig. 1. The lower roll, A, is arranged in the frame C in the usual manner. The upper and adjustable roll, B, has its bearings in the lower and shorter arms of levers, D, pivoted to ythe frame C, so that their pivotal points, c, shall be eccentric to the bearings of the roller B, as may belilcowise seen in the combined wringer and mangle, for which Letters Patent, No. 45,071, were issued to SIDNEY W. and J. FOREMAN PALMERLtwo of the parties to the present applicatiomcn the_15th November, 1864. The levers' D extend upward above the frame, and are jointed at their upper ends to link-pieces or levers, E. The :lever E, on that .side of the machine, preferably, where the gear mechanism is located, is jointed at its other to one end of a lever, I", the other end of which is pivoted to the top of the frame C, and from the centre of which, Ior thereabouts, extends a leverl handle, G. A compound lever'i's thus formed which, when the handle G is raisedV or lowered, will raise or lower in a corresponding degree the roll B, which, aboveexplained, is hung in the

mp1s

shorter arms of the ievers D. . It will be understoodthat this system of levers is the same on both sides of the

frame, withthe exception ofthe lever-handle G, which need only be attached toene set of levers, motion boing

communicated tothe levers on the other side of the frame by a rod or shaft, H, which extends from the point where the handle G is attached to the lever F to a corresponding 'point on the lever F on the other' side of the frame. The levers on both sidesoi' the frame are thus moved'alike by the lever handle, which may be actuated

by hand, weights,'or other means whichwill readily suggest themselves.' On one side ofthe machine, the

journals of the rollers A- extend out from the -frame, and have mounted on them gear-wheels, The wheel d of the upper roll is an internal gear-wl1ecl,while the'lowe'r wheel f has its teeth formed upon itsfexterior. These gears do not mesh with one another, but with a third or _intermediate gear, g,lwhich is arranged and secured in place so that its axis shall be the pivotal-point 'c of the levers New, as the centres of motionof the upper roll B and levers D arc at a fixed and unchangeable distance from each other, `it follows, of course,

that _the distance between the gears d and g'will be likewise lixedand invariable; 4and as the gea-r f of the lower

roll A also meshes at all times with theintermcdiatepinion g, the latter thus constitutes the medium for communi

cating motion from one, roll to the other, no matter at what distance the rolls are from each other. , The crank

o_r handle h, by which the rollers are revolved, may be mounted on the hub o`f the lower wheel f, or "it' 'may be arranged in connection with an auxiliary gear, 7c, so asl to obtain more power; The gears may be either on one

or on both sides of Vthe machinc,with~ an additional shaft and pinion extending from the Wheel g, to transmit

motion tothe gear ont-he other'side ofthe frame. j '_lhis arrangement, however, need only be used when it is ncccssaryto obtain a'considerablei increase of poner. The construction and arrangement of the gear are such

that -there is a great gainin'poweroofver'ordinarygearing employed forolike purp'o'ses. Under our invention, the toothed wheels d j' maybe cf'any dianiete'rinot _exceeding the sum of the diameters of the two rolls A B. _One of the wheels is an ,internal gear-wheel', and _the other' has its teeth formed upon its exterior. They mesh with

a pinion which, lin order togear with both, must engage with the external gear-wheel, and then extend out tar

enough to tit in the internal gear of the-othervIheel. It follows, therefore, that when thus arranged, _the two wheels do not lie- in vthe same vertical. plane, but that, in order. to avoid interfering with each other, they are placed so as ~to bc'partly-sidc -by si'de,.as _shown in the drawings, the one lapping over the' other'. The great increase in the diameter of the -wheels which this arrangementl admits ot', causes, of course, a correspondingly great increase of lever power, and 'enables the rolls to be revolved with comparative ease. We prefer, for the

salreof 'convenience and accuracy, to use the internal or female gear, d, as the mould in which to cast the external gear Infthis way _the two> gear-wheels have the same diameter of pitch, and Will-move entirely in unison. This gearing is therefore well adapted for triangles, wringers, or other machines in which the rollers

are required to move with regularity and in unison. If it be necessary to vary the speed of thc'two rolls-4. e.,

if' it be desired to produce friction between them-then of course thc diameters of4 the wheels may vary. 'lf i;

be desired,- letters or ornamental devices may be engraved or cut in either one or both of the mangle rolls, as

_shown at s, figs. y2 and'l, so that the articles passingbetween the rolls shall receive the impression of the device,

which will appear upon it in relief. In this manner towels,.napkins, and other articles may be marked with the

name of the owner, or ornamented with devices of any desired pattern.

we claim, and desire to secure by Letters Patent, is-_

_

,

_

_ -

Having described our invention, and the manner in which the'same is or may be-carried into effect, what

_ _

`

1.v The application to the rollers of mangles of hard >rubber or yulcanite, substantially in the manner and

for the purposesl described. _

'2. Combining and connecting the levci frames, in lwhich the stationary and movable'jollers are hung, by a system of links and lovers, arranged substantially as describcfhso rthat the same Vmay be actuated by hand, Weights, or otherwise, substantially as and for the purposes hereinslrown and described. 3. In combination with the movable roller when hung in the short arms of angular levers for the purpose of_ adjustment with'reierence'to the stationary roller, we claim the internal and external gear-Wheels, and inter

mediate pinion, under the arrangement shown and described, so that the said gear-wheels, while at variable dis

tances from each other, shall bear fixed and invariable relations to the saidlp'inions, substantially as and for the

purposes set forth. _ ' _ v

4. We claim the method of gearing the rolls of mangles, or other-like machines, when 'arranged so as_,to move with equal or diierentvelocities, but at variable distances from each other, by mountingA upon the said

rolls, respectively, internal and external gear-Wheels, which mesh with an intermediate pinion, stationary with

relation to said rolls,- substantially as shown and set forth.v _ '

5. In a mangling machine, weclaim marking and ornamenting the material passing between the mangle

rolls, by means of letters or other _devices or designs, cutor formed in intaglio in one or both'oi said rolls, sub

stantially as hereinshown and described. _ ' t

In testimony whereof We have signod-olir names to this specification before two. subscribing witnesses.

'

,

Witnesses: ' l .

'

s. w. PALMER,

J. F. PALMER, _

.NELSON PALMER.

Henson T. Coon,

'

'

A. PoLLoK.

Vous aimerez peut-être aussi

- @értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioDocument1 page@értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioasdfasfPas encore d'évaluation

- Us 60951Document2 pagesUs 60951asdfasfPas encore d'évaluation

- Patented Jan. 1, I867 V: Z. SperryDocument3 pagesPatented Jan. 1, I867 V: Z. SperryasdfasfPas encore d'évaluation

- Us 60949Document3 pagesUs 60949asdfasfPas encore d'évaluation

- Us 60945Document2 pagesUs 60945asdfasfPas encore d'évaluation

- N. Puckett. - : Centering ToolDocument2 pagesN. Puckett. - : Centering ToolasdfasfPas encore d'évaluation

- H. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867Document3 pagesH. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867asdfasfPas encore d'évaluation

- F. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867Document2 pagesF. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867asdfasfPas encore d'évaluation

- Making Eyelets'.: L. RichardsDocument3 pagesMaking Eyelets'.: L. RichardsasdfasfPas encore d'évaluation

- Gems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkDocument1 pageGems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkasdfasfPas encore d'évaluation

- Nit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6mDocument1 pageNit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6masdfasfPas encore d'évaluation

- Nitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofDocument1 pageNitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofasdfasfPas encore d'évaluation

- TTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTT A DDocument2 pagesTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTT A DasdfasfPas encore d'évaluation

- Guivt?h Gist" Gamut @F?M: Richard B. Stevenson, F-York Township, OhioDocument1 pageGuivt?h Gist" Gamut @F?M: Richard B. Stevenson, F-York Township, OhioasdfasfPas encore d'évaluation

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocument2 pagesNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfPas encore d'évaluation

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Document5 pagesRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfPas encore d'évaluation

- No. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllDocument2 pagesNo. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllasdfasfPas encore d'évaluation

- Guitar Girders Gaunt @ffirr: Frank W. Sterry, of Morrisania, New YorkDocument1 pageGuitar Girders Gaunt @ffirr: Frank W. Sterry, of Morrisania, New YorkasdfasfPas encore d'évaluation

- Nitrh Tatte-Lgaunt @ffirt.: Simon Stevens, On New York, N. YDocument1 pageNitrh Tatte-Lgaunt @ffirt.: Simon Stevens, On New York, N. YasdfasfPas encore d'évaluation

- No. 60,958. Patented Jan. I, 1867.: H. C. Stewart. Glue PotDocument2 pagesNo. 60,958. Patented Jan. I, 1867.: H. C. Stewart. Glue PotasdfasfPas encore d'évaluation

- Blanking Box Holder.: .G. W. TaylorDocument2 pagesBlanking Box Holder.: .G. W. TaylorasdfasfPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Gantt ChartDocument4 pagesGantt ChartSyed FaridPas encore d'évaluation

- An Experimental Analysis of Clustering Algorithms in Data Mining Using Weka ToolDocument6 pagesAn Experimental Analysis of Clustering Algorithms in Data Mining Using Weka Toolmishranamit2211Pas encore d'évaluation

- Coding Assignment 18-WPS OfficeDocument9 pagesCoding Assignment 18-WPS Officetamj tamjPas encore d'évaluation

- Prosper & Sucker RodDocument20 pagesProsper & Sucker RodOmar AbdoPas encore d'évaluation

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Document371 pagesW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectPas encore d'évaluation

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Examples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsDocument44 pagesExamples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsNguyen Anh TuPas encore d'évaluation

- LTE Rach ProcedureDocument4 pagesLTE Rach ProcedureDeepak JammyPas encore d'évaluation

- Biomechanics of The KneeDocument8 pagesBiomechanics of The KneeJorge LopezPas encore d'évaluation

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraPas encore d'évaluation

- Opatch AutoDocument2 pagesOpatch Autoshuvo_ami24Pas encore d'évaluation

- Numbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainDocument9 pagesNumbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainRomela EspedidoPas encore d'évaluation

- Bodybuilder Guidelines: Update: 2011-22Document438 pagesBodybuilder Guidelines: Update: 2011-22thkimzone73100% (12)

- International Marketing-Assignment No. 01Document36 pagesInternational Marketing-Assignment No. 01Faisal Shahzad60% (5)

- Agilis AAV680 FullC PDFDocument2 pagesAgilis AAV680 FullC PDFhendpraz88Pas encore d'évaluation

- Sci - Short Circuit IsolatorDocument2 pagesSci - Short Circuit IsolatorVictor MoraesPas encore d'évaluation

- CISCO Router Software - Configuration PDFDocument408 pagesCISCO Router Software - Configuration PDFasalihovicPas encore d'évaluation

- 16 - Bit RISC Processor Design For Convolution Application Using Verilog HDLDocument64 pages16 - Bit RISC Processor Design For Convolution Application Using Verilog HDLchandra sekhar100% (1)

- Newvhdl Syllabus (It&Cse)Document2 pagesNewvhdl Syllabus (It&Cse)Mude Kishore NaikPas encore d'évaluation

- FP 3000 PDFDocument1 pageFP 3000 PDFClaudio Godoy ZepedaPas encore d'évaluation

- Awards Gold Medals Grade VIDocument11 pagesAwards Gold Medals Grade VIBernadeth Escosora DolorPas encore d'évaluation

- A Report On Traffic Volume StudyDocument33 pagesA Report On Traffic Volume StudyManoj Durairaj100% (1)

- Lecture 5Document35 pagesLecture 5MAHAMA SADIKPas encore d'évaluation

- ASUS U47A Repair GuideDocument5 pagesASUS U47A Repair GuideCarlos ZaratePas encore d'évaluation

- IFoA Directory of Actuarial Employers 2016-17-14102016Document22 pagesIFoA Directory of Actuarial Employers 2016-17-14102016Mian BialPas encore d'évaluation

- Ra 6938Document2 pagesRa 6938GaryPas encore d'évaluation

- Assigment Comouter Science BSCDocument3 pagesAssigment Comouter Science BSCutkarsh9978100% (1)

- PET524 Saturation 1Document12 pagesPET524 Saturation 1Ronald NguelePas encore d'évaluation

- LAAMS Technical Summary Tensar+Document17 pagesLAAMS Technical Summary Tensar+Janaki RamPas encore d'évaluation

- Estimating QuotientsDocument7 pagesEstimating Quotientssheila mae neri100% (1)